Low-friction oil seal for shock absorber

A shock absorber oil and low-friction technology, which is applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve problems such as dry friction, oil seal leakage, abnormal noise shock absorbers, etc., to reduce the contact area, reduce the Friction generates heat and reduces friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

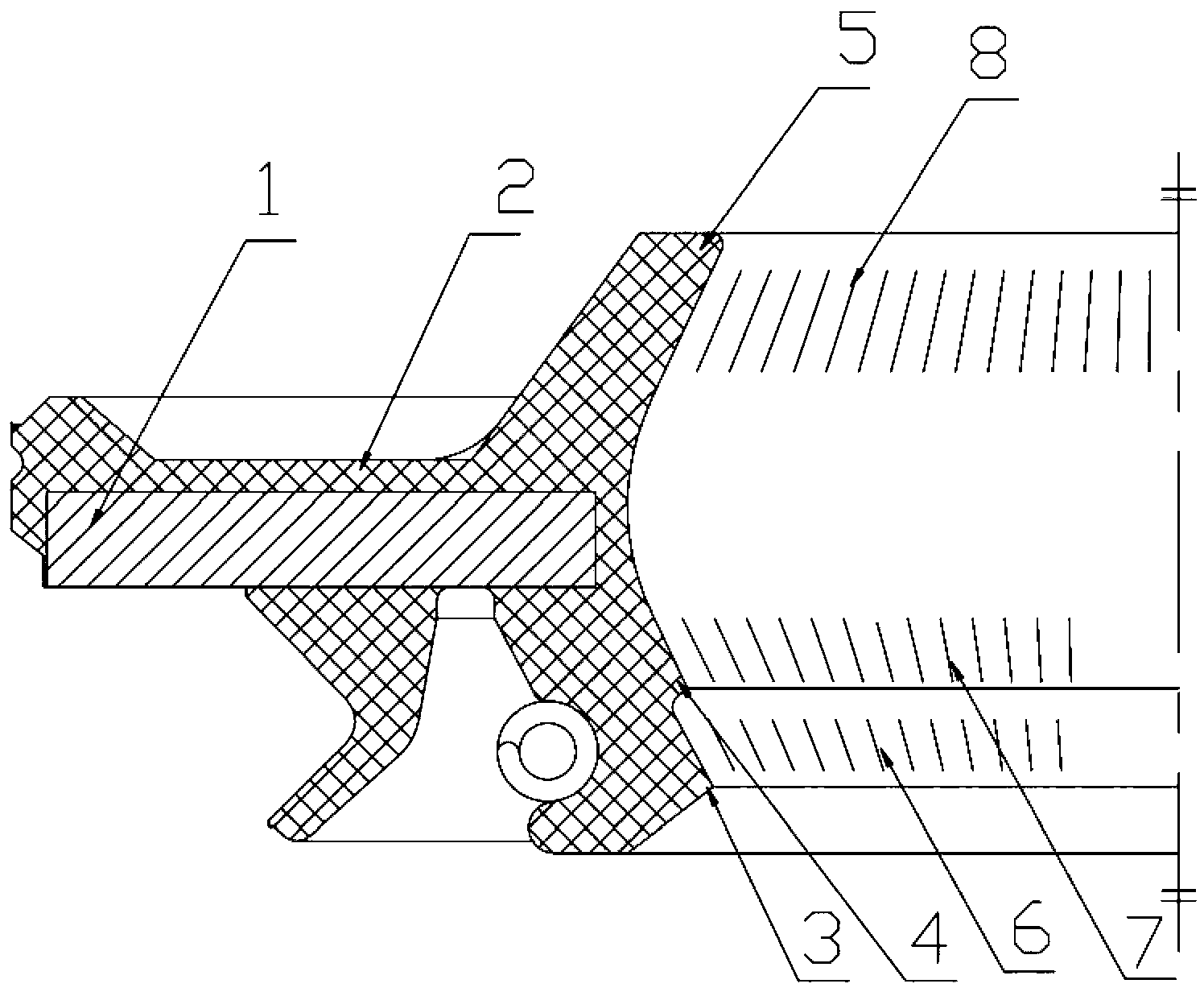

[0029] Such as figure 1 As shown, a low-friction shock absorber oil seal includes a skeleton 1 and an oil seal body 2, the oil seal body 2 includes at least one sealing lip, and axial parallel lines are provided on the annular sealing surface formed by the sealing lip.

[0030] The sealing lip includes a first sealing lip 3 and a second sealing lip 4, on the annular sealing surface formed by the first sealing lip 3 and the second sealing lip 4 are respectively provided with a first axial parallel groove 6 and a second sealing lip. Two axial parallel threads 7 .

[0031] The oil seal body 2 also includes a dust-proof lip 5 , and a third axial parallel groove 8 is provided on the annular sealing surface formed by the dust-proof lip 5 .

[0032] The cross-section of the axial parallel lines along the radial direction is wavy, arc-shaped, triangular or trapezoidal.

[0033] The oil seal body 2 is an elastomer such as nitrile butadiene rubber, hydrogenated nitrile butadiene rubbe...

Embodiment 2

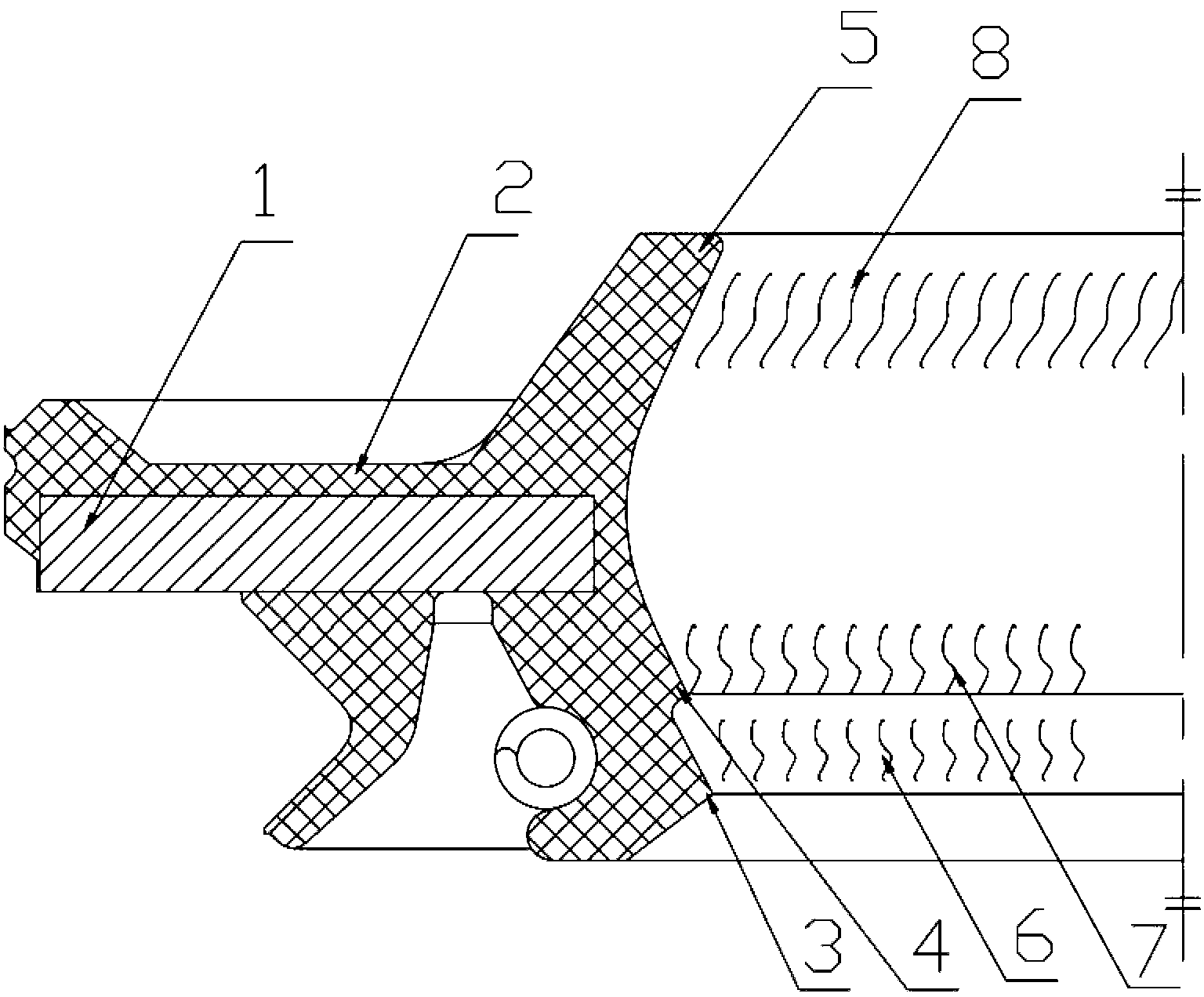

[0035] Such as figure 2 As shown, it is another structural schematic diagram of the present invention, which is different from the above-mentioned embodiment 1 in that the axial parallel lines are wave-shaped along the axial direction.

Embodiment 3

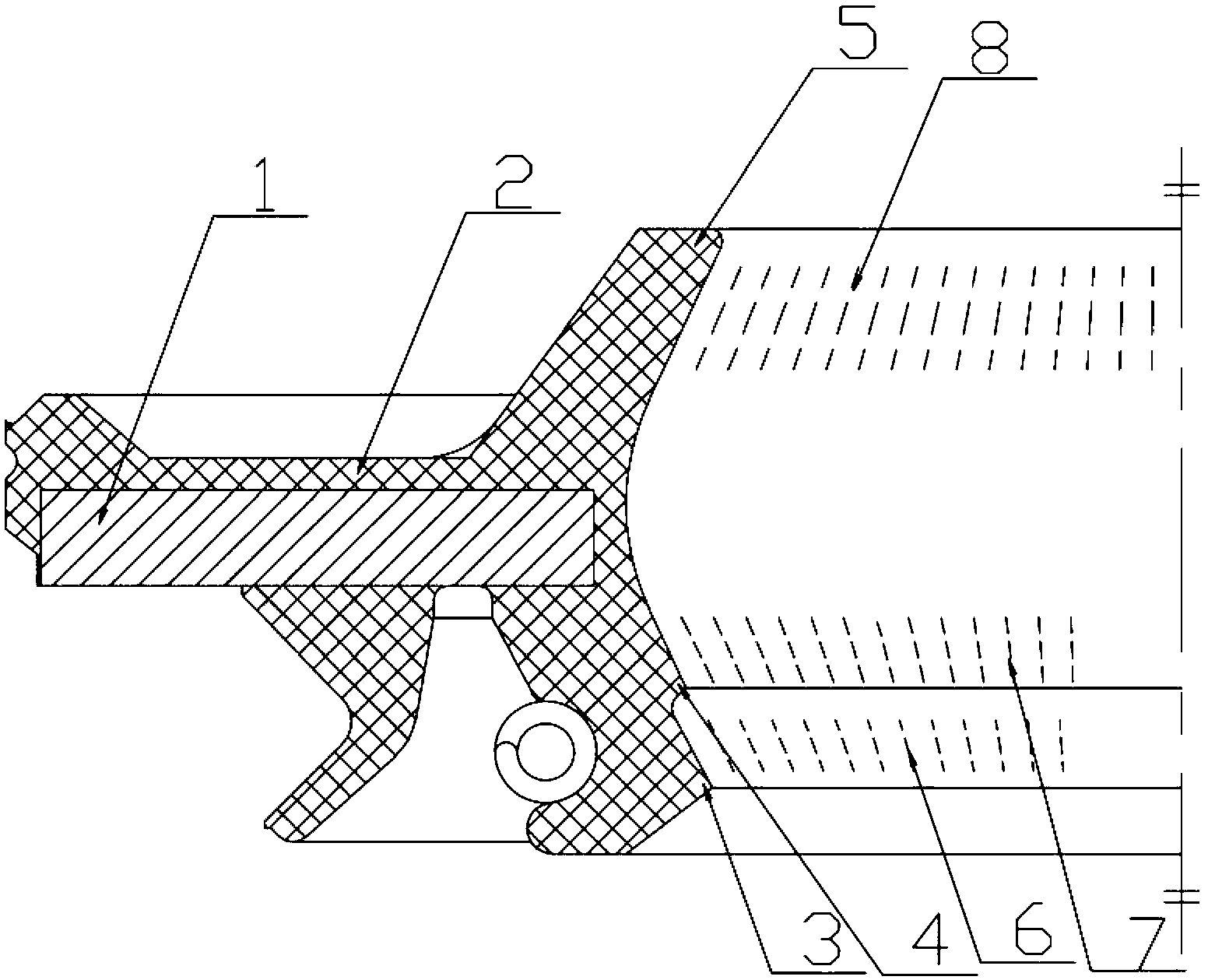

[0037] Such as image 3 As shown, it is another structural schematic diagram of the present invention, which is different from the above-mentioned embodiment in that the axially parallel lines are intermittently linear along the axial direction.

[0038] Such as Figure 4 As shown, it is an example of the cross-sectional view of the axial parallel lines in the present invention along the radial direction, and the cross-section of the axial parallel lines in the radial direction is wavy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com