Patents

Literature

86results about How to "Small braking torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

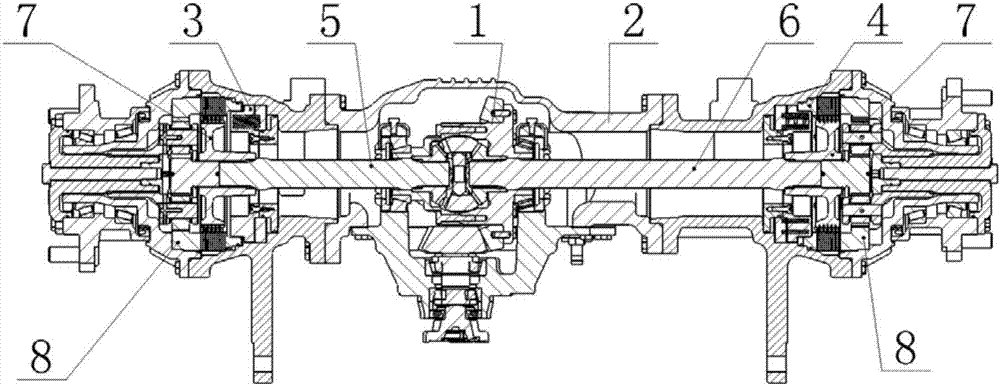

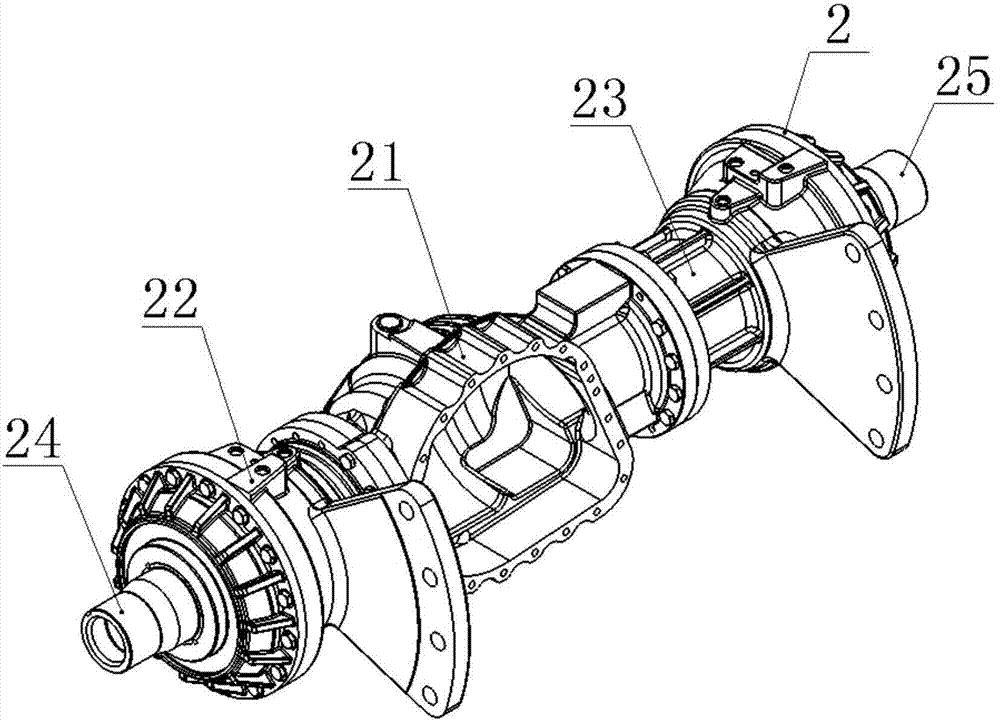

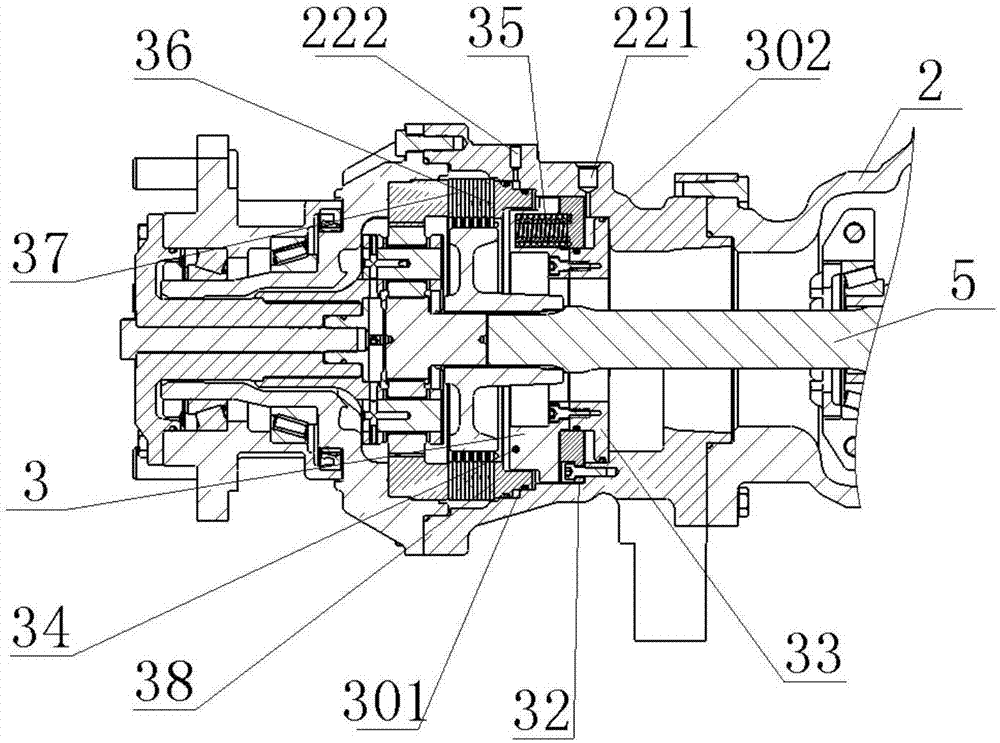

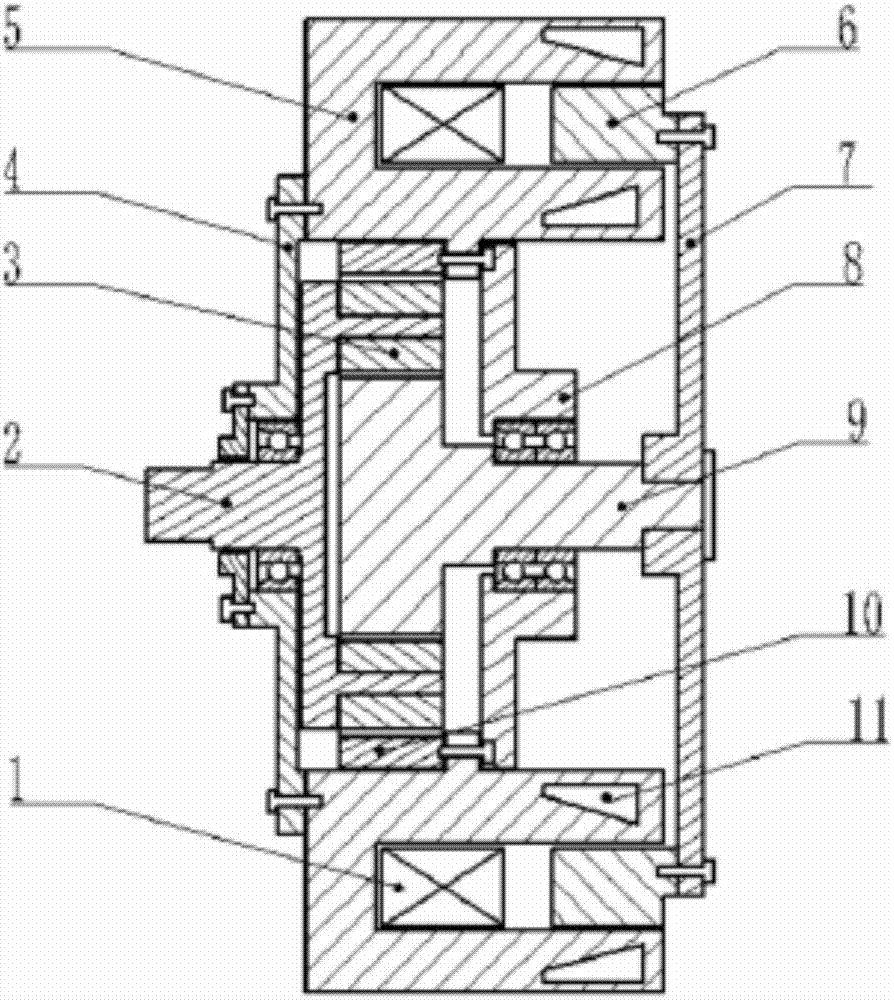

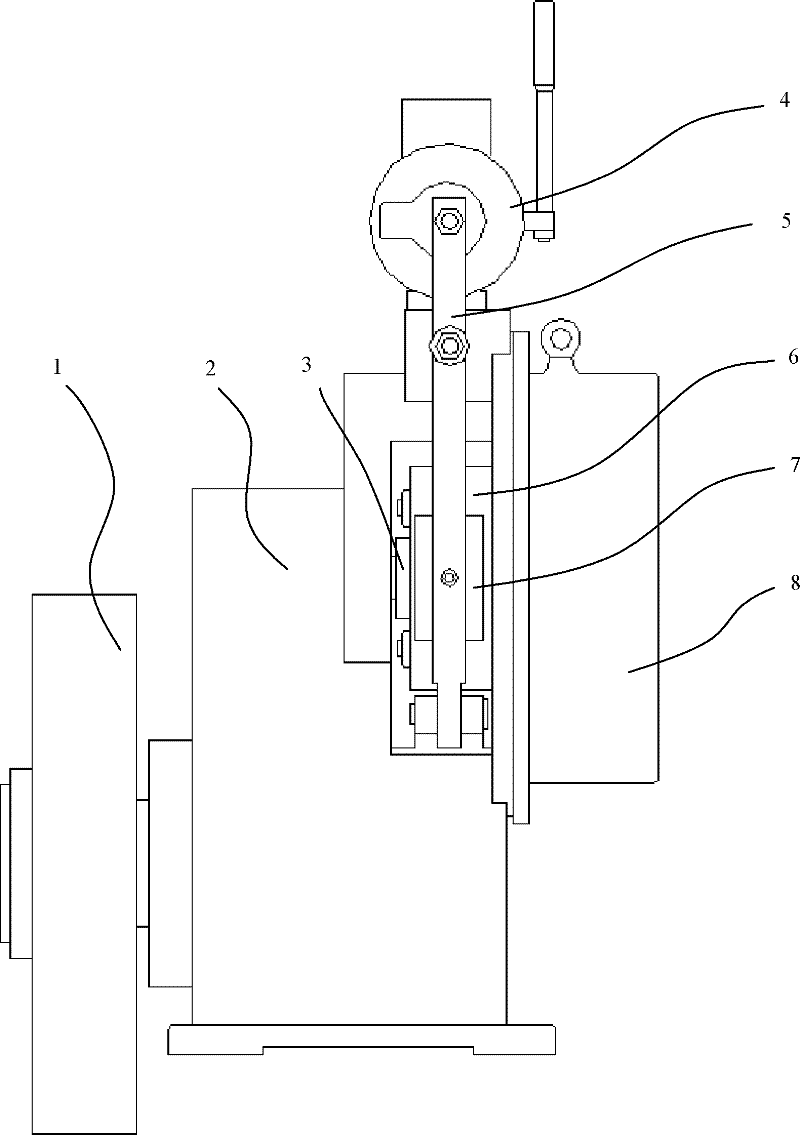

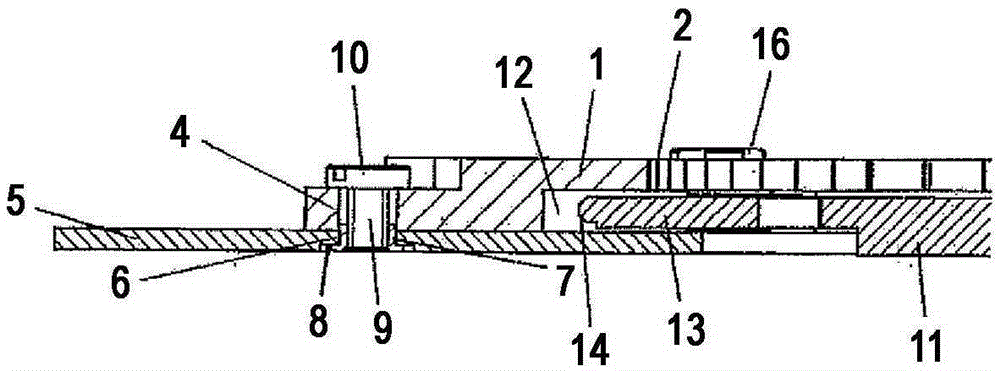

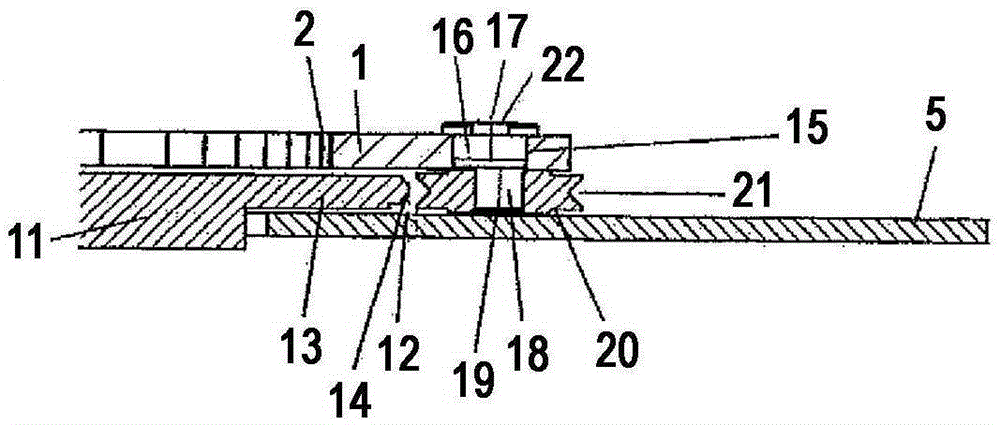

Forklift travelling and parking integrated wet-type brake driving axle

ActiveCN107265354AStable brakingImprove comfortFluid actuated brakesLifting devicesReduction driveReducer

The invention discloses a forklift travelling and parking integrated wet-type brake driving axle which comprises a main reducer assembly, an axle housing assembly, a left brake assembly, a right brake assembly, a left half axle, a right half axle, spline sleeves and fixing gear rings. A group of friction plates are arranged on each spline sleeve; a group of diaphragms are arranged in a groove of an inner hole of the left axle housing and a group of diaphragms are arranged in a groove of an inner hole of the right axle housing in the axle housing assembly; the friction plates and the diaphragms are alternately mounted; the left brake assembly and the right brake assembly are each provided with a parking brake mechanism and a travelling brake mechanism; hydraulic oil is guided into the left axle housing, and thus travelling brake and parking brake is completed in the parking brake mechanism and the travelling brake mechanism correspondingly under the action of the hydraulic oil. The friction plates are separated from the diaphragms through centrifugal force and inertia force after a vehicle moves. The influence on the parking brake from external factors like mud, water and oil is avoided, and the maintenance is convenient since the friction plates and the diaphragms can be maintained and replaced without disassembling an axle assembly.

Owner:ANHUI HELI CO LTD

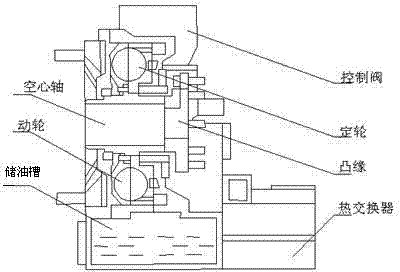

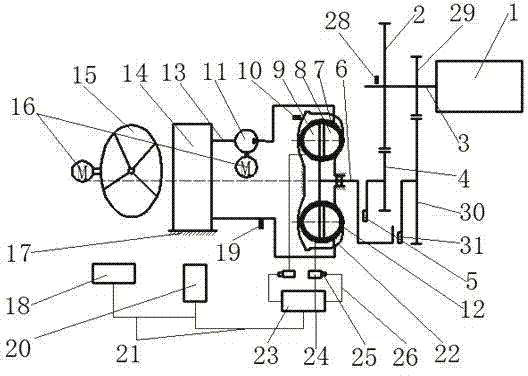

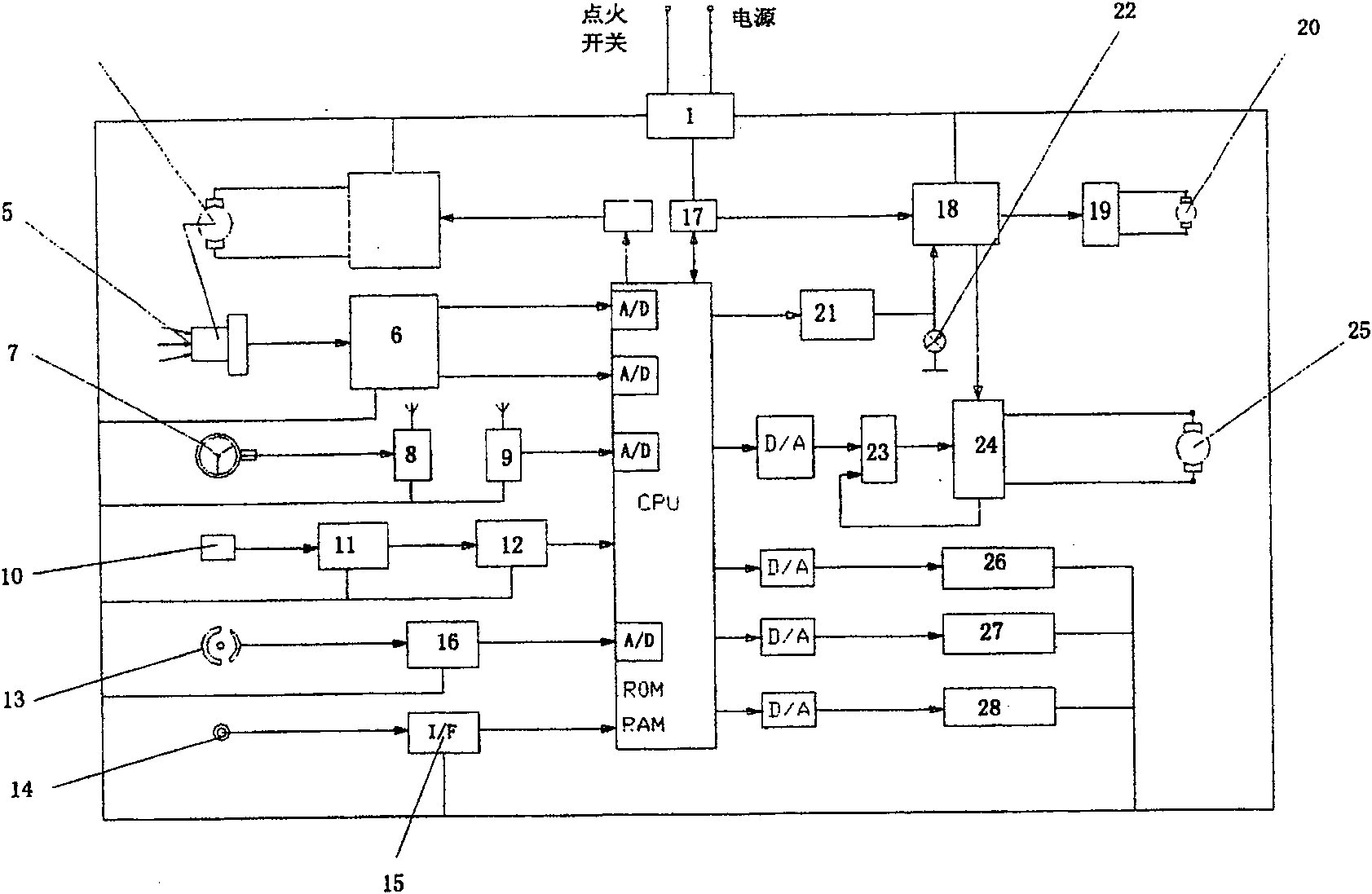

Independent type hydraulic retarder based on magnetorheological fluid and control method thereof

ActiveCN102927167ASave powerSolve the problem that the braking torque is not large and the braking effect is not goodLiquid resistance brakesNon-rotating vibration suppressionBrake torqueDrive wheel

The invention discloses an independent type automobile hydraulic retarder based on a magnetorheological fluid and a control method thereof. A working cavity is sealed, the magnetorheological fluid is filled in the working cavity, a driving wheel, a fixed wheel, a coil and a cooling water jacket are accommodated in the working cavity, the moving wheel and the fixed wheel are coaxially opposed with clearance, the coil is winded around the outer edges of the moving wheel and the fixed wheel, the coil is fixed at the outer edge of the moving wheel, a clearance exists between the coil and the outer edge of the fixed wheel, the coil is connected with a vehicle power supply outside the working cavity, an output end of a moving wheel shaft extends out of the working cavity and is connected with a speed changer through a driving gear pair, the cooling water jacket is fixedly sleeved on the fixed wheel outer ring, the cooling water jacket is connected with a water pump and a radiator outside the working cavity, according to vehicle information of a vehicle controller, an electronic control unit calculates the current which is input into the coil, establishes magnetic field in the working cavity and generates a braking torque which acts on the moving wheel shaft, the electronic control unit controls the water pump to work so that the cooling water can circularly flows among a cooling water pipeline, the cooling water jacket and the radiator, and the temperature of the magnetorheological fluid can be decreased.

Owner:JIANGSU UNIV

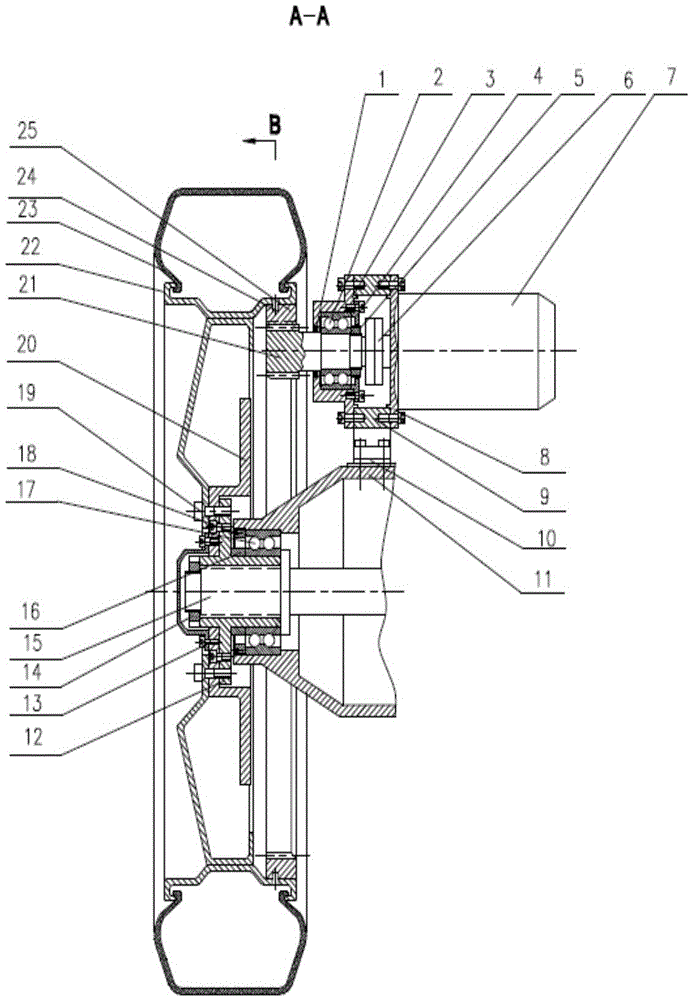

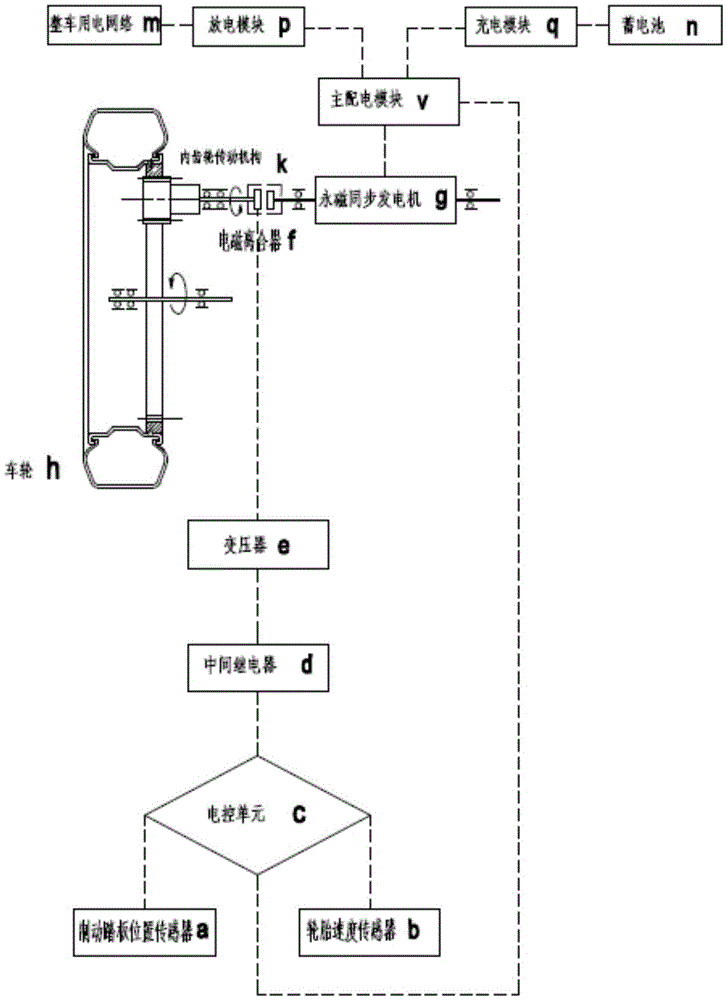

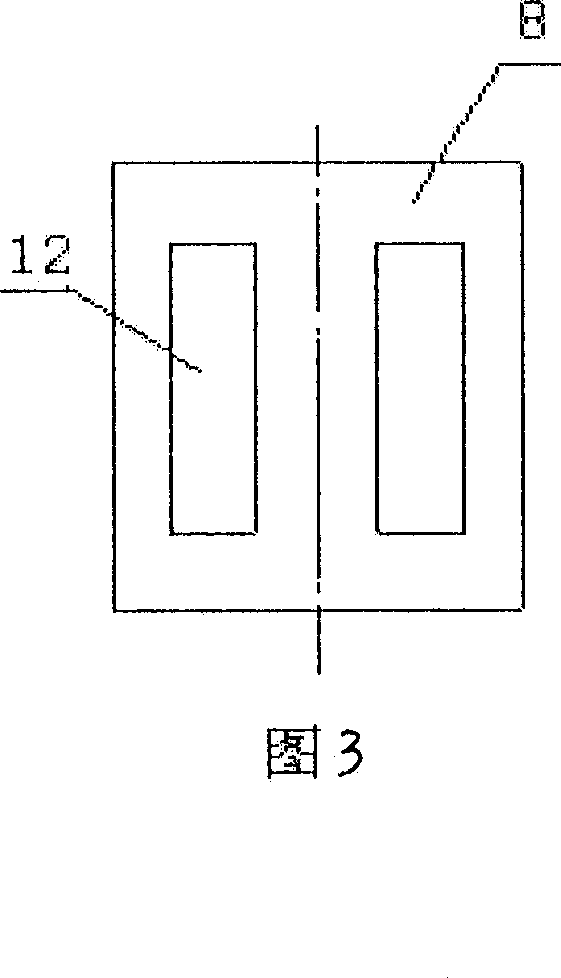

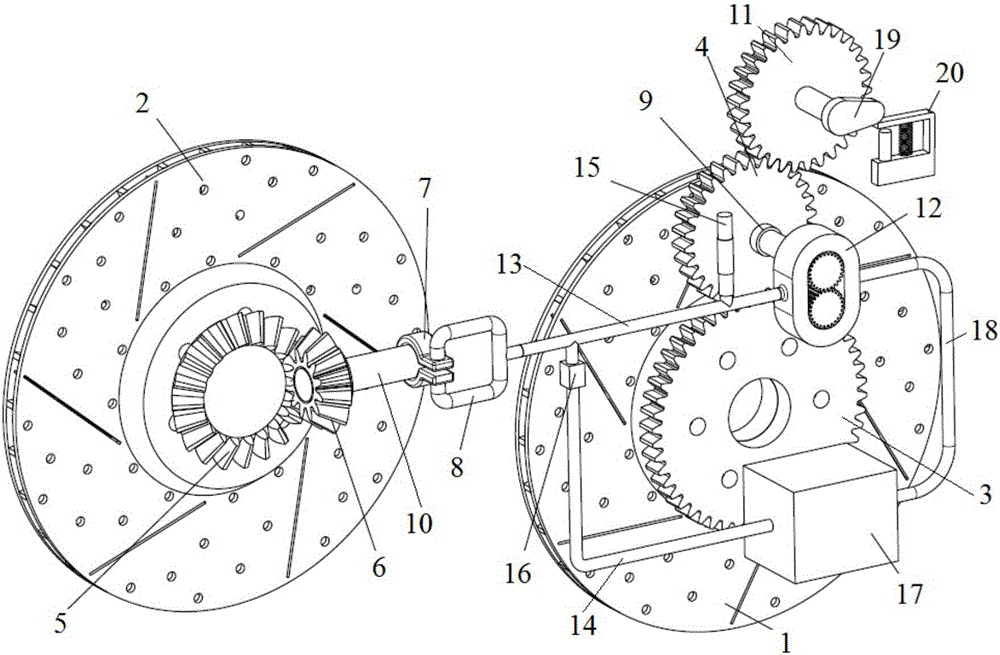

Automobile wheel inertial energy recycling device and method

ActiveCN105667303ADrive chain shortHigh transmission efficiencyElectric/fluid circuitEnergy efficient vehicular chargingGear transmissionHigh energy

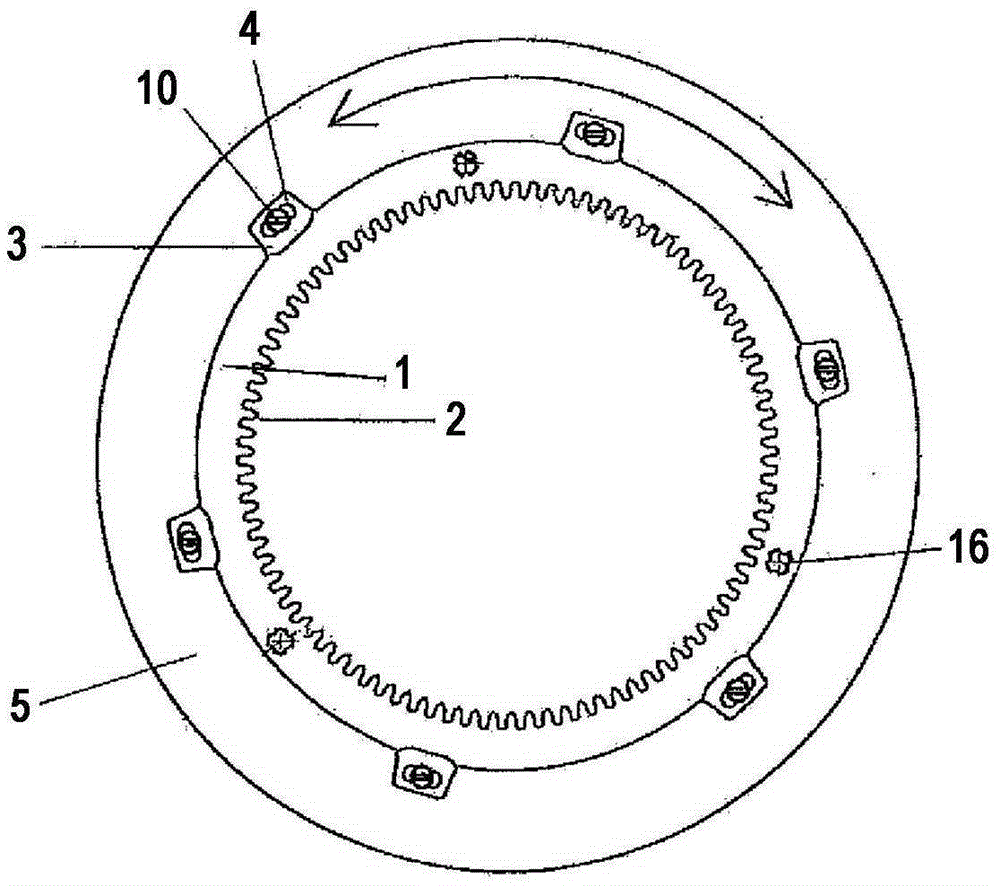

The invention provides a device and method for recovering the inertial energy of automobile wheels, belonging to the fields of automobile energy saving and emission reduction and new energy electric vehicles. The invention adds a fixed internal gear insert on the inner ring of the automobile wheel hub. When the automobile wheel rotates, the power increases through the internal gear transmission mechanism and directly drives the permanent magnet synchronous generator to generate electricity, which is generated by the brake pedal sensor and the tire speed sensor. The signal controls the opening and closing of the electromagnetic clutch, which directly drives the permanent magnet synchronous generator to generate electricity. At the moment of braking and deceleration of the car, it can quickly release and recover the inertial energy of the car wheels in large quantities, and provide power to the battery or the power network of the whole vehicle. The device has the advantages of simple structure, small volume, high energy recovery rate, good reliability, low manufacturing cost, and certain technical and economic feasibility.

Owner:JIANGSU UNIV

Auxiliary braking device for magnetic rheological body petroleum drilling rig

ActiveCN1945047ALarge amount of liquidLarge heat capacityLiquid resistance brakesPetroleumConductive materials

The auxiliary braking device with magnetic rheological body for petroleum rig includes one cylinder of non-magnetic conductive material and two end caps of magnetic conductive material to form one sealed cylindrical cavity, two magnetic conductive columns with wound exciting coil outside the cylinder and between the two end caps, one shaft of non-magnetic conductive material with fixed magnetic conductive blades set between the two end caps, and magnetic rheological body filled in the sealed cylindrical cavity. The present invention can provide great braking moment at all rig winch speeds, and has stepless regulation of braking moment, fast response, low cost and long service life.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

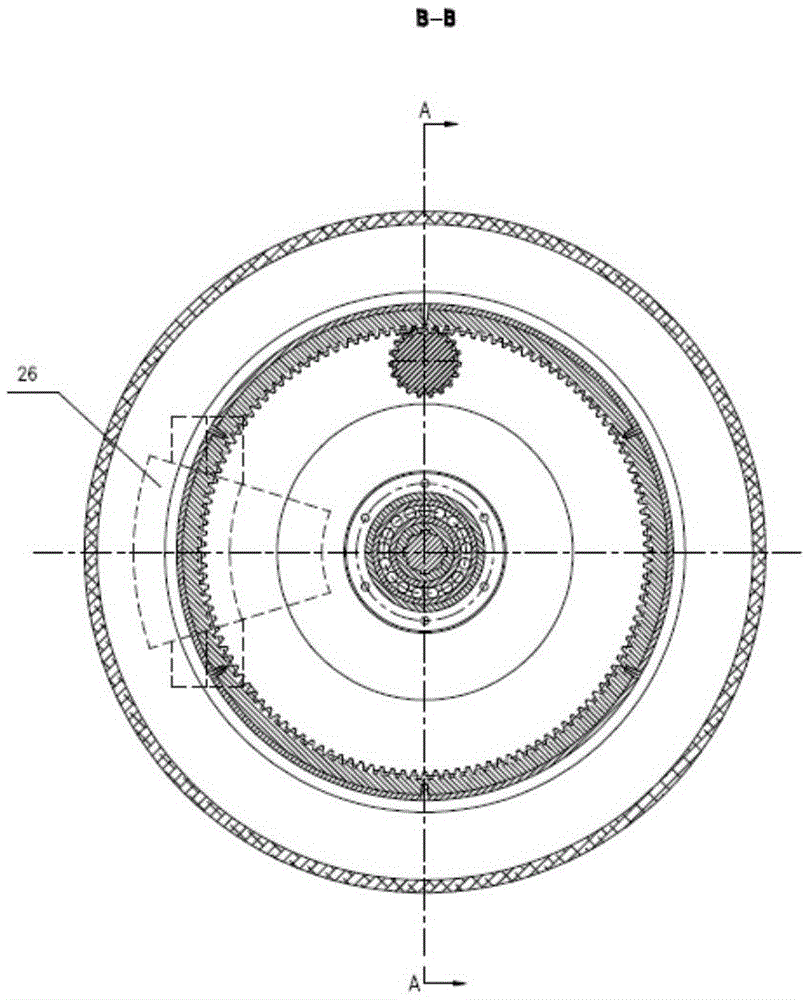

Combined recycling and comprehensive utilizing apparatus and method of inertia energy of car wheels and vibration energy of suspension

InactiveCN106335362AImprove reliabilityImprove power densityAuxillary drivesMachines/enginesHydraulic pumpRoad surface

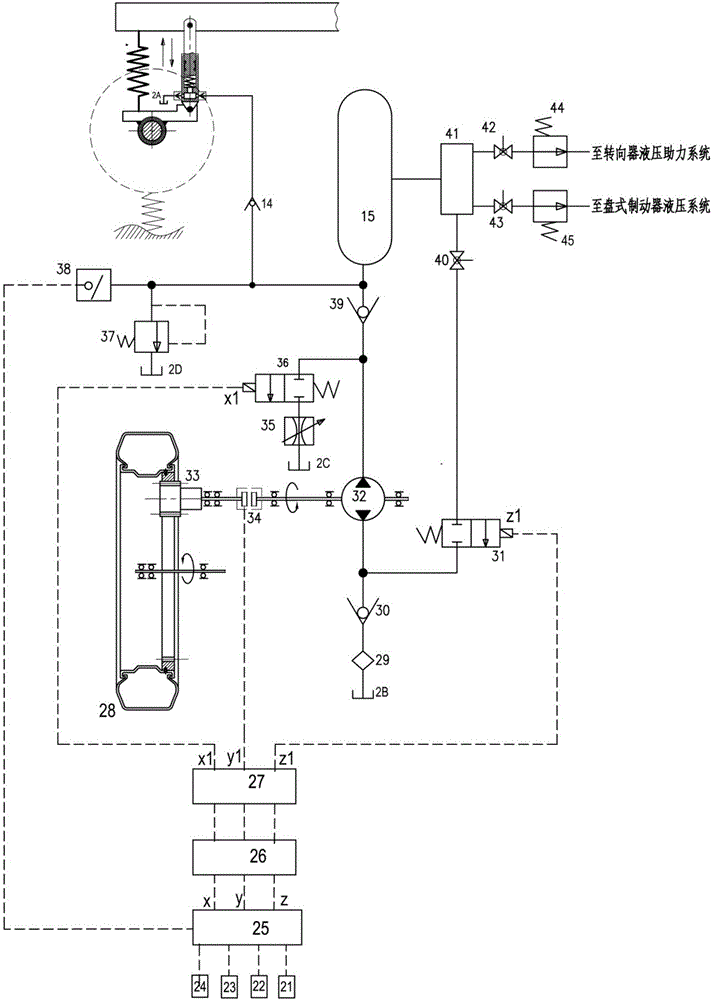

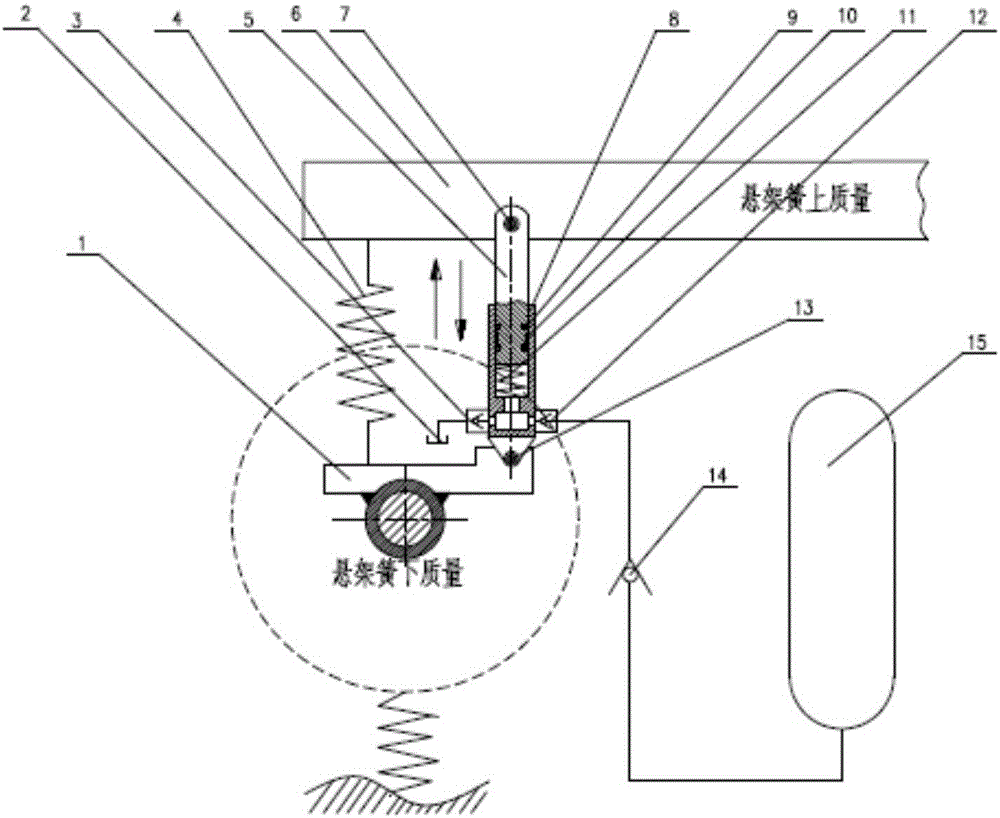

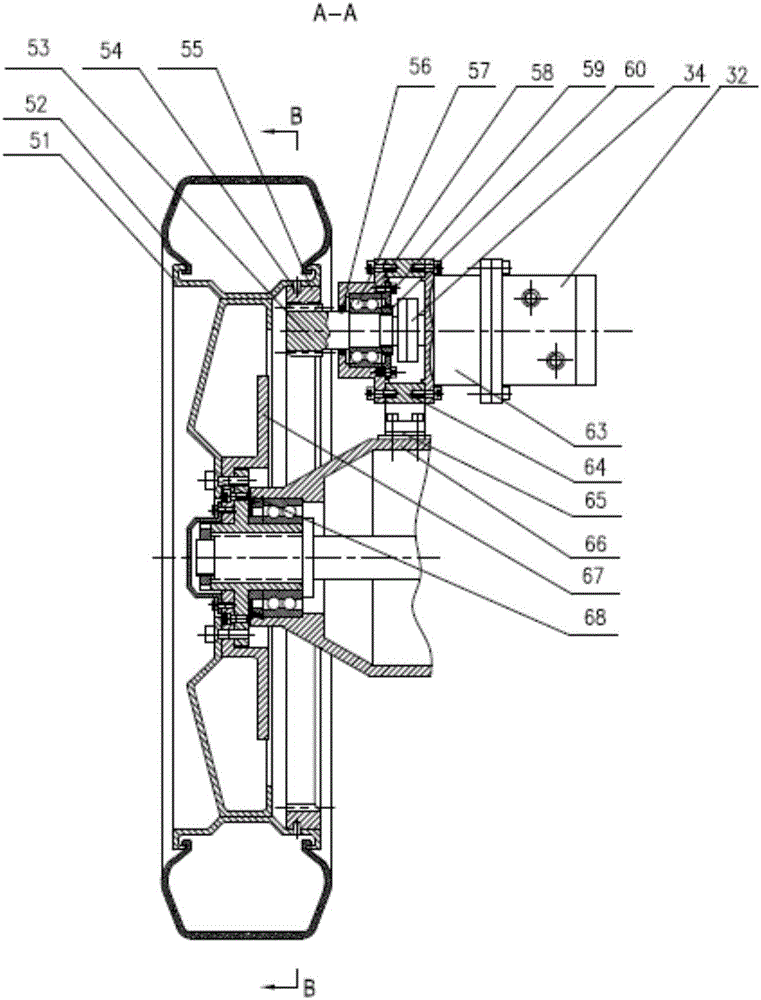

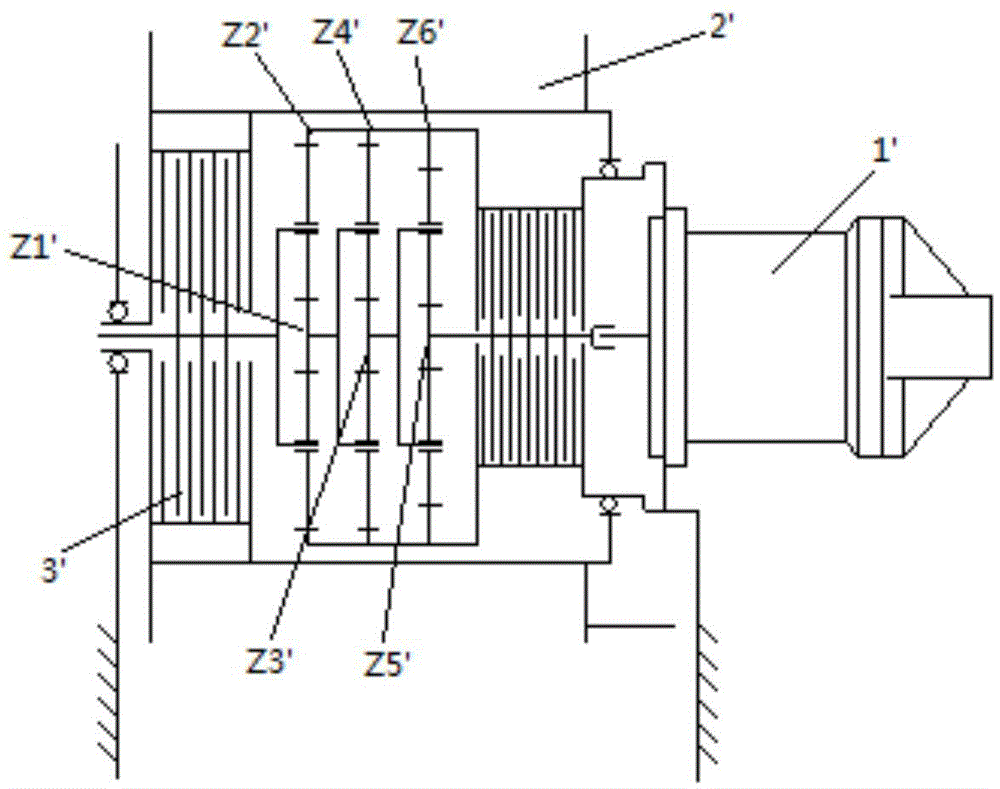

The invention discloses a combined recycling and comprehensive utilizing apparatus and method of inertia energy of car wheels and vibration energy of a suspension, belonging to the technical field of car energy conservation and emission reduction. The method comprises the following steps: first connecting a plunger pump between a sprung mass and an unsprung mass of a car suspension in a floating manner, and driving a hydraulic pump to work by using vibration displacement generated when a car drives on a fluctuated pavement; additionally fixing an inner gear ring on a car wheel hub, when the car wheel rotates, enabling power to be sped up by virtue of an inner gear transmission machine, and directly driving the hydraulic pump / hydraulic motor to work; when a car brakes and decelerates, rapidly converting a great amount of inertia energy of the wheel to hydraulic energy to be stored; and when the car is started and sped up, directly providing two portions of hydraulic energy converted from the vibration energy of the car suspension and the inertia energy of the car to the wheel by virtue of a hydraulic motor mode. The recycled hydraulic energy can select a corresponding mode according to a road condition and can be applied to hydraulic assistance of a car steering device and a disc-type brake hydraulic system.

Owner:JIANGSU UNIV

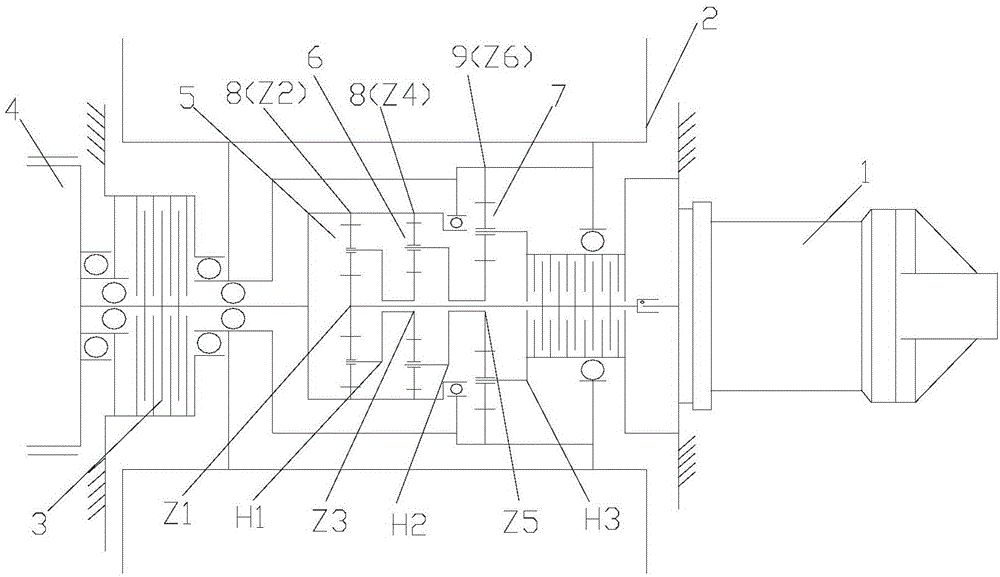

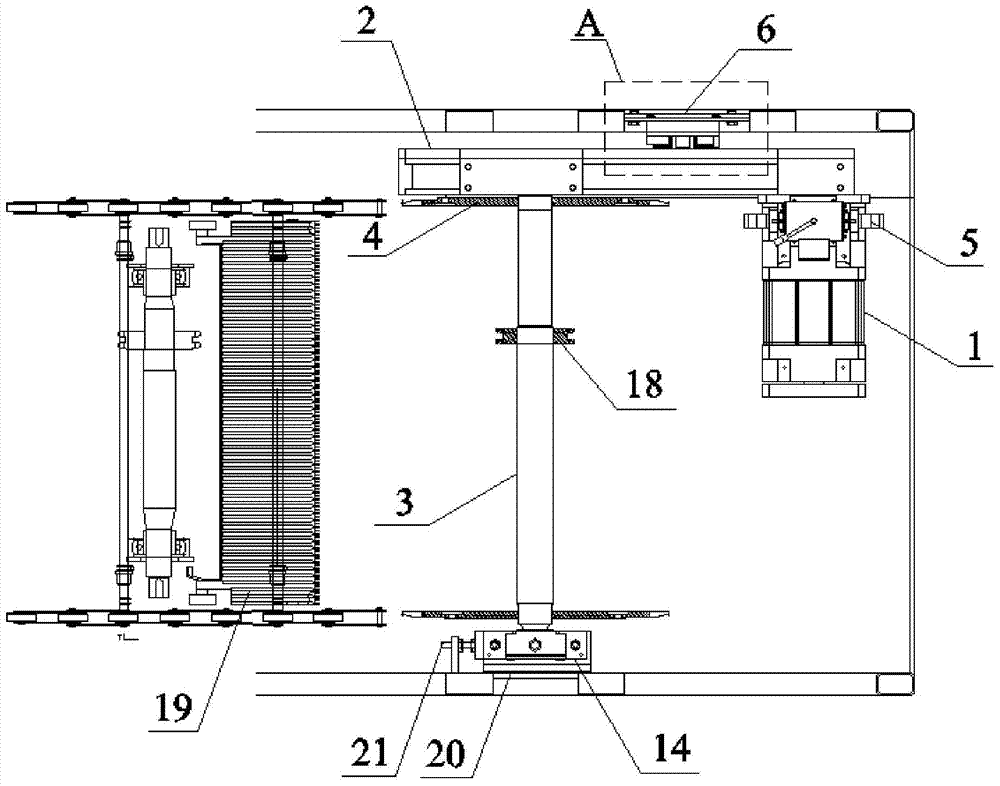

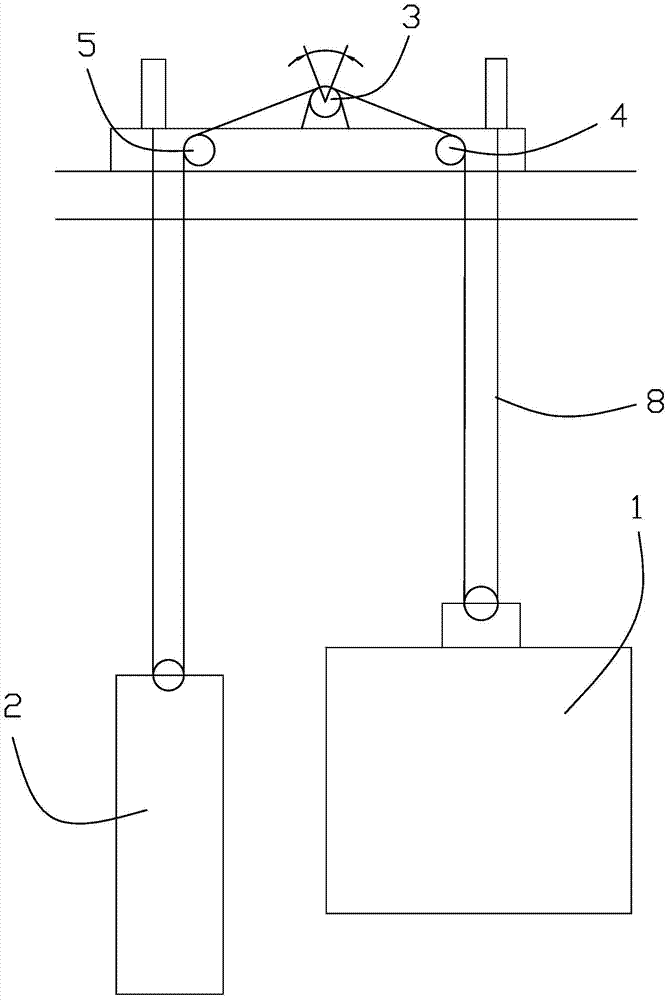

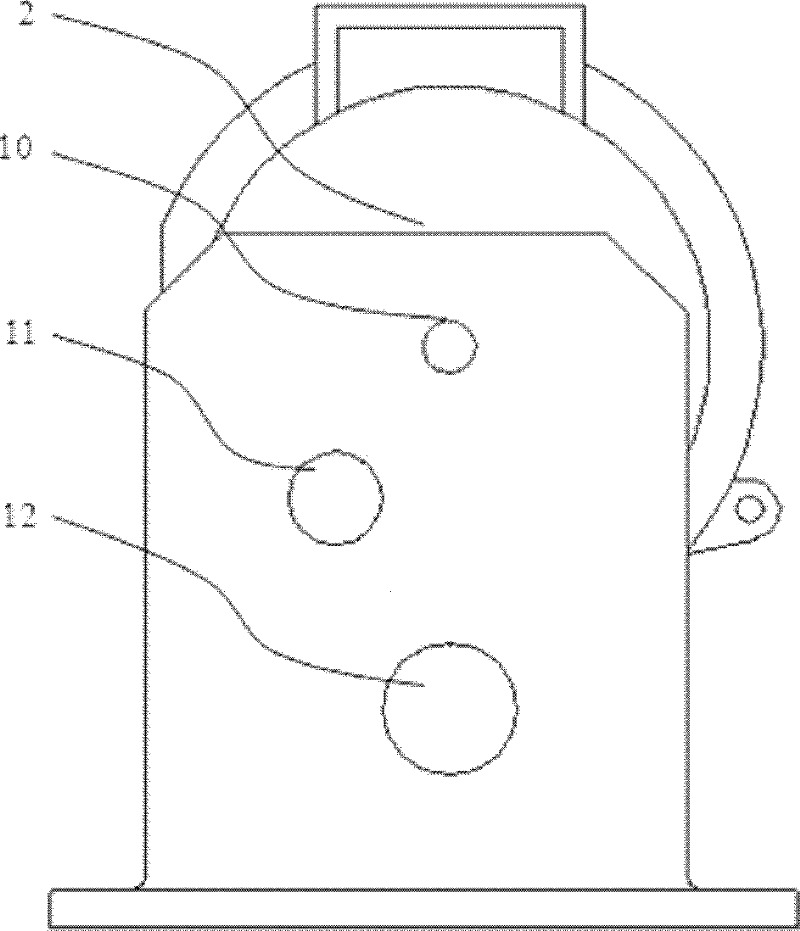

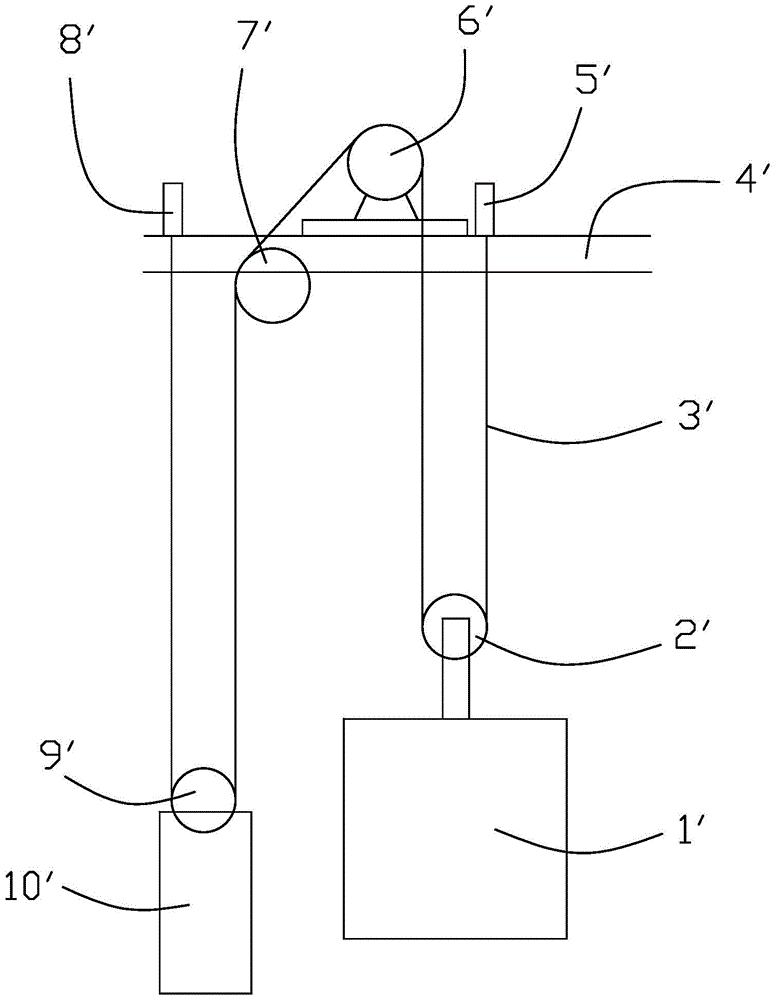

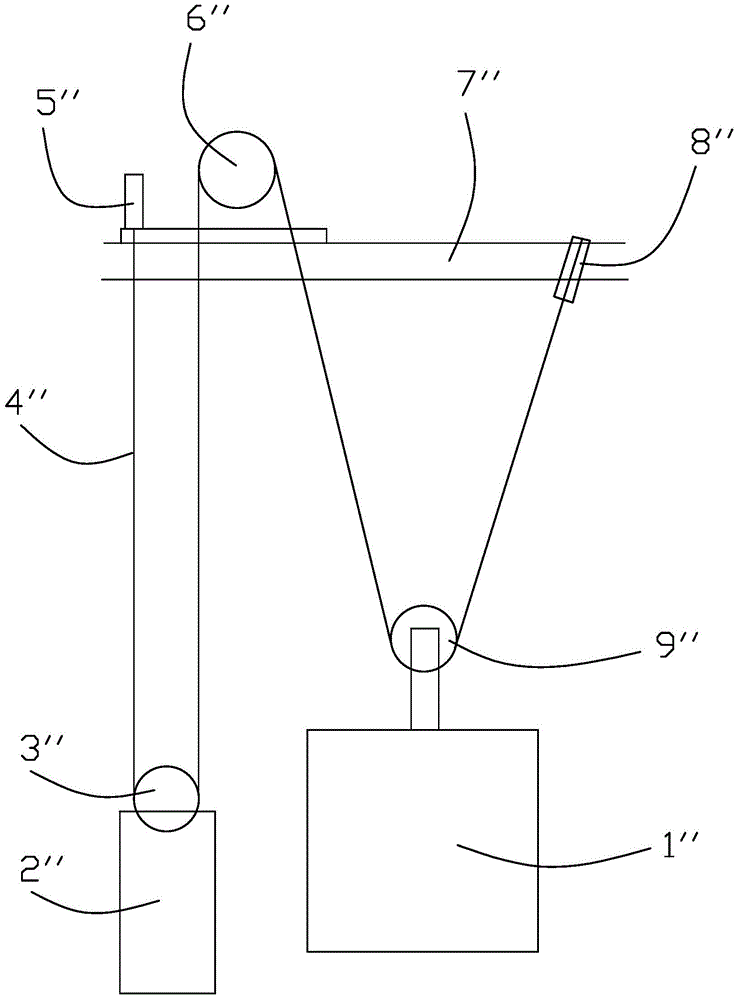

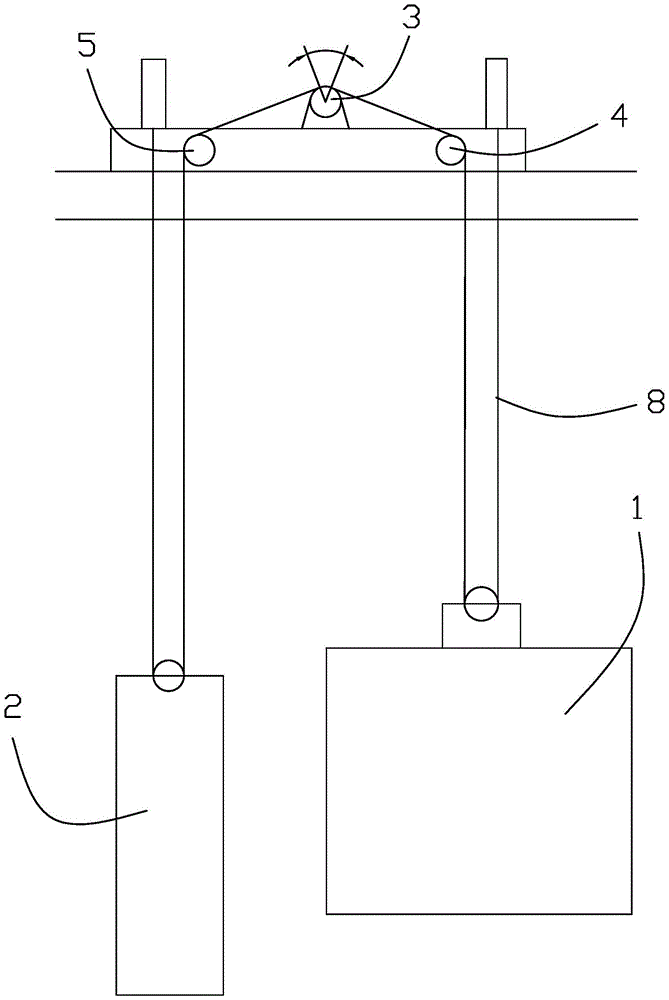

Crane and hoisting mechanism thereof

The invention discloses a hoisting mechanism. When the hoisting mechanism is in a rising mode or a falling mode, a speed reducer motor functions in driving, a clutch is closed, and the output shaft of the speed reducer motor is connected with a winding drum by use of a planetary gear mechanism and drives the winding drum t rotate; when the hoisting mechanism is in a free hook dropping mode, the speed reducer motor stops, the clutch is opened, the winding drum drives the planetary gear mechanism to speed up so as to drive a brake hub to rotate, and then the stop of the rotation of the winding drum is realized at last by use of a brake. According to the hoisting mechanism, when the hoisting mechanism is located at the braking phase of the free hook dropping mode, due to speeding up of the planetary gear mechanism, the rotating speed of the brake hub is greatly increased and the braking torque of the brake is quickly reduced, and therefore, the volume of the brake hub is remarkably reduced and the braking capacity of the brake is enhanced. According to the technology, the mounting space is reduced, and the hoisting mechanism is enabled to hoist more heavy materials and drop the hook freely in the free hook dropping mode. The invention also provides an engineering machine.

Owner:ZOOMLION HEAVY IND CO LTD

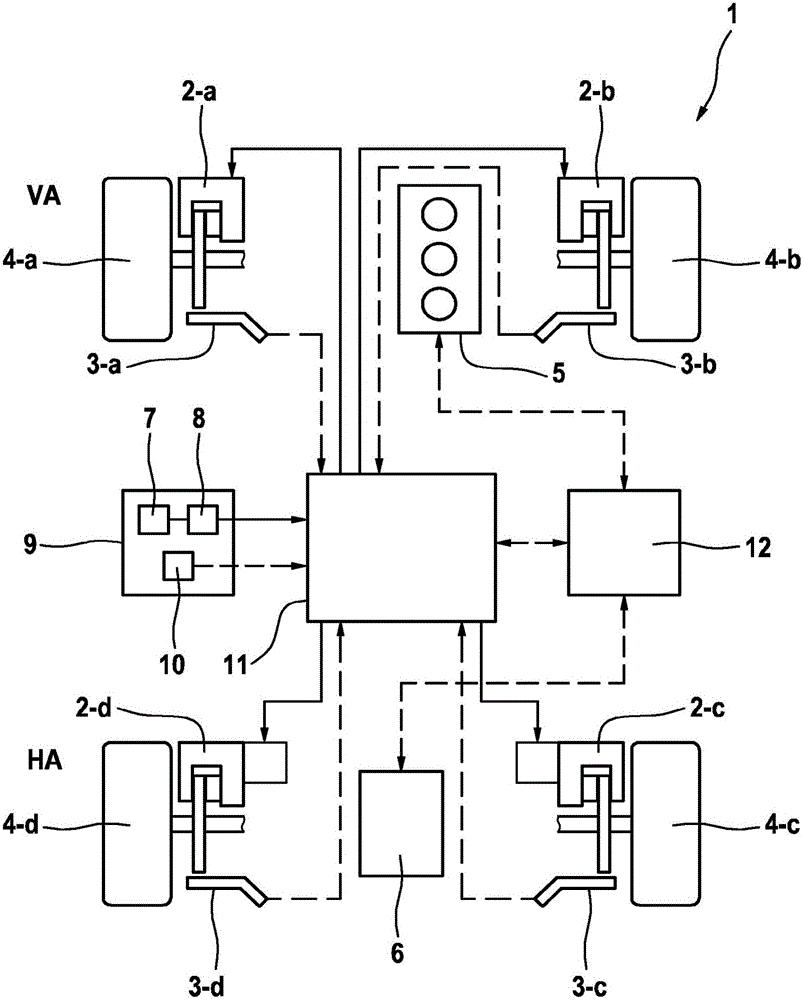

Method for operating a brake system, brake system in which the method is performed, and uses of the brake system

InactiveCN105026229ARegenerative braking is comfortable and effectiveIncrease pressureBrake control systemsElectricityDriver/operator

Owner:CONTINENTAL TEVES AG & CO OHG

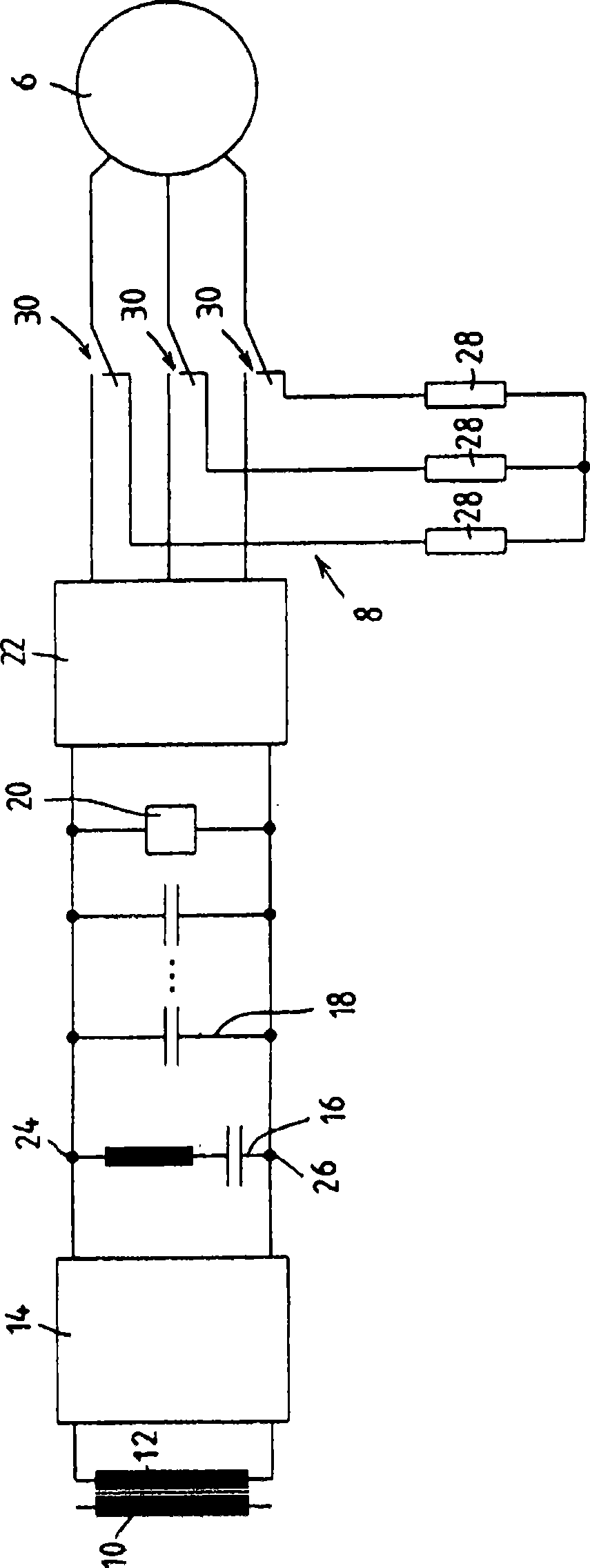

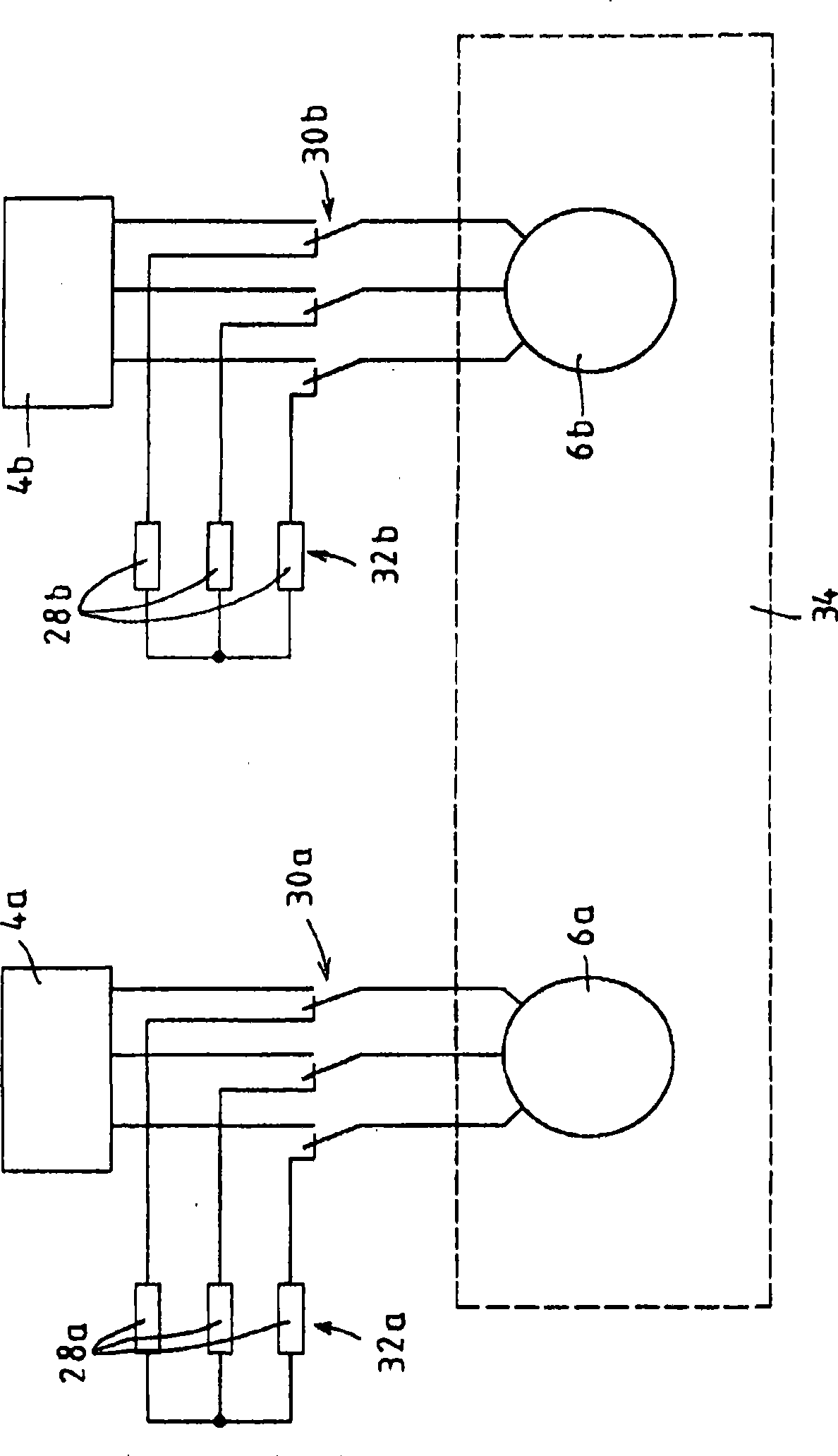

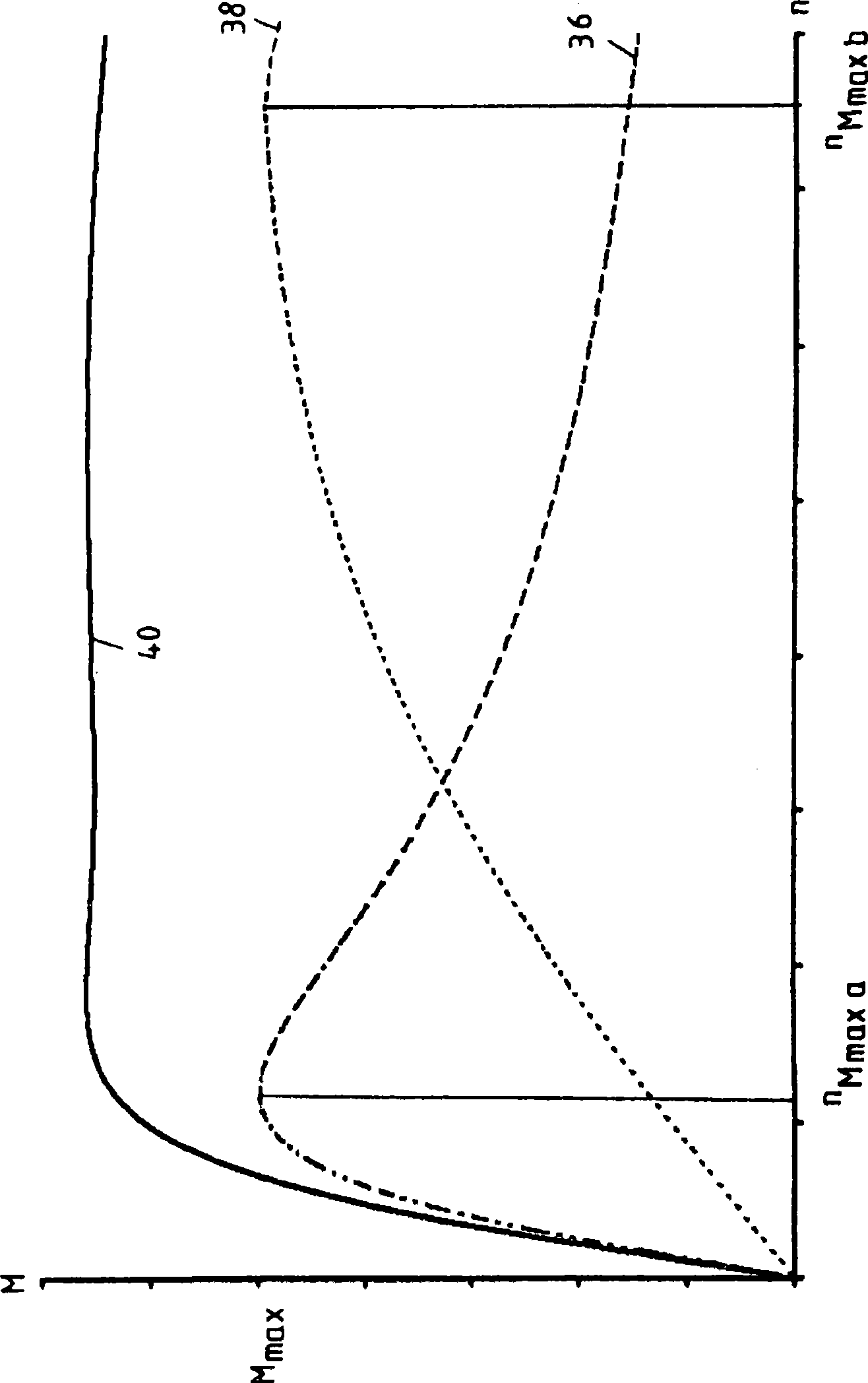

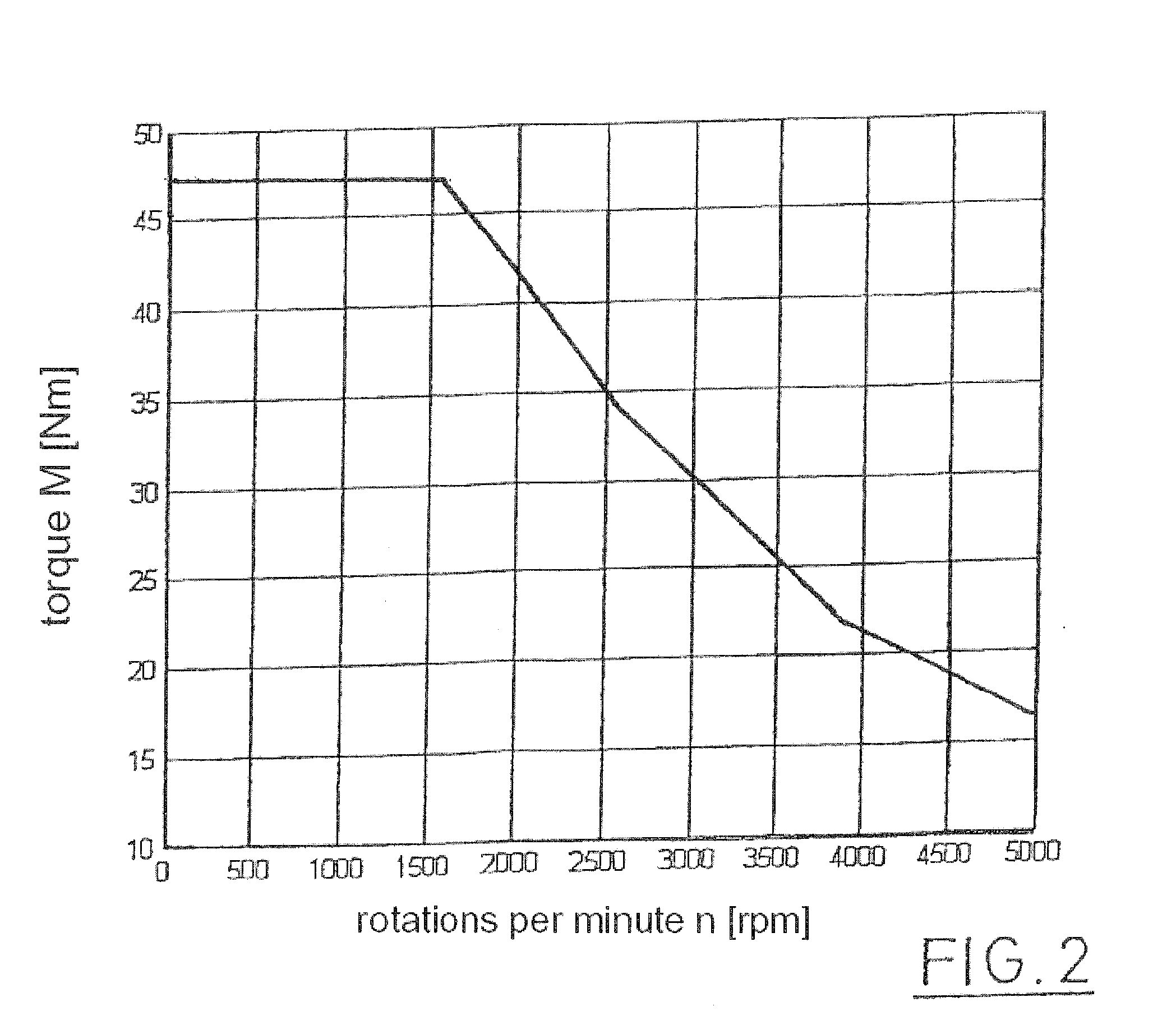

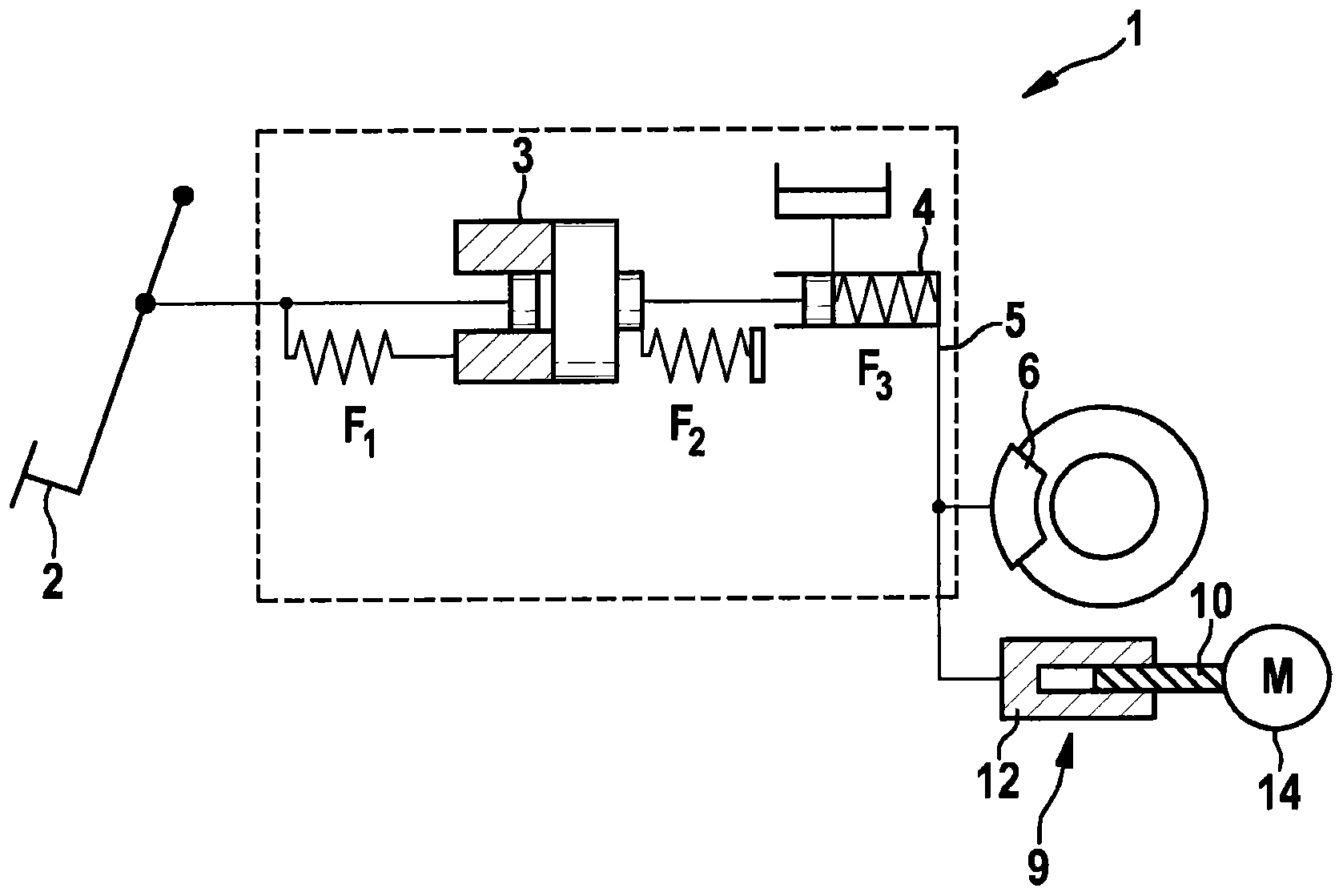

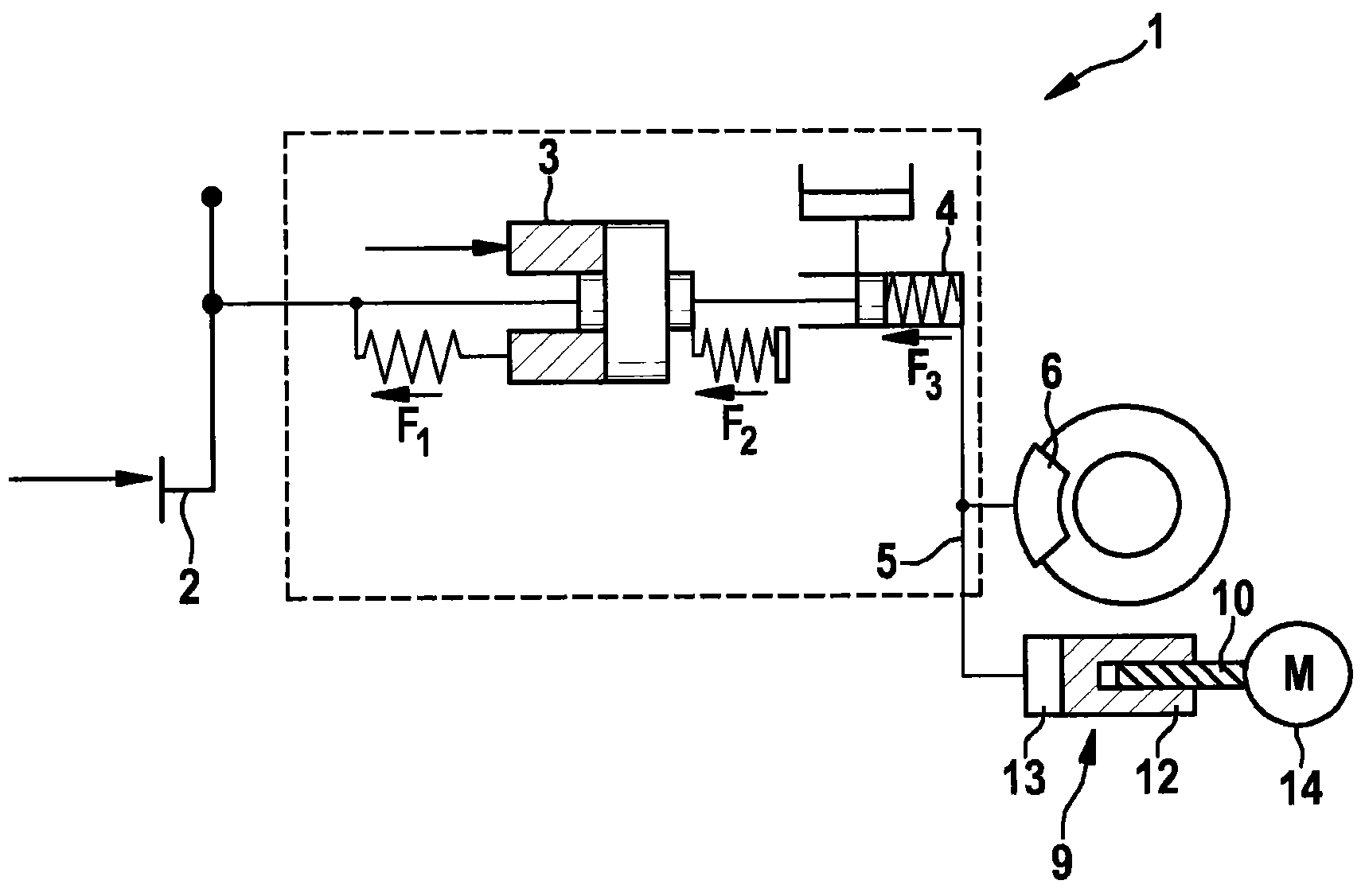

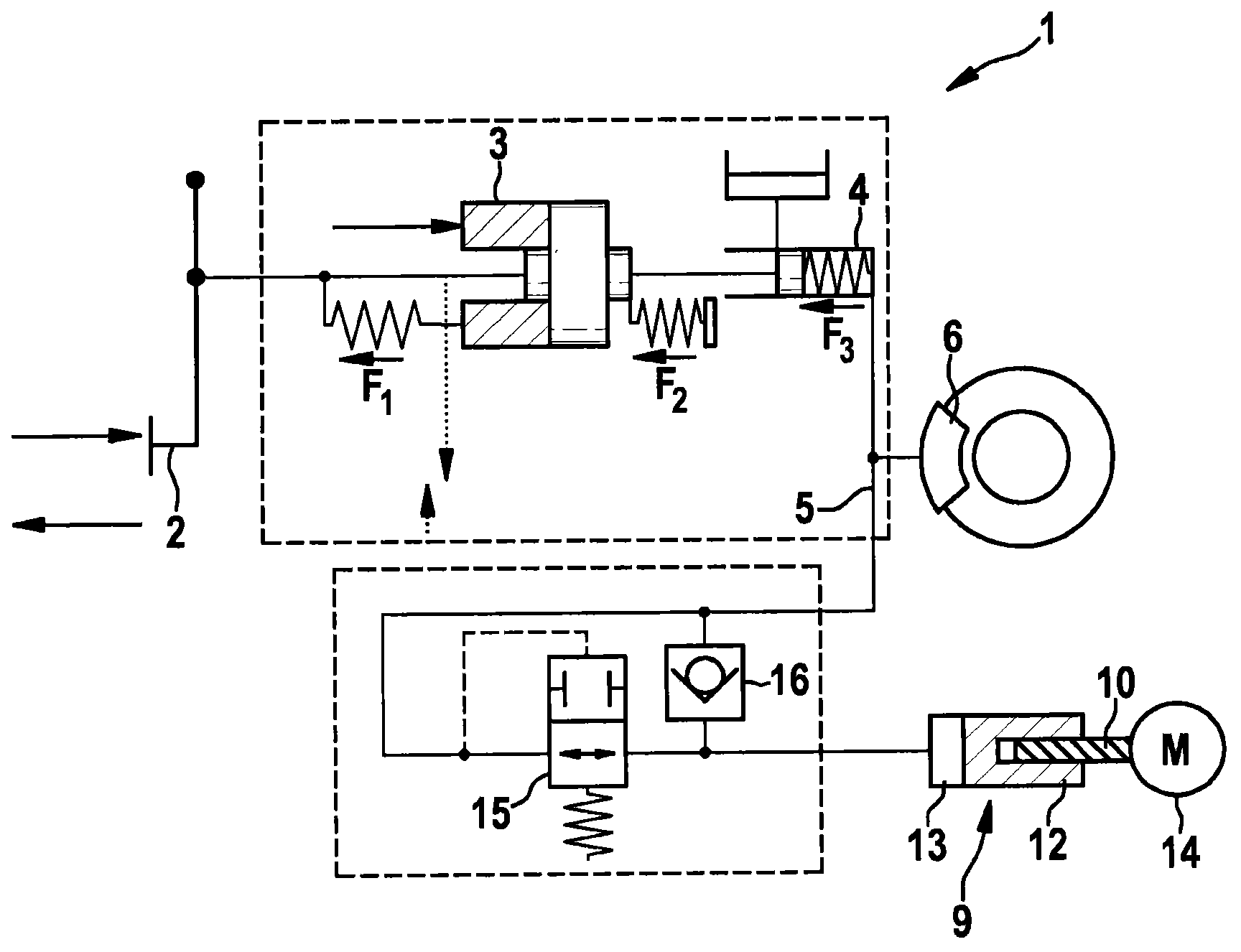

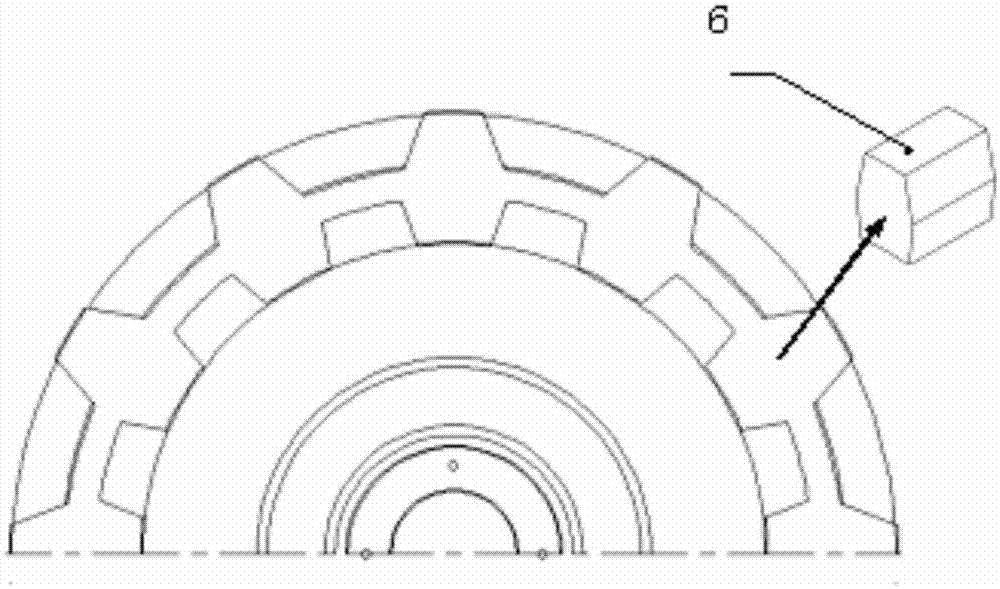

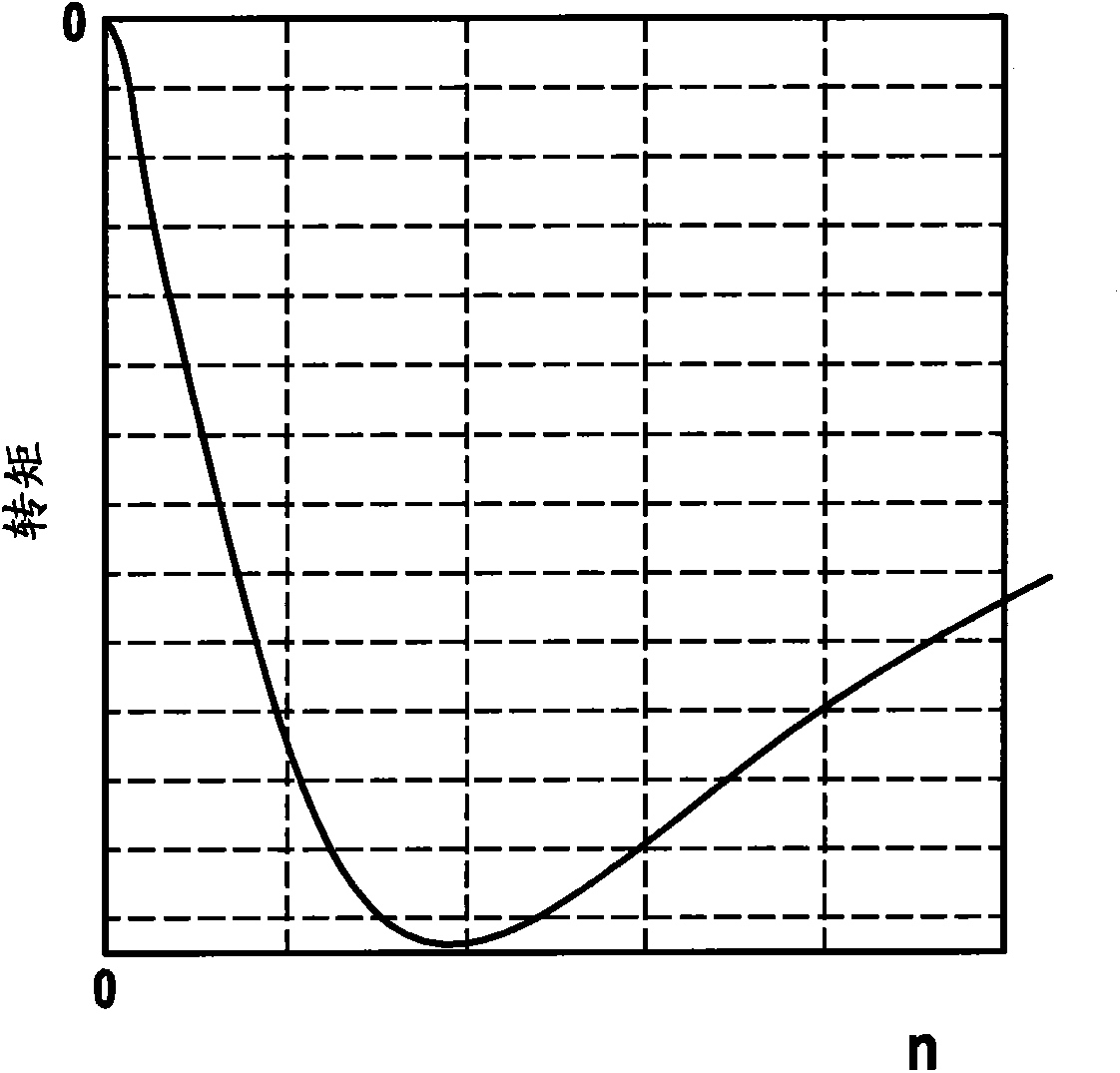

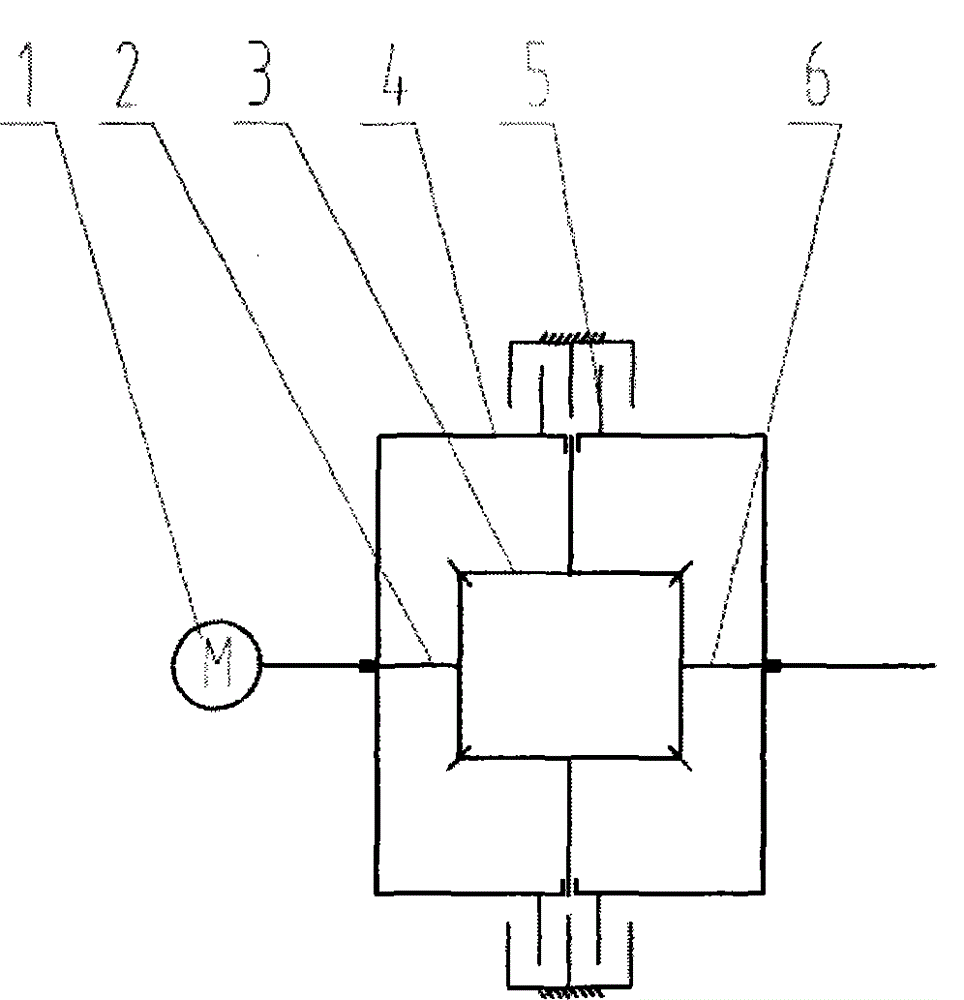

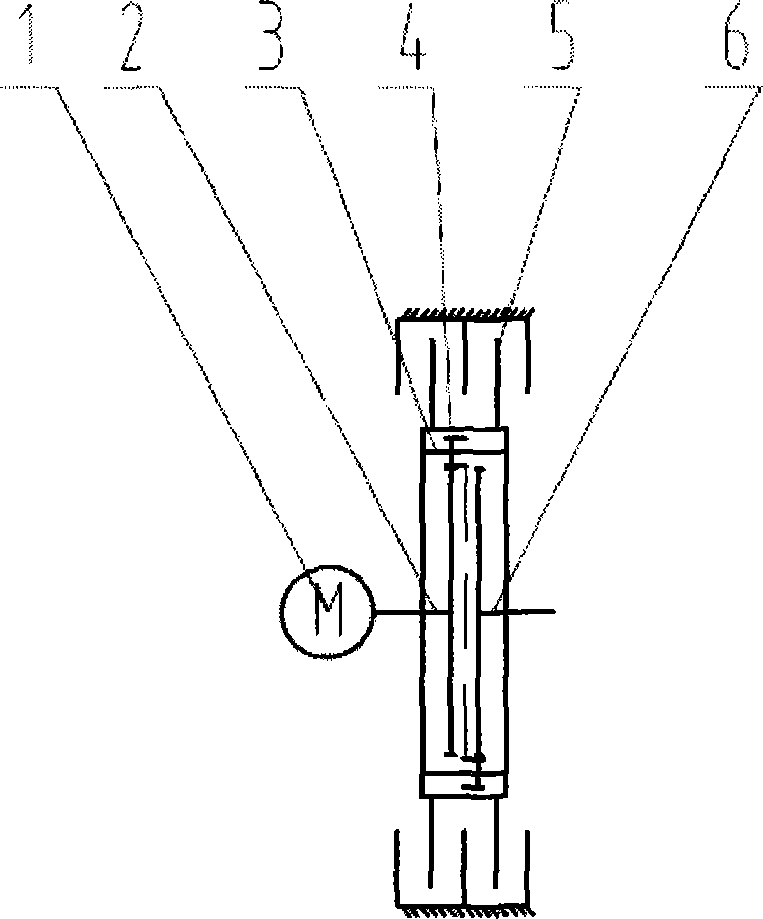

Traction drive of a rail vehicle for driving and generative braking

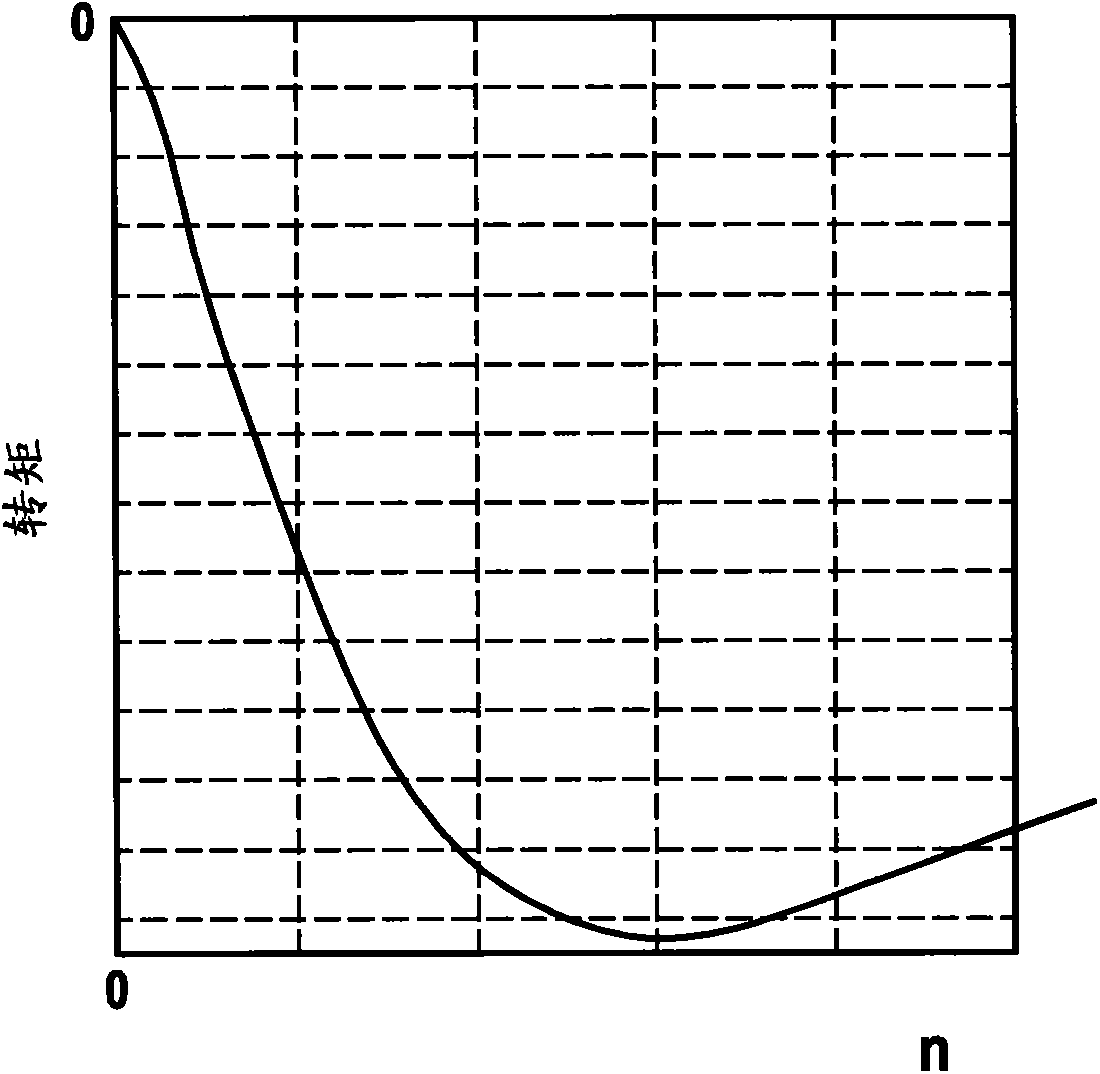

InactiveCN101536300ASimple structural designSmall braking torqueElectric motor controlElectric devicesBrake torqueLoad circuit

The invention relates to a traction drive (1) for the driving and generative braking of a rail vehicle or a combination of rail vehicles, a permanent-field synchronous motor (6a, 6b) and a traction current converter (4a, 4b) being respectively associated with at least two axles of the rail vehicle or combination of rail vehicles. The traction current converter (4a, 4b) comprises at least one pulse current converter (22) on the engine side, and the clamps of the permanent-field synchronous motor (6a, 6b) are connected to a change-over switch (30a, 30b) such that the permanent-field synchronous motor (6a, 6b) can be connected to a load circuit (32a, 32b) containing at least one load element (28a, 28b), in order to drive the pulse current converter (22) or for generative braking. According to the invention, the load circuits (32a, 32b) connected to the permanent-field synchronous motors (6a, 6b) for generative braking are designed such that the brake characteristic lines of the permanent-field synchronous motors (6a, 6b) differ in terms of characteristic features such as the position of the maximum of the brake torque according to the rotational speed.

Owner:KNORR BREMSE SYST FUR SCHIENENFAHRZEUGE GMBH

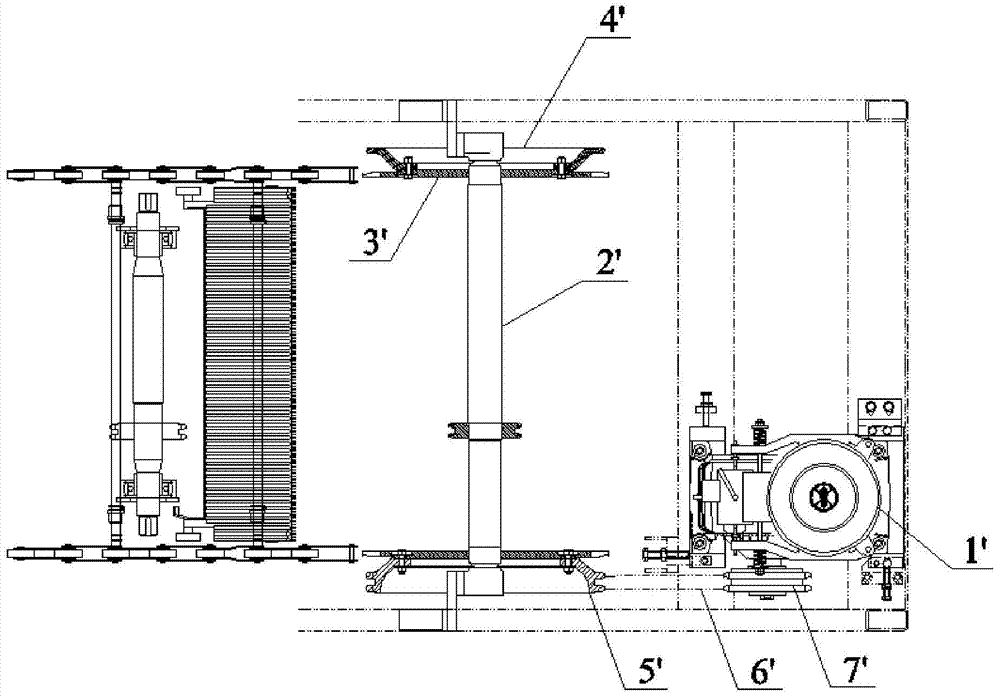

Integrated safe driving device

The invention discloses an integrated safe driving device. The integrated safe driving device comprises a driving motor, a speed reduction box, a main driving shaft and a bearing seat which are pre-integrated and in sequential transmission fit, wherein the bearing seat is arranged at the end, far away from the speed reduction box, of the main driving shaft, installation positions for being fixed to a truss are arranged at the bottoms of the speed reduction box and the bearing box, and an output gear of the speed reduction box and the main driving shaft are positioned through tightly matched conical surfaces. The invention further provides an installation method of the integrated safe driving device. The driving motor, the speed reduction box, the main driving shaft and the bearing seat are pre-integrated, installation of the driving device is facilitated, installation difficulty is reduced, installation accuracy is improved through matching of the conical surfaces, installation efficiency is guaranteed, and products meet national standards and have large market prospects.

Owner:UNITE ELEVATOR

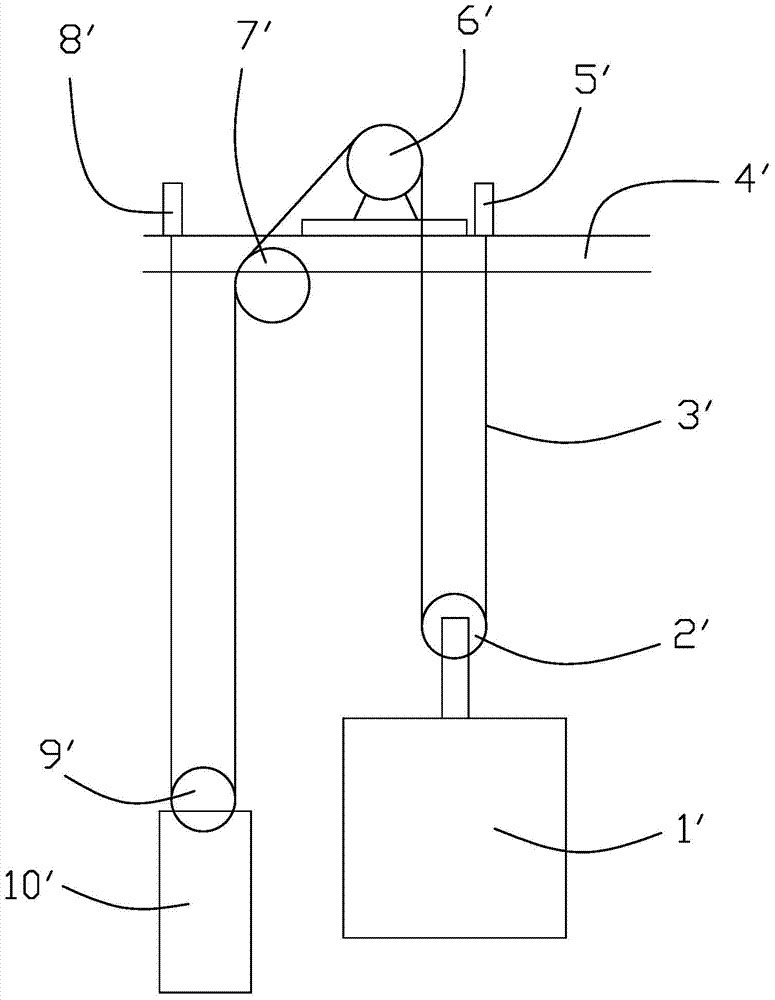

Elevator traction system

The invention relates to an elevator traction system which solves the problem that in the prior art, the diameter of a traction wheel is difficultly further reduced. The elevator traction system comprises a traction machine and guide wheels. A traction wheel is connected to a traction machine shaft. A traction rope winds the traction wheel and the guide wheels, the two ends of the traction rope are connected with an elevator car and a counter weight respectively, the two guide wheels are respectively the elevator car guide wheel and the counter weight guide wheel, the elevator car guide wheel and the counter weight guide wheel are symmetrically arranged below the two sides of the traction wheel, and the traction rope is of a band-shaped structure and composed of multiple rows of steel cores and nonmetal covering materials covering the steel cores. The elevator traction system has the advantages that the size of the traction wheel is reduced, torque is smaller, and therefore the size of the traction machine and the size of a brake device are smaller, the size is reduced, cost is lowered, energy is saved, and service life is prolonged.

Owner:XIZI OTIS ELEVATOR

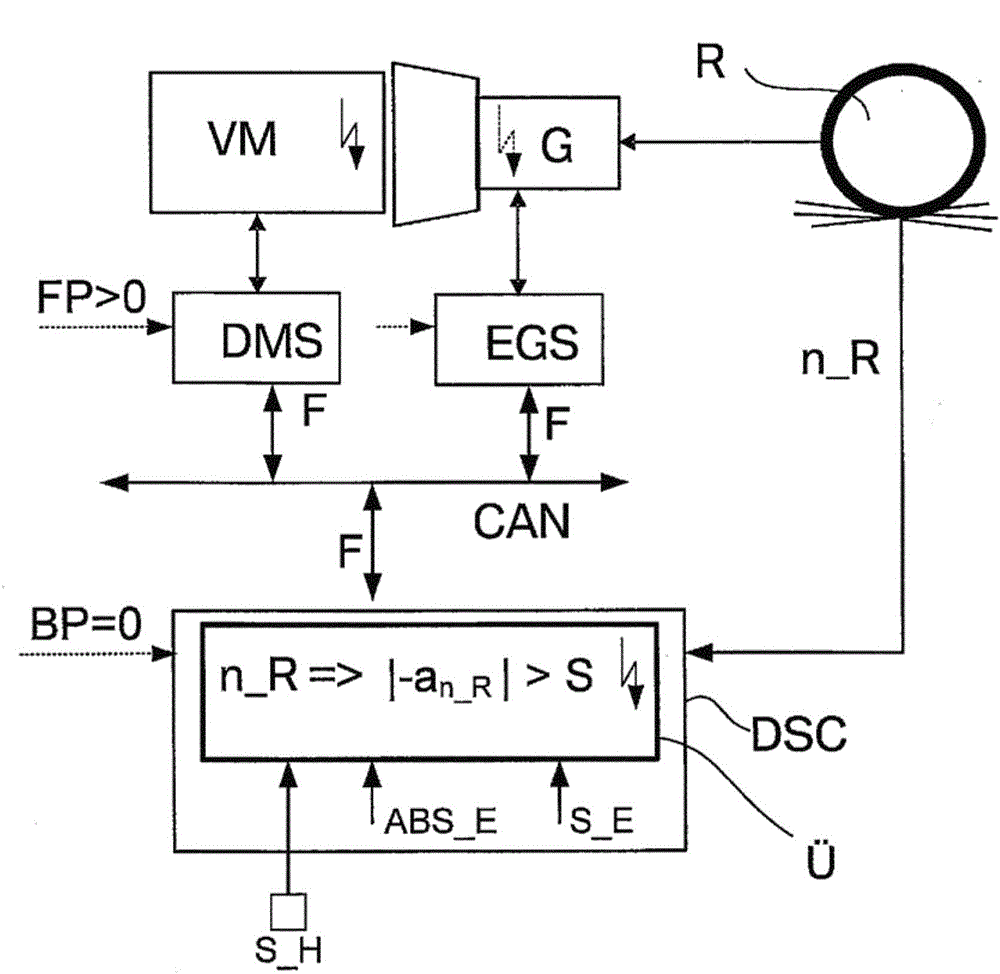

Method and safety concept for recognizing defects in a drive system of a motor vehicle

ActiveCN103562029ASmall braking torqueLimit monitoringRegistering/indicating working of vehiclesBrake control systemsComputer moduleDrive motor

The invention relates to a method and safety concept for recognizing defects in a drive system of a motor vehicle having an electronically controllable brake regulation system and having at least one electronically controllable drive motor and / or having an electronically controllable clutch and / or having an electronically controllable transmission, wherein an electronic brake control device is allocated to the brake regulation system and is connected to an independent monitoring module, wherein the independent monitoring module verifies the occurrence of an implausible braking torque in order to recognize a defect in the drive system.

Owner:BAYERISCHE MOTOREN WERKE AG

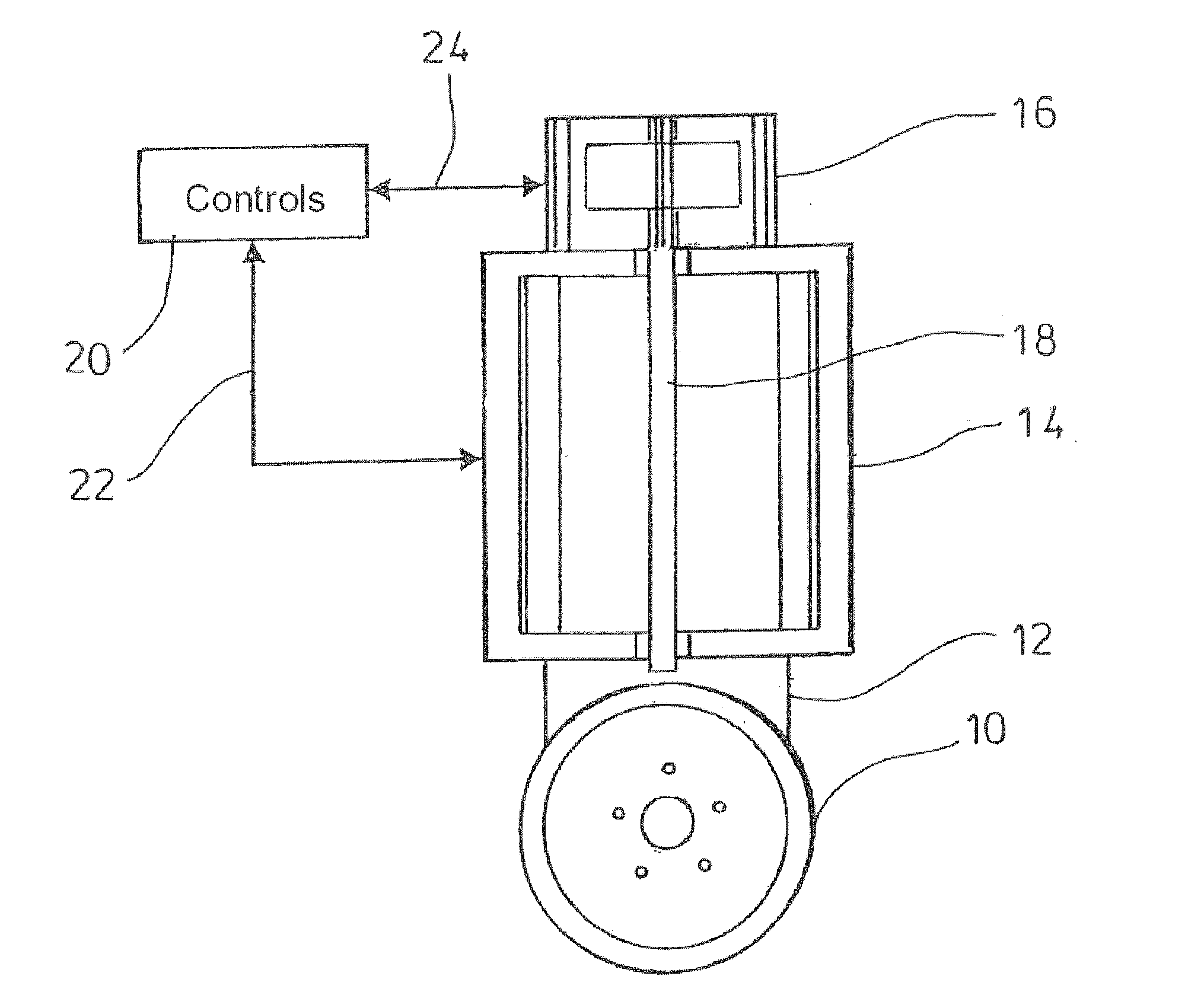

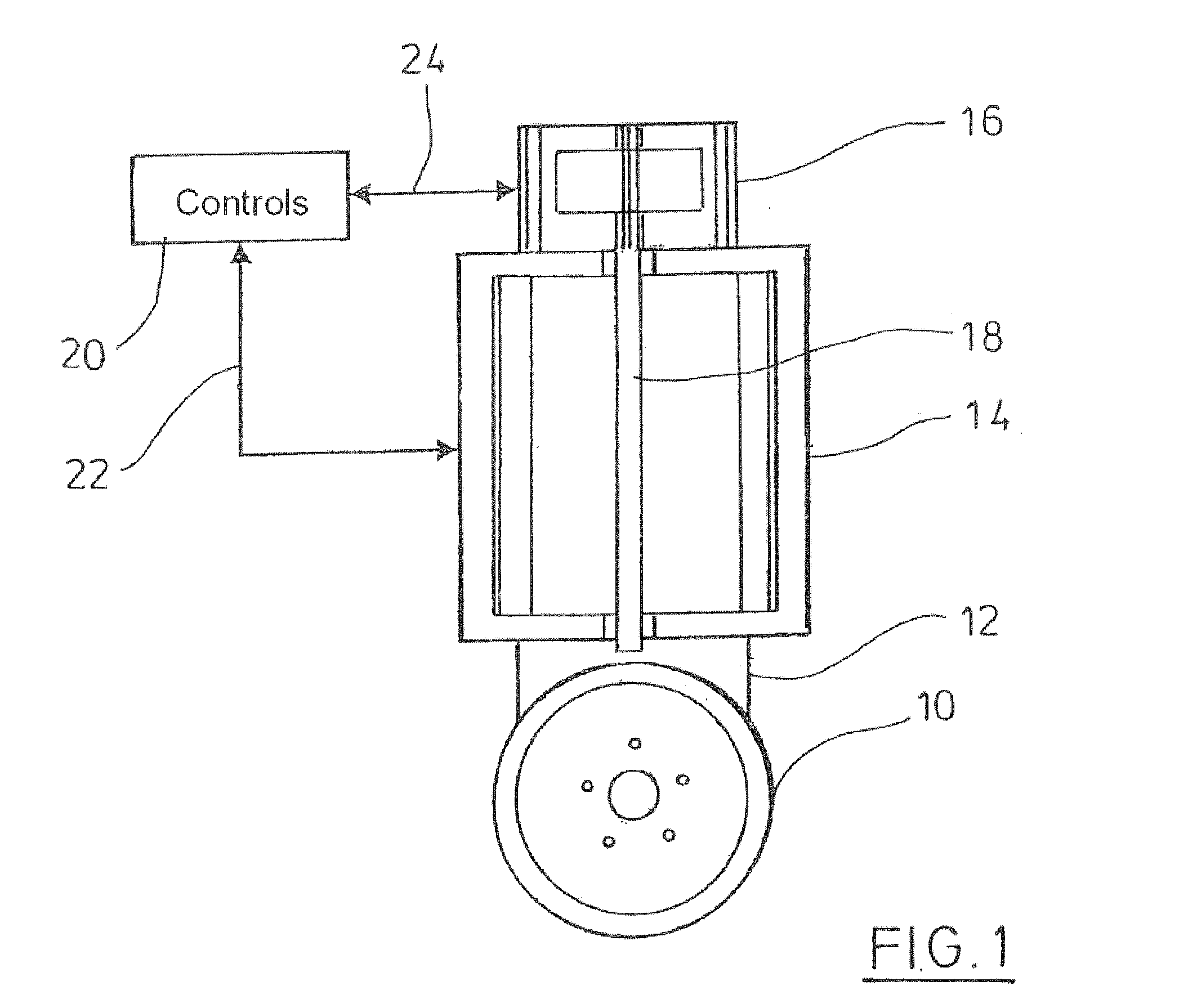

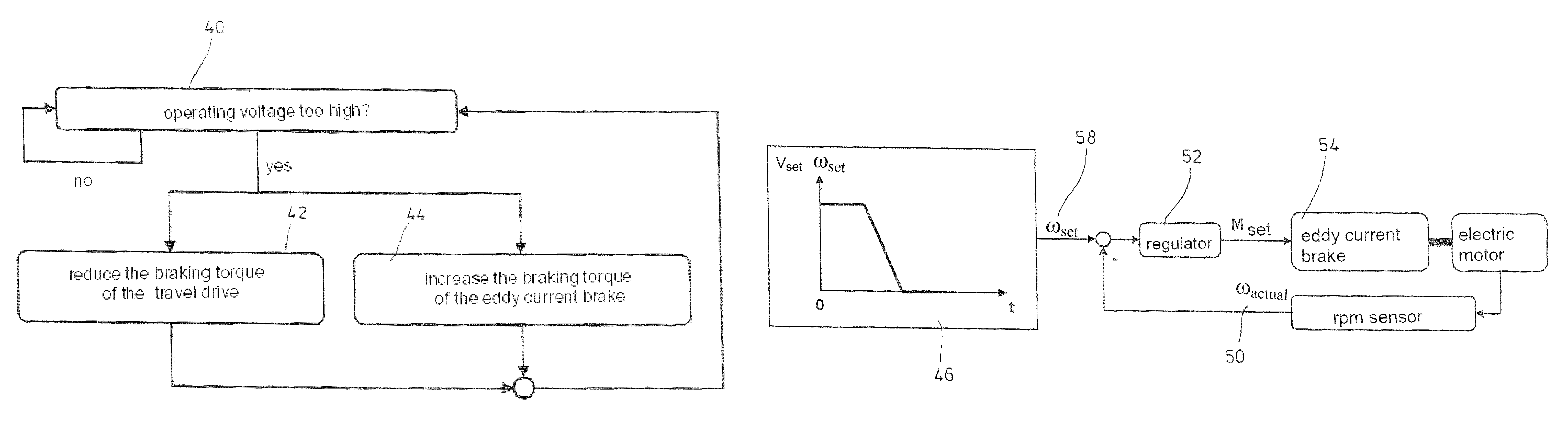

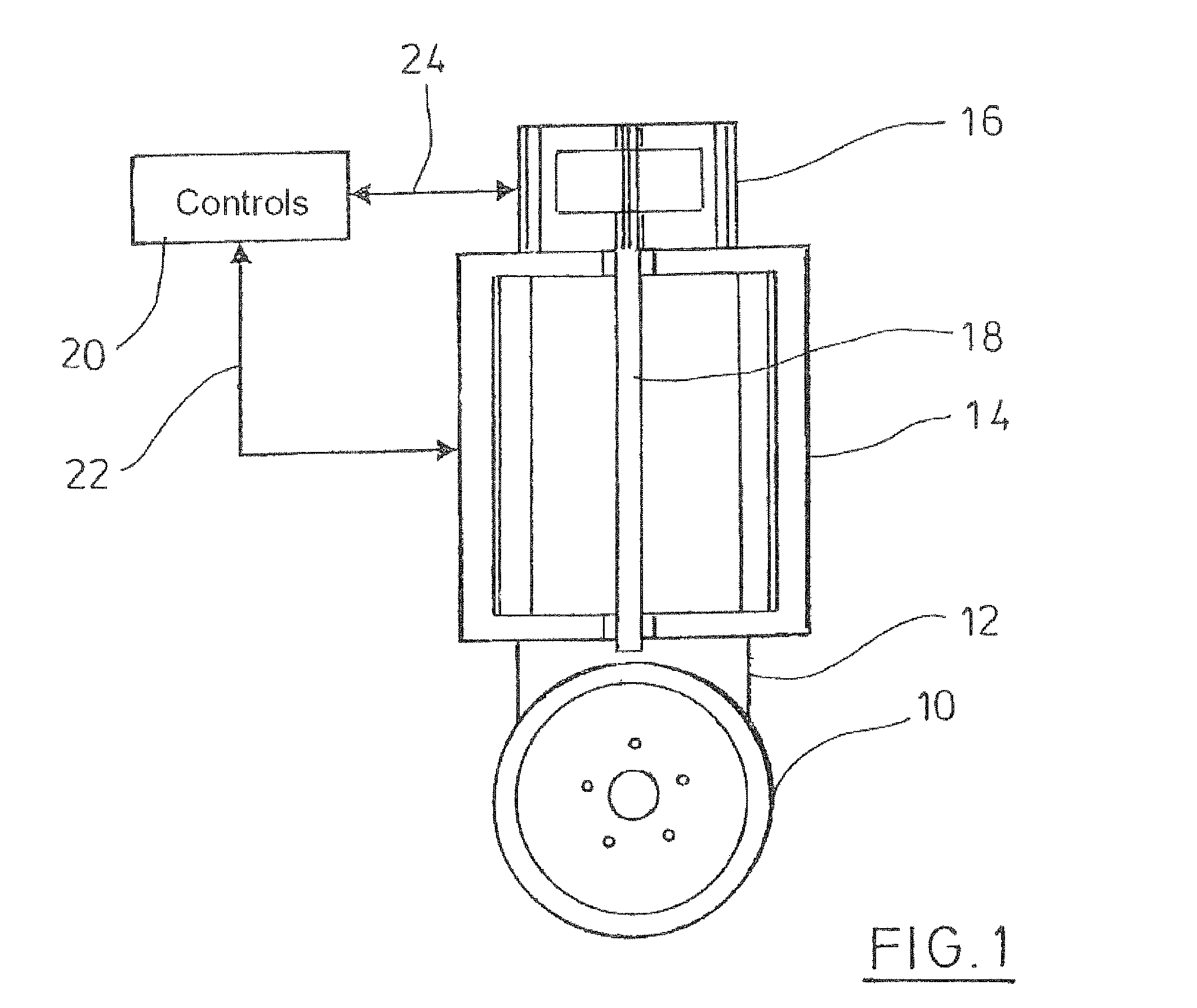

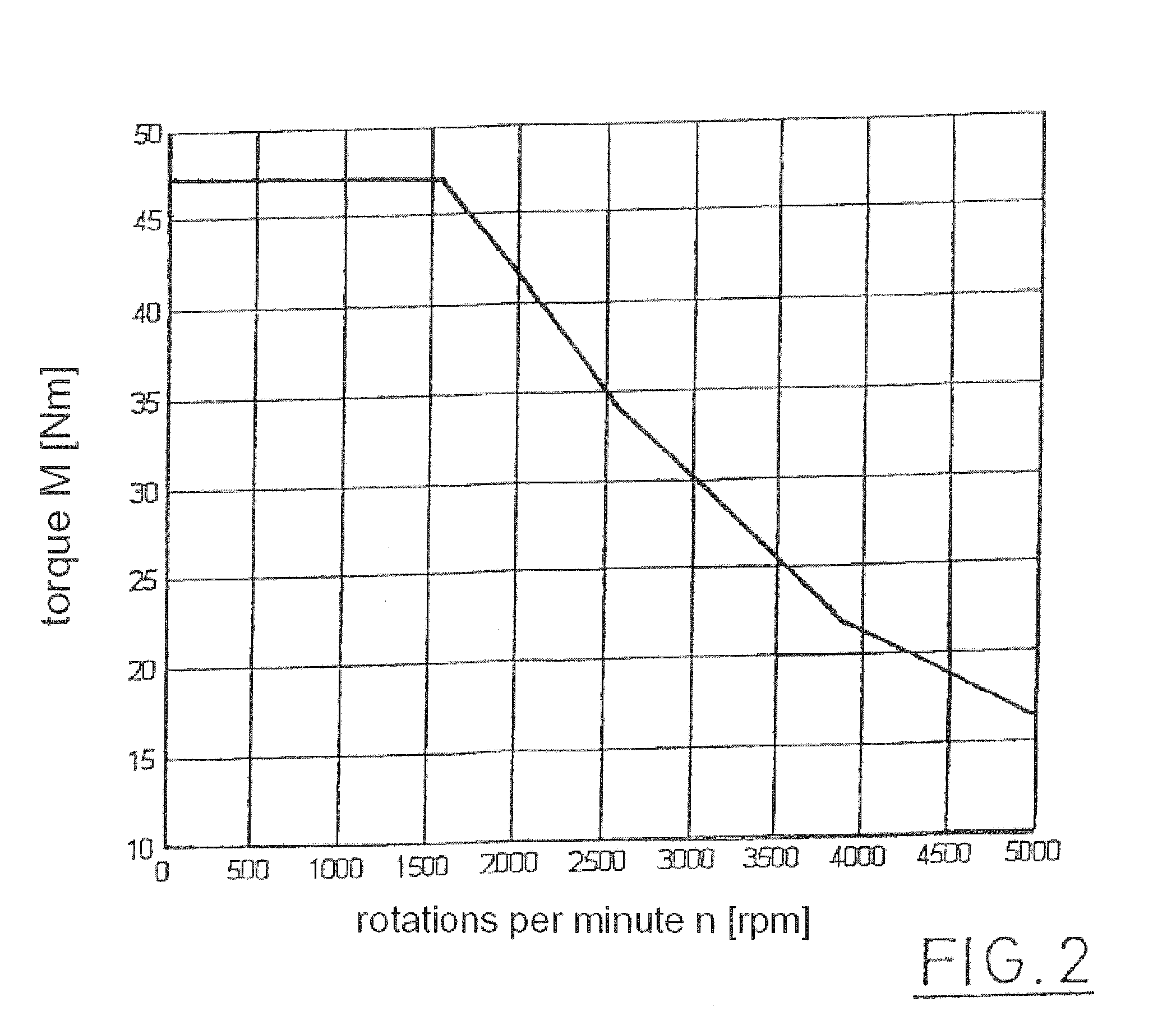

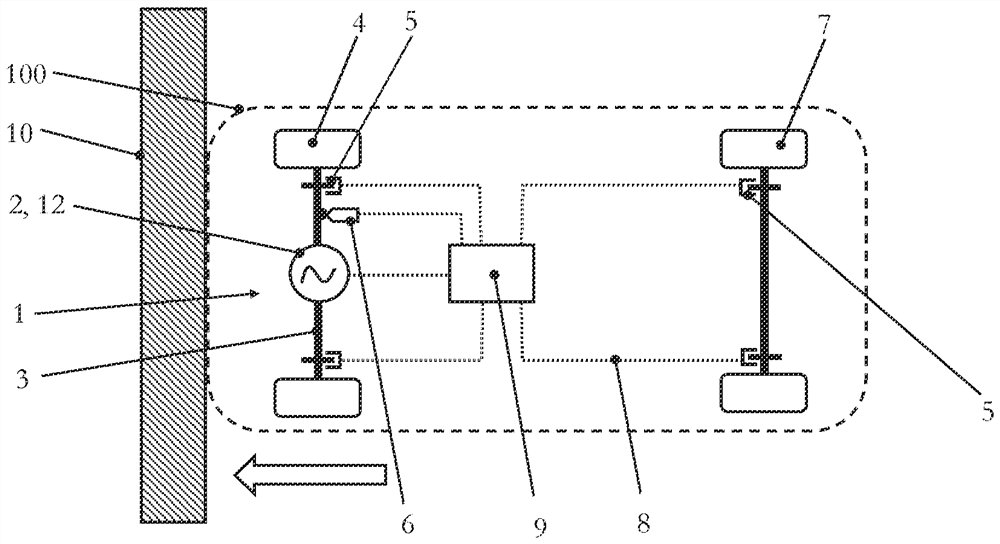

Industrial truck with an electric travel drive

ActiveUS20120226419A1Avoid it happening againReduce stepsAnalogue computers for trafficElectrodynamic brake systemsBrake torqueTruck

Industrial truck with an electric travel drive and controls that can switch the electric travel drive to regenerative operation to brake the industrial truck, wherein an eddy current brake is provided that can be controlled or regulated by the controls during regenerative operation to brake the industrial truck, wherein the controls control or regulate the eddy current brake depending on the rpm of the electric travel drive, and wherein the controls control or regulate the eddy current brake in a manner such that the braking torque of the travel drive is supplemented at high rpms by the braking torque generated by the eddy current brake.

Owner:JUNGHEINRICH AG

Method for operating floor planer with vertically adjustable planing roller

InactiveCN102844497ASink inSmall braking torqueSoil-shifting machines/dredgersRoads maintainenceLoop controlClosed loop

The present invention relates to a method for operating a ground milling machine which comprises at least one height-adjustable milling roller, wherein the milling roller performs a tumbling movement (T′) which is controlled by way of open-loop and / or closed-loop control during lowering in operation. The present invention further relates to a control device for the closed-loop and / or open-loop control of this method, and also to a ground milling machine with such a control device.

Owner:BOMAG

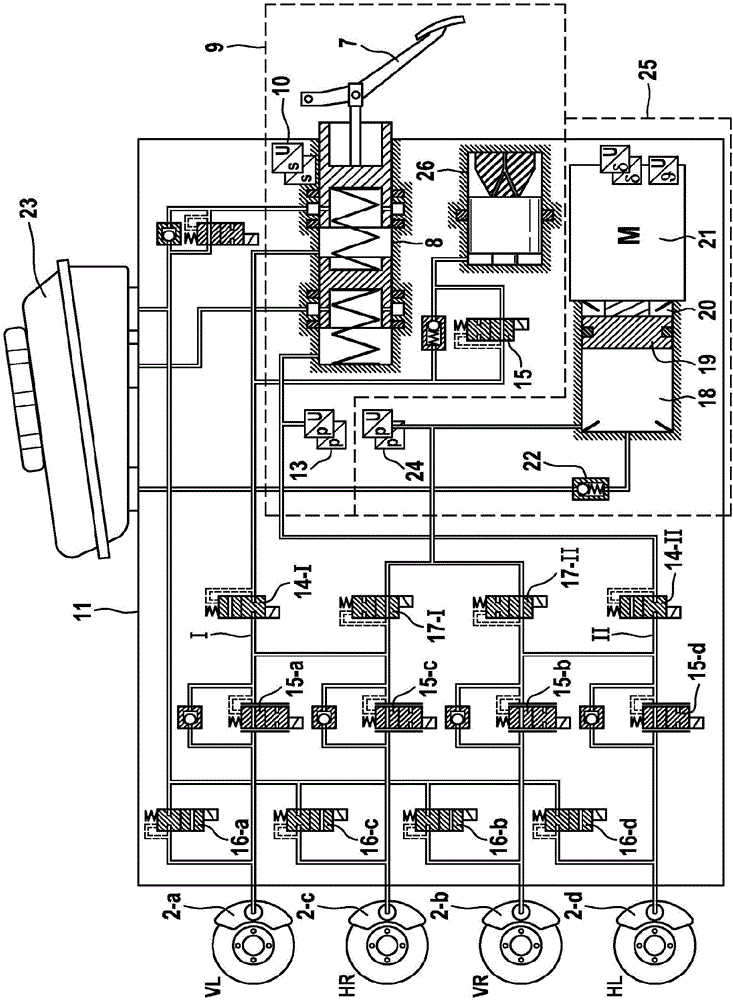

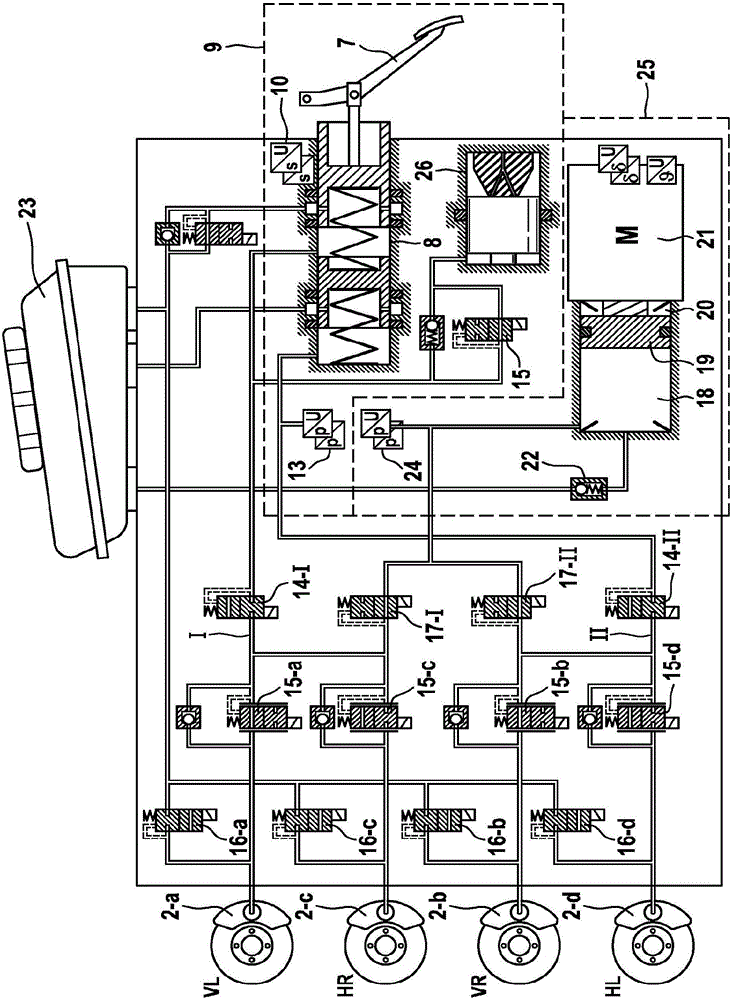

Compensation device for a brake system, and brake system having a compensation device of this type

InactiveCN103906661AProtection of large opening cross-sectionsDoes not impede flowBraking action transmissionBrake control systemsActuatorPressure threshold

The invention relates to a compensation device (9) having a variable compensation volume (13, 22) for use in a brake system (1) in order to carry out a recuperation operation, comprising: an electrohydraulic actuator (10) for providing a variable compensation volume (13, 22); and a guard valve (15) which is configured to separate the compensation volume (13, 22) from an inlet-side inlet volume (31) with respect to an external pressure change if an absolute pressure in the inlet volume (31) exceeds a predefined pressure threshold value. Furthermore, the invention relates to a motor-vehicle brake system having a compensation device of this type.

Owner:ROBERT BOSCH GMBH

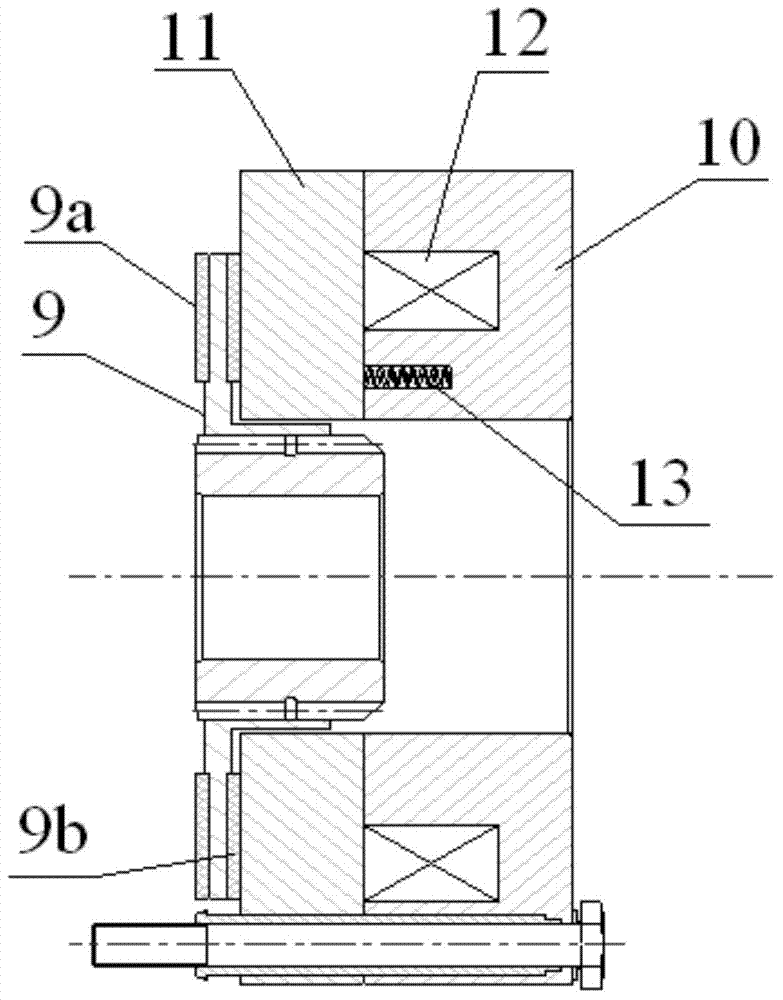

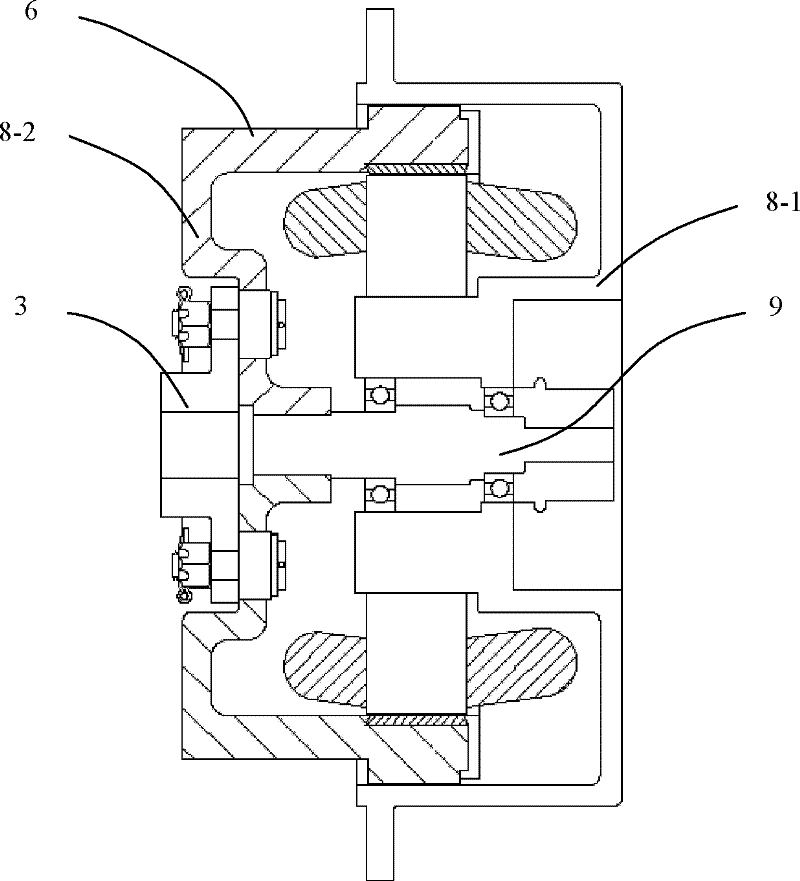

Embedded electromagnetic liquid cooling retarder with speed increaser

InactiveCN107968547AOvercoming low braking power densitySmall braking torqueAsynchronous induction clutches/brakesCooling/ventillation arrangementBrake torqueStator

An embedded electromagnetic liquid cooling retarder with a speed increaser belongs to the automobile auxiliary braking field. The retarder comprises an eddy current retarder portion and a planetary gear mechanism portion. The eddy current retarder portion comprises a retarder stator, a retarder rotor and an excitation coil. An axial section of the retarder stator is a C-shaped structure. A water channel is arranged in the stator and an external layer surface is provided with a water inlet and a water outlet. The excitation coil is wound into a shape and then is directly and fixedly arranged inthe stator. The rotor is divided into a magnetic conductive tooth portion and a connection portion. A magnetic conductive tooth is embedded between internal and external layers of the stator. A rotorflange is connected to a sun gear of a planetary gear mechanism. The retarder increases a rotation speed of the retarder rotor through the planetary gear mechanism and a speed n of an input shaft isincreased by k times (the k is between 2 and 3). Under the condition that braking power P is not changed, a braking torque T of the retarder can be reduced to T / k so that a massic volume of a retarderbody can be greatly reduced. The structure is simple, a rotational inertia of the rotor is small, a water cooling effect is good and braking safety of an automobile is improved.

Owner:BEIJING UNIV OF TECH

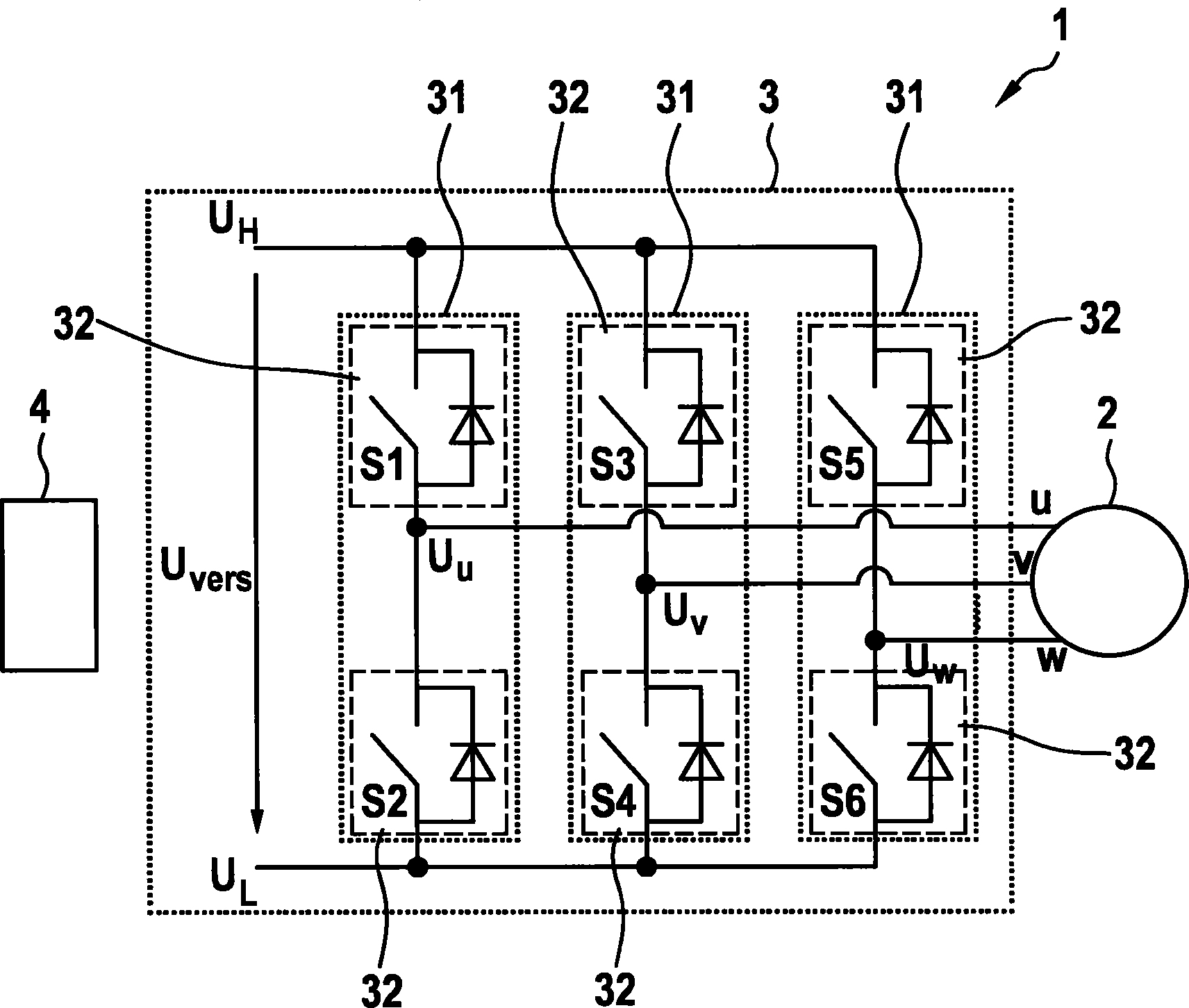

Method and apparatus for operating an electronically commutated electrical machine in the event of a fault

ActiveCN103999352AIncrease resistanceSmall braking torqueAC motor controlElectric motor controlDriver circuitElectrical resistance and conductance

The invention relates to a method for operating a multiphase electrical machine (2) in the event of a fault, wherein the electrical machine (2) is driven with the aid of a driver circuit (3), wherein the driver circuit (3) has half-bridge circuits (31), each associated with a phase (U, V, W), and bridge paths (32) for connecting or disconnecting predetermined voltage potentials to / from the respective phases (U, V, W) of the electrical machine (2), wherein one or more of the bridge paths (32) are operated according to a first fault operating mode if a fault is detected, wherein, in the first fault operating mode, the one or more bridge paths (32) are controlled in such a manner that said paths connect a first of the predetermined voltage potentials to the phase (U, V, W) via a predetermined electrical resistor.

Owner:ROBERT BOSCH GMBH

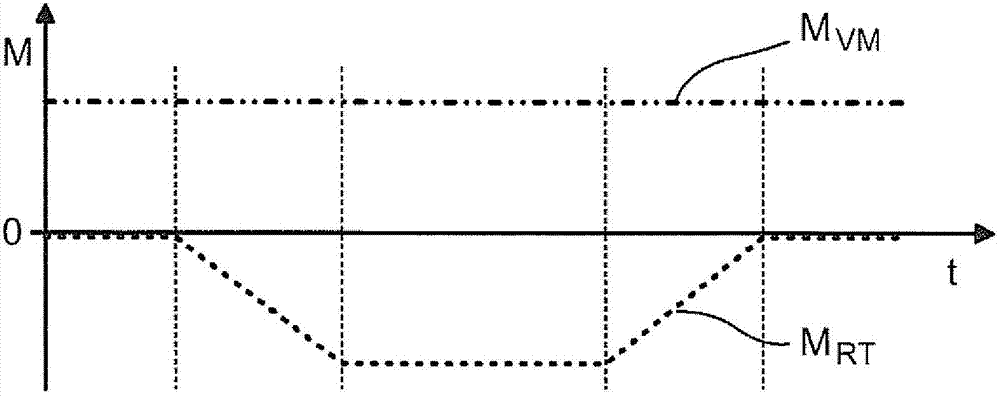

Method for performing gear shifting control on automated gear shifting transmission

InactiveCN102889376AReduce pulling forceIncrease braking torqueBraking element arrangementsHydrodynamic brakesImpellerDrive shaft

A method for performing gear shifting control on an automated gear shifting transmission. A torque conversion clutch device is placed in front of the transmission and includes: a hydraulic torque converter which has a pump impeller connected with a transmission shaft of a driving motor of an internal combustion engine configured for turbocharging, and a turbine connected with a middle shaft; a retarder of a rotor which is in transmission connection with the middle shaft; and a cut-off clutch configured to be an automated friction clutch and arranged between the middle shaft and an input shaft of the transmission, during traction and gear shafting, the input shaft of the transmission remains torque-free as far as possible through reduction of a load when gear shifting begins. To prevent weakening of motive force of the driving motor when traction and gear shifting finish and the load is established, the arrangement is that: in the circumstance of maintaining motor torque output by the driving motor, the reduction of the load on the input shaft is caused by absorbing correspondingly high retarding torque in the retarder, and the retarding torque absorbed from the retarder increases to above the motor torque of the driving motor at the beginning of traction and gear shifting, and reduces to zero when traction and gear shifting finish.

Owner:ZF FRIEDRICHSHAFEN AG

Elevator tractor

InactiveCN102515001AIncrease powerGuaranteed uptimeMechanical energy handlingBuilding liftsSynchronous motorBrake shoe

The invention relates to an elevator tractor which comprises a synchronous motor, a speed reducing box, a traction wheel and an electromagnetic brake, wherein the electromagnetic brake comprises a brake wheel and a brake shoe which are matched with each other for braking; the synchronous motor comprises a main motor body and an outer rotor; and the brake wheel is integrated on the outer rotor and is positioned between the main motor body of the synchronous motor and the speed reducing box. Compared with an asynchronous geared tractor, the elevator tractor can work at lower rotating speed and is lower in noise; a helical gear is adopted by the elevator tractor in a matching way and is taken as a speed reducing mechanism of a transmission part, so that the whole transmission efficiency of the elevator tractor can be improved; the speed reducing box is arranged, so that the requirement on the output torque of the synchronous motor can be reduced, the cost increase of an elevator caused by the facts that larger moment is output by the synchronous motor and a great deal of magnetic steel is needed to be used is avoided; an input end of the speed reducing box is braked, so that the braking moment is small, and the requirement on the brake is low; and meanwhile, by adopting a structure integrating a brake disc, a coupler and the outer rotor of the motor, the elevator tractor is compact in structure and meets the using requirement of a small machine room elevator.

Owner:HITACHI ELEVATOR CHINA

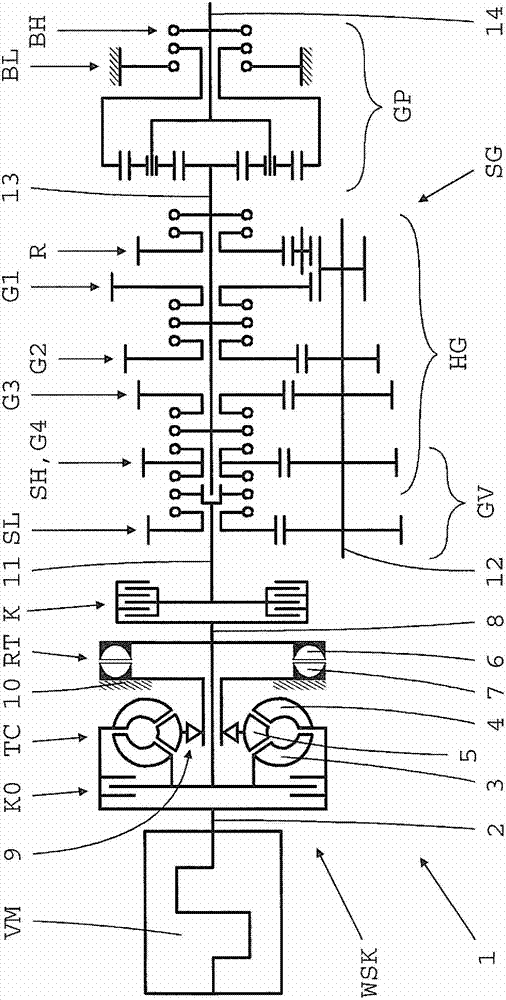

Industrial truck with an electric travel drive

ActiveUS8639421B2Generate additional braking torqueSmall braking torqueAnalogue computers for trafficElectrodynamic brake systemsBrake torqueTruck

Industrial truck with an electric travel drive and controls that can switch the electric travel drive to regenerative operation to brake the industrial truck, wherein an eddy current brake is provided that can be controlled or regulated by the controls during regenerative operation to brake the industrial truck, wherein the controls control or regulate the eddy current brake depending on the rpm of the electric travel drive, and wherein the controls control or regulate the eddy current brake in a manner such that the braking torque of the travel drive is supplemented at high rpms by the braking torque generated by the eddy current brake.

Owner:JUNGHEINRICH AG

Coupler with controllable start function

The invention provides a coupler capable of achieving stable start. A motor is connected with a left half shaft of a bevel gear planet differential mechanism. A right half shaft is an output shaft. A planet carrier is connected with a friction plate in a hydro-viscous brake. The output torque is controlled by controlling the braking torque of the hydro-viscous brake.

Owner:方振江

High-temperature resistant friction material and preparation method thereof

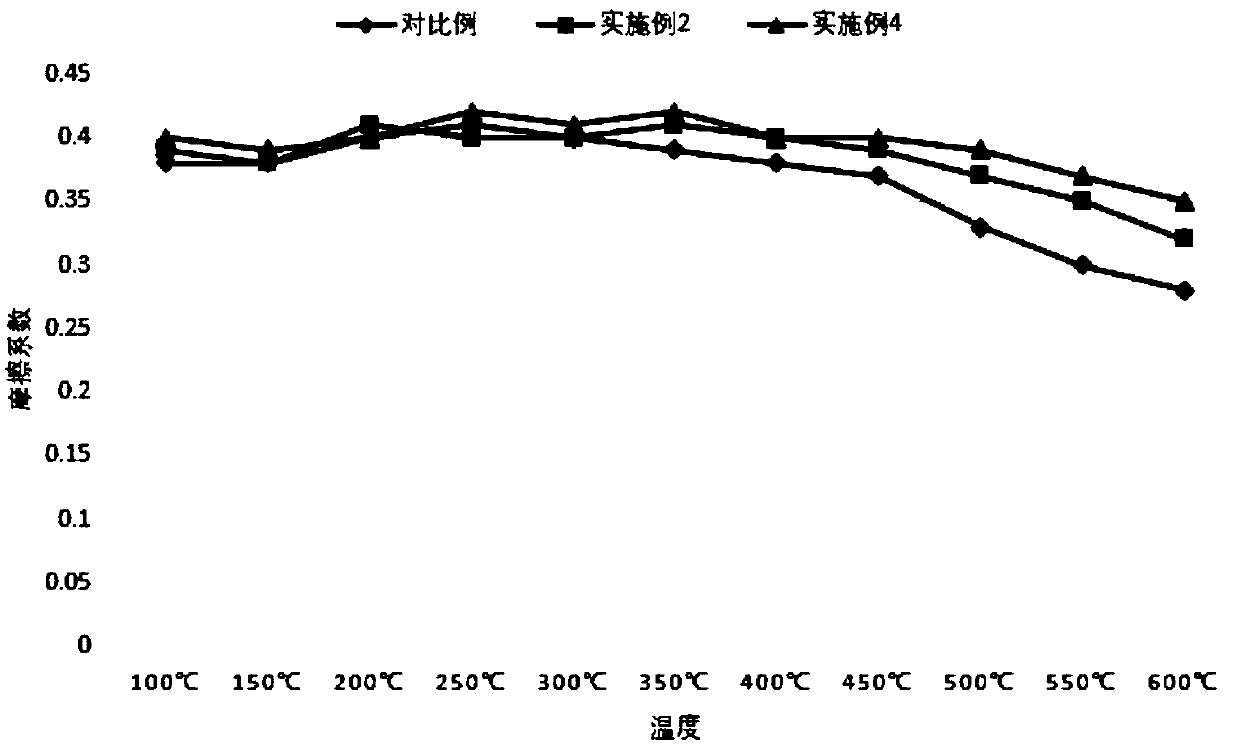

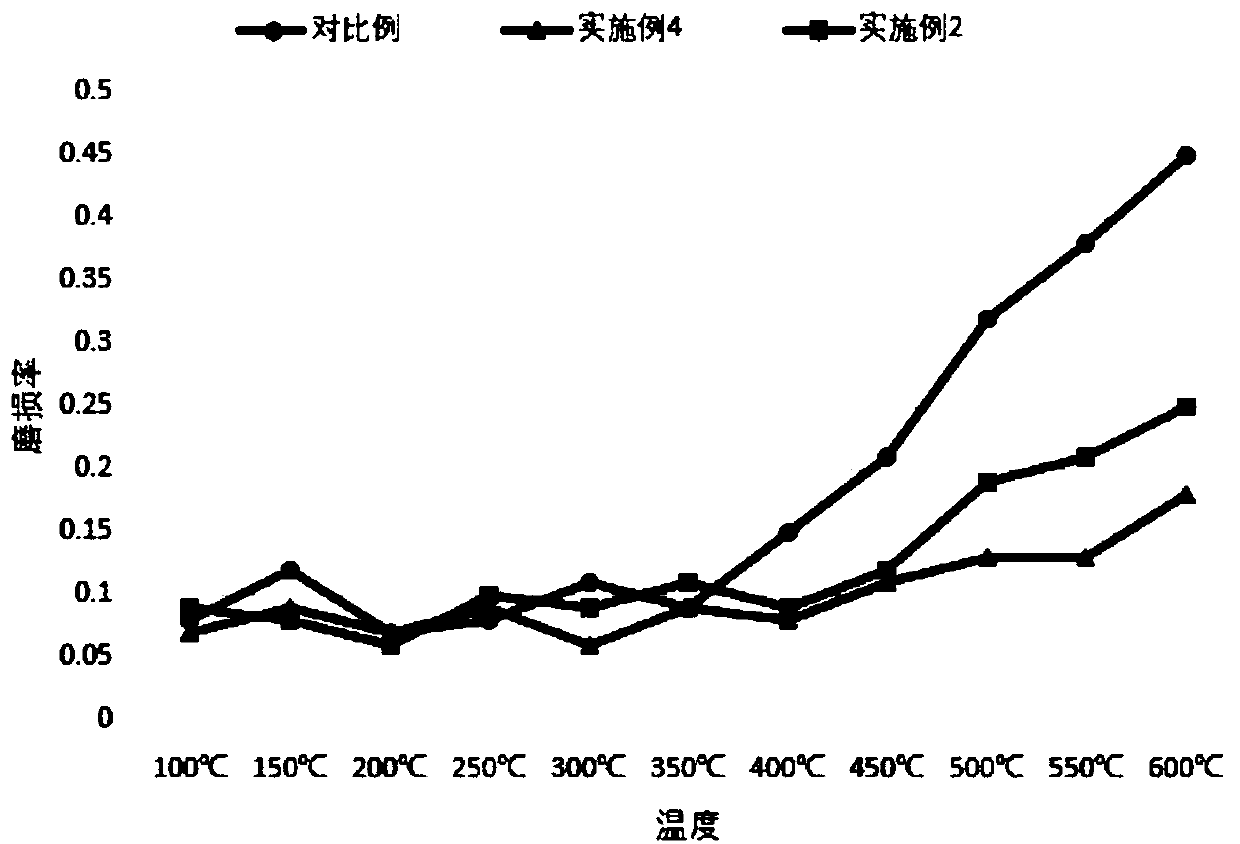

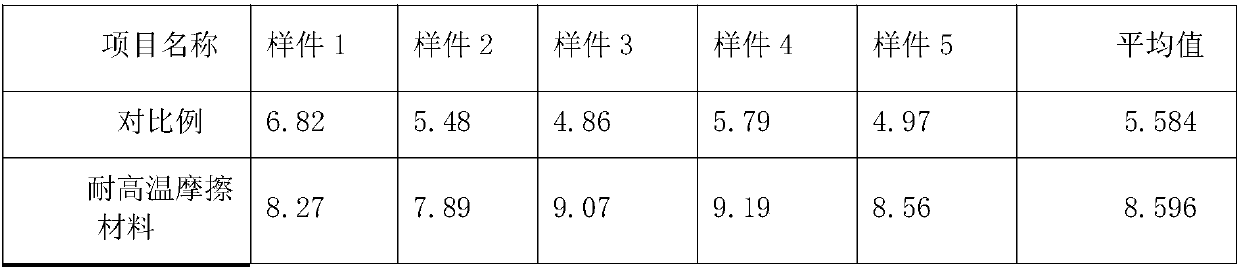

InactiveCN107740828AAvoid carbonizationReduce hardnessOther chemical processesFriction liningFiberMass ratio

The invention discloses a high-temperature resistant friction material. The high-temperature resistant friction material comprises heat-conduction mineral fibers, inorganic high-temperature adhesivesand porous mineral powder. A preparation method of the high-temperature resistant friction material comprises the following steps of (1) taking and mixing the heat-conduction mineral fibers, the inorganic high-temperature adhesives and the porous mineral powder according to the mass ratio; (2) cleaning, degreasing and polishing the surface of a steel backing and spraying the adhesives to the surface of the steel backing for standby application; (3) conducting pressing; (4) conducting heat treatment; (5) conducing grinding treatment; and (6) spraying plastic paint to the surface of the steel backing. The high-temperature resistant friction material is scientific in proportion, easy to manufacture and low in cost, has remarkable physical performance and stable friction coefficient. Meanwhile, the high-temperature resistant friction material is stable in friction coefficient, small in degeneration, good in recovery performance, moderate in hardness, comfortable and reliable in braking andcapable of lowering braking noise.

Owner:WUHAN YOUFIN FRICTION MATERIAL

Support device

ActiveCN105573100ASave construction spaceReduce weightVisual indicationFrameworksEngineeringFrictional resistance

The invention relates to a support device for a component which can rotate or carry out translational movements of a watch with a movement and at a fixed component of the watch. The movable component has one or more edges 14 extending along its path of movements with constant cross sections, which mutually spaced bearing rollers 20 with radially encircling grooves 21 on their radially circumferential peripheries are meshed into. Axes 19 extending perpendicular to the movement path of the movable component are provided. The bearing rollers 20 are freely rotatably around the axes. Eccentric bearing projections 16 axially adjoining the axis 19 are also provided, and are rotatably mounted adjustably in corresponding bearing recesses 15 of the fixed component of the watch under frictional resistance.

Owner:LANGE UHREN

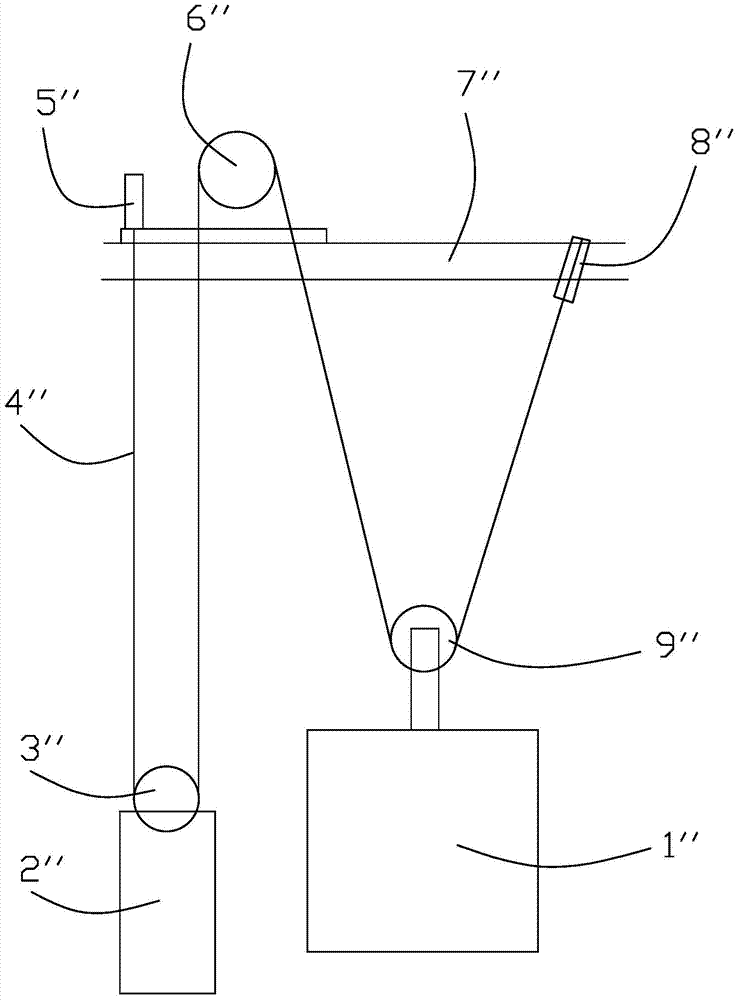

Auxiliary braking system

ActiveCN106184146AReduce frictionReduce lossBraking element arrangementsFluid braking transmissionForce generationEnergy loss

The invention discloses an auxiliary braking system which comprises a first braking disk, a second braking disk, a first gear transmission mechanism connected with the first braking disk, a second gear transmission mechanism connected with the second braking disk, and a braking force generation device which is connected with a power output shaft of the first gear transmission mechanism and is used for supplying braking force to a power output shaft of the second gear transmission mechanism. The auxiliary braking system disclosed by the invention reduces friction of the braking disks and energy loss, and can provide a reliable braking force and improve the braking reliability.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

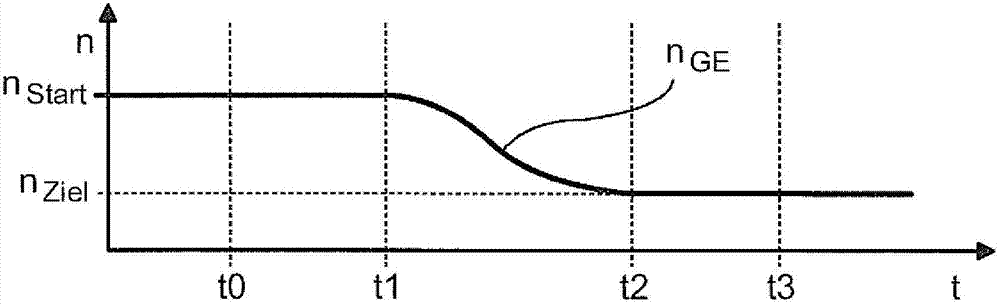

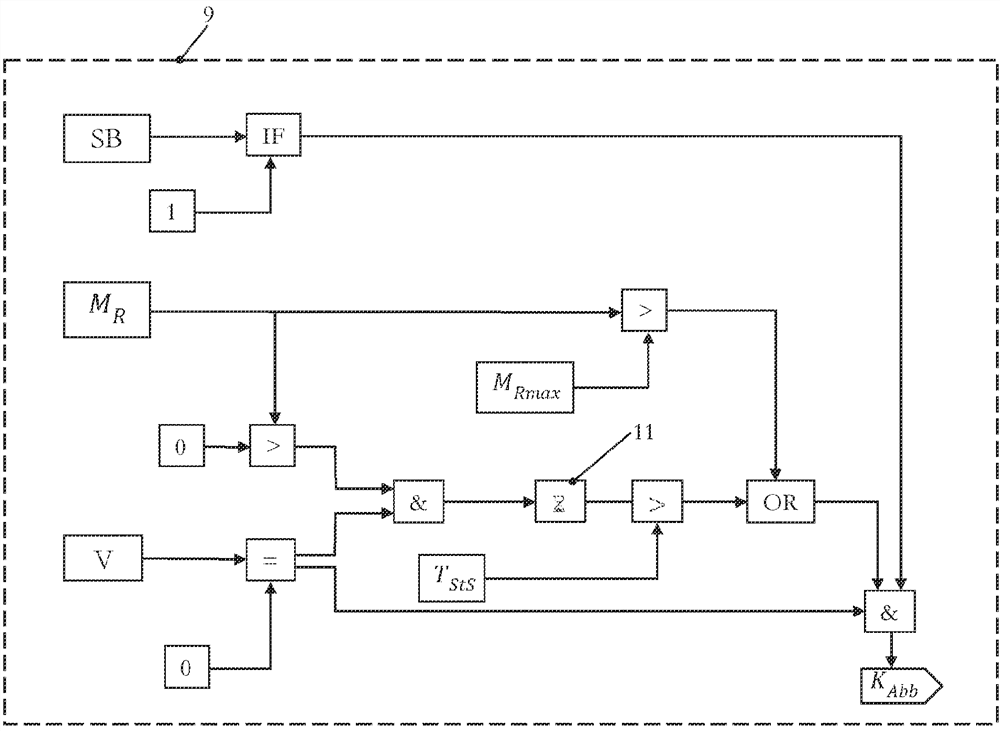

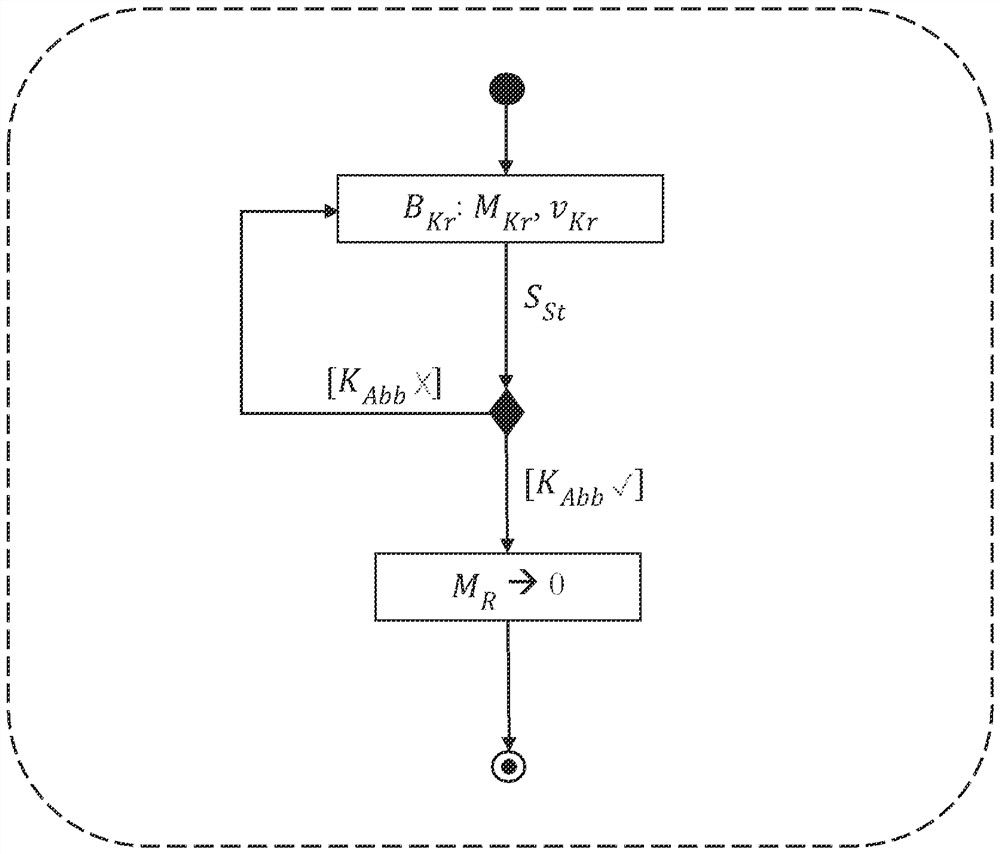

Method for adjusting a cranking operating state, controller, drive assembly and vehicle

ActiveCN111661053ASmall braking torqueReduce energy consumptionSpeed controllerElectric devicesElectric driveControl theory

The invention relates to a method for adjusting a creep operating state, a controller, a drive assembly and a vehicle. The invention relates to a method for controlling a creep operating state (BKr) of a vehicle (100) having an electric drive (1), comprising: starting the creep operating state (BKr); establishing a wheel torque (MR) up to a creep torque (MKr) for establishing and maintaining a creep speed (vKr); detecting a wheel stop signal (SSt); checking an interrupt criterion (KAbb) for interrupting the creep operating state (BKr); wheel torque (MR) is eliminated by deactivating the electric drive (1) and ending the creep operating state (BKr) in the presence of an interruption criterion (KAbb). The invention further relates to a control device (9), to a drive assembly (1) and to a vehicle (100), each of which is suitable for carrying out the method according to the invention.

Owner:VOLKSWAGEN AG

Safety apparatus for monitoring and controlling driving of motor vehicle

InactiveCN100544993CShort delay timeEnsure driving safetyTractorsPropulsion unit safety devicesLow speedDriver/operator

The invention relates to a motor vehicle driving monitoring safety device, which is characterized by a driver's sitting posture frequency detection device, a driver's head and face infrared detection device, a driving steering wheel grip detection device, a driving steering wheel rotation angle and a rotation angular speed detection device, etc.; through each detection device, Detect the dangerous driving operation state such as the irregular driving operation state of the driver when driving and the misoperation in the occasional emergency, according to the speed of the vehicle, through the processing of the microprocessor CPU, the optimal safety control of the safe driving of the motor vehicle is realized, and the speed is high. Early alarm and early braking time, late alarm and late braking time at low vehicle speeds, large braking torque at high vehicle speeds, small braking torque at low vehicle speeds, and adjust the length of braking time according to different vehicle speeds, thus effectively ensuring the driving safety of motor vehicles. A slight improvement can also be applied to monitoring safety devices on other equipment operating tables.

Owner:刘红旗

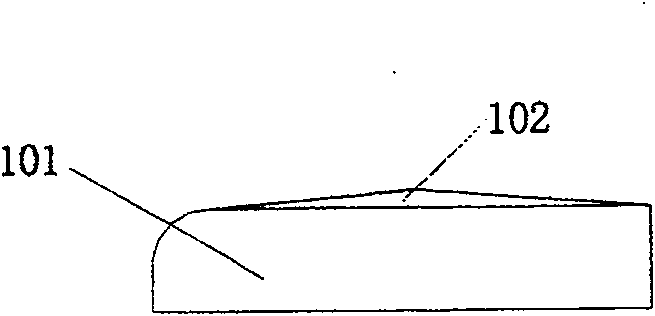

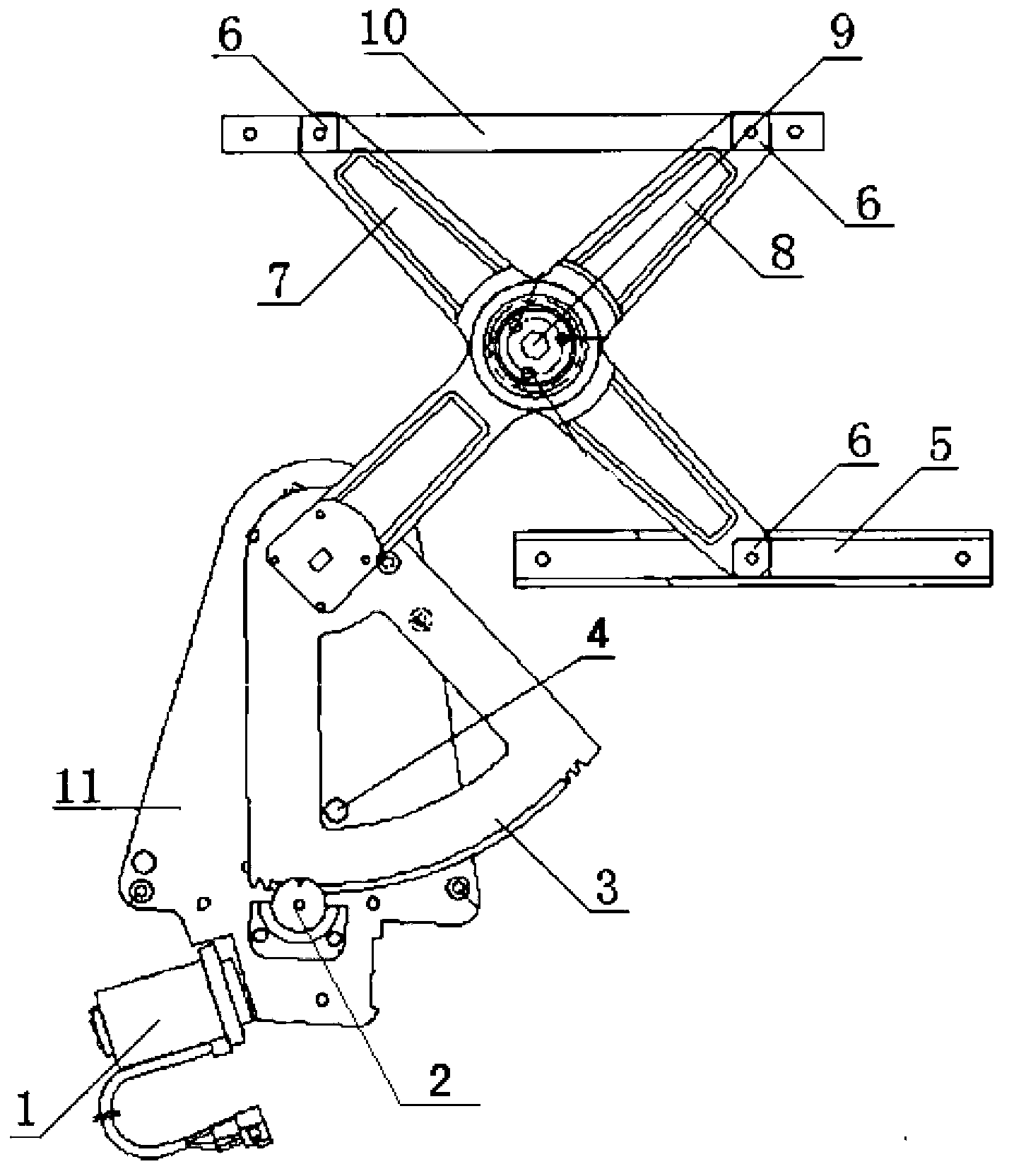

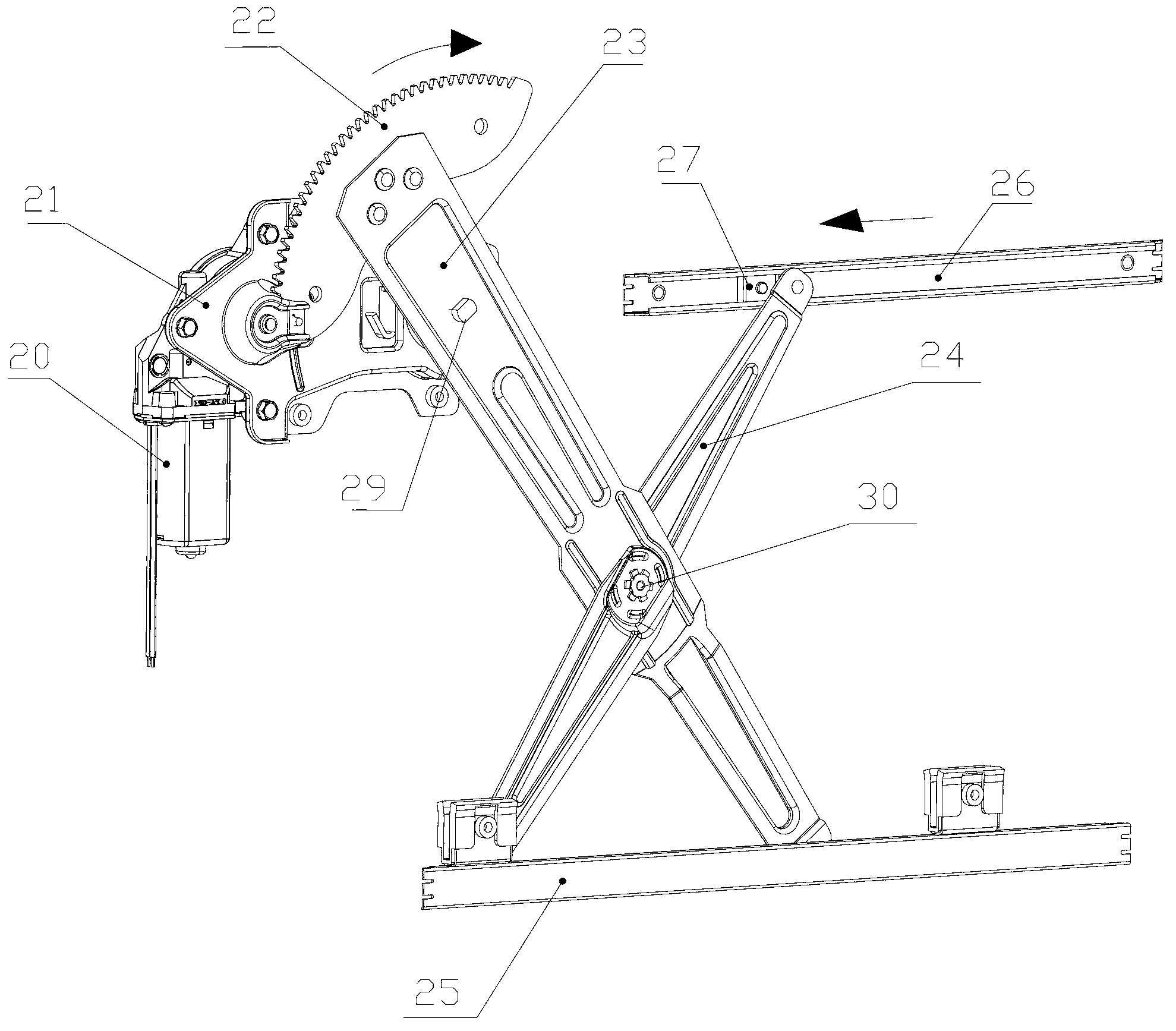

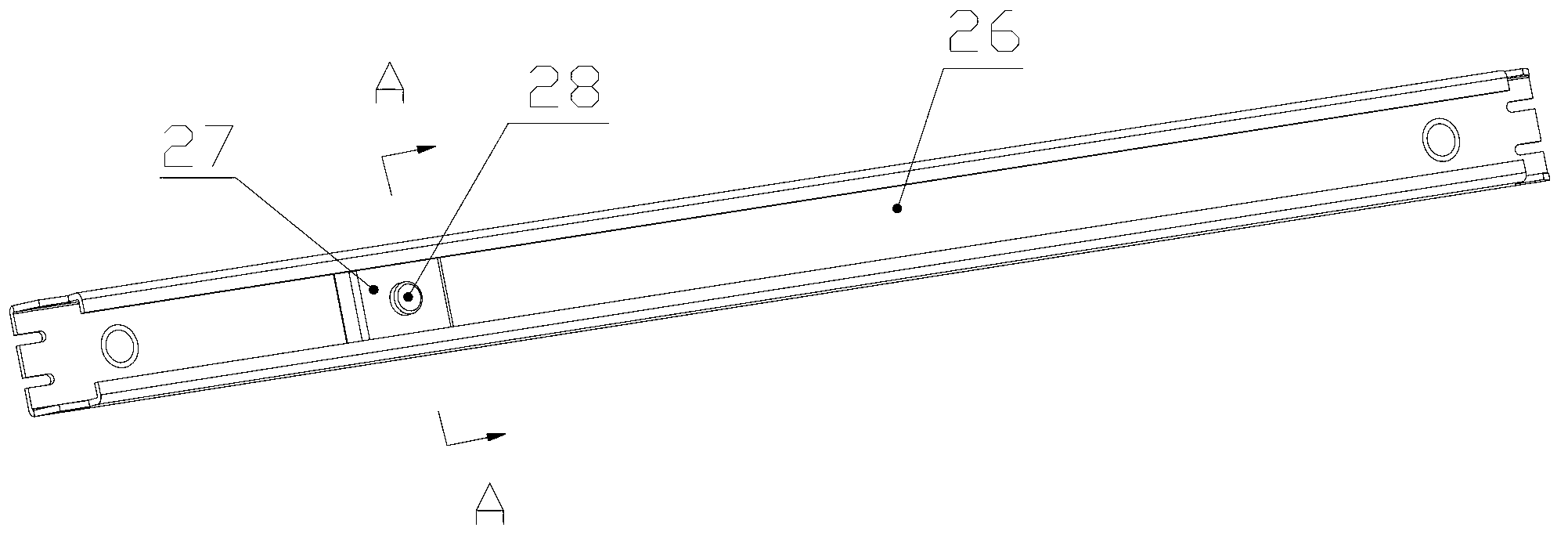

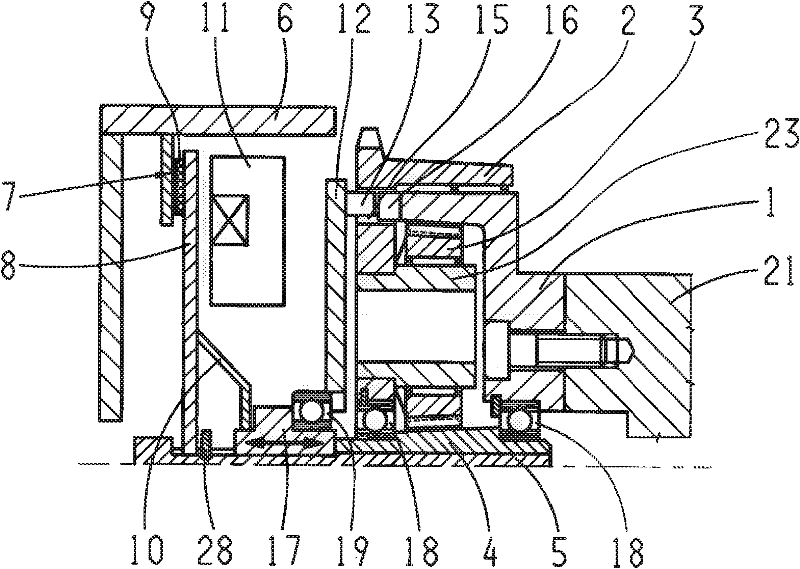

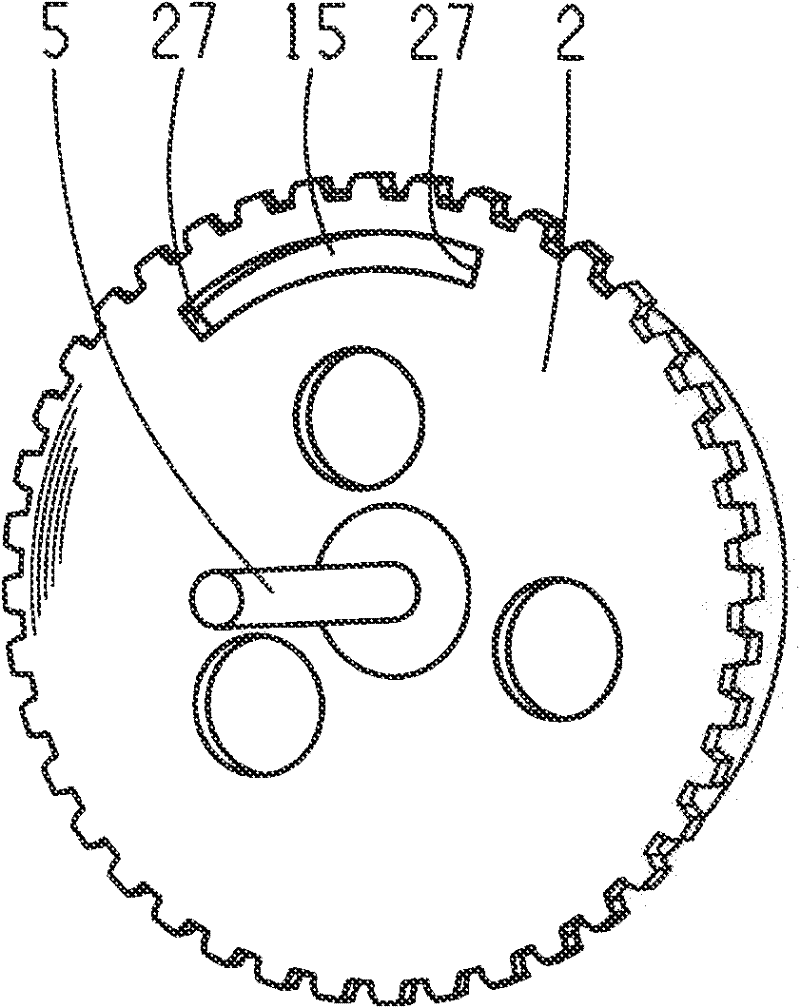

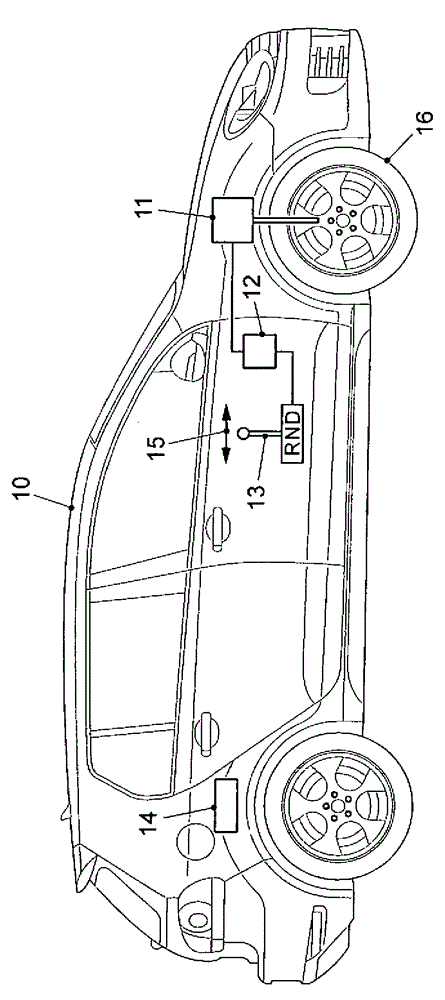

Glass lifter, automobile cab and automobile

The invention discloses a glass lifter, an automobile cab and an automobile. A limiting component is arranged on the glass lifter and can be arranged on a fixed sliding groove or a movable sliding groove. In the glass lifting and descending process, when glass lifts or descends (or is about to lift or descend) to a limit position, a driven arm and / or a driven arm is subjected to limitation of the limiting component and cannot continuous moving, and the braking effect of the glass lifter is achieved. During braking, due to the fact that the limiting component is farther away from a motor, when braking force is transmitted to an output shaft of the motor, braking torque which the motor is subjected to is smaller, impact to the motor is reduced, service life of the motor is prolonged, and quality of the whole glass lifter is improved.

Owner:SANY AUTOMOBILE MFG CO LTD

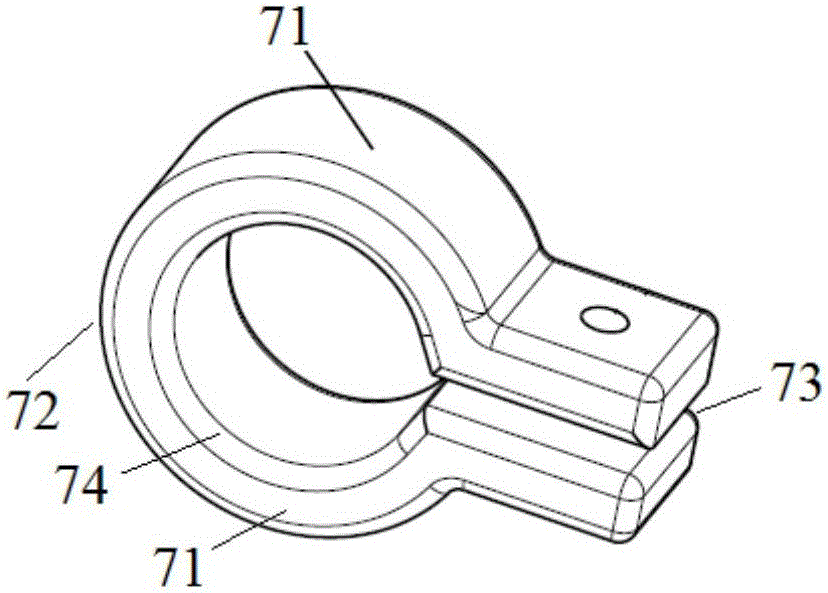

Adjusting system for camshafts of an internal combustion engine

InactiveCN102197199AReduce frictional heatMaintain emergency operating positionValve arrangementsMachines/enginesBrake torqueEngineering

An adjusting system for camshafts of an internal combustion engine with an emergency running function, comprising a superposition gearing (1, 2, 3, 4) having a drive input element (2) which is driven by a crankshaft of the internal combustion engine, having a drive output element (1) which drives a camshaft (21) of the internal combustion engine and having an actuating element (4) by means of which a relative rotation between the drive input element (2) and the drive output element (1) can be realized by means of a device (7, 8, 9, 10, 11) for imparting a braking torque, which is variable fornormal operation, to the actuating element (4), wherein in the event of failure of the device (7, 8, 9, 10, 11) and / or of the control thereof, an emergency running position of the camshaft (21) can be attained and held by braking or arresting the actuating element (4). According to the invention, said adjusting system is characterized in that a lining carrier (8) of the device (7, 8, 9, 10, 11) is arranged in an axially movable and rotationally fixed manner on a shaft (5) which bears the actuating element (4), in that the braking torque for normal operation can be varied by means of an electromagnet (11) which acts on the lining carrier (8) counter to the force of a spring (10) and in contactless fashion, which is stationary and which can be acted on with variable voltage, and in that, inthe event of failure of the voltage applied to the electromagnet (11) and / or of the control thereof, the lining carrier (8) can be pressed against a stationary counterpart friction surface (7, 24) bythe force of the spring (10), and the emergency running position can thereby be set.

Owner:ZF FRIEDRICHSHAFEN AG

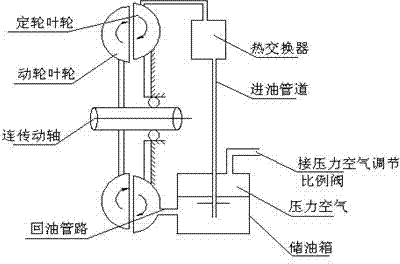

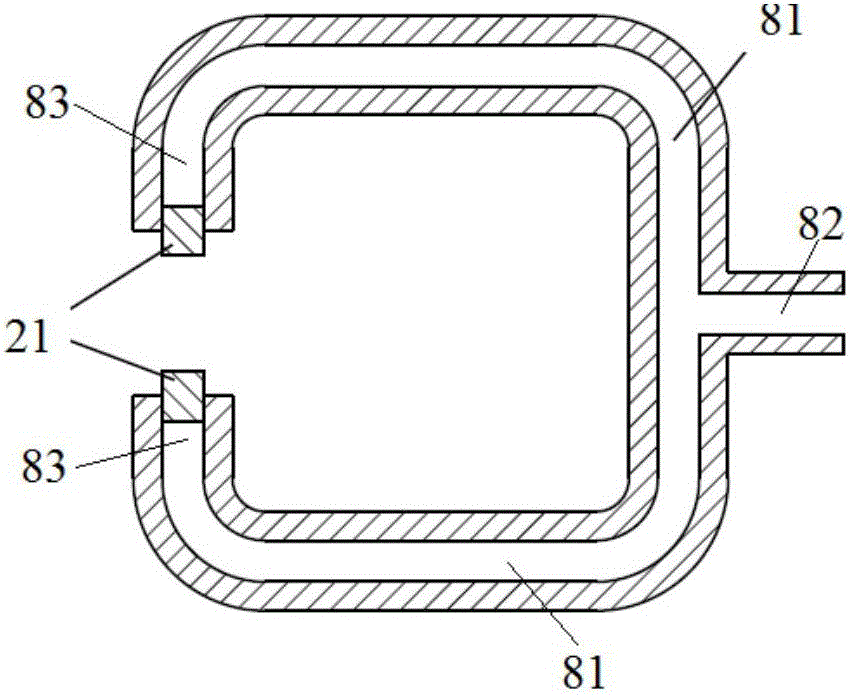

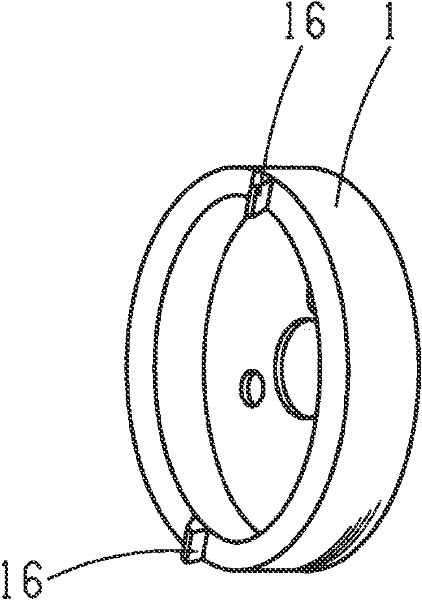

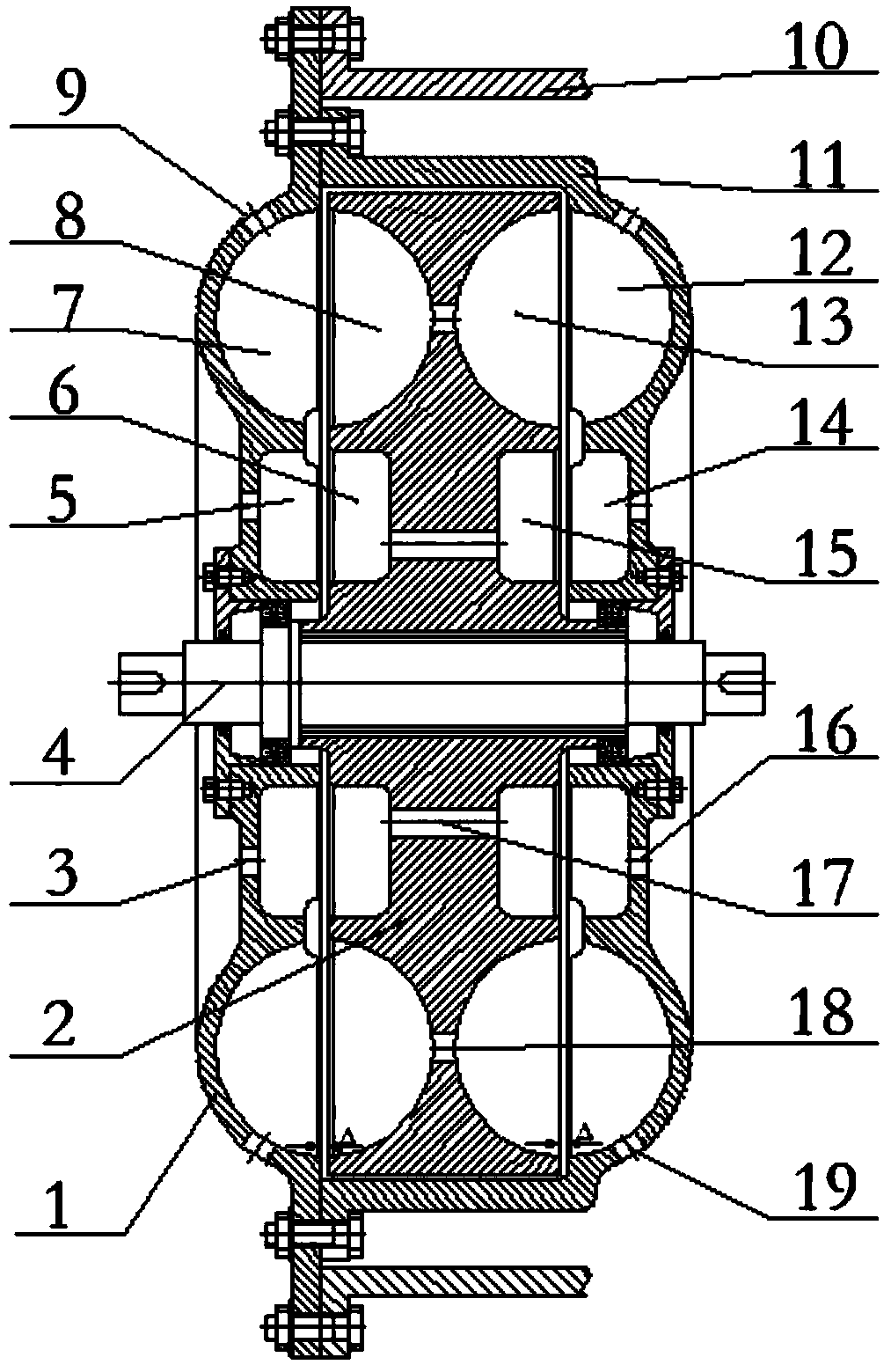

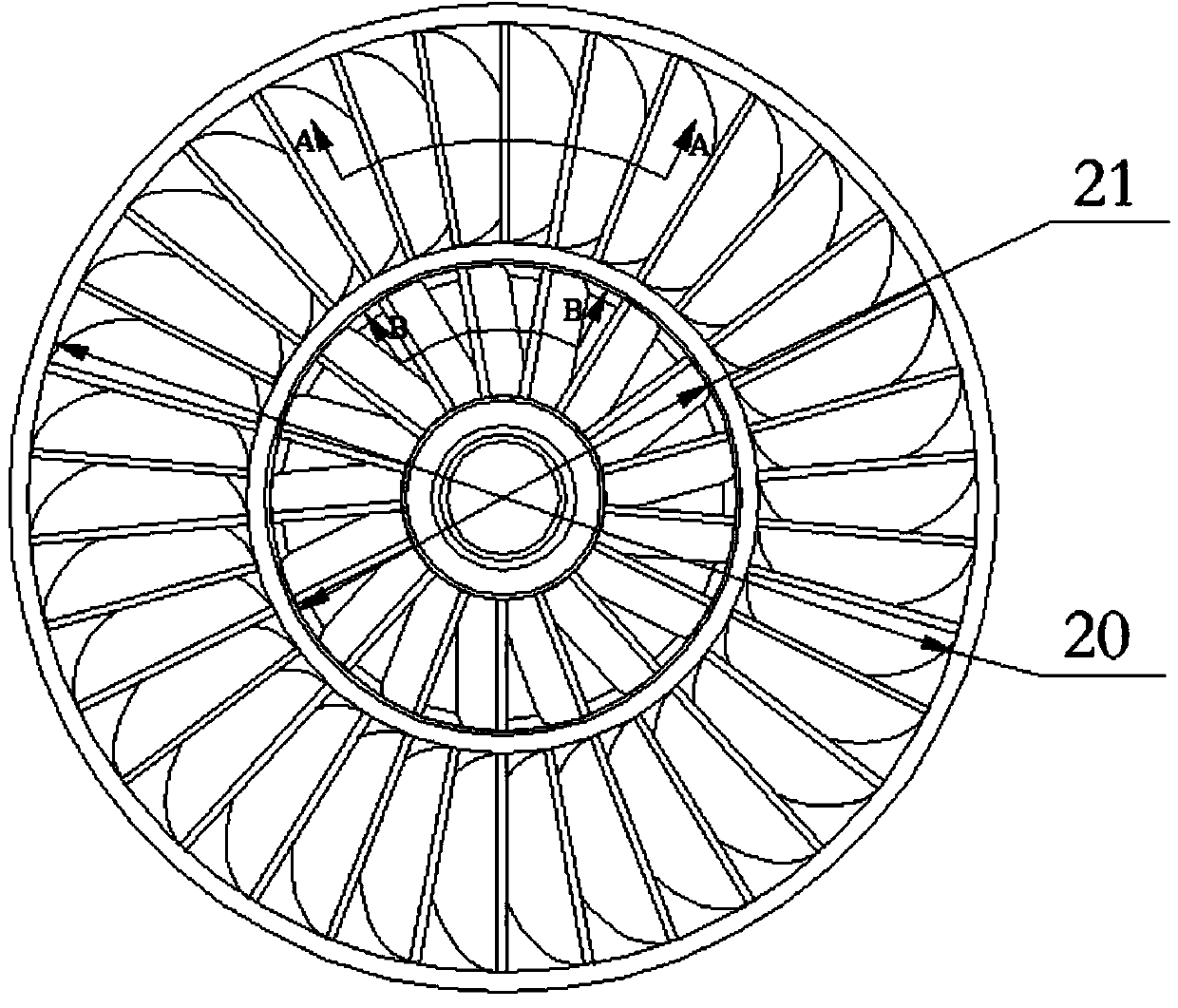

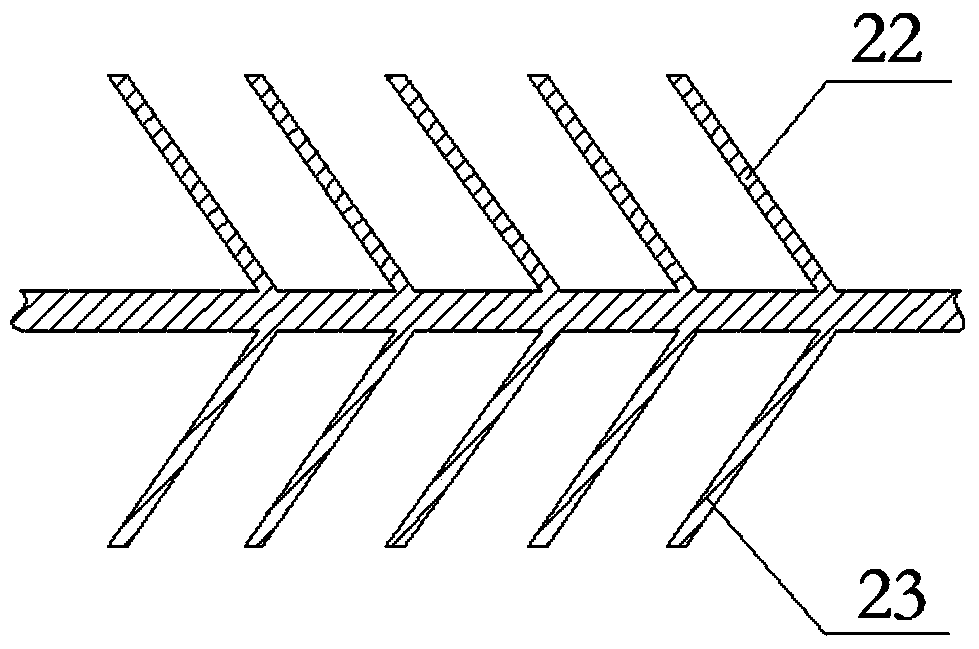

Closed two-cavity and two-row blade hydraulic retarder

InactiveCN104196923AOvercoming the large diameter of the circular circleOvercoming small braking torqueLiquid resistance brakesBrake torqueAxial force

The invention discloses a closed two-cavity and two-row blade hydraulic retarder. The closed two-cavity and two-row blade hydraulic retarder comprises a left stator, a rotor and a right stator, and consists of four working cavities, wherein the four working cavities comprise two circular working cavities with larger radius and two square working cavities with smaller radius; each of the circular working cavities consists of left and right semicircular working cavities; each of the square working cavities consists of left and right semi-square working cavities; semicircular blades are arranged in the semicircular working cavities; and square blades are arranged in the square working cavities. The closed two-cavity and two-row blade hydraulic retarder overcomes the defects of large diameter of circulating circles, low brake torque, slow dynamic response and axial force in a traditional hydraulic retarder; and the brake torque needed for constant-speed stepping down of long slopes and brake of a heavy-duty truck and a motor bus can be provided by the smaller diameter of the circulating circles. The hydraulic retarder, provided by the invention, has the advantages of small diameter of the circulating circles, high brake torque, quick dynamic response, balanced axial force and improved bearing working conditions.

Owner:JILIN UNIV

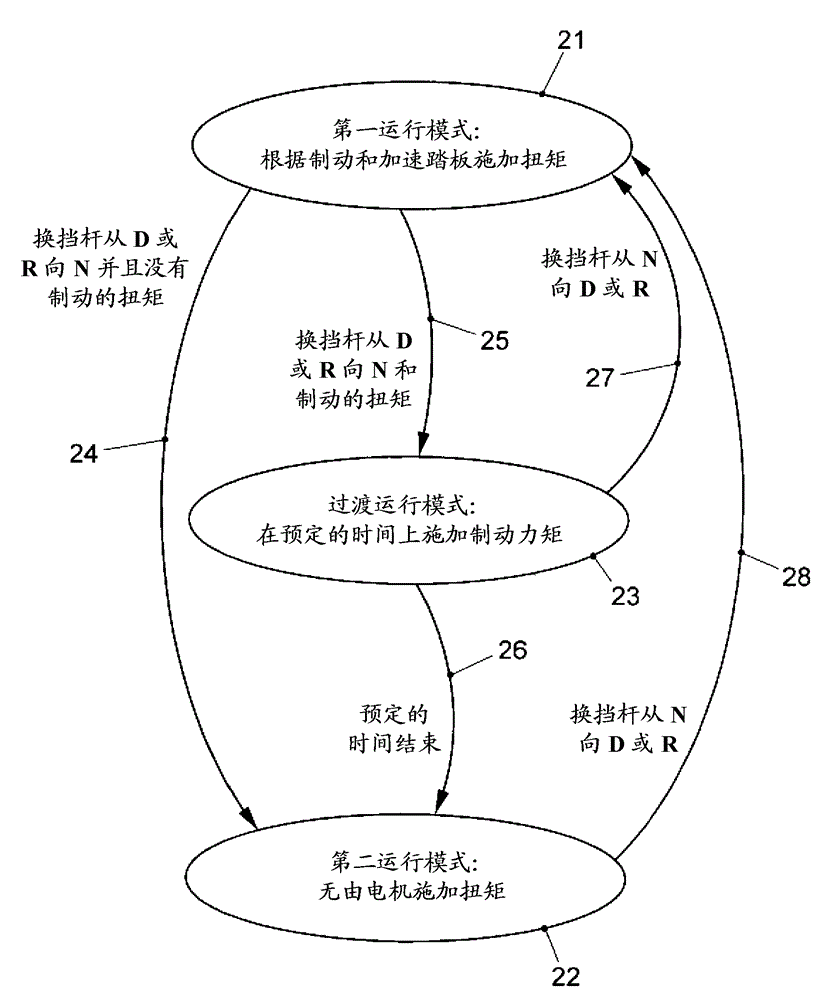

Method for a vehicle having an electric machine

ActiveCN103562040AAvoid dangerous situationsMeet the characteristicsHybrid vehiclesSpeed controllerElectric machineAutomotive engineering

Owner:VOLKSWAGEN AG

An elevator traction system

ActiveCN103803383BIncrease the number ofSave design materialElevatorsBuilding liftsTraction systemBand shape

Owner:XIZI OTIS ELEVATOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com