High-temperature resistant friction material and preparation method thereof

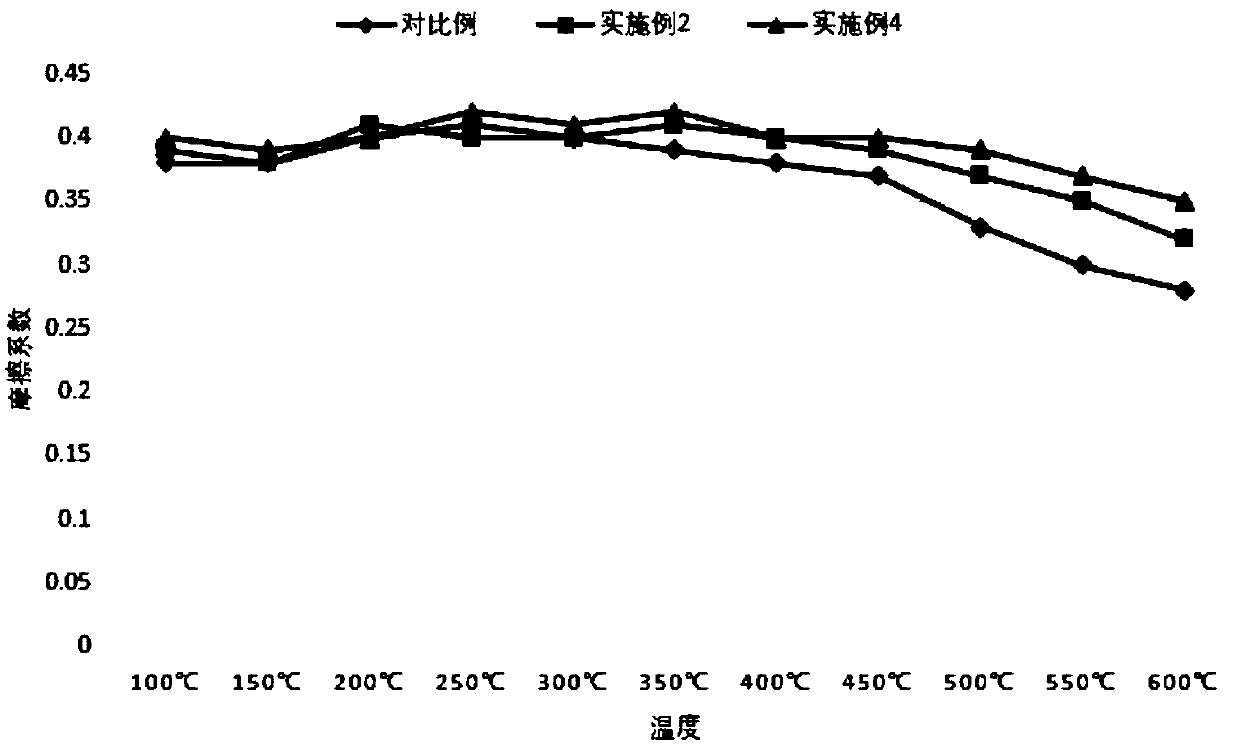

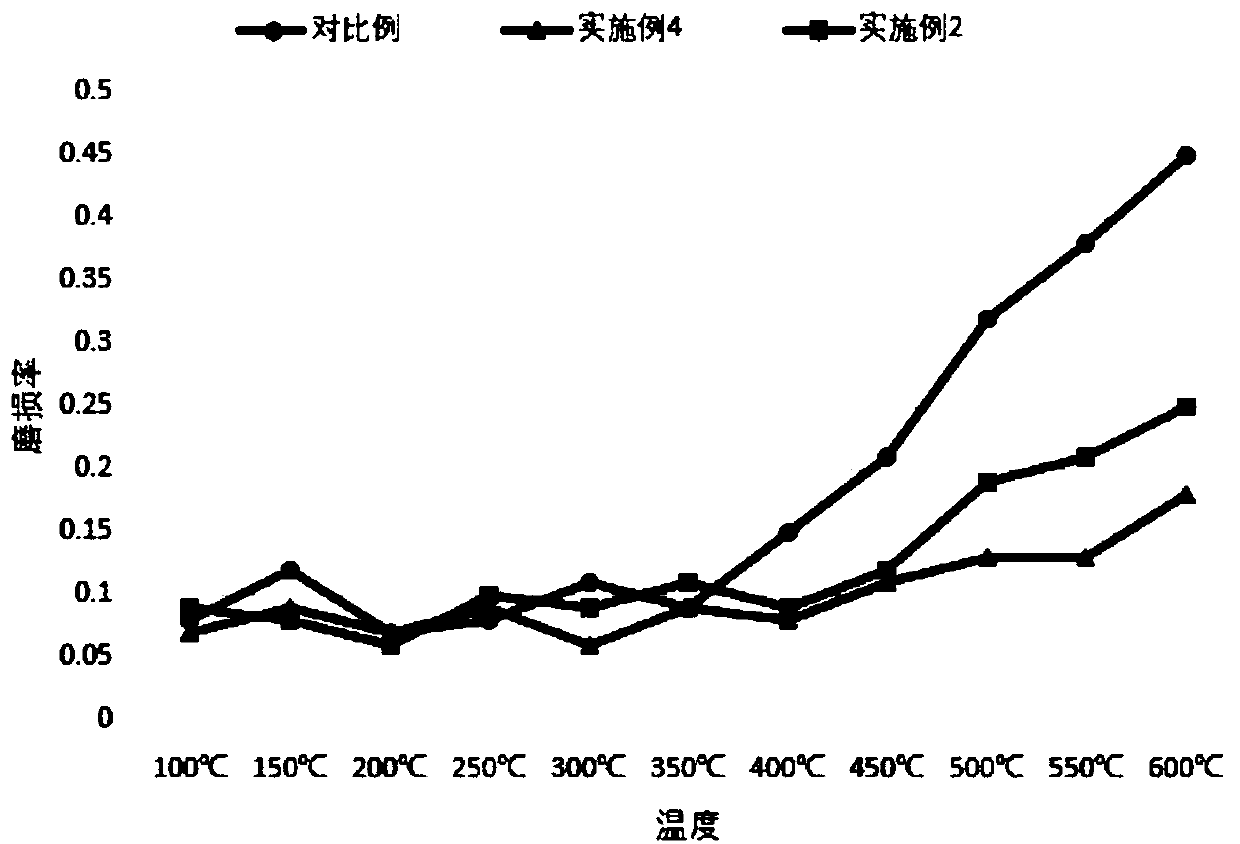

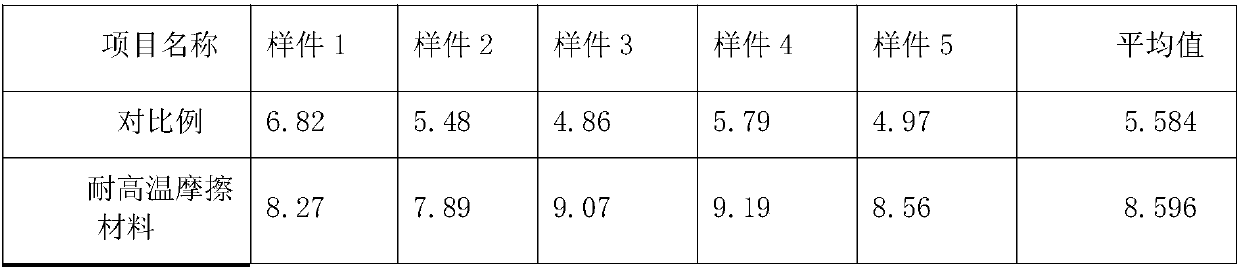

A technology of friction materials and high temperature resistance, which is applied in the direction of friction linings, chemical instruments and methods, mechanical equipment, etc., which can solve the problems of friction surface tissue damage, small braking torque, and falling block surface, etc., to achieve improved anti-fading performance, The effect of improving the wear condition and scientific proportioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing a high temperature resistant friction material, comprising the following steps:

[0025] Step 1, mixing thermally conductive mineral fibers with a mass ratio of 4:3:1, an inorganic high-temperature adhesive, and porous mineral powder; wherein, the specific preparation process of the porous mineral powder is as follows:

[0026] Crush the mineral particles, put the mineral powder into the silica sol according to the ratio of 1g / 50ml, and keep stirring during the adding process. In the muffle furnace, the temperature was raised to 300°C at 10°C / min, kept for 30 minutes, then raised to 500°C at 5°C / min, kept for 20 minutes to obtain a gel solid, and then pulverized to obtain the porous mineral powder.

[0027] Step 2. Clean, degrease and polish the surface of the steel back, and spray adhesive on the surface of the steel back for later use;

[0028] Step 3, putting the steel back and the mixture obtained in step 1 into a pressing mold for pressing; ...

Embodiment 2

[0033] A method for preparing a high temperature resistant friction material, comprising the following steps:

[0034] Step 1, mixing thermally conductive mineral fibers with a mass ratio of 4:4:2, an inorganic high-temperature adhesive, and porous mineral powder; wherein, the specific preparation process of the porous mineral powder is as follows:

[0035] Crush the mineral particles, put the mineral powder into the silica sol according to the ratio of 1g / 50ml, and keep stirring during the adding process. In the muffle furnace, the temperature was raised to 300°C at 10°C / min, kept for 30 minutes, then raised to 500°C at 5°C / min, kept for 20 minutes to obtain a gel solid, and then pulverized to obtain the porous mineral powder.

[0036] Step 2. Clean, degrease and polish the surface of the steel back, and spray adhesive on the surface of the steel back for later use;

[0037] Step 3, putting the steel back and the mixture obtained in step 1 into a pressing mold for pressing; ...

Embodiment 3

[0042] A method for preparing a high temperature resistant friction material, comprising the following steps:

[0043] Step 1, mixing thermally conductive mineral fibers with a mass ratio of 4:6:4, inorganic high-temperature adhesives, and porous mineral powders; wherein, the specific preparation process of the porous mineral powders is as follows:

[0044] Crush the mineral particles, put the mineral powder into the silica sol according to the ratio of 1g / 50ml, and keep stirring during the adding process. In the muffle furnace, the temperature was raised to 300°C at 10°C / min, kept for 30 minutes, then raised to 500°C at 5°C / min, kept for 20 minutes to obtain a gel solid, and then pulverized to obtain the porous mineral powder.

[0045] Step 2. Clean, degrease and polish the surface of the steel back, and spray adhesive on the surface of the steel back for later use;

[0046] Step 3, putting the steel back and the mixture obtained in step 1 into a pressing mold for pressing; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com