Automatic devulcanizing and plasticizing device and method for waste rubber powder

A technology of waste rubber powder and rubber powder, which is applied in the field of plasticization of waste rubber powder for automatic sulfur breaking, which can solve the problems of insufficient material reaction, difficulty in control, and accidents caused by combustion, so as to fully stir the spiral blade and reduce the production cost of the product , The effect of self-cleaning spiral blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The invention provides an automatic sulfur-breaking plasticizing device for the plasticizing treatment of vulcanized rubber powder, and also provides a plasticizing method using the device.

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

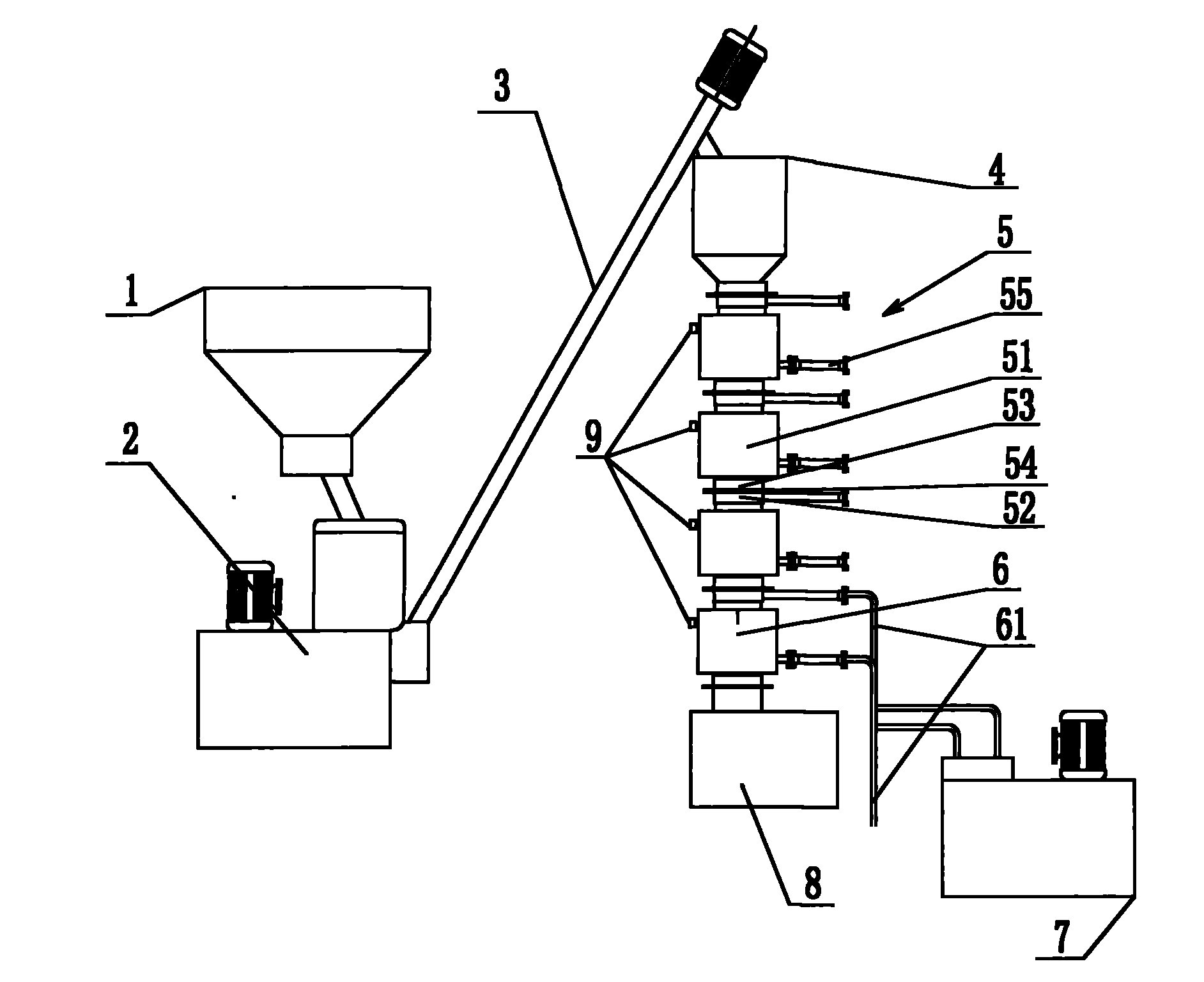

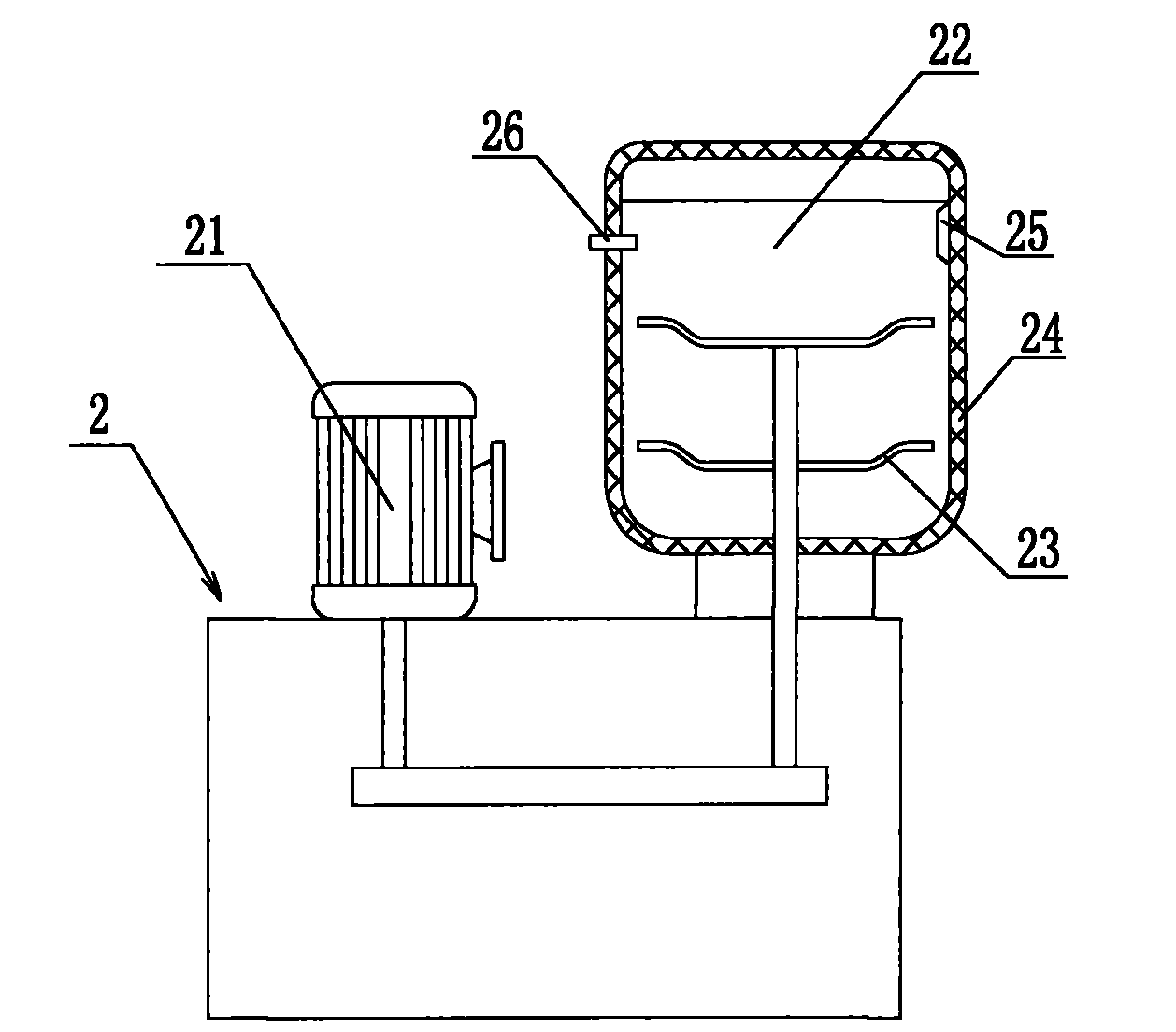

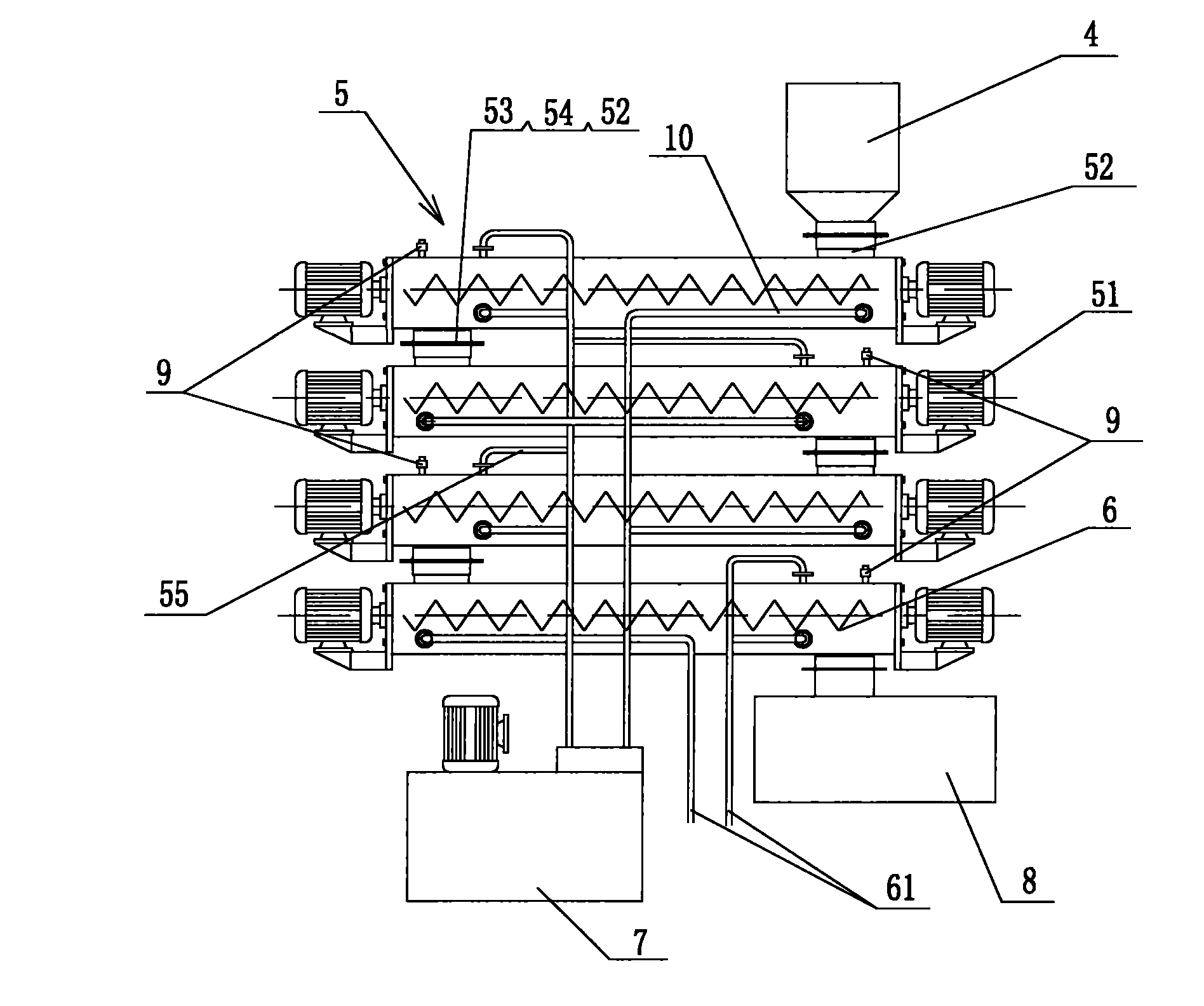

[0034] see figure 1 The waste rubber powder automatic sulfur-cutting and plasticizing device includes a batching box 1, a high-speed stirring device, a thermal reaction device 5, a cooling device 6 and an electrical control device (not shown in the figure), and also includes a feeding device and an insulating material box 4. The discharge port of the high-speed stirring device is communicated with the feed port of the feeding device, the discharge port of the feeding device is connected with the feed port of the thermal reaction device 5, and the discharge port of the thermal reaction device 5 is connected with the feed port of the cooling device 6. The mouth is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com