Forklift travelling and parking integrated wet-type brake driving axle

A technology for driving brakes and driving axles, which is applied in the direction of hydraulic brakes, brake actuators, lifting devices, etc. It can solve problems affecting the reliability of parking brakes, achieve low noise, stable braking performance, and easy maintenance and use. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

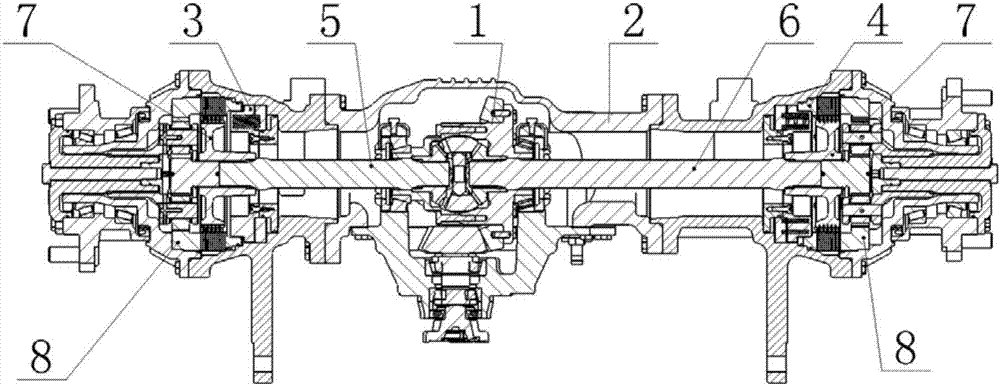

[0041] see figure 1 , a forklift driving and parking integrated wet brake drive axle, comprising a final drive assembly 1, an axle housing assembly 2, a left brake assembly 3, a right brake assembly 4, a left half shaft 5, a right half shaft 6, Spline sleeve 7 and fixed ring gear 8.

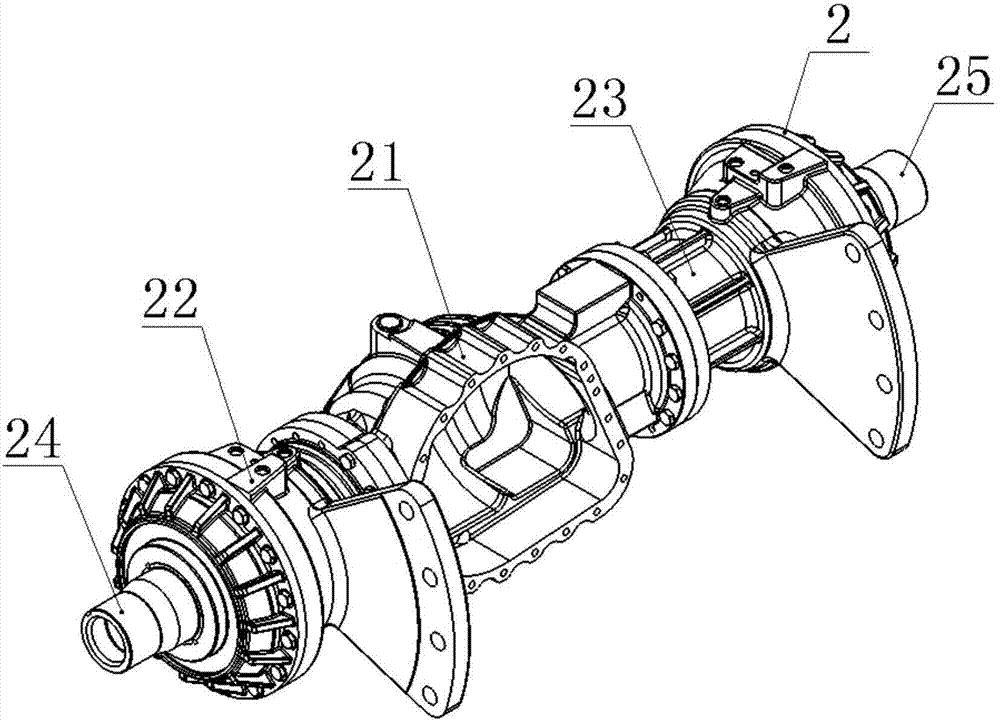

[0042] see figure 2 , the axle housing assembly 2 includes a middle axle housing 21, a left axle housing 22 and a right axle housing 23, the active reducer assembly 1 is installed in the middle axle housing 21, and the left half Shaft 5, spline sleeve 7 and fixed ring gear 8, the left side of the left axle housing 22 is connected to the left axle head 24, and the right axle shaft 6, spline sleeve 7 and fixed gear ring 8 are installed in the right axle housing 23, and the right axle The right side of the shell 23 is connected with the right shaft head 25 .

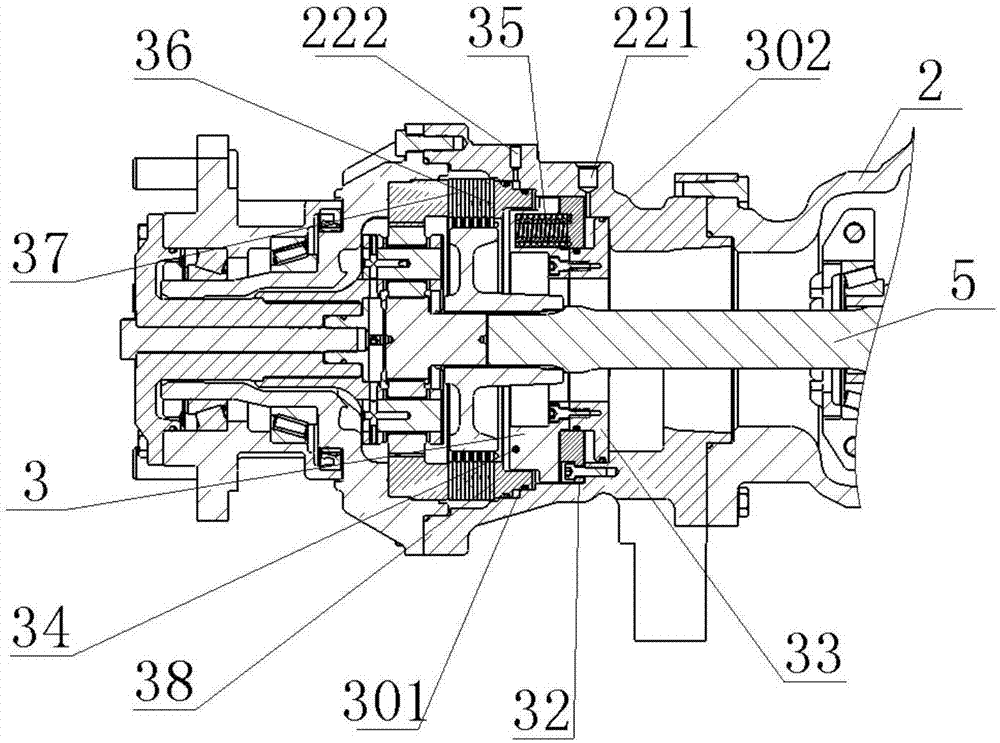

[0043] see image 3 , the left brake assembly 3 is provided with a parking brake mechanism and a service brake mechanism. The parking b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com