Automatic locomotive air damping control method for locomotive in emergency state or power-off state and system

A control system and air brake technology, applied in the direction of brake safety system, hydraulic brake transmission device, etc., can solve the problem of difficulty in taking into account, fluctuation of locomotive brake cylinder brake pressure, and the ability of small brakes to control locomotive brake cylinder pressure. Weak and other problems, to achieve the effect of clear and simple design ideas, enhanced comprehensive control capabilities, and easy learning and mastery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

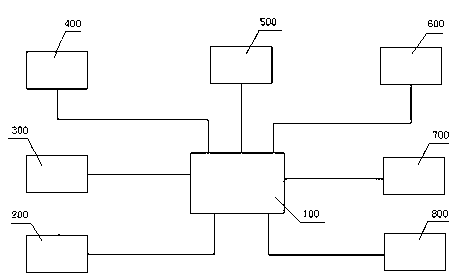

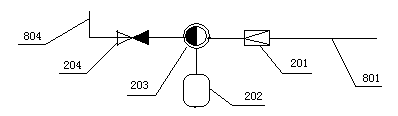

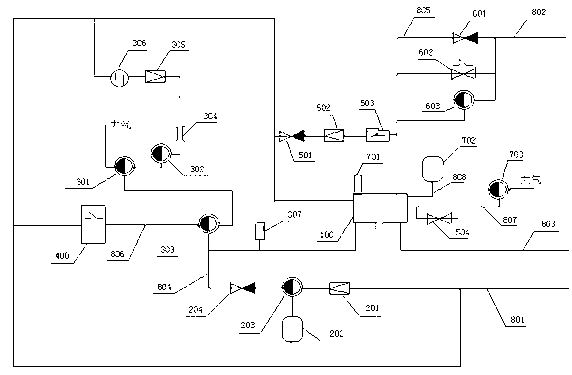

[0051] The specific example is as figure 1 , figure 2 and image 3 As shown, the distribution valve 100, the locomotive emergency or power failure automatic braking control system 200, the locomotive common braking control system 300, the small gate control system 400, the no-fire branch control system 500, the train management backup control system 600, Other standby control system 700, air pipe branch system 800, etc., constitute the distribution valve comprehensive control system.

[0052] The distribution valve 100, as a main air valve in the locomotive braking system, can perform complex air circuit control and conversion functions.

[0053] The invention described above is an emergency or power-off automatic braking control system 200 for a locomotive. Cooperating with the air duct branch system 800, the distribution valve 100 can be controlled to automatically brake the locomotive when the locomotive is in an emergency or power-off state.

[0054] Adjust the first p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com