A heat-dissipating brake pad

A brake pad and heat-dissipating technology, which is applied in the direction of brake types, brake components, mechanical equipment, etc., can solve the problems of oil temperature rise, volume change, impact on brake accuracy and stability, etc., to achieve braking performance Stabilize, reduce abnormal noise, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

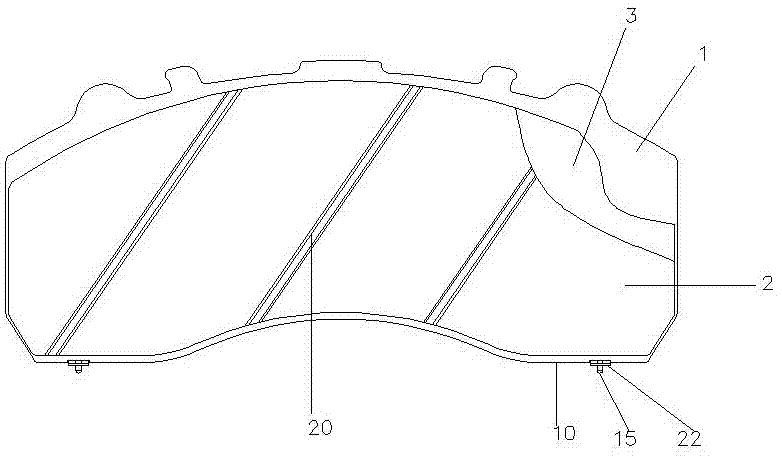

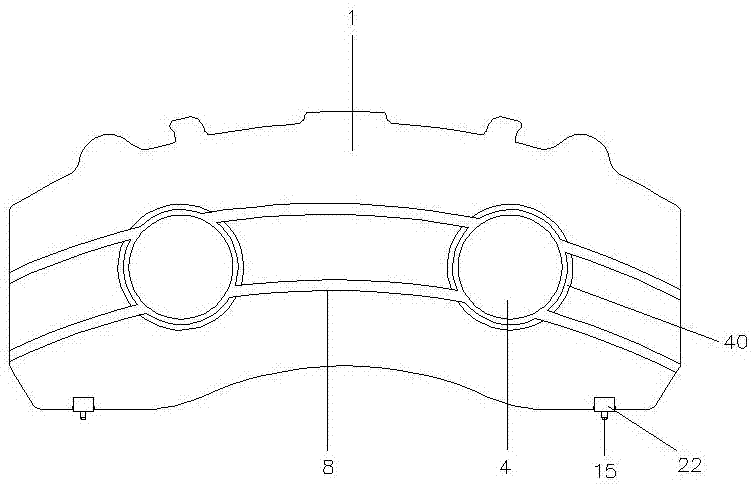

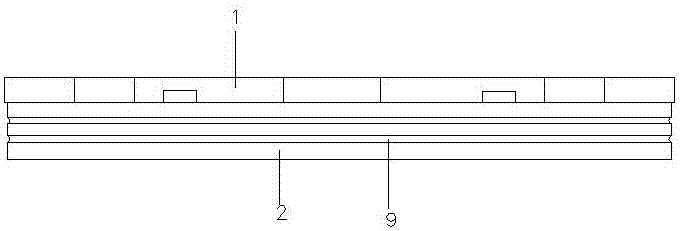

[0022] like figure 1 and figure 2 The heat-dissipating brake pad shown includes a back plate 1 and a friction block 2, a heat insulating layer 3 is provided between the back plate and the friction block, and a piston rod limit hole 4 is provided on the outer surface of the back plate, such as Figure 4 As shown, the bottom of the piston rod limit hole is provided with a heat insulation cavity 5, and the heat insulation cavity is filled with a heat insulation filler 6. The heat insulation filler can be any one of asbestos and glass fiber, and the opening end of the heat insulation cavity is set There is a cover plate 7; the front of the friction block 2 is provided with several inclined slag discharge grooves 20, and the cross section of the slag discharge groove is inverted trapezoidal; image 3 As shown, the edge of the friction block is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com