Adjusting system for camshafts of an internal combustion engine

A technology for regulating systems and internal combustion engines, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as cumbersome structure, troublesome control, and complexity, and achieve the effect of reducing frictional heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

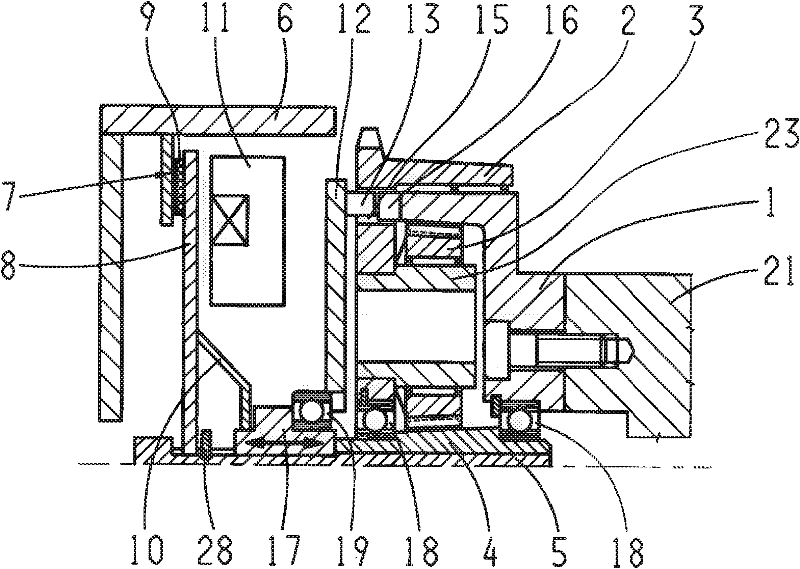

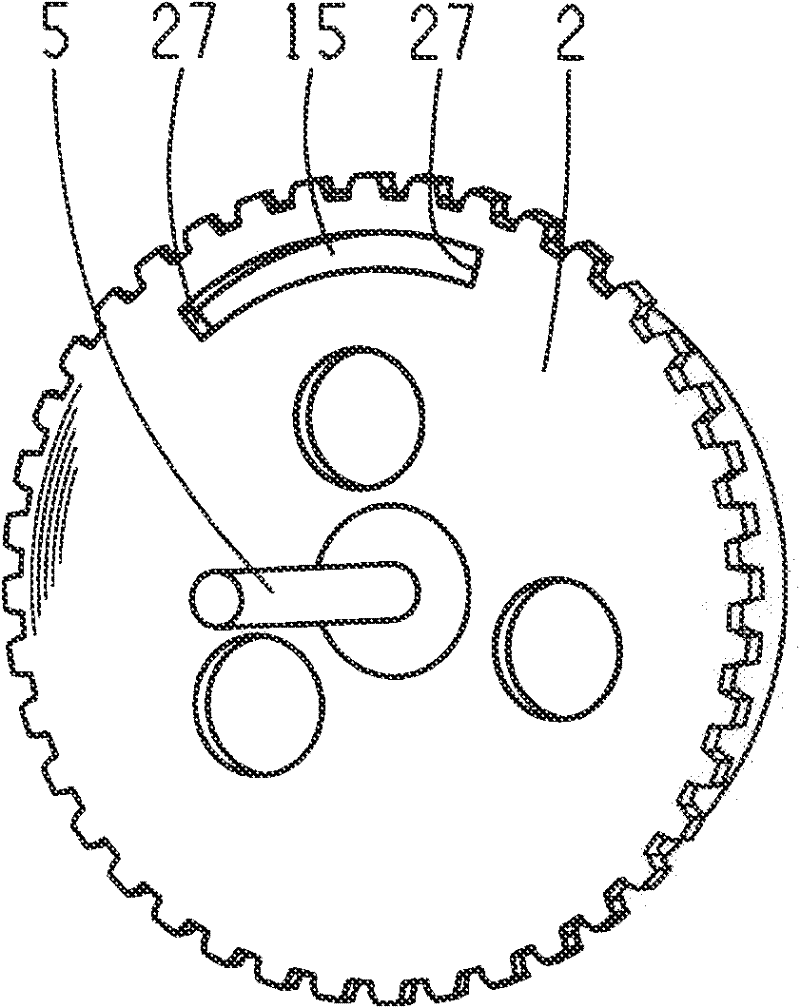

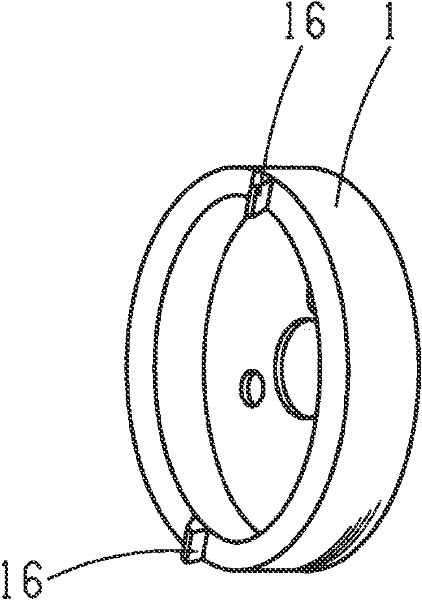

[0025] according to figure 1 The regulating system of the ® contains a superposition transmission constituted as a planetary transmission, which comprises: a hollow gear 1, which forms the driven element; a planetary carrier 2, which forms the driving element, which has a sprocket for A chain or toothed chain connects the sprocket to the crankshaft of the internal combustion engine; the planet gears 3 are rotatably mounted on a bearing shaft 23 ; and the sun gear 4 is mounted on a central shaft 5 as an adjusting element. A camshaft 21 in the cylinder head of the internal combustion engine is driven via the driven element 1 . For this purpose, the driven element 1 is connected in a rotationally fixed manner to the camshaft 21 by means of a screw connection.

[0026]The stationary component 6 of the internal combustion engine, which may be part of the cylinder head, has a counter friction surface 7 which cooperates with a friction lining carrier 8 provided with friction linings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com