A kind of chlorine peroxide-resistant cross-linked polyethylene pipe and its preparation method

A technology of cross-linking polyethylene and peroxide, which is applied in the field of plastic pipes, can solve the problems of reduced pressure resistance of pipes, shortened service life of pipes, reduced cross-linking efficiency, etc., so as to avoid the reduction of physical properties and the low degree of cross-linking. , the effect of long oxidation induction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

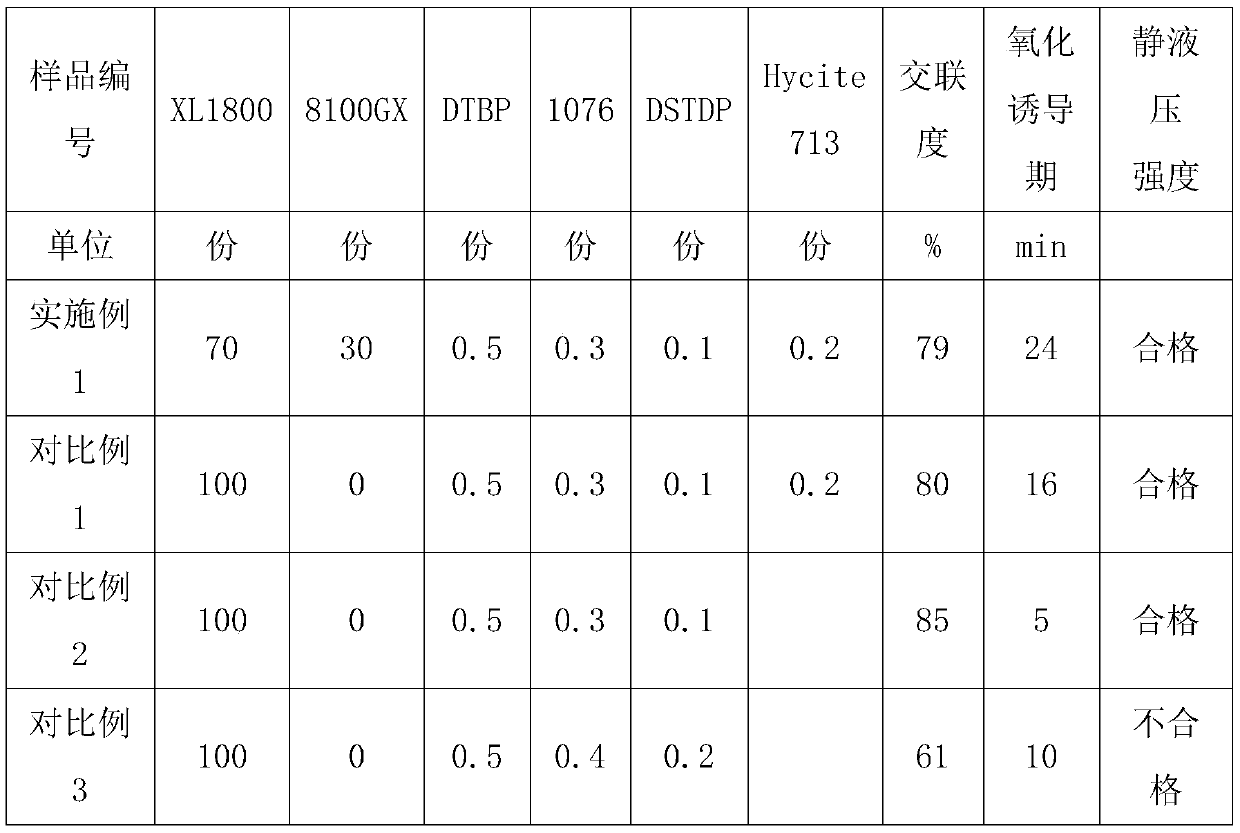

Examples

Embodiment 1

[0028] In the present embodiment, each raw material component that adopts is as follows:

[0029] Brand XL1800 high-density polyethylene resin produced by Korea LG Chemicals 70kg

[0030] Brand 8100GX high-density polyethylene resin produced by Hunan Petrochemical in South Korea 30kg

[0031] DTBP 0.5kg

[0032] Antioxidant 1076 0.3kg

[0033] Antioxidant DSTDP 0.1kg

[0034] Acid Scavenger Hycite 713 0.2kg

[0035] The preparation process is as follows:

[0036] Mix brand XL1800 high-density polyethylene resin produced by Korea LG Chemical, brand 8100GX high-density polyethylene resin produced by South Korea Hunan Petrochemical, DTBP, antioxidant 1076, antioxidant DSTDP and acid scavenger Hycite 713, and then place it at high speed Stir in a mixer for 10 minutes;

[0037] A plunger extruder is used to extrude the above compounded mixture to produce a peroxide crosslinked polyethylene pipe with a specification of dn20*en2.8 (dn20*SDR7.4). Among them, the temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com