Cargo lifting device with safety alarm function

A technology of safety alarm and lifting device, applied in the direction of lifting equipment safety device, lifting device, lifting frame, etc., can solve problems such as danger of technicians, and achieve the effects of high braking reliability, simple structure and enhanced safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

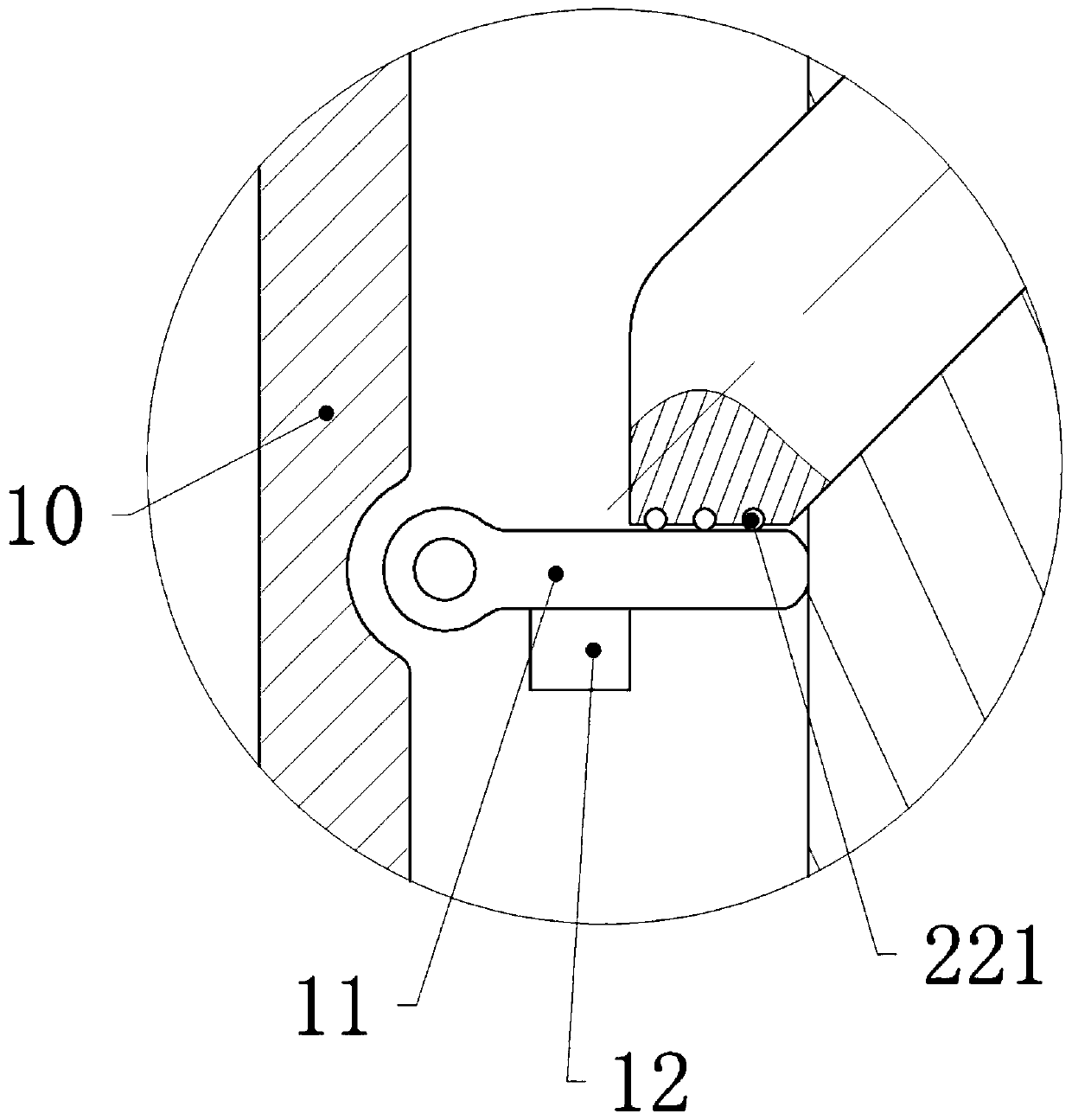

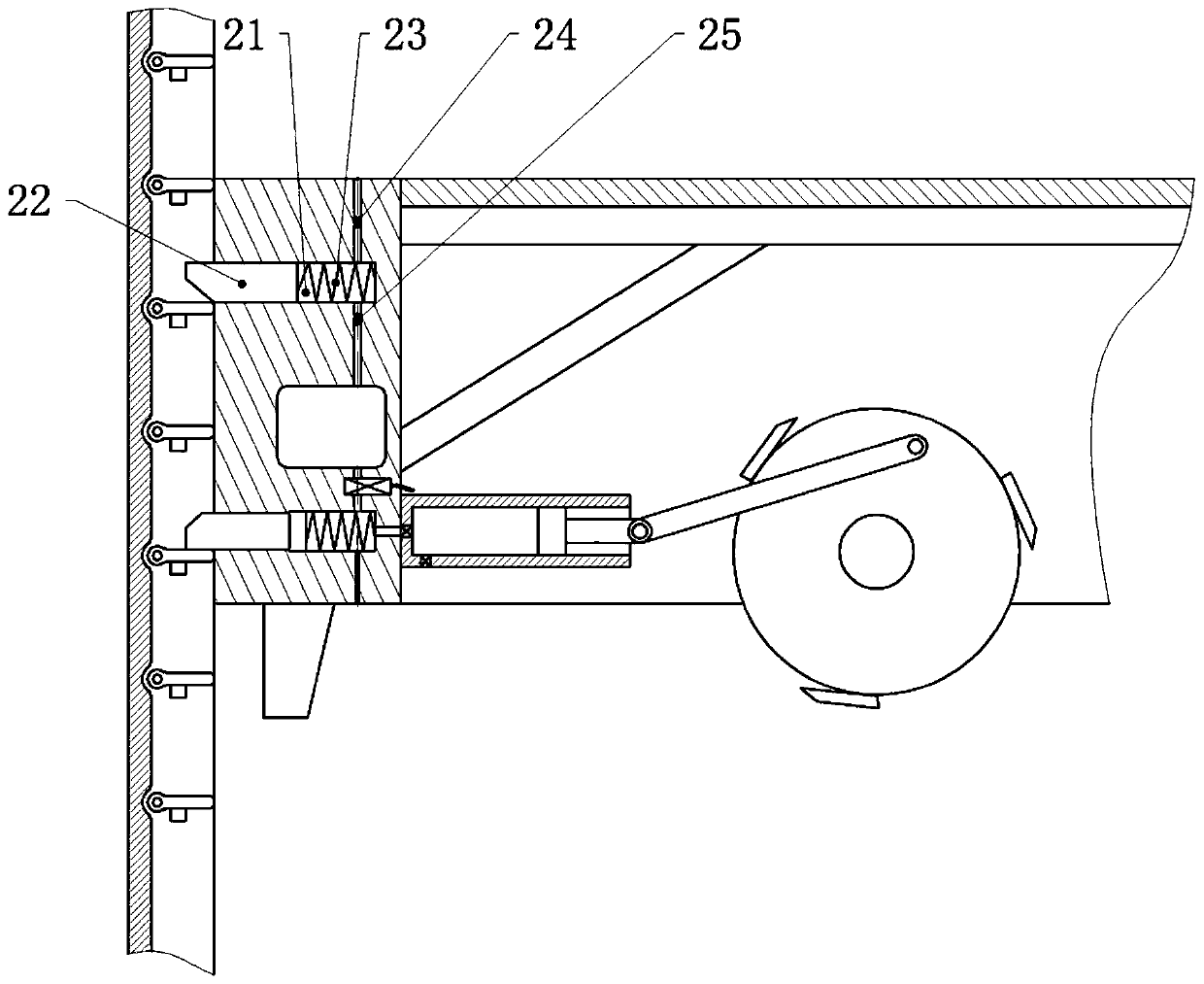

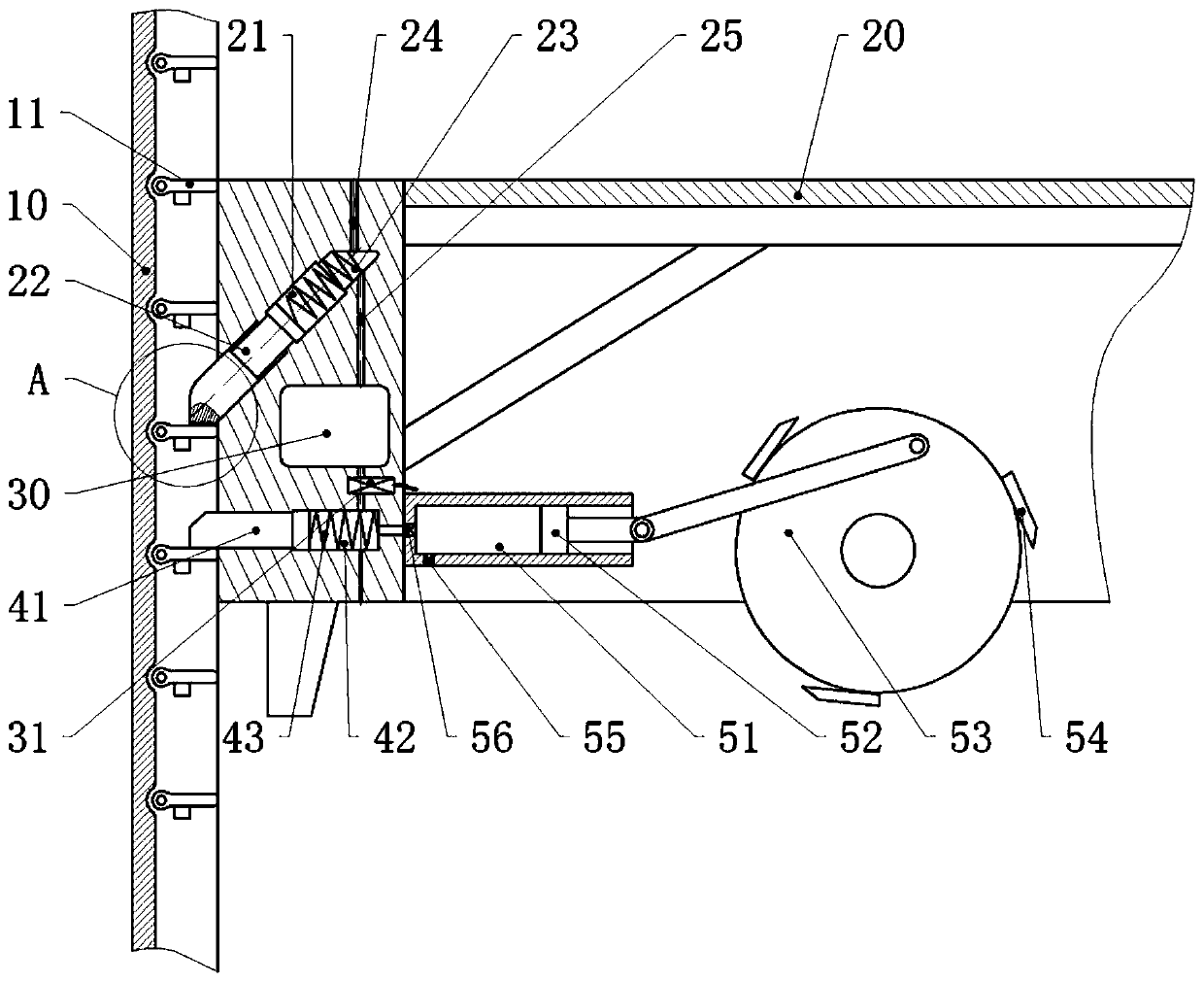

[0022] The cargo lifting device with safety alarm function includes installation brackets arranged in the vertical direction, such as figure 1 As shown, the cargo lifting platform 20, the power mechanism and the track 10 arranged in the vertical direction are installed on the mounting bracket, and the left and right sides of the mounting bracket are provided with rails 10, and the rails 10 are arranged symmetrically along the vertical plane. The cargo lifting platform 20 is a quilted frame structure to reduce the weight of the cargo lifting platform 20. The cargo lifting platform 20 is slidingly connected with the mounting bracket through the rail 10, and the rail 10 has a limiting effect on the cargo lifting device to prevent the cargo lifting platform 20 from deviating from the installation. Bracket; In the present embodiment, the power mechanism adopts a winch, and the winch is installed at the bottom of the mounting bracket, and the winch is used as a power output structure...

Embodiment 2

[0029] The difference between Embodiment 2 and Embodiment 1 is that, as image 3 As shown, in the second embodiment, the cylinder body 21 is arranged horizontally, and the end face of the wedge block 22 protruding from one end of the opening of the cylinder body 21 is set as a wedge surface, and the wedge surface is set downward, and the angle between the wedge surface and the horizontal plane is 45° . When the cargo lifting platform 20 goes down, when the block 11 cooperates with the wedge surface of the wedge 22, the wedge 22 will be pressed back into the cylinder 21, so that the wedge 22 can reciprocally slide in the cylinder 21.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com