Vertical-axis wind-power generation equipment and power generation method

A technology for wind power generation equipment and vertical axis, which is applied to wind power generation, wind turbines, and wind turbines at right angles to the wind direction, etc., can solve the problems of high manufacturing, transportation, installation, and maintenance costs, low vertical axis fan efficiency, and blade forming. Difficulty and other problems, to achieve the effect of reducing material costs, reducing site requirements, and flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

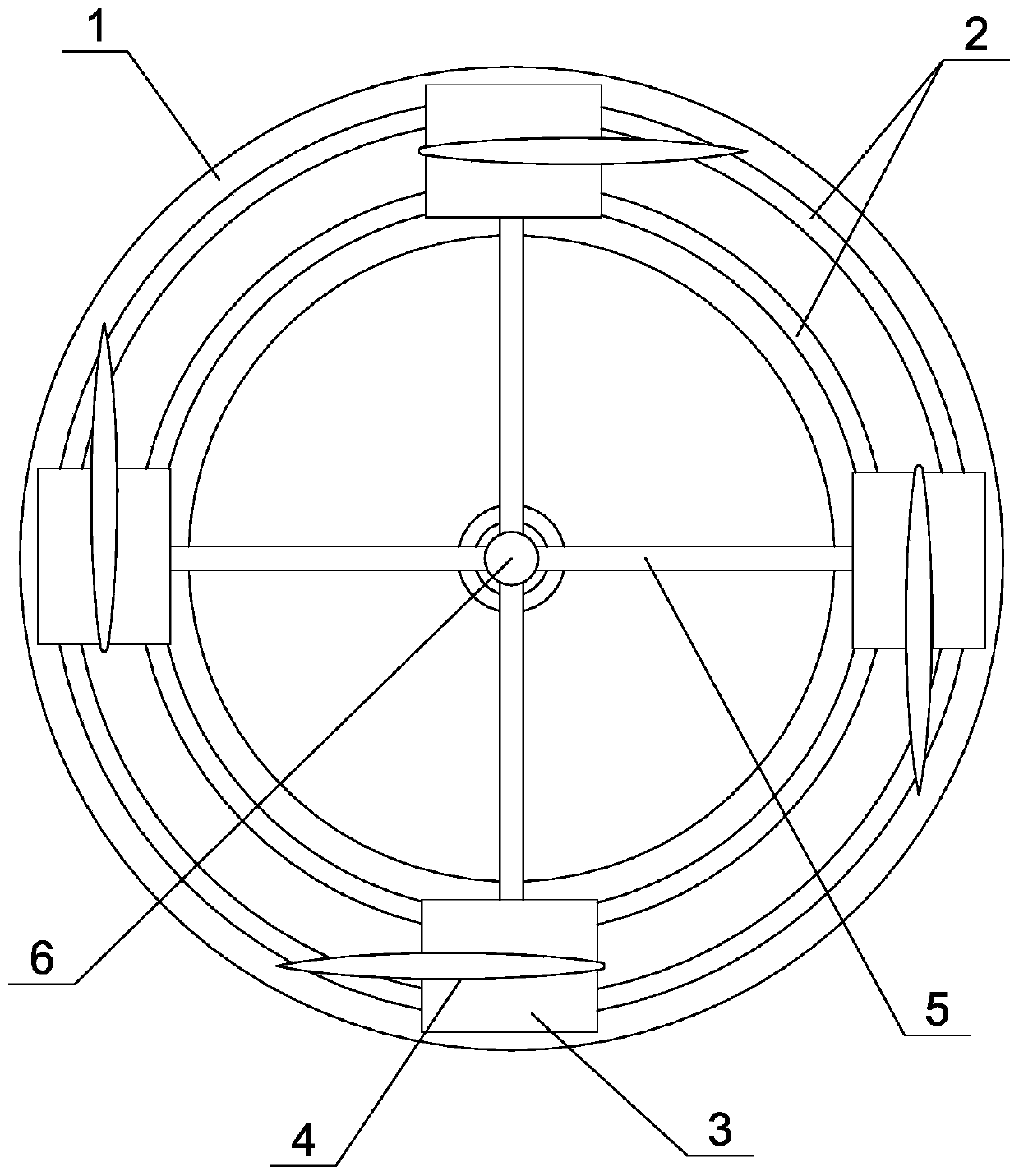

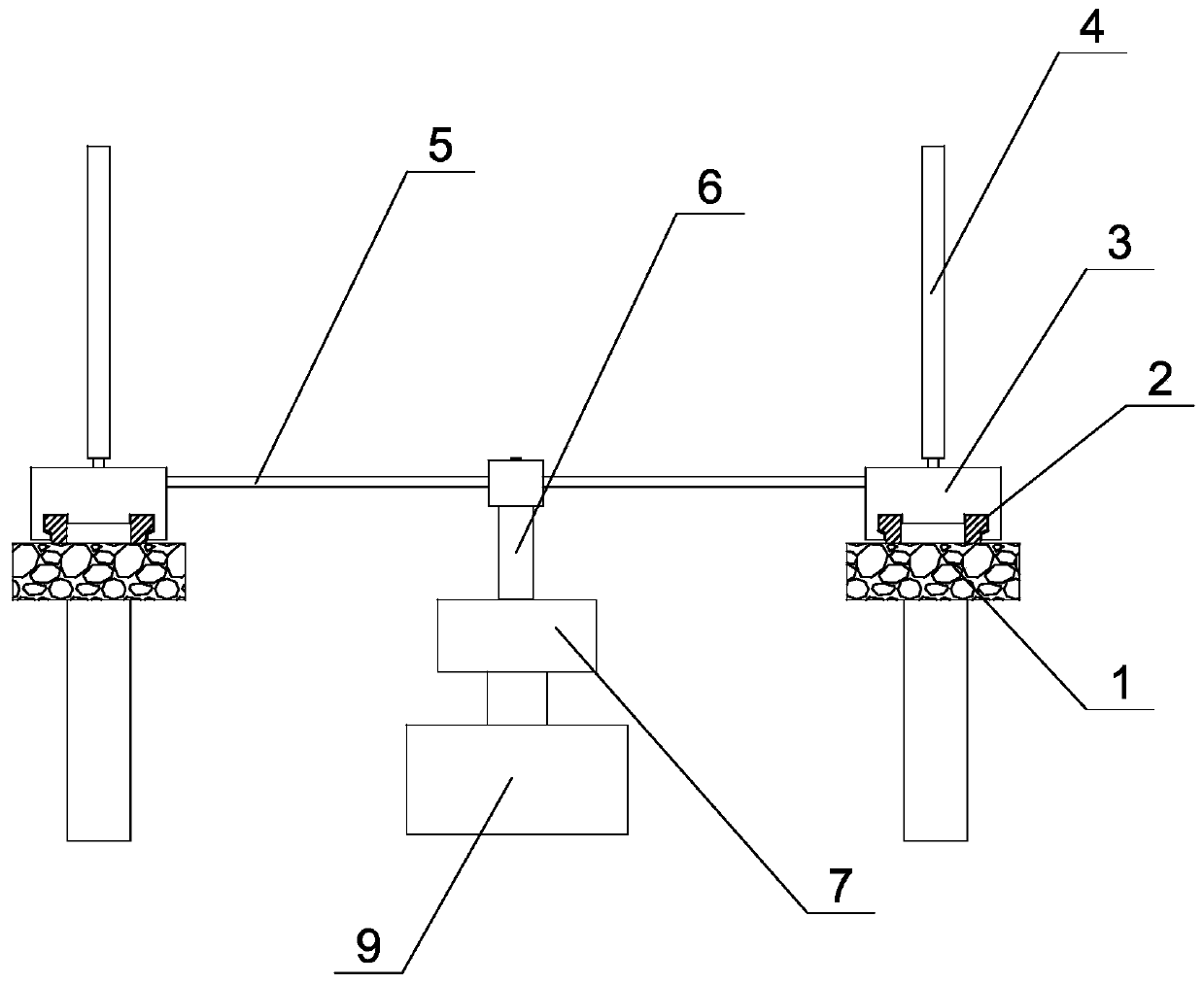

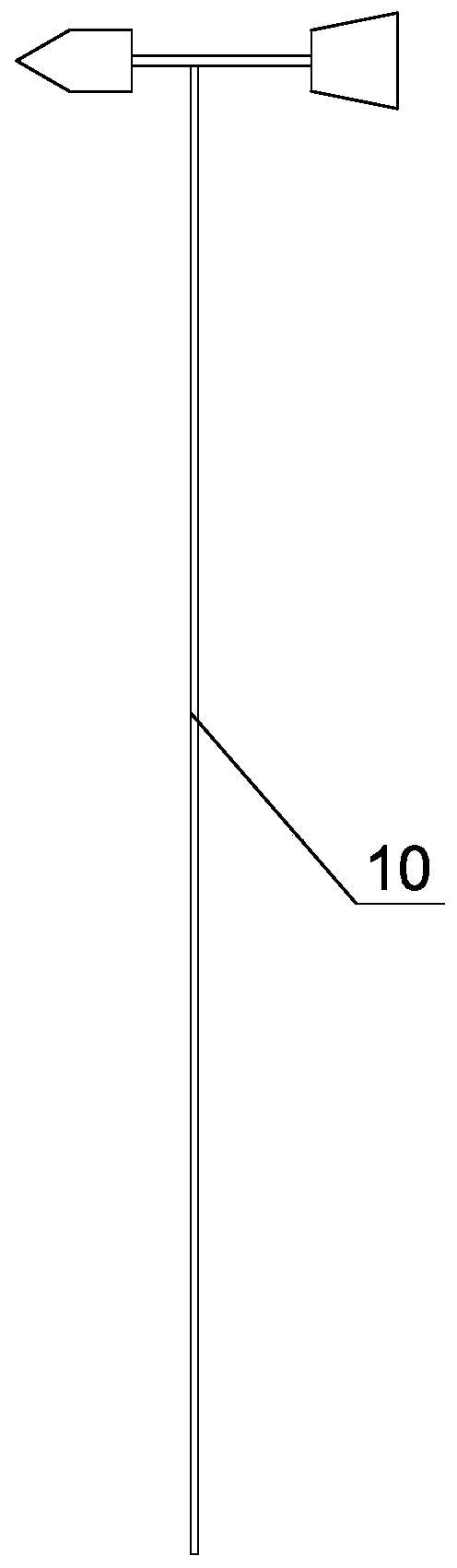

[0025] like Figure 1 ~ Figure 3As shown, the vertical axis wind power generation equipment of this embodiment includes a base 1, a ring track 2, four railcars 3, a generator 9, and a vertical main shaft 6 that drives the generator 9 to generate electric energy. The generator 9 is set On the ground or near the ground, the annular track 2 is fixed on the base 1. In this embodiment, the base 1 is a civil construction base with low cost. Of course, a steel structure base can also be used, so Said ring track 2 is double track, better stability, also can adopt the form of monorail of course, described rail car 3 is erected on the described ring track 2, and described rail car 3 can move circularly along described ring track 2, A lifting blade 4 is installed on each said rail car 3, and each said rail car 3 is fixedly connected with said vertical main shaft 6 by a crossbeam 5, and each said rail car 3 takes said vertical main shaft 6 as geometric center Uniform and balanced layout,...

Embodiment 2

[0029] Such as Figure 4 As shown, the difference between the vertical axis wind power generation equipment of this embodiment and Embodiment 1 is that in this embodiment, there are two opposite and symmetrically arranged rail cars 3, and three lift blades 4 are installed on each of the rail cars 3 Each rail car 3 is fixedly connected to the vertical main shaft 6 through two beams 5, which can enhance the structural strength and reduce the size of each beam 5.

[0030] The remaining features of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0032] Such as Figure 5 As shown, the difference between the vertical axis wind power generation equipment of this embodiment and Embodiment 2 is that in this embodiment, there are three railcars 3 arranged symmetrically at an angle of 120° along the circumference, and three railcars 3 are installed on each of the railcars 3. Each of the rail cars 3 is fixedly connected to the vertical main shaft 6 through a crossbeam 5, and the blade driving device is driven by a small motor device.

[0033] All the other features of this embodiment are the same as those of Embodiment 2

[0034] The vertical axis wind power generation equipment of the present invention is a vertical axis wind power generation equipment with a brand new structure. By using the rail car 3 as the load-bearing carrier and transmission carrier of the lifting blade 4, the conventional vertical axis wind power generation equipment avoids the The cantilever beam structure in which the blades are directly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com