Closed two-cavity and two-row blade hydraulic retarder

A hydraulic retarder and vane technology, applied in the direction of liquid resistance brakes, brake types, mechanical equipment, etc., can solve the problems of large circular diameter, small braking torque, slow dynamic response, etc., and achieve small circular diameter , large braking torque and fast dynamic response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in detail below in conjunction with accompanying drawing:

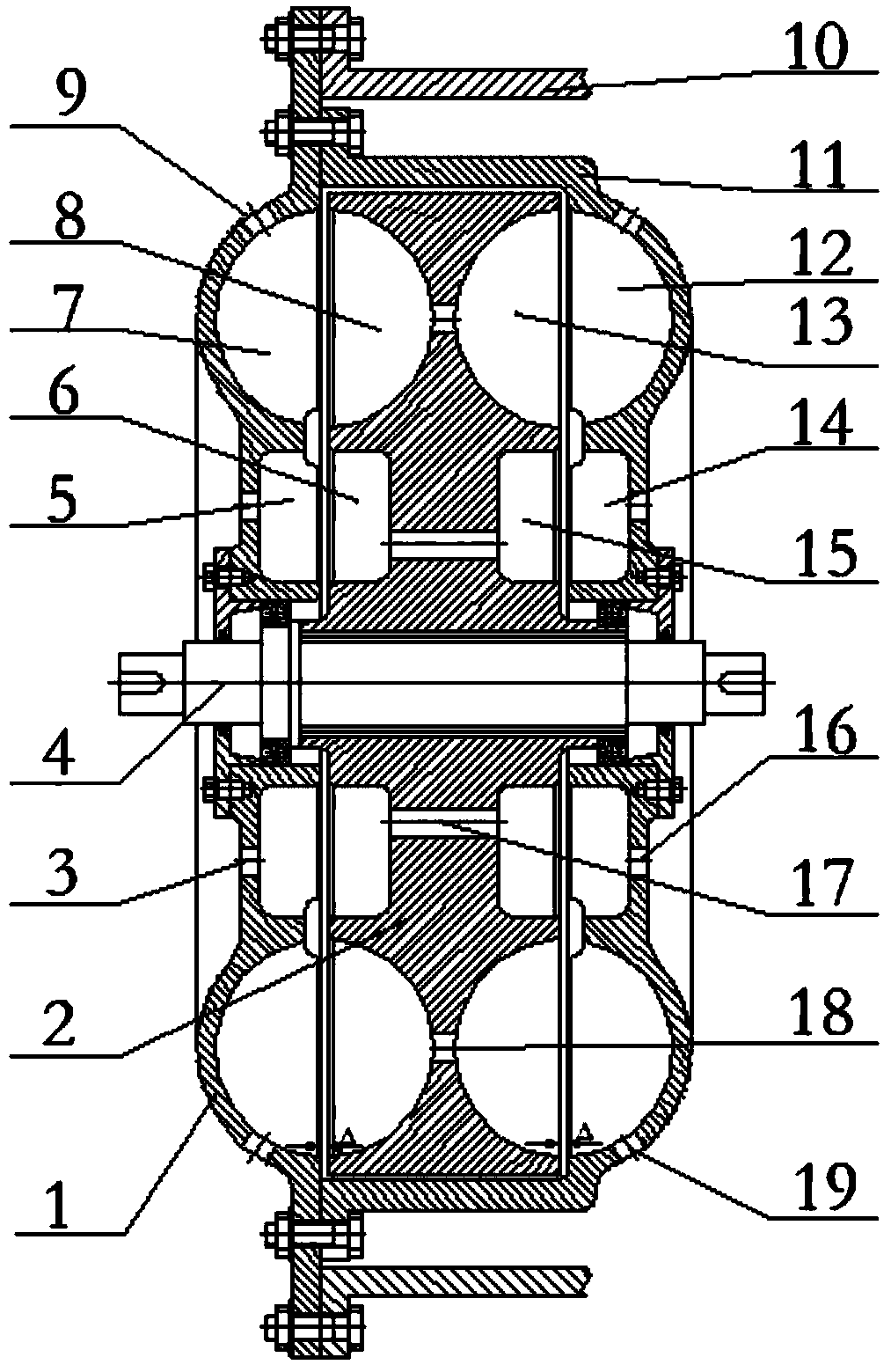

[0028] as attached figure 1 As shown, the closed double-chamber double-row blade hydraulic retarder is composed of a left stator 1, a rotor 2 and a right stator 11. The rotor 2 is connected with the spline shaft 4 through the spline, the spline shaft 4 is connected with the rotating parts of the vehicle transmission system through the key, the left stator 1 is fixed on the mechanical transmission case 10 through the hexagon cylinder head bolt, and the right stator 11 is fixed through the hexagon The cylindrical head bolt is connected with the left stator 1, and the left stator 1 is supported by the deep groove ball bearing, and the deep groove ball bearing is axially positioned by the shoulder of the spline shaft 4 and the bearing end cover, and the bearing end cover is fixed by the hexagon socket head cap screw On left stator 1. The right stator 11 is supported by deep groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com