Method and apparatus for operating an electronically commutated electrical machine in the event of a fault

一种运行方式、故障的技术,应用在用电装置、运输和包装、输出功率的转换装置等方向,能够解决减小电机可靠性、增大电机结构尺寸、限制功率等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

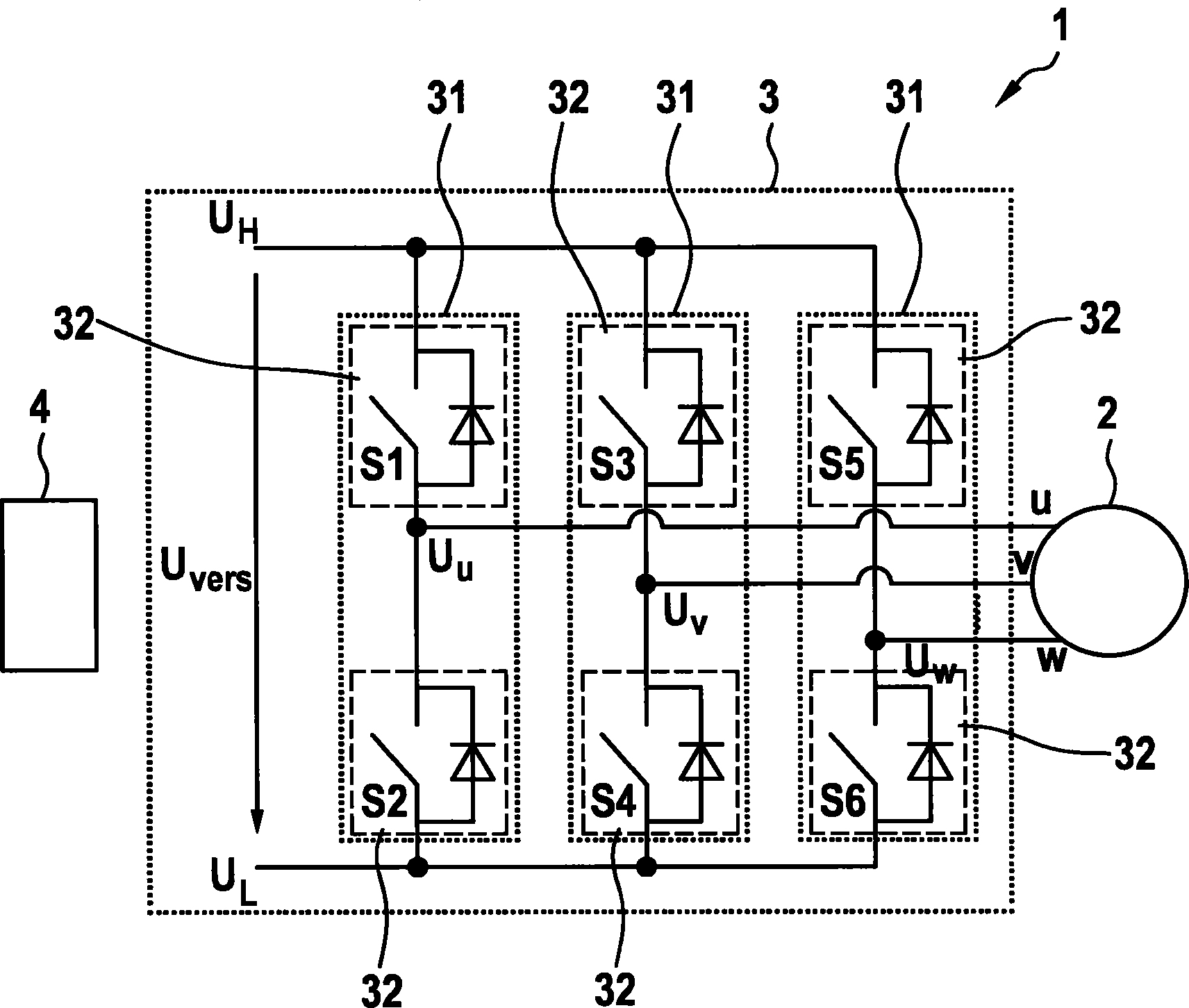

[0031] figure 1 A schematic diagram of a motor system 1 with an electronically commutated motor 2 is shown. The electric machine 2 can be designed, for example, as a synchronous machine, an asynchronous machine, a reluctance machine or the like. The electric machine 2 is designed as a multiphase, in the exemplary embodiment shown, as a three-phase and has phases U, V, W. The electric machine 2 is electronically commutated, that is to say varying phase voltages or phase currents are applied to the electric machine 2 or to phase branches of the electric machine 2 according to a commutation pattern.

[0032] Phase voltage U U , U V , U W It is produced by means of a driver circuit 3 which is controlled by a control unit 4 . The control unit 4 can be designed, for example, as a microcontroller or the like and supplies control signals with which the semiconductor switches S1 to S6 of the driver circuit 3 can be controlled. The semiconductor switches S1 to S6 are preferably co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com