Method for operating a brake system, brake system in which the method is performed, and uses of the brake system

A brake system, brake master cylinder technology, applied in the direction of the brake control system, brakes, brake components, etc., can solve the problems of understeer tendency, driving dynamics is not critical, the influence of vehicle steering ability, etc., to achieve high Driving comfort, comfortable regenerative braking and effective regenerative braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

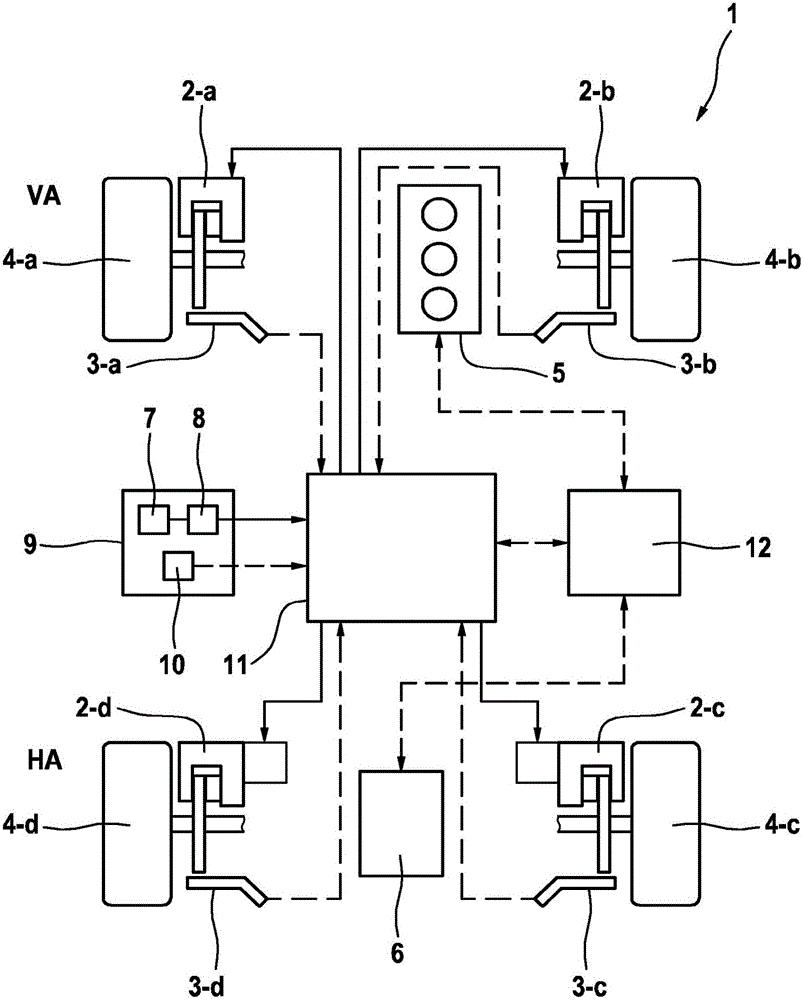

[0033] figure 1 A motor vehicle 1 is shown which has a braking system which is suitable for carrying out the method according to the invention. The vehicle according to the example is a hybrid vehicle with an internal combustion engine 5 and an electric drive 6 with one or more electric machines which can be controlled as generators for charging the battery , in order to charge one or more vehicle batteries not shown. In this case, an engine control unit 12 is provided for controlling the electric drive, which is connected to the electrohydraulic control unit 11 of the brake system. In the example shown, the electric drive 6 acts on the rear axle HA of the vehicle. The method according to the invention can in principle be recycled regardless of which wheels 4-a, 4-b, 4-c, 4-d are attached to the friction brakes 2-a, 2-b, 2-c, 2-d In particular, an electric drive connected only to the front axle VA can be provided as an alternative. The wheels of one or more axles may be co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com