Wear-resistant and heat-resistant modified polyformaldehyde composite material and preparation method thereof

A composite material, polyoxymethylene technology, applied in the field of modified polyoxymethylene composite materials, can solve the problems that pure polyoxymethylene cannot meet the use requirements, achieve excellent mechanical properties and friction resistance, reduce capacity, and have good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

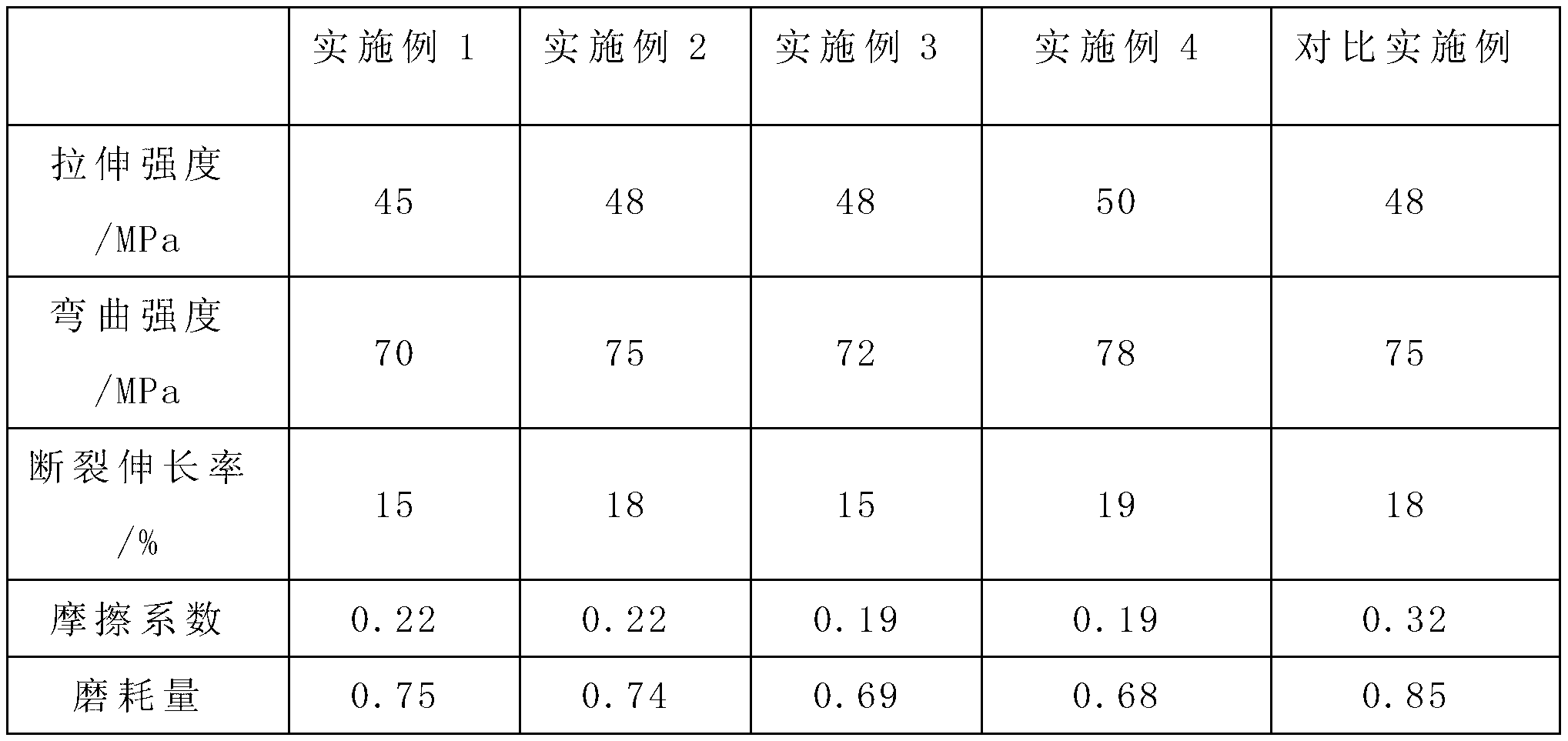

[0018] Table 1 embodiment 1-4 and the parts by weight of each composition of comparative example

[0019] Among them, the compatibilizer is PP-g-MAH; the antioxidant is antioxidant 1010 and antioxidant 168; other additives are color additives, light stabilizers and surface modifiers.

[0020] According to the components of each embodiment in Table 1 and the parts by weight of each component, a kind of nano TiO with anti-light aging is prepared respectively 2 / ABS composite material, the specific process is as follows:

[0021] (1) Polytetrafluoroethylene surface pretreatment: Weigh polytetrafluoroethylene according to the weight described in claim 1, and after drying, immerse in frozen THF sodium naphthalene solution for 5 minutes, rinse with acetone for 2-3 minutes after the reaction is completed. times, suction filtration, put into 80 ° vacuum oven and dry to constant weight;

[0022] (2) Weighing raw materials: weighing each component according to the wear-resistan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com