Connection structure between steering wheel and direction controlling device

A technology of direction control and connection structure, applied in the direction of mechanical steering gear, etc., can solve the problems of inability to fold parts, high manufacturing cost, complex structure, etc., and achieve the effect of simple structure, low production cost and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

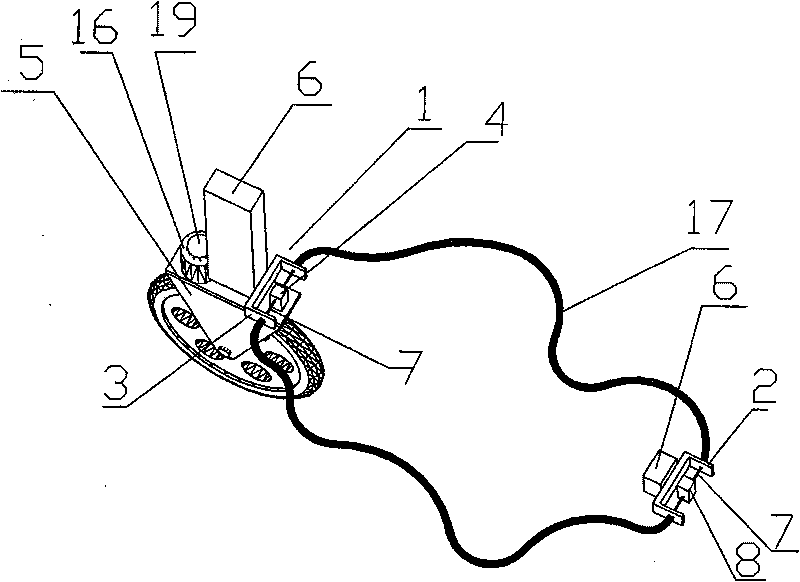

[0019] Embodiment 1: A connection structure between a direction wheel and a direction control device, which includes a direction wheel force receiving device 1 and a direction control clamping plate 2, the direction control clamping plate 2 is fixed on the vehicle main body 6, and the direction wheel The force-bearing device 1 includes a force-bearing block frame 3 and a force-bearing block 4, the force-bearing block 4 is located in the force-bearing block frame 3, the force-bearing block 4 is fixedly arranged on the direction wheel frame 5, and the force-bearing block is clamped The bit frame 3 is fixed on the vehicle main body 6, the axle sleeve 16 on the steering wheel is fixed on the vehicle main body 6, and the steel cable 7 passes through the direction control clamping plate 2 and the force block clamping frame 3 respectively, and the steel cable 7 guides the direction The control device 8 and the stressed block 4 are connected in series to form a loop, and the steel cabl...

Embodiment 2

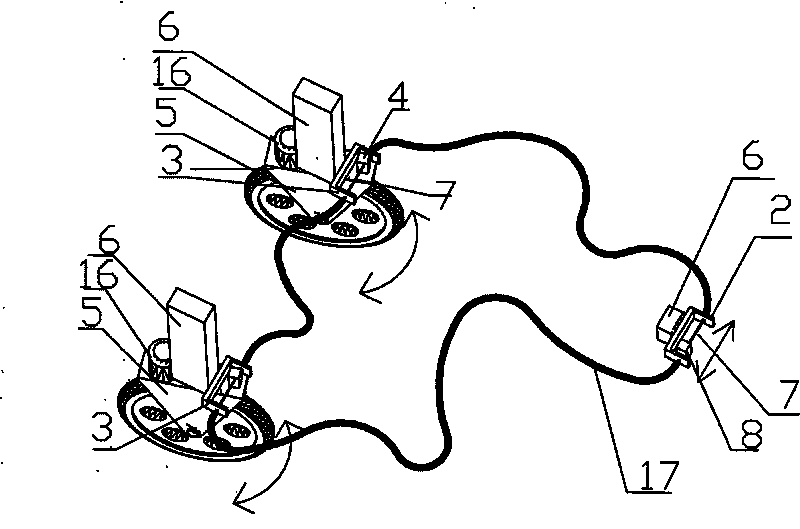

[0020] Embodiment 2: a connection structure between a direction wheel and a direction control device, which includes two direction wheel force-bearing devices 1 and a direction control clamping plate 2, the direction control clamping plate 2 is fixed on the vehicle main body 6, and the direction The wheel stress device 1 comprises a force block frame 3 and a force block 4, the force block 4 is located in the force block frame 3, the force block 4 is fixedly arranged on the direction wheel frame 5, and the force block The locking frame 3 is fixed on the vehicle main body 6, the axle sleeve 16 on the steering wheel is fixed on the vehicle main body 6, and the steel cables 7 pass through the direction control locking plate 2 and the force block locking frame 3 respectively, and the steel cables 7 will The direction control device 8 is connected in series with the two force-bearing blocks 4 to form a loop, and the steel cable 7 between the direction control clamping plate 2 and the...

Embodiment 3

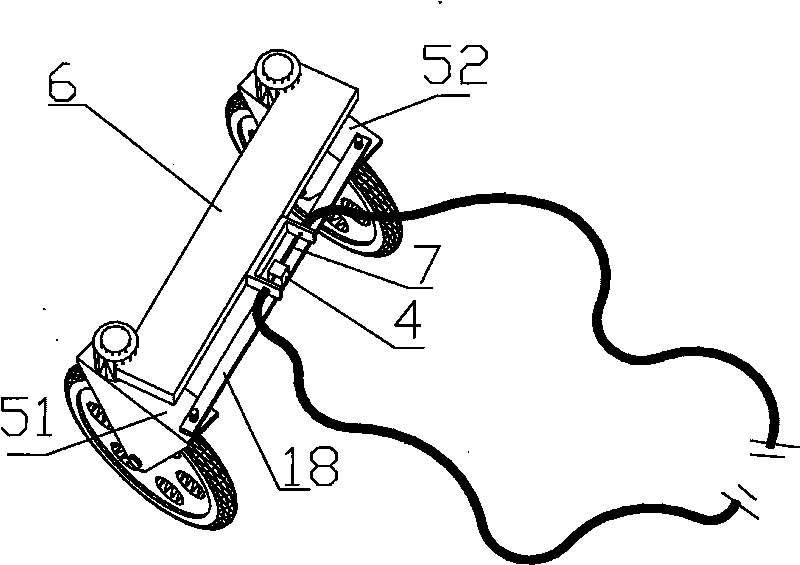

[0021] Embodiment 3: The other parts are the same as Embodiment 1, the difference is that there are 2 steering wheels, 1 steering wheel force-bearing device 1, and between the first steering wheel frame 51 and the second steering wheel frame 52 Fixed by the cross bar 18, the force bearing block 4 is fixed on the cross bar 18.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com