Embedded electromagnetic liquid cooling retarder with speed increaser

A technology of eddy current retarder and retarder, applied in the direction of electric brake/clutch, asynchronous induction clutch/brake, electrical components, etc., which can solve the problems of low braking power density, reducing the mass and volume of the retarder body, etc. , to achieve convenient control, reduce rotor weight, and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

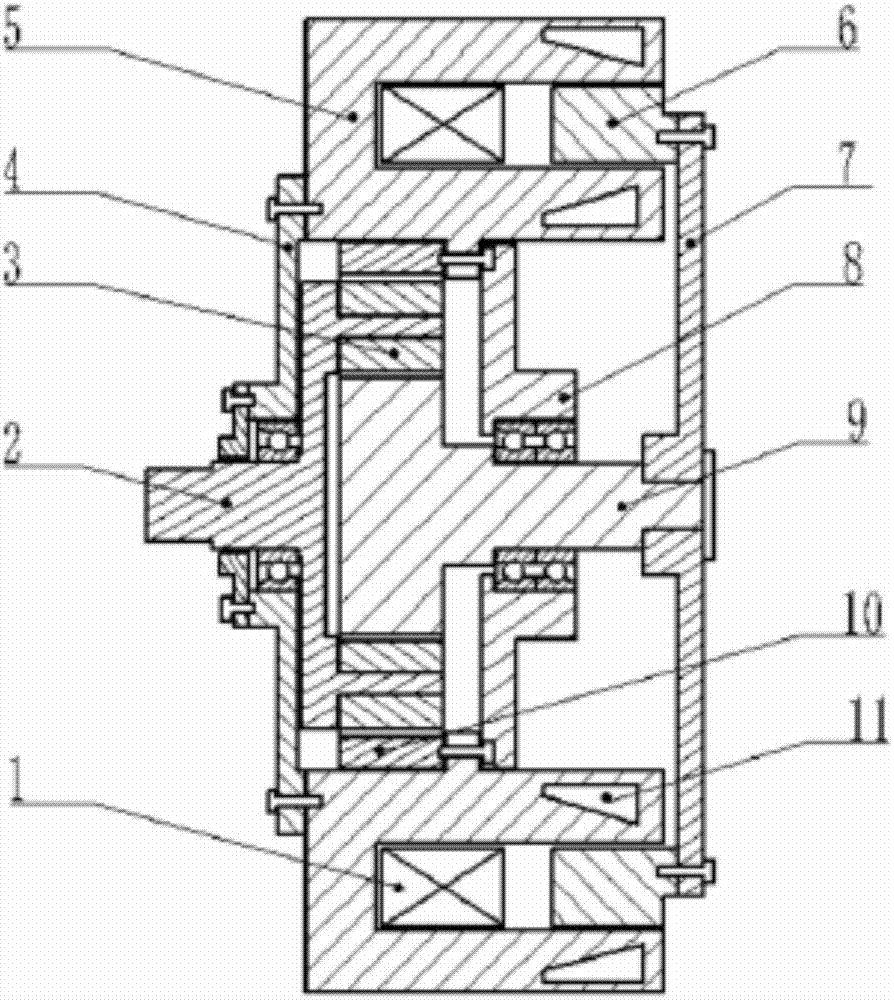

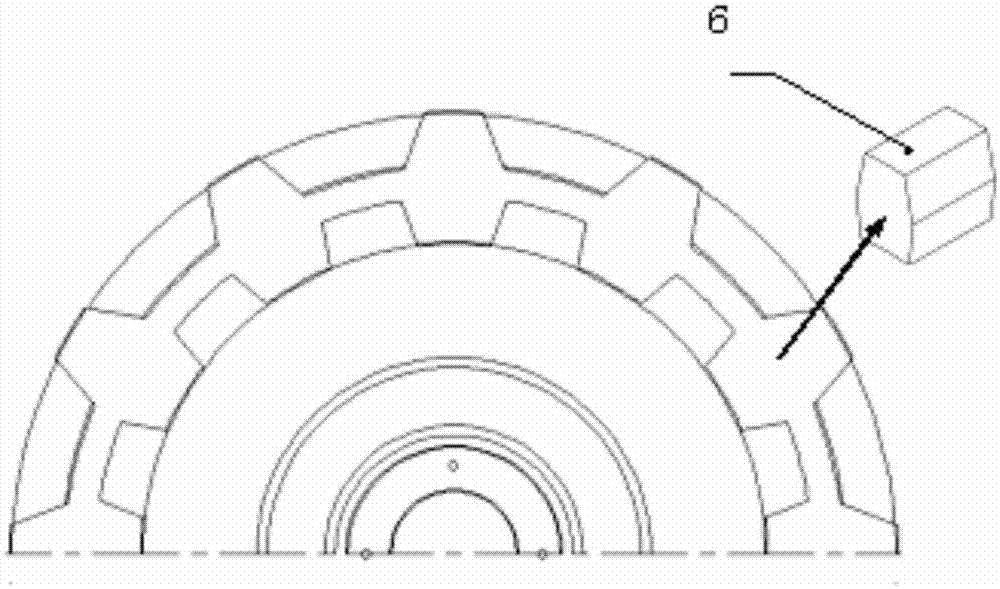

[0018] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 and figure 2 As shown, the rotor of the retarder in the embodiment of the present invention is connected with the sun gear, and connected with the output shaft of the automobile transmission or the output half shaft of the differential through the planetary gear mechanism. In the retarder stator groove. The ring gear 10 in the planetary gear is connected with the retarder stator 5 by bolts and fixed together on the vehicle frame. The controller controls the magnitude of the braking torque by adjusting the excitation current in the excitation coil 1 of the retarder according to the signal of the Hall sensor or the driver's instruction. A gap of 1-2 millimeters is maintained between the addendum arc of the rotor magnetically conducting tooth 6 and the arc of the inner surface of the stator 5 outer layer, and the arc of the tooth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com