Glass lifter, automobile cab and automobile

A glass lifter and driver's cab technology, applied in the mechanical field, can solve the problems of affecting the use effect of the glass lifter, affecting the service life of the motor, and the impact of the motor, so as to reduce the impact, prolong the service life and improve the quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

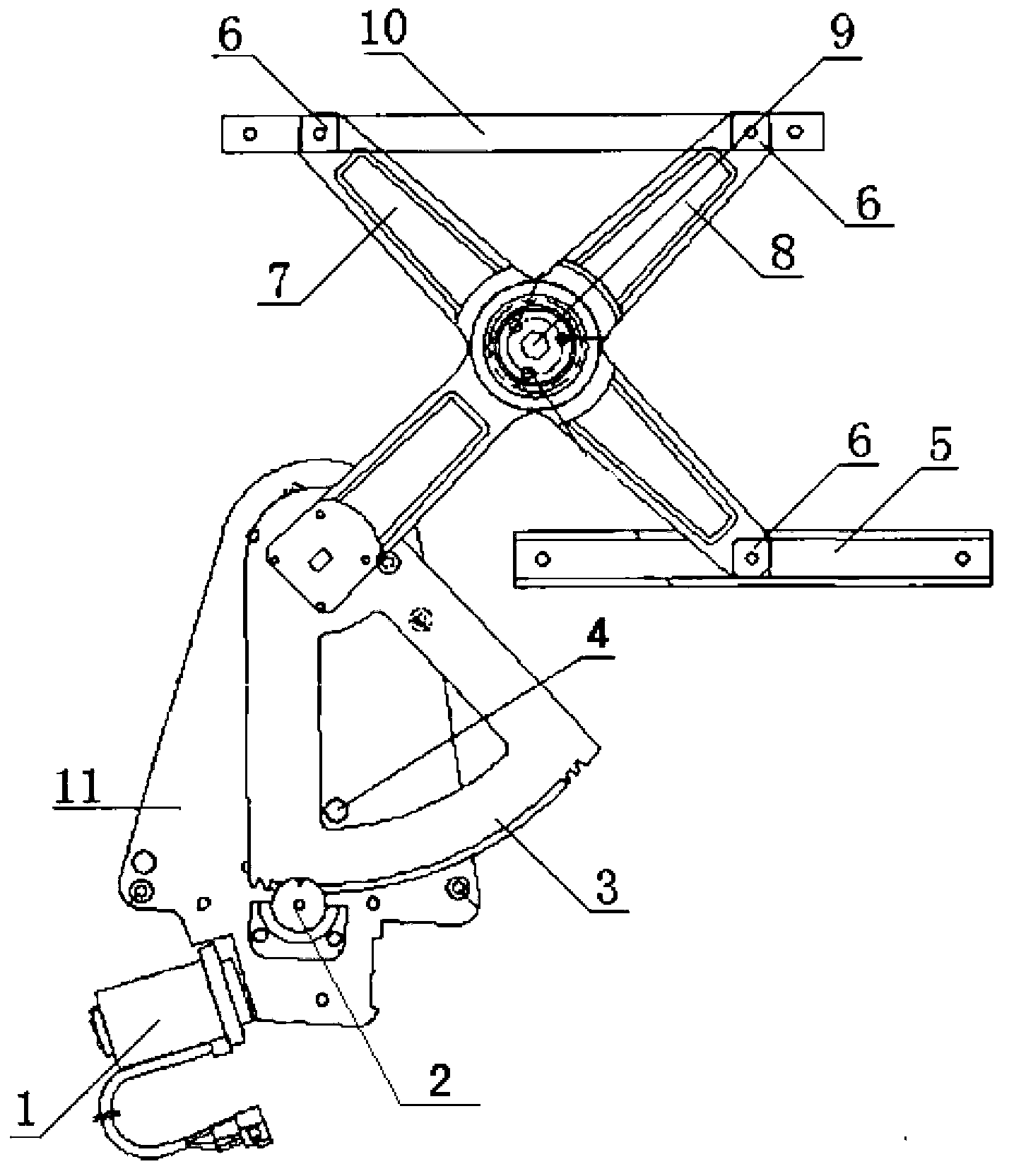

[0023] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The following will be combined with Figures 2 to 4 Specific examples of the present invention will be described in detail.

[0024] For the convenience of expression, the orientation words in this article are defined as follows: figure 1 , above is up, below is down, left is left, and right is right.

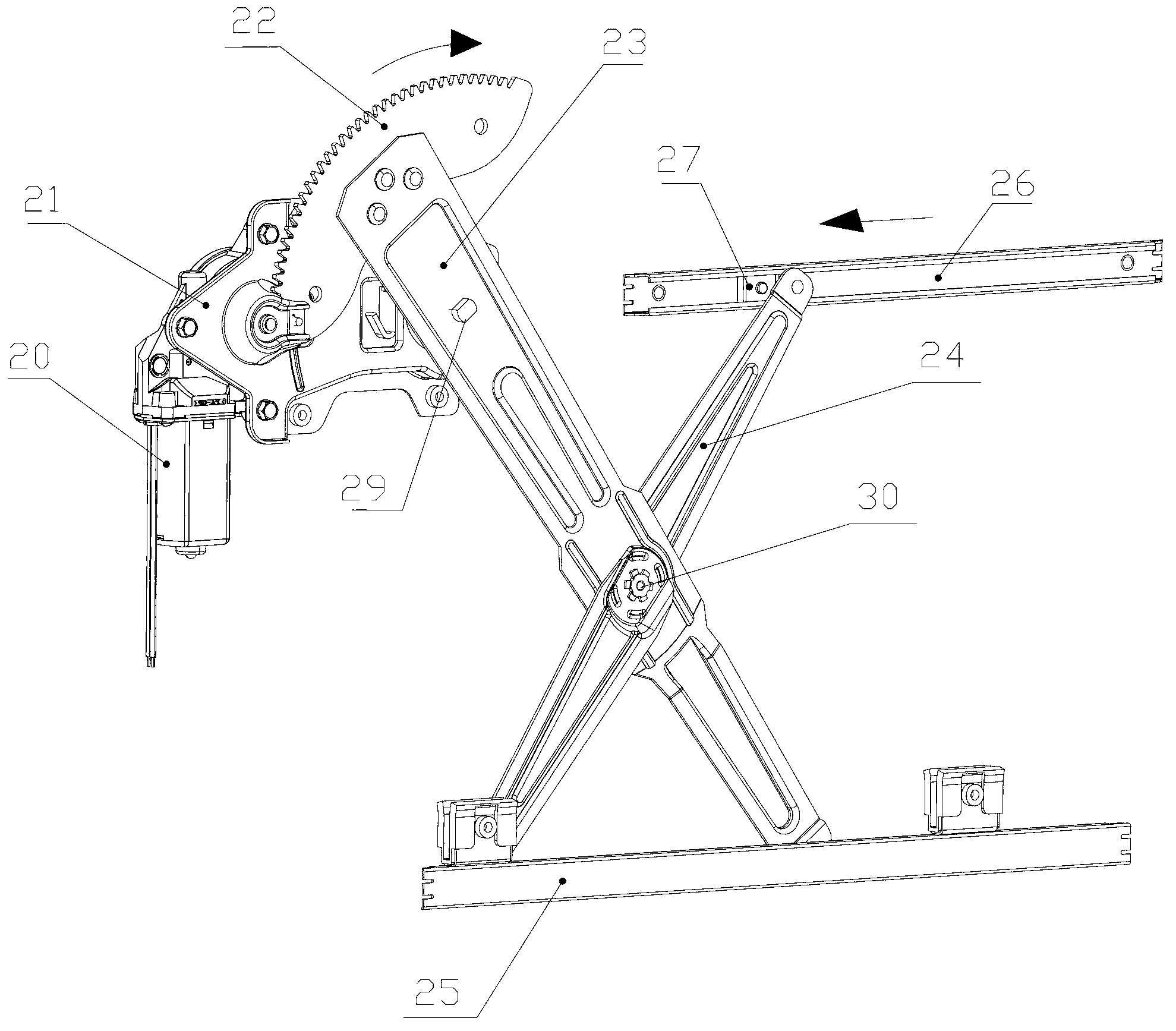

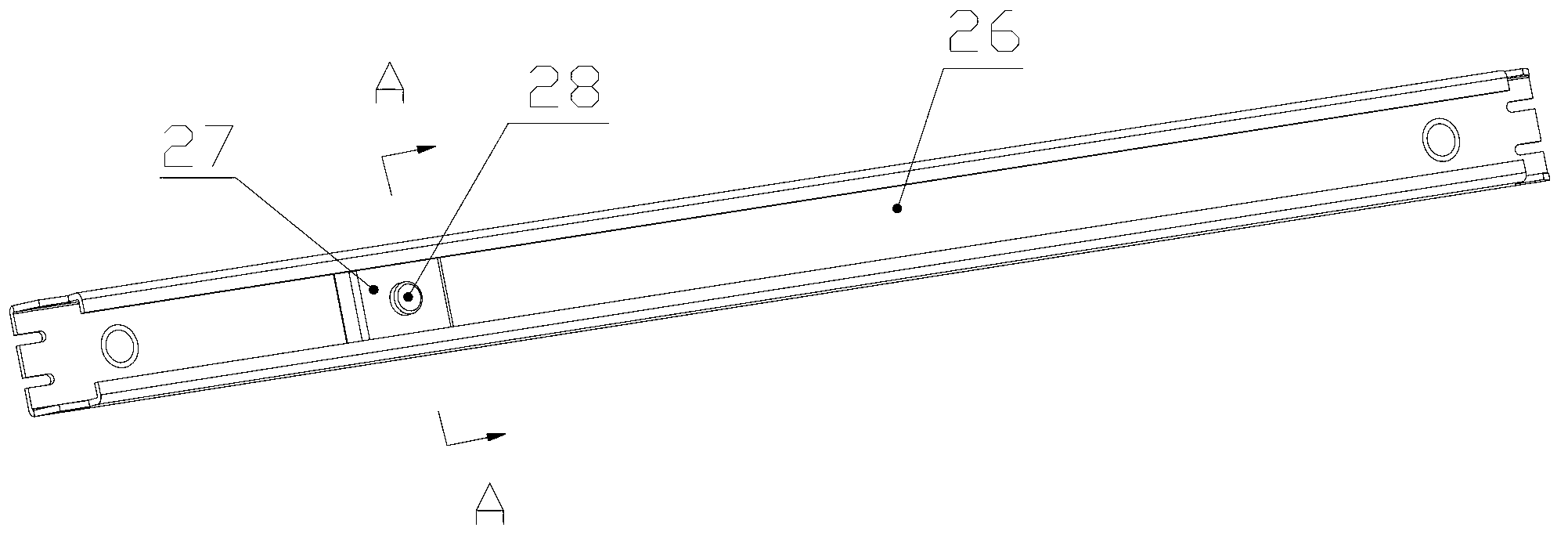

[0025] Such as figure 1 As shown, the glass lifter proposed by the specific embodiment of the present invention includes a motor 20, a bottom plate 21, a driving arm 23, a driven arm 24, a fixed chute 26, a movable chute 25 and a glass mounting clip fixed relatively to the movable chute 25 , the motor 20 is used to drive the main arm 23 to rotate; one end of the driven arm 24 is slidably arranged in the movable chute 25, and the other end is slidably arranged in the fixed chute 26; the main arm 23 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com