Patents

Literature

35results about How to "Large amount of liquid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

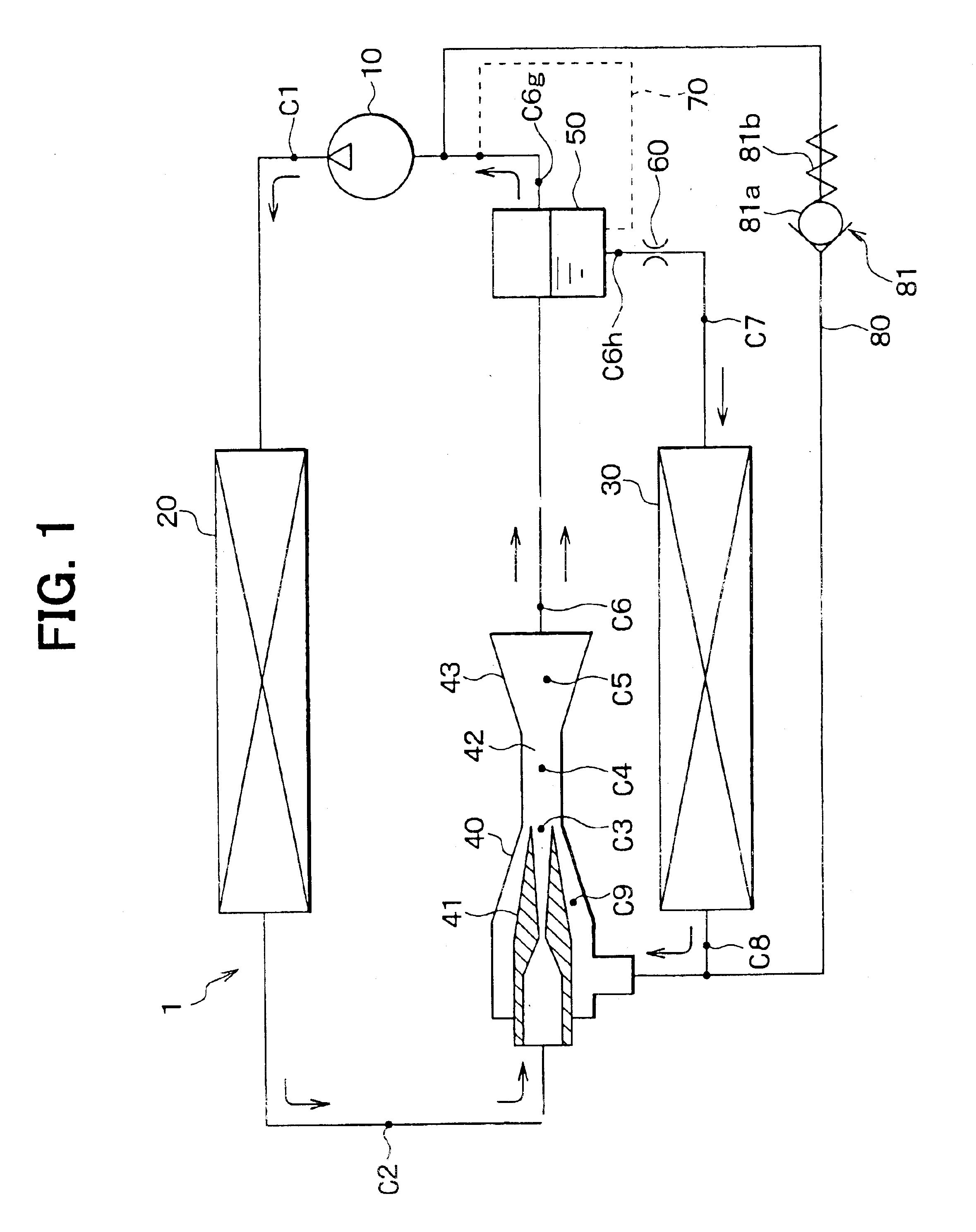

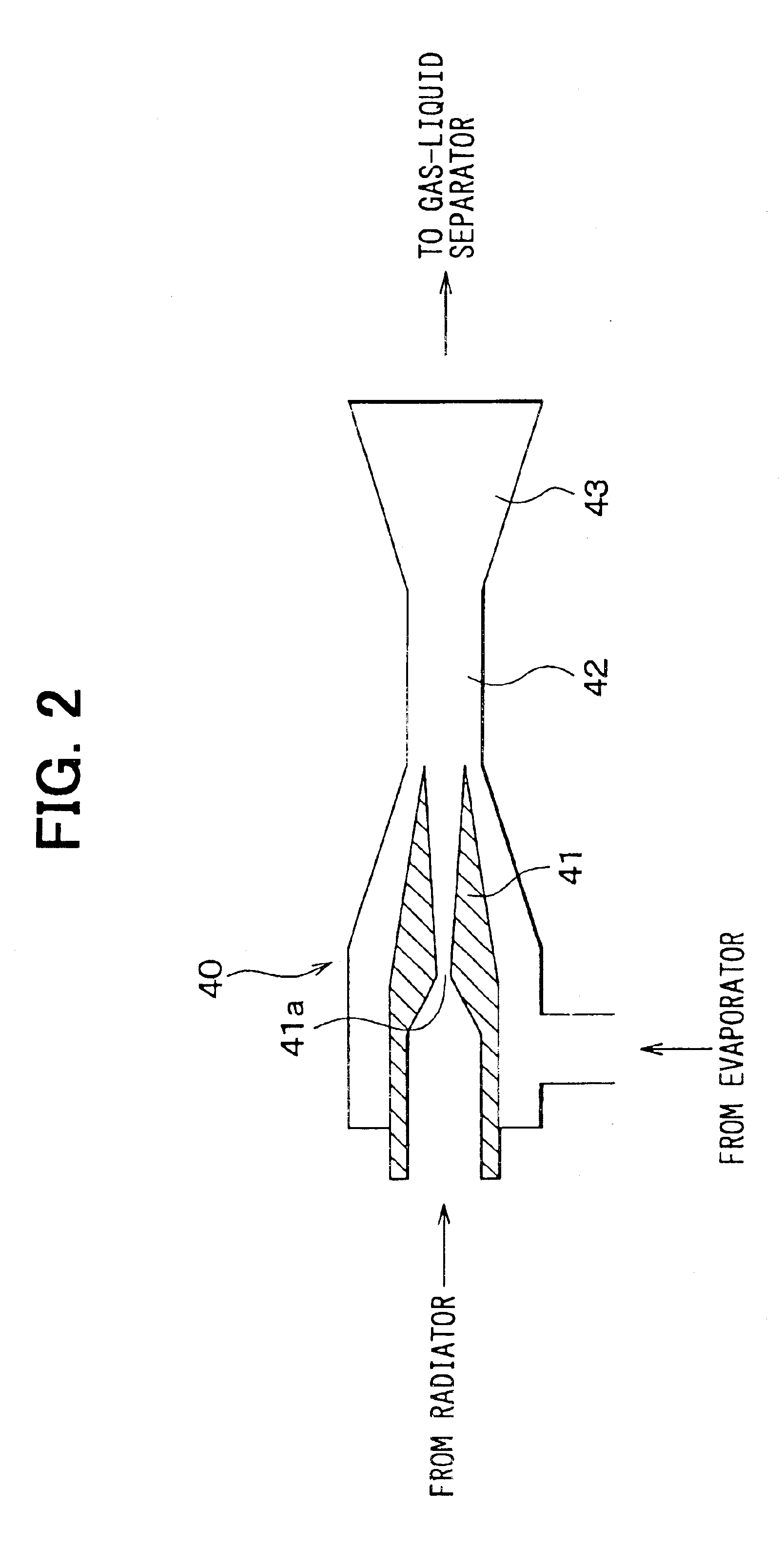

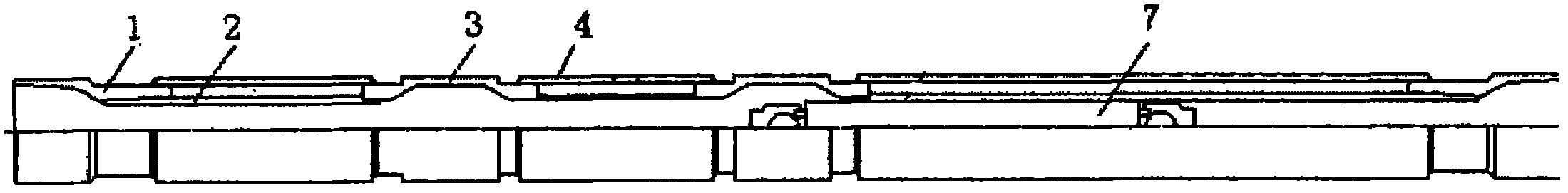

Ejector cycle

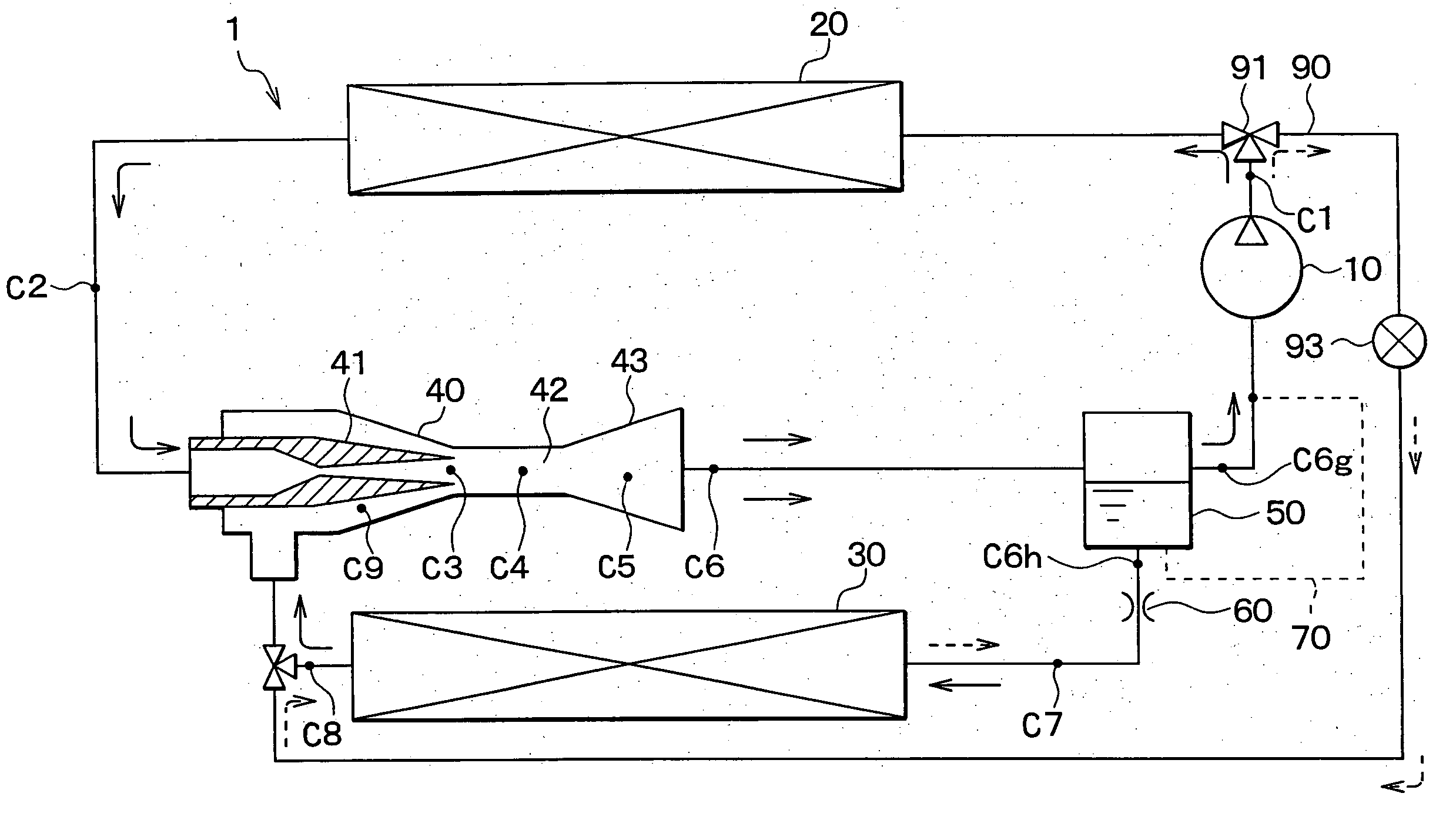

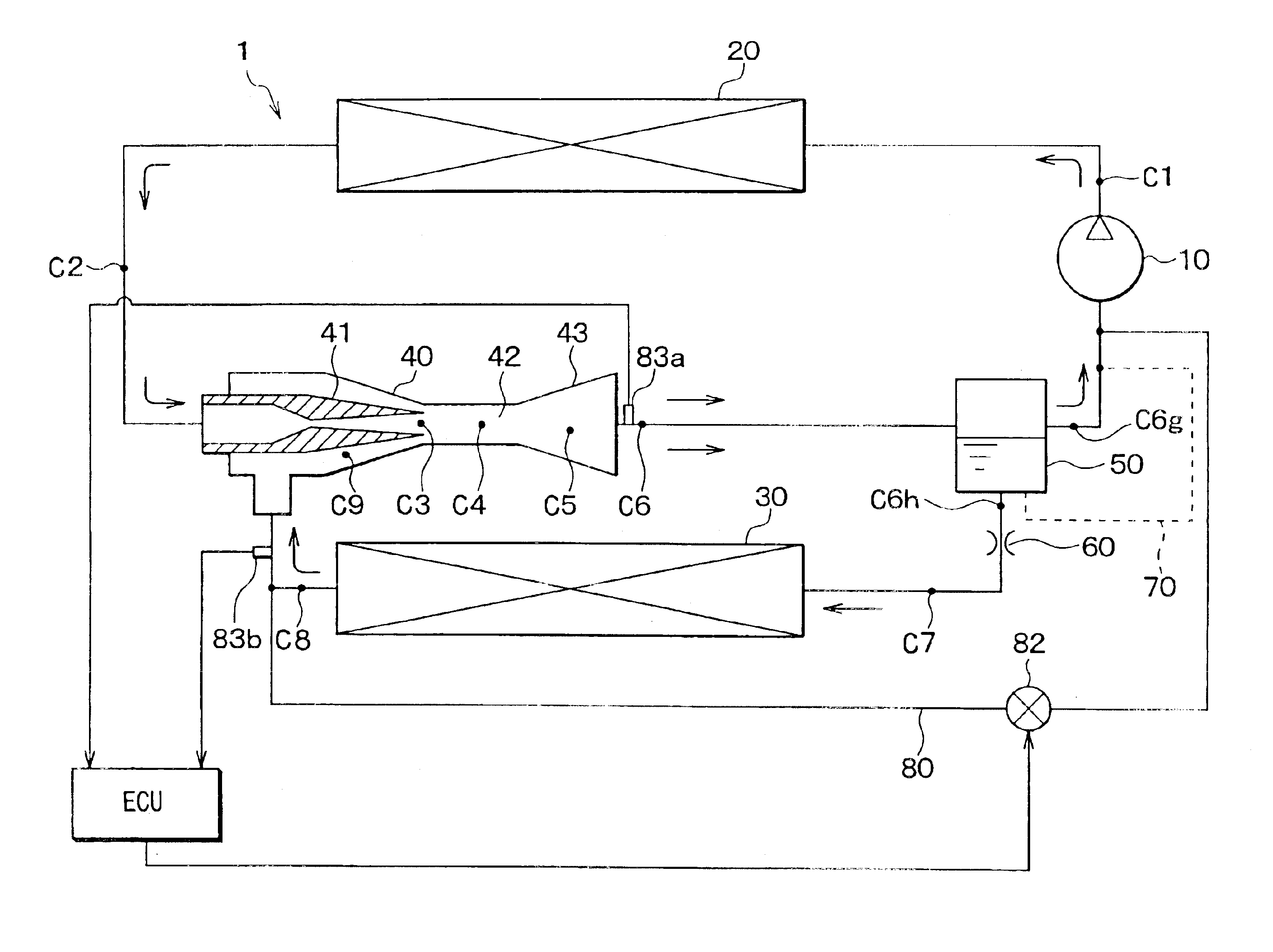

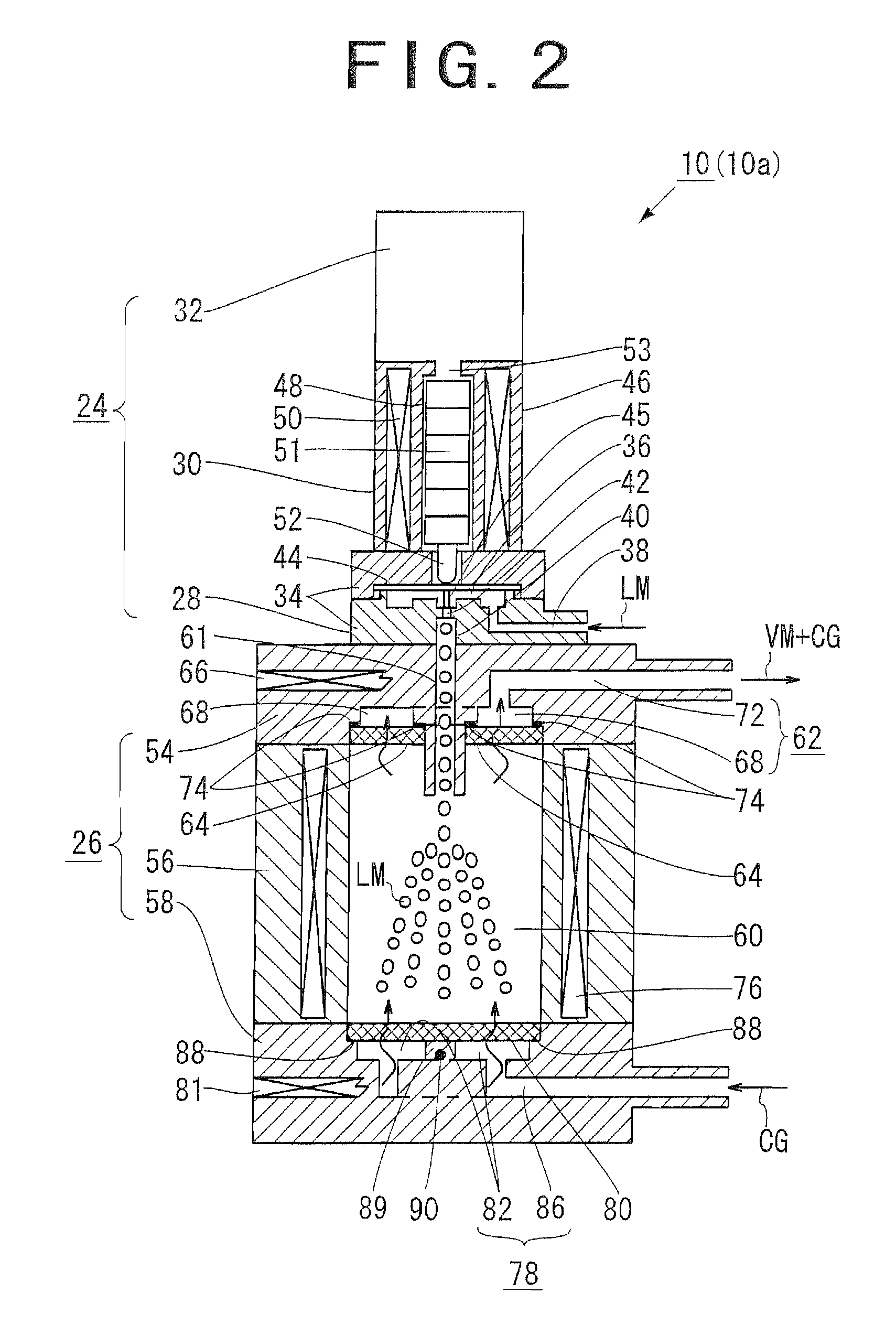

ActiveUS20040003608A1Small sizeReduce lubricationCompressorAir-treating devicesOperation modeCheck valve

In an ejector cycle having an ejector for decompressing refrigerant, a check valve is disposed in an oil return passage through which refrigerant including a lubrication oil is introduced from a refrigerant outlet side of an evaporator to a refrigerant suction side of a compressor while bypassing the ejector. When the lubrication oil amount staying in the evaporator reduces, the check valve is automatically closed, and a normal operation mode of the ejector cycle is automatically set. On the contrary, when a large amount of lubrication oil stays in the evaporator, the check valve is automatically opened, and an oil return mode is automatically set. Therefore, the lubrication oil staying in the evaporator can be controlled equal to or lower than a predetermined amount, thereby effectively returning the lubrication oil to the compressor.

Owner:DENSO CORP

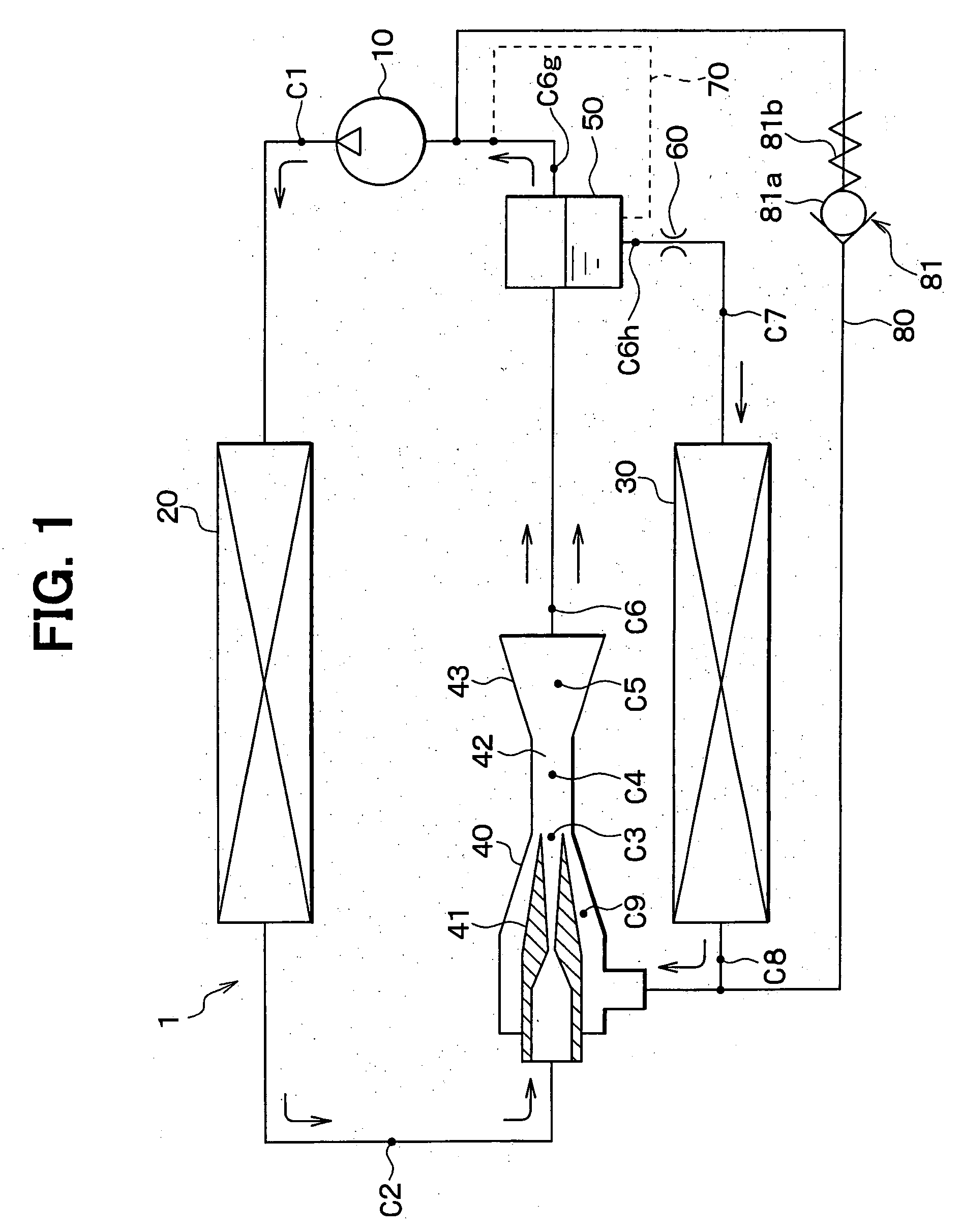

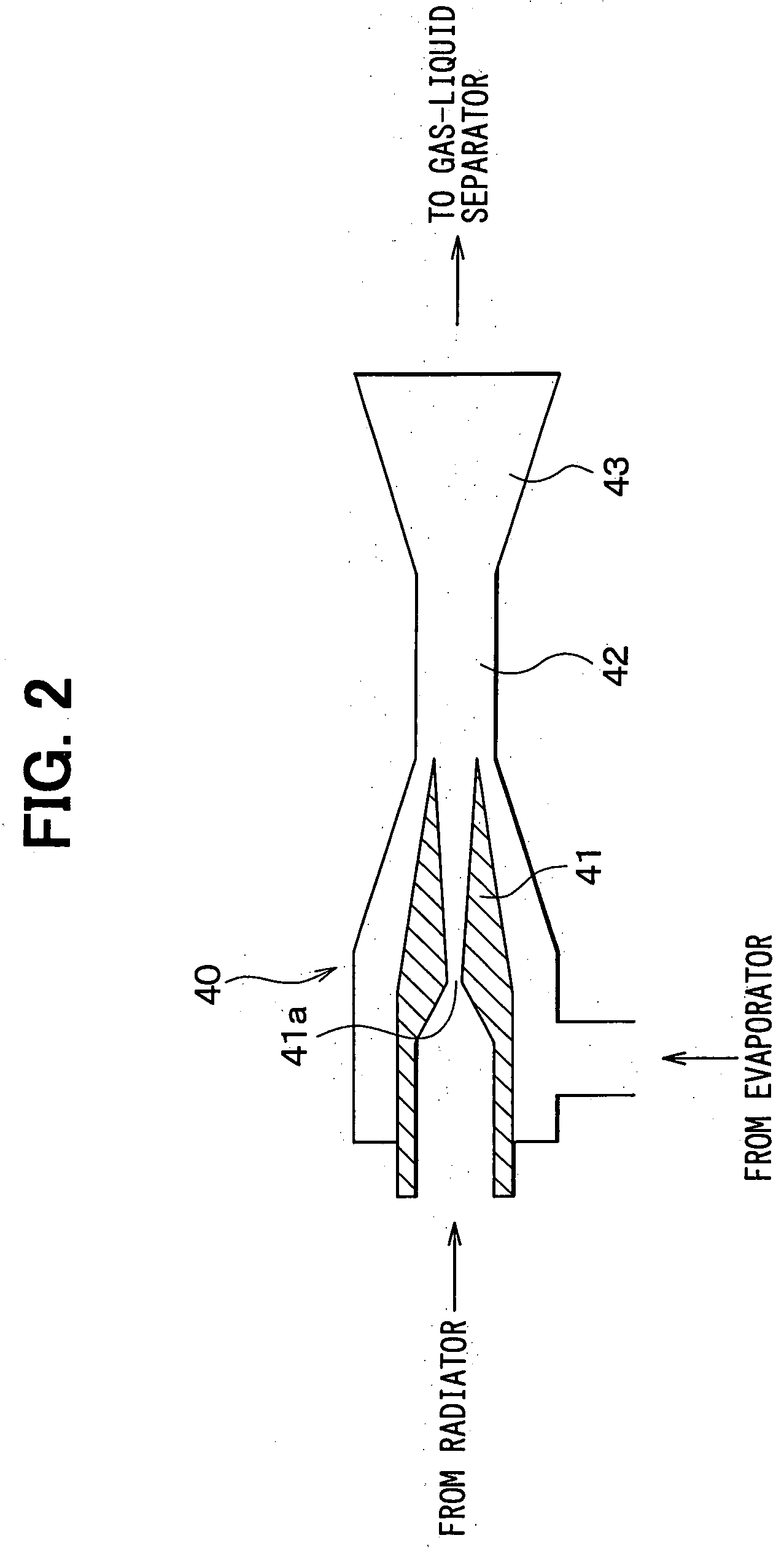

Ejector cycle

InactiveUS6834514B2Small sizeReduce lubricationCompressorAir-treating devicesOperation modeEngineering

Owner:DENSO CORP

Method for fermentative production of n-acetyl-d-glucosamine by microorganism

InactiveUS20110059489A1Large amount of liquidLow yieldMicroorganismsMicroorganism based processesBiotechnologyMicroorganism

N-Acetyl-D-glucosamine can be produced by cultivating a fungus capable of producing N-acetyl-D-glucosamine, such as Trichoderma hamatum AB 10282 strain (FERM BP-10623) or Trichoderma harzianum AB10283 strain (FERM BP-10624), in a culture medium supplemented with a carbon source other than chitin and chitin oligosaccharide and a nitrogen source to produce and accumulate N-acetyl-D-glucosamine in the culture medium and then collecting N-acetyl-D-glucosamine from the culture medium.

Owner:HOKKO CHEM IND CO LTD (JP)

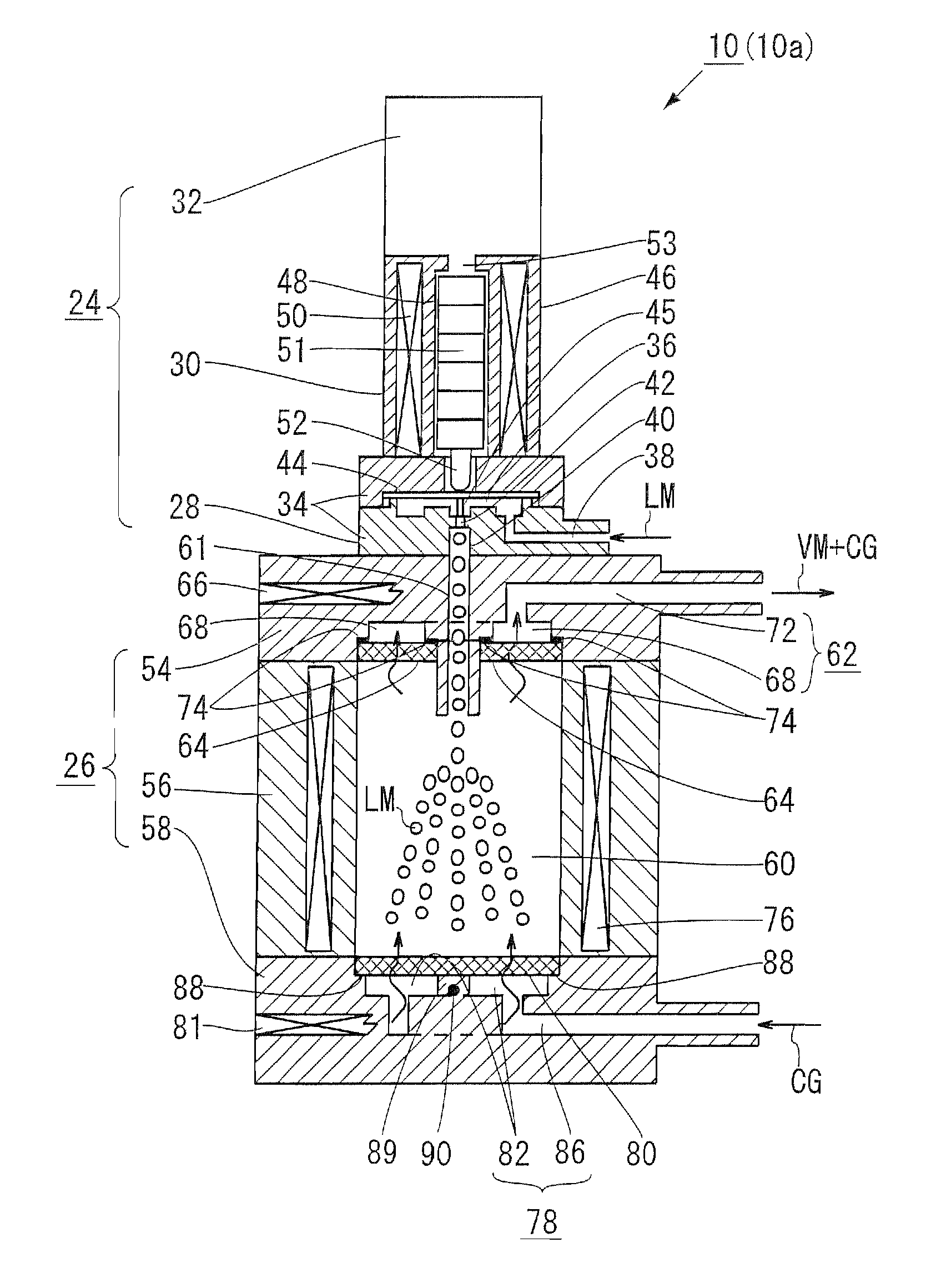

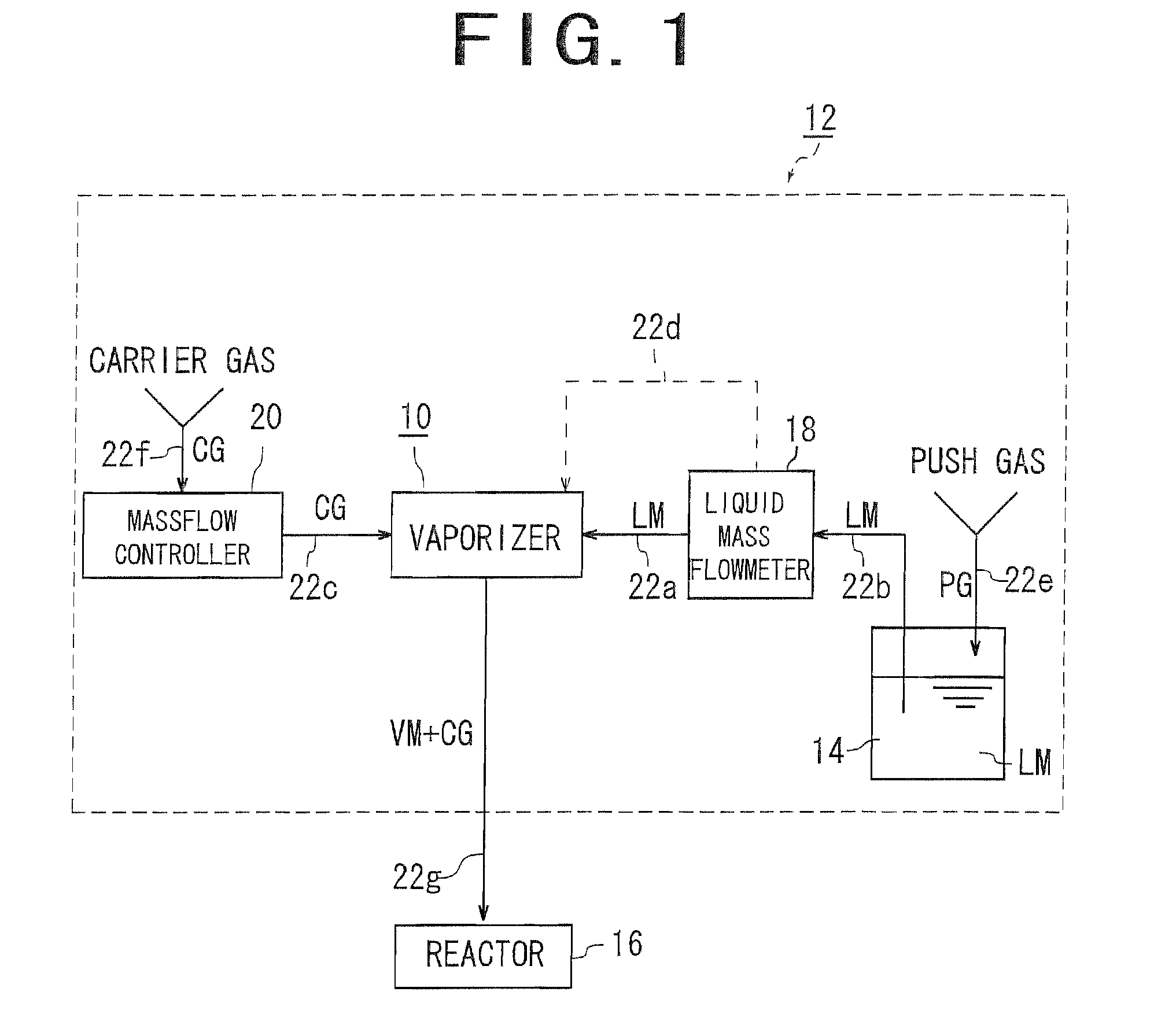

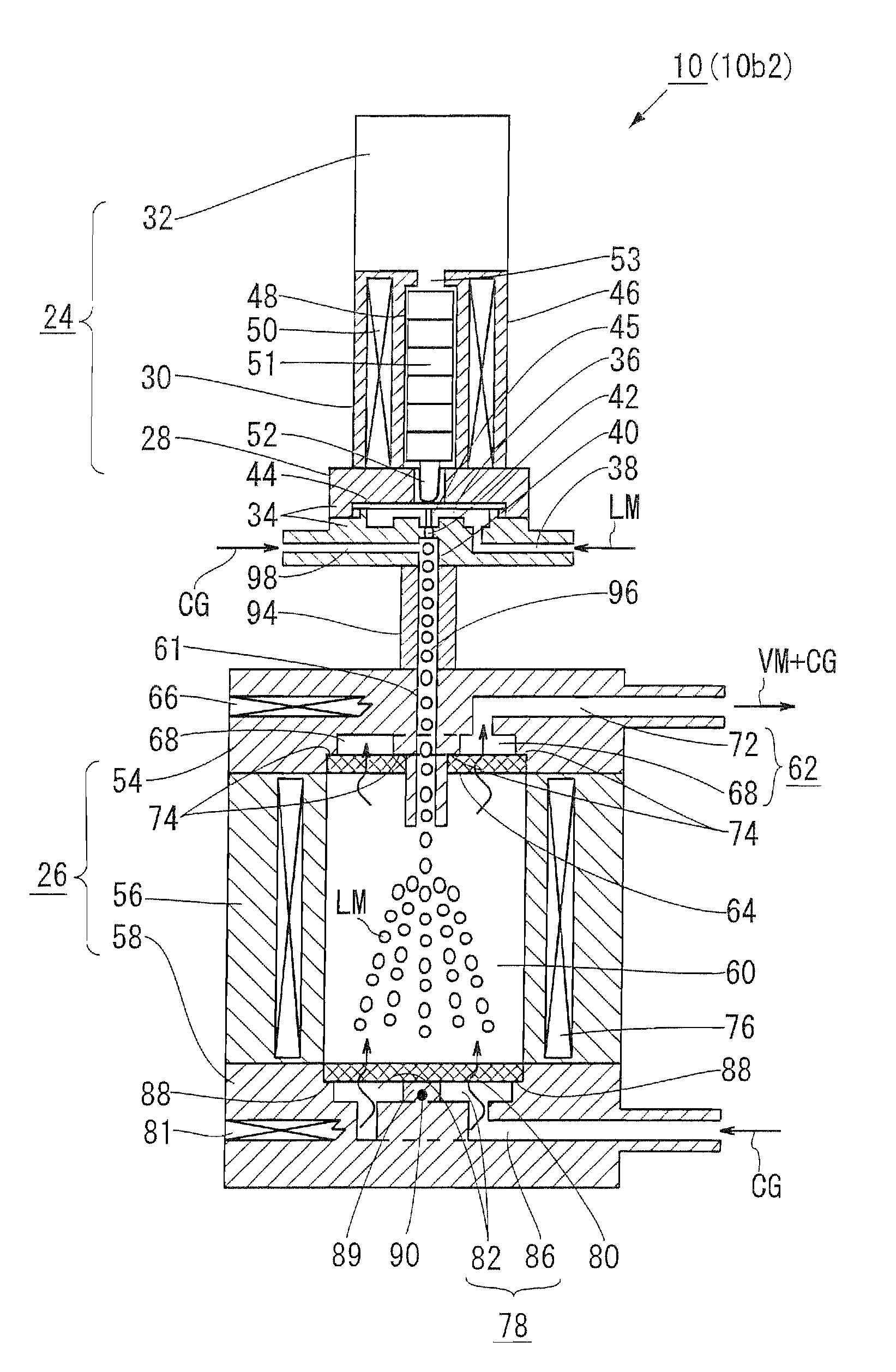

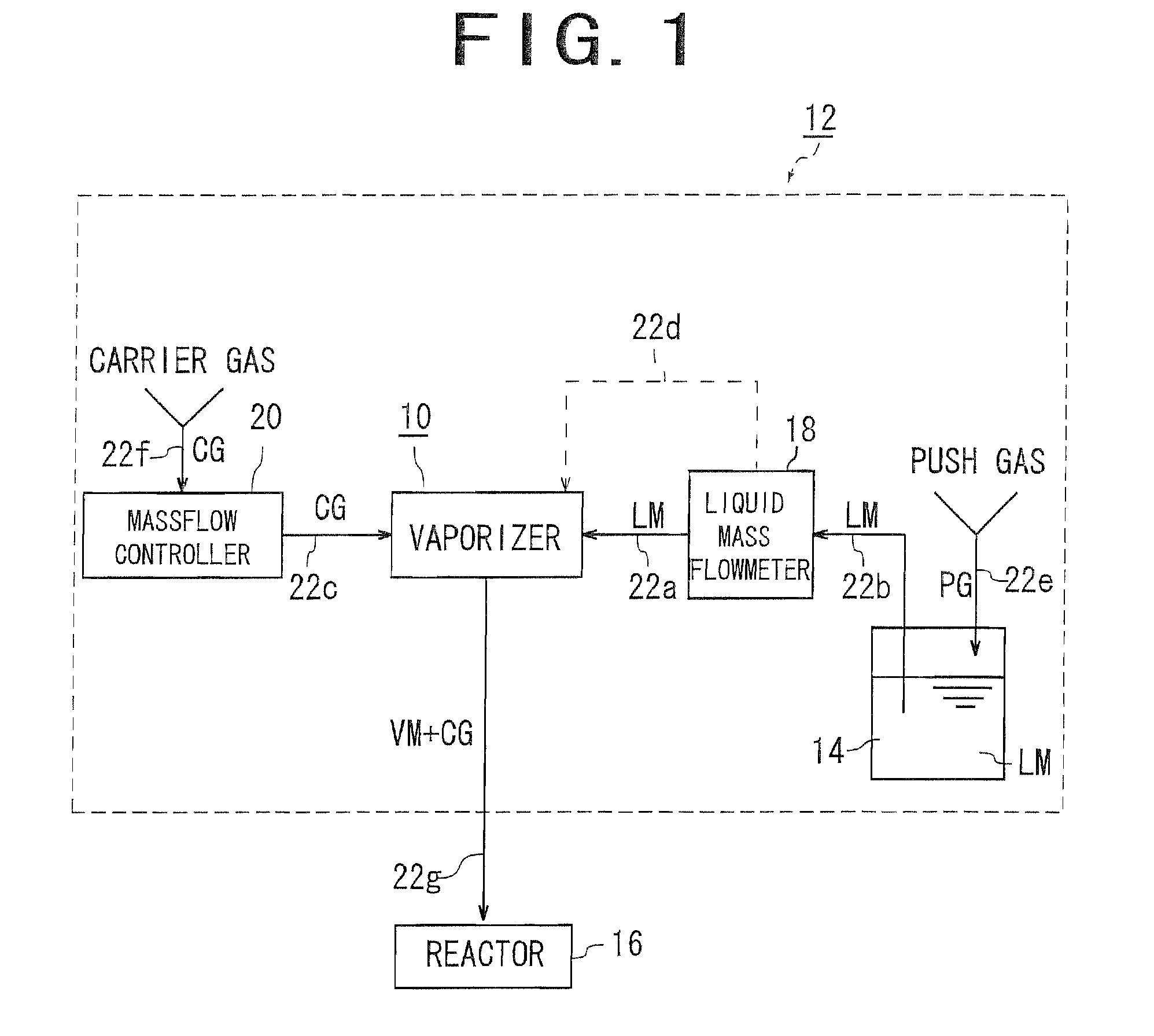

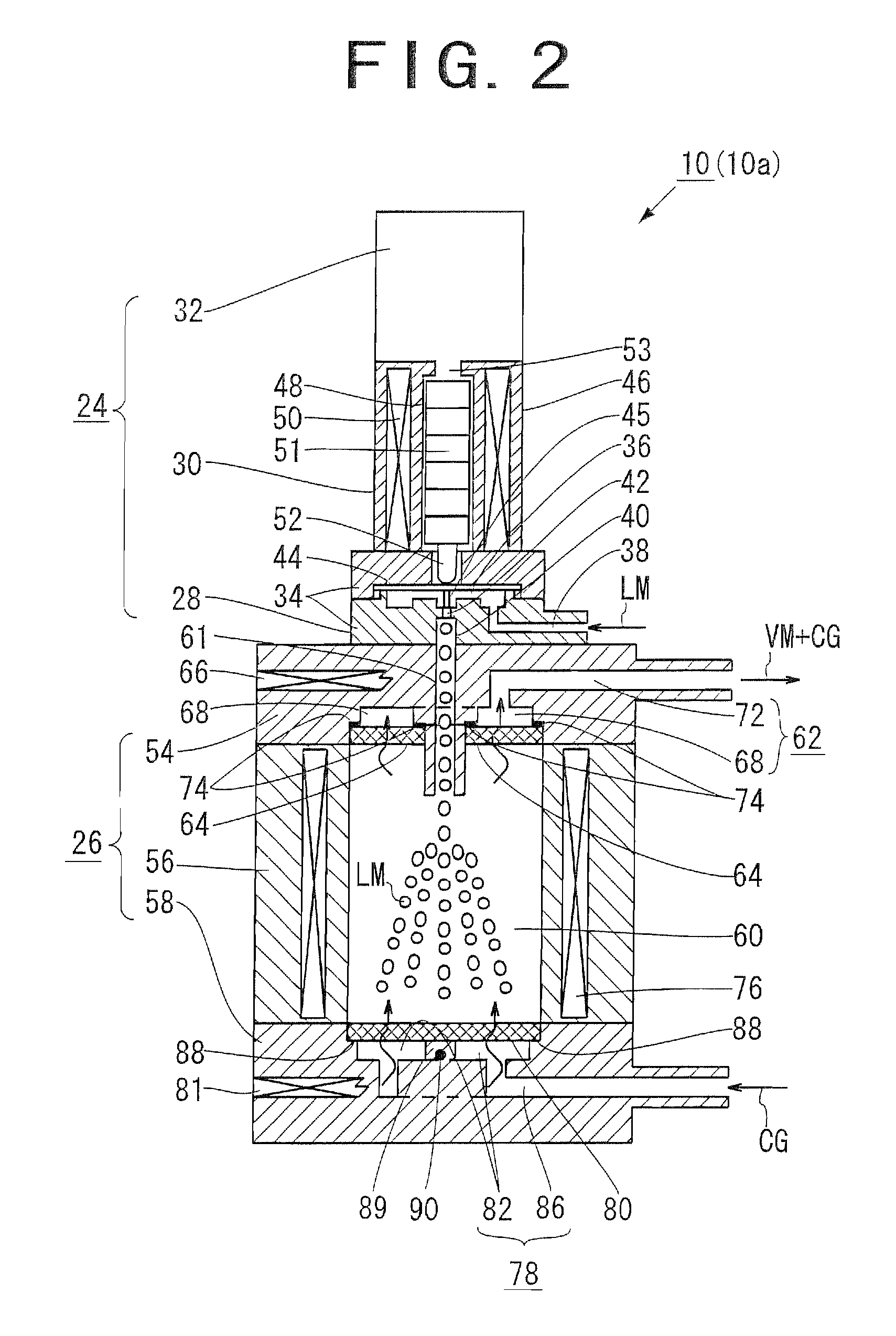

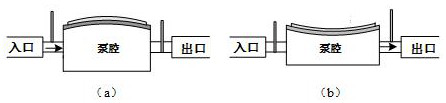

Method for vaporizing liquid material capable of vaporizing liquid material at low temperature and vaporizer using the same

ActiveUS20090065066A1Low vaporization temperatureAvoid accumulationLighting and heating apparatusUsing liquid separation agentProduct gasMaterial supply

A vaporizer is provided with a vaporizing chamber heated by heaters; a primary filter positioned in a bottom end portion of the vaporizing chamber and heated by the heater; a liquid material supply portion for dropping down a flow-controlled liquid material from upper portion of the vaporizing chamber toward the primary filter; a carrier gas guiding passage for guiding a carrier gas into the underside of the primary filter; and a material delivering passage for discharging a mixed gas including the carrier gas and a vaporized liquid material from the top of the vaporizing chamber. The liquid material dropped down onto the primary filter is partially vaporized, while the rest thereof is atomized by being subjected to bubbling effect provided by the carrier gas flowing from underneath.

Owner:LINTEC CO LTD

Defervescence paste

InactiveCN101336960APromote absorptionReduce fever and reduce feverHydroxy compound active ingredientsAntipyreticGlycerolPeppermints

The invention relates to an auxiliary article in medical treatment, an antipyretic paste, which is mainly prepared from the following raw material of (wt%), peppermint 0.1-15, ethanol 1-30, glycerol 1-30, borneol 0.1-15, and spreadable gel base or ointment base in balancing amount. The antipyretic paste made from the above formula can be applied on the skin surface of a pyretic patient to conduct auxiliary antipyretic treatment under physical and medical dual antipyretic effect. The inventive antipyretic paste has physical and medical dual antipyretic effect, resulting in better and safer antipyretic effect, and has no toxic and adverse effects.

Owner:徐宝恒

Auxiliary braking device for magnetic rheological body petroleum drilling rig

ActiveCN1945047ALarge amount of liquidLarge heat capacityLiquid resistance brakesPetroleumConductive materials

The auxiliary braking device with magnetic rheological body for petroleum rig includes one cylinder of non-magnetic conductive material and two end caps of magnetic conductive material to form one sealed cylindrical cavity, two magnetic conductive columns with wound exciting coil outside the cylinder and between the two end caps, one shaft of non-magnetic conductive material with fixed magnetic conductive blades set between the two end caps, and magnetic rheological body filled in the sealed cylindrical cavity. The present invention can provide great braking moment at all rig winch speeds, and has stepless regulation of braking moment, fast response, low cost and long service life.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

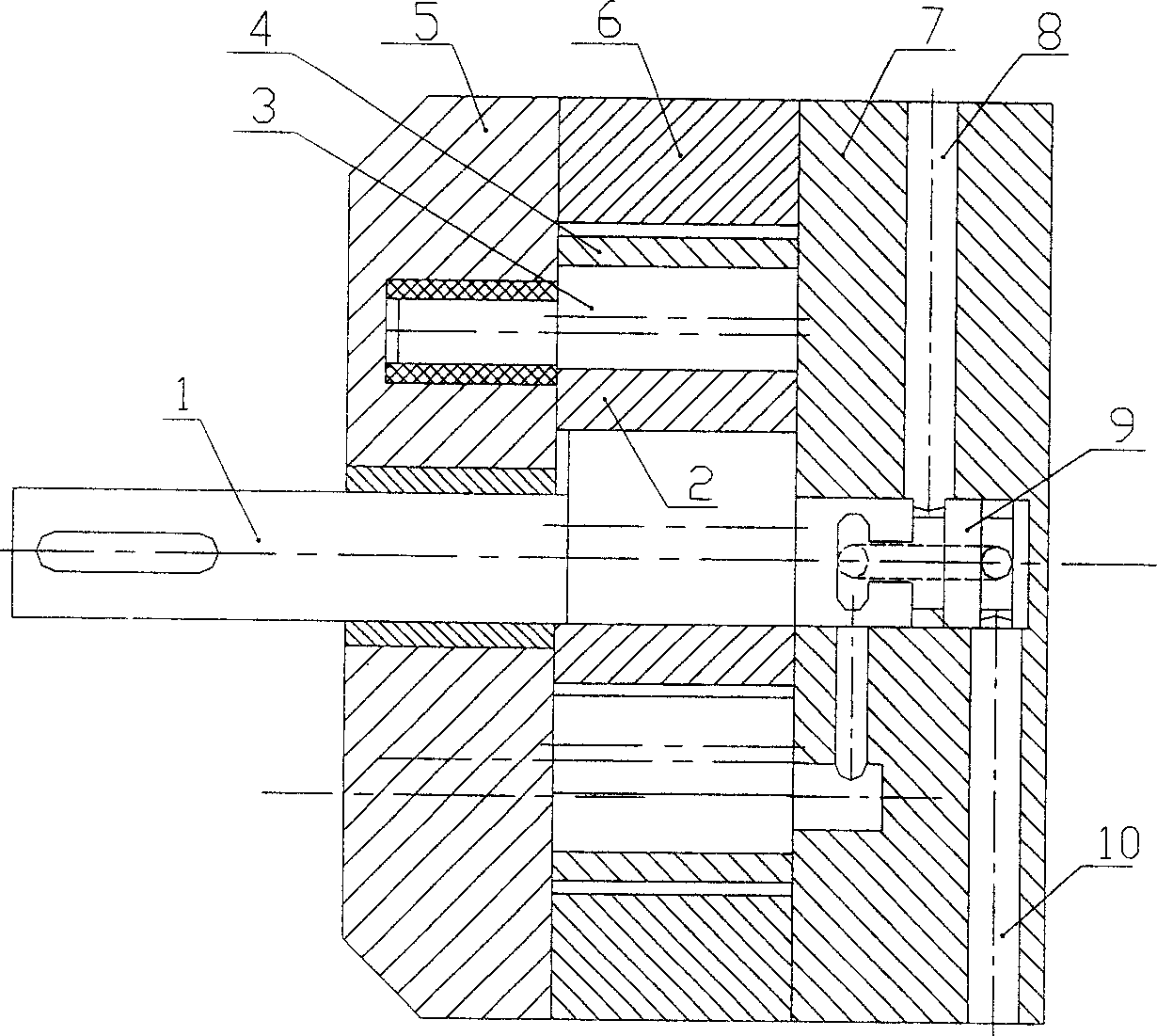

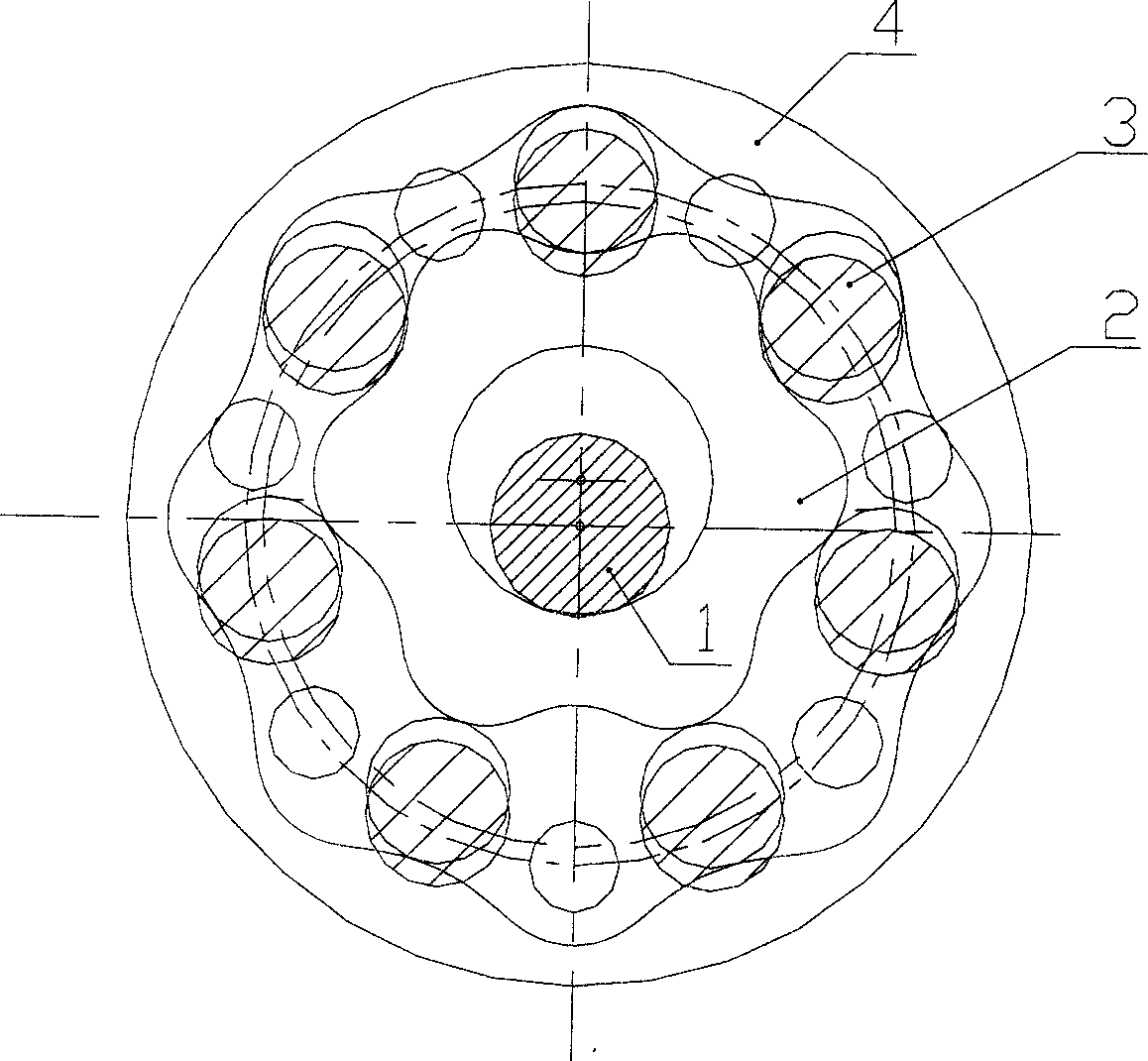

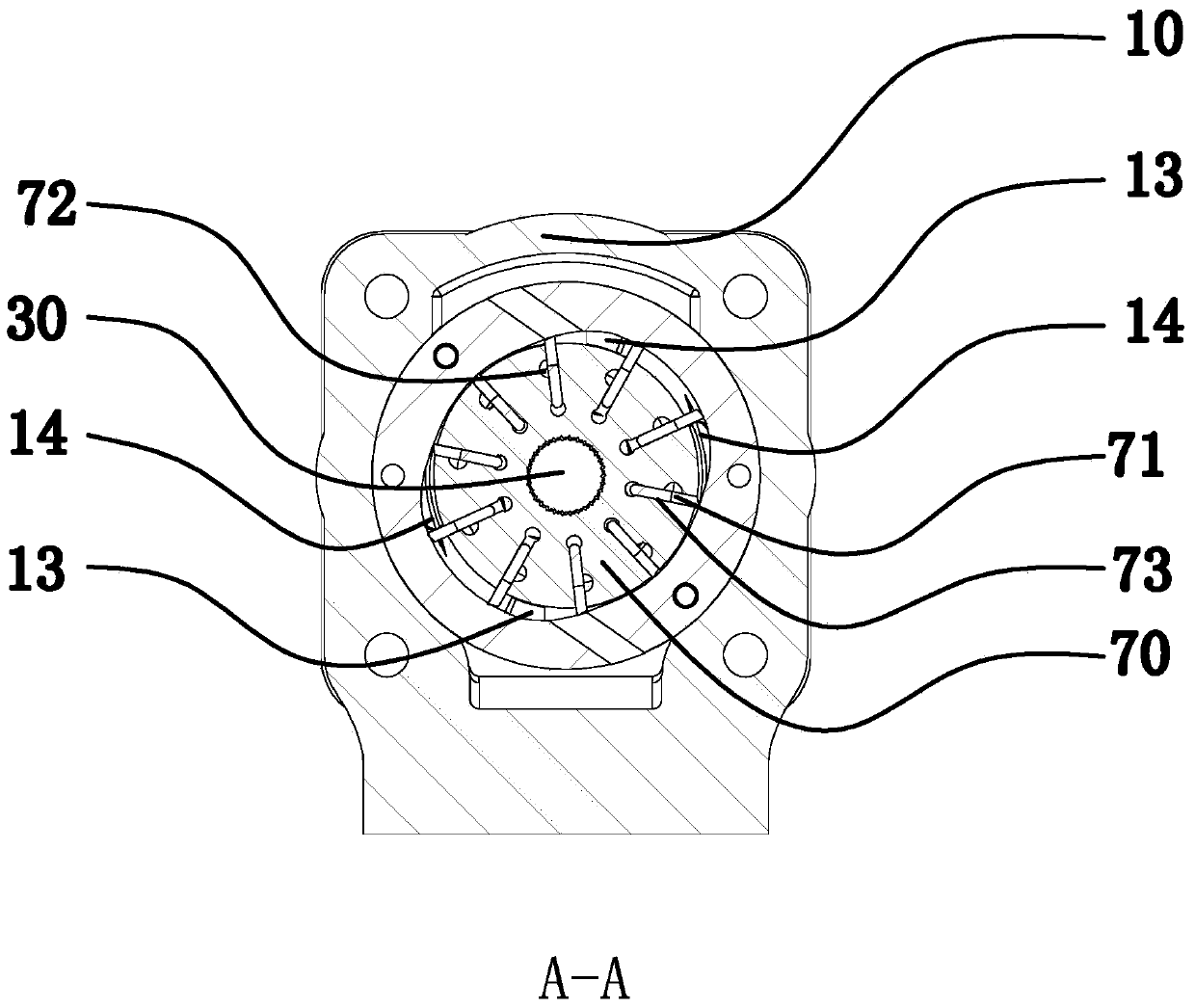

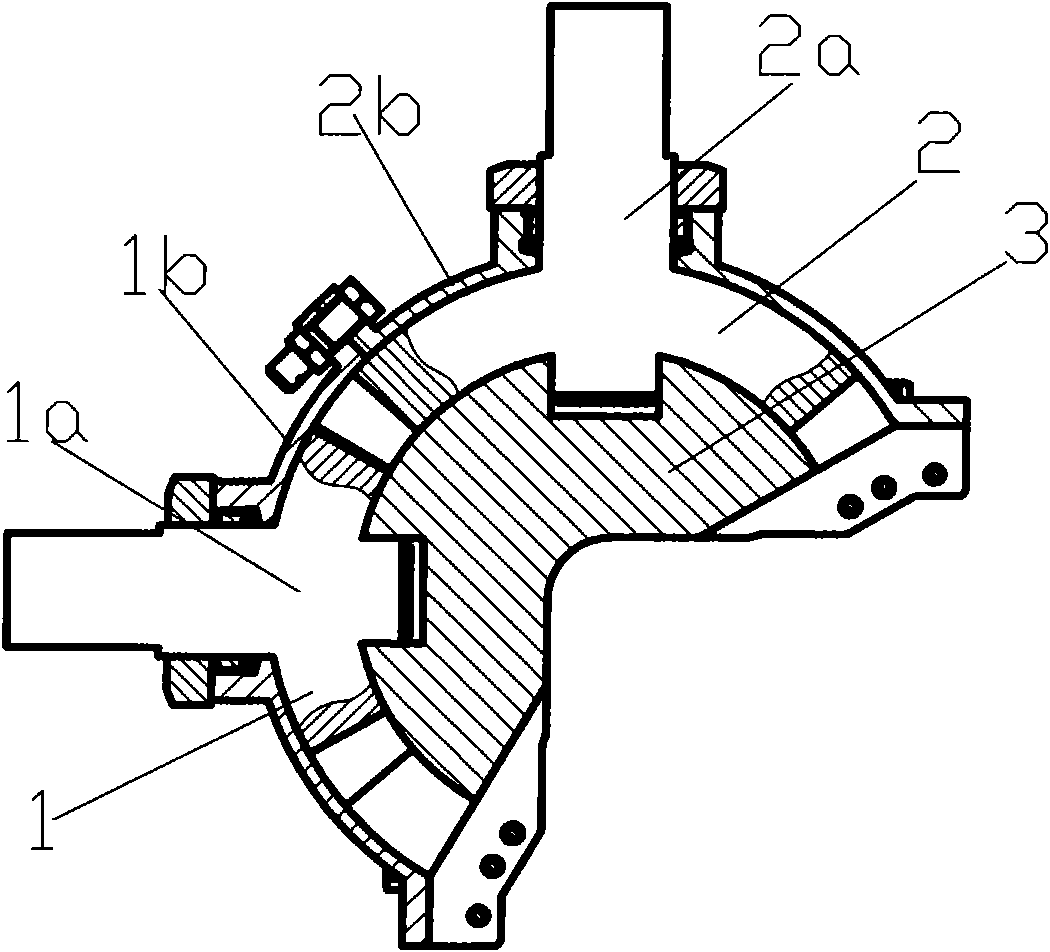

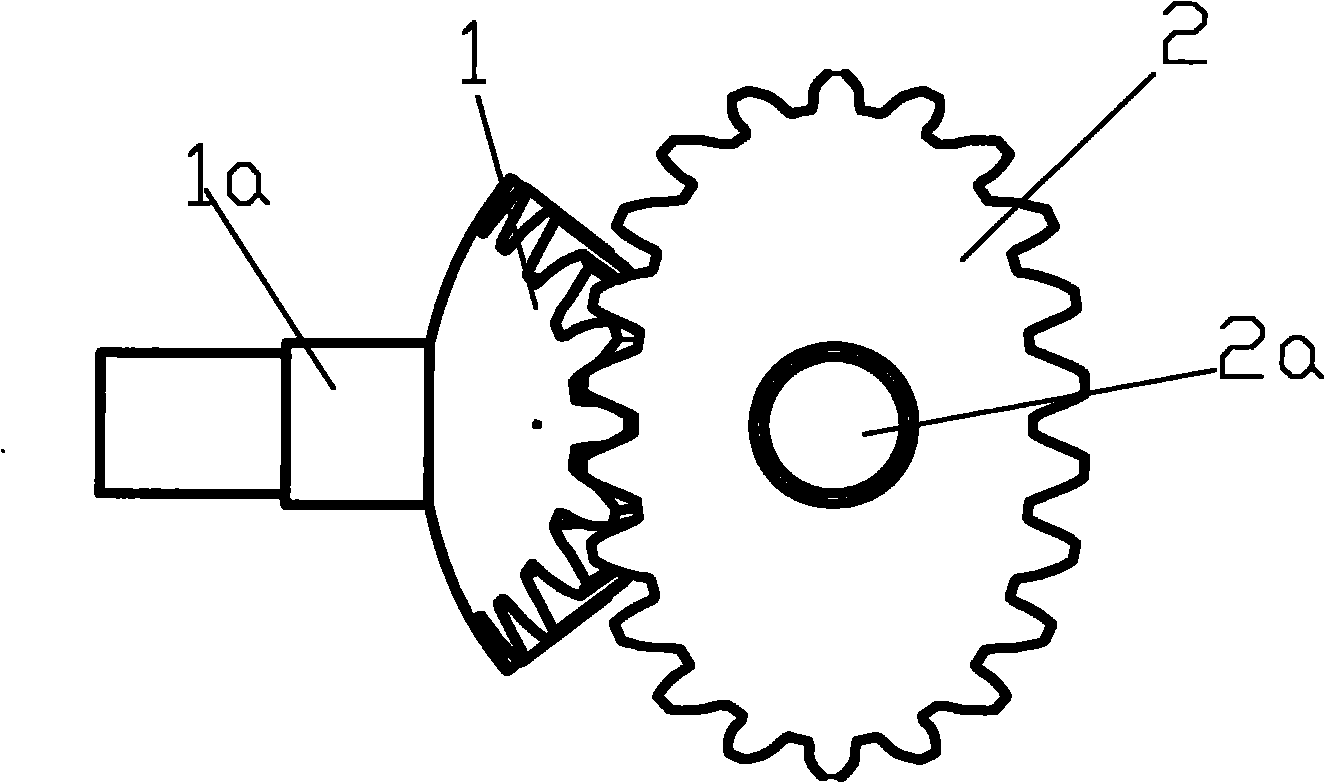

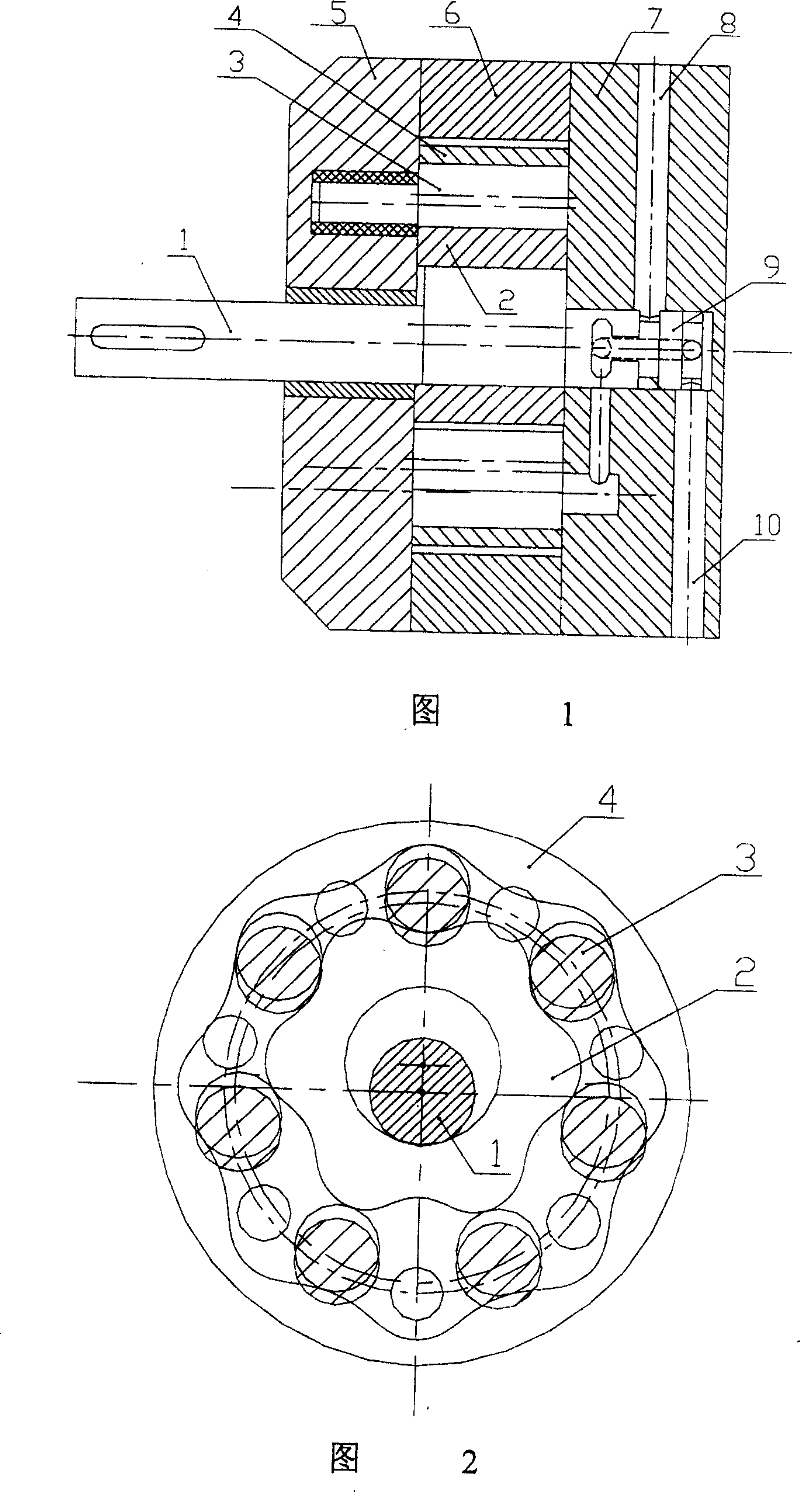

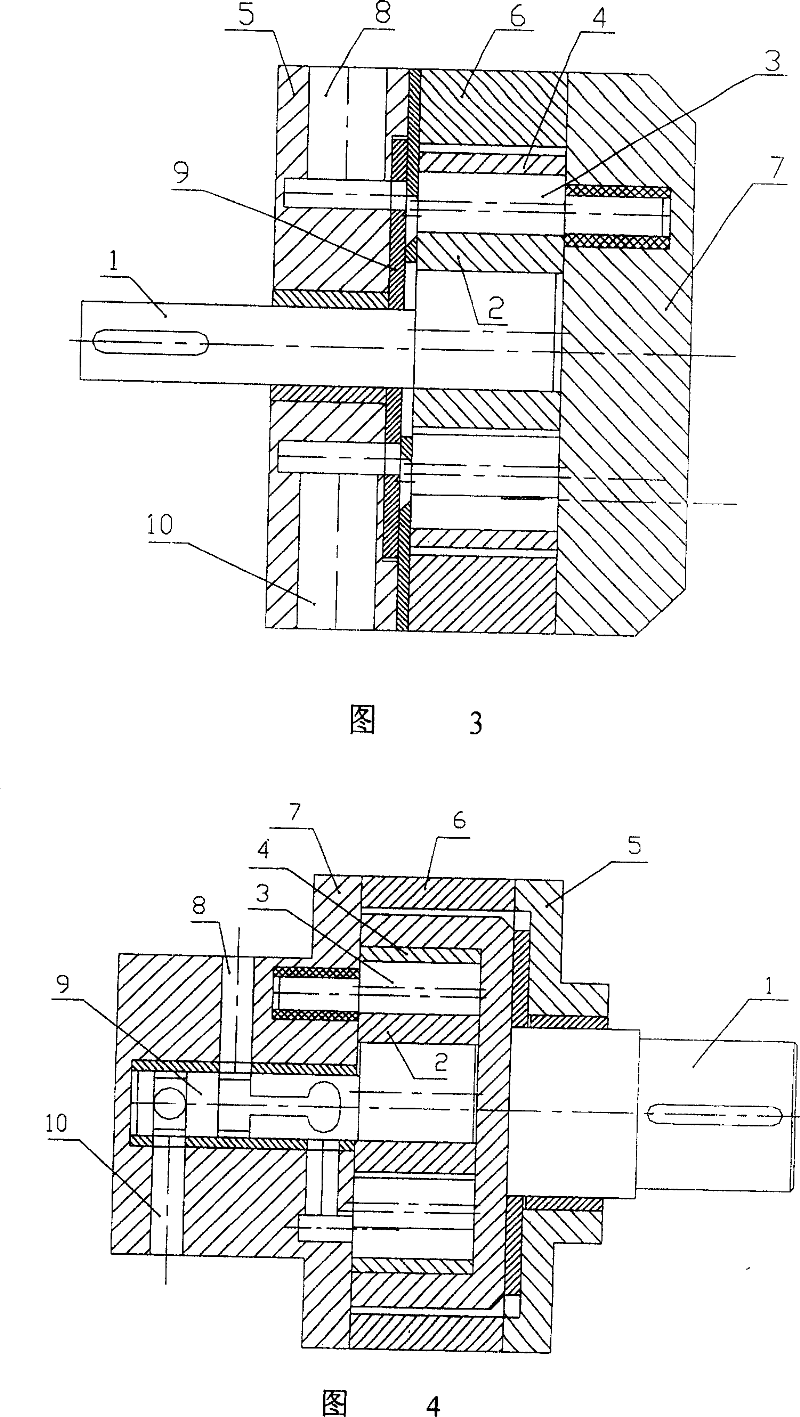

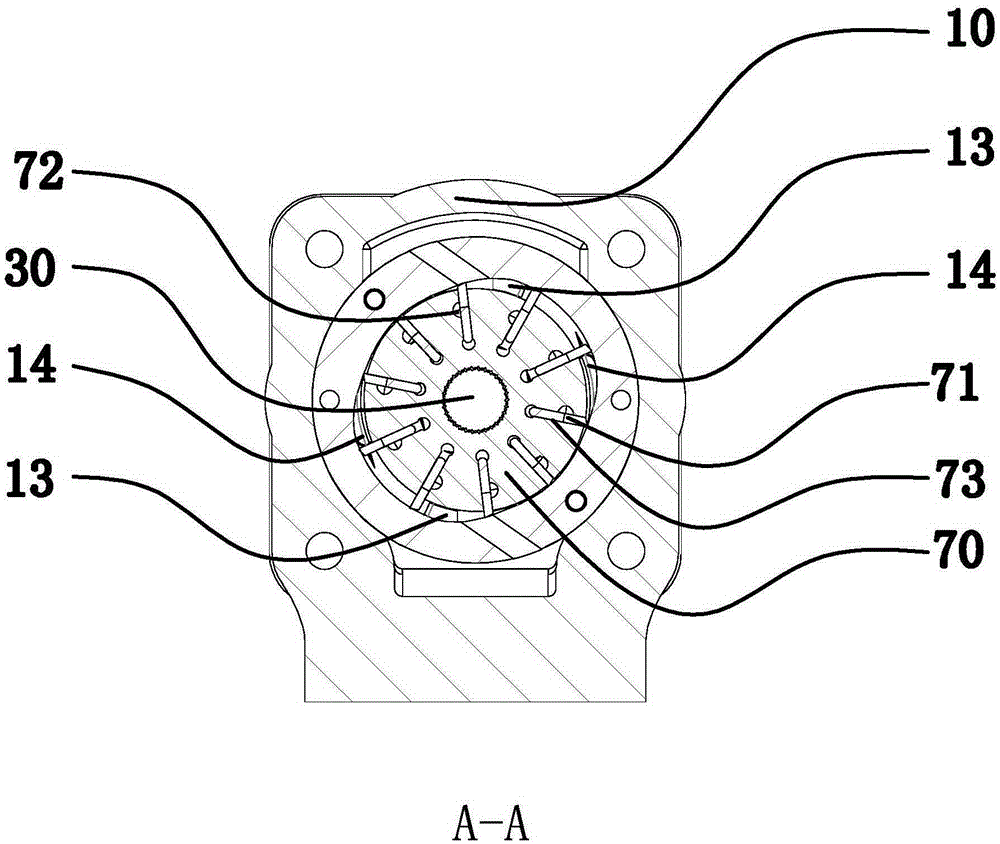

Cycloidal pin gear hydraulic pump

InactiveCN1616825AReduce stressSimple structureRotary piston pumpsRotary piston liquid enginesDrive shaftHydraulic pump

The pin gear-cycloid gear hydraulic pump has driving shaft, pump core and valve inside the pump body. The pump core is rotated with the driving shaft, and has drawing cavity connected to conveying pipeline via valve. The pump core is one pin gear-cycloid gear mechanism comprising inner rotor, pin gear, and inner cycloid gear; the inner rotor is set eccentrically relative to the inner cycloid gear and meshed with the pin gear and the inner cycloid gear successively. The inner rotor and the inner cycloid gear and two adjacent pin gears constitute one drawing cavity. The pin gear is eccentric and has fixed rotating shaft and rotating axis distributed on one cylindrical surface with the rotating shaft of the inner cycloid gear as the axis. The hydraulic pump of the present invention has the advantages of several drawing cavities, no fluctuation in flow rate, less liquid pressure impact, less noise, less energy loss, less wear, long service life, etc.

Owner:SHANGHAI NORMAL UNIVERSITY

Method for vaporizing liquid material capable of vaporizing liquid material at low temperature and vaporizer using the same

ActiveUS7975993B2Low vaporization temperatureAvoid accumulationLighting and heating apparatusUsing liquid separation agentEngineeringMaterial supply

A vaporizer is provided with a vaporizing chamber heated by heaters; a primary filter positioned in a bottom end portion of the vaporizing chamber and heated by the heater; a liquid material supply portion for dropping down a flow-controlled liquid material from upper portion of the vaporizing chamber toward the primary filter; a carrier gas guiding passage for guiding a carrier gas into the underside of the primary filter; and a material delivering passage for discharging a mixed gas including the carrier gas and a vaporized liquid material from the top of the vaporizing chamber. The liquid material dropped down onto the primary filter is partially vaporized, while the rest thereof is atomized by being subjected to bubbling effect provided by the carrier gas flowing from underneath.

Owner:LINTEC CO LTD

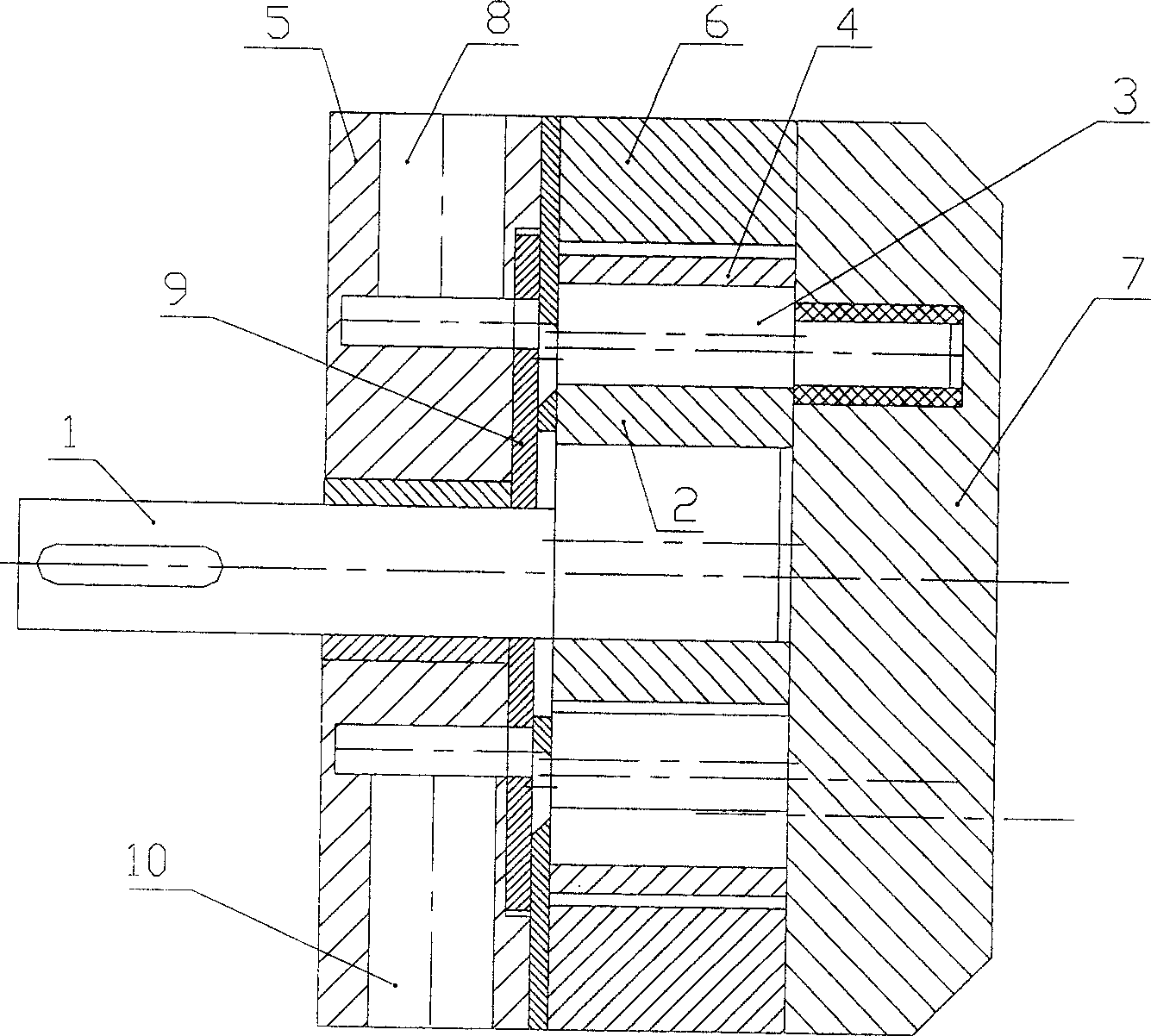

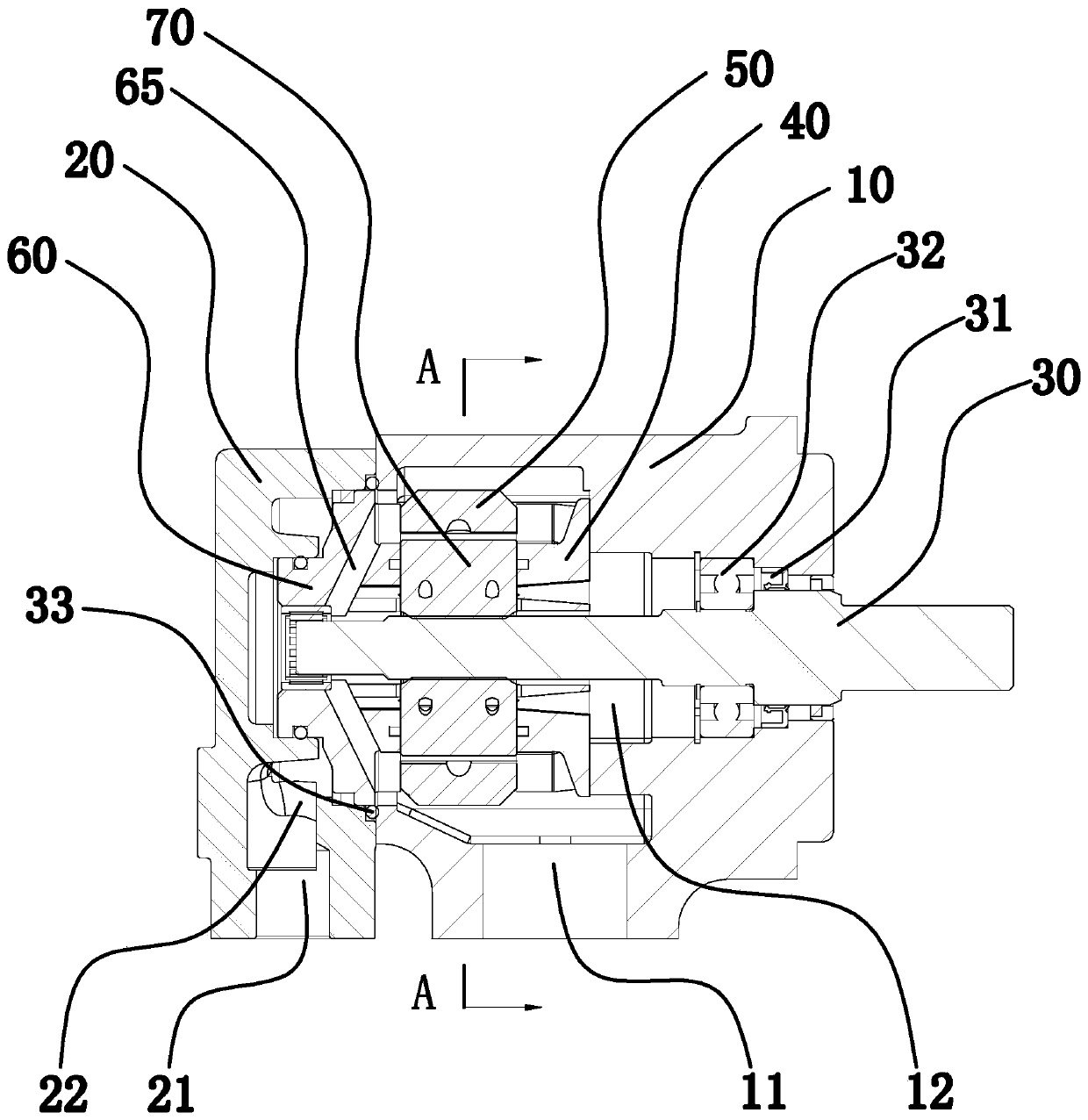

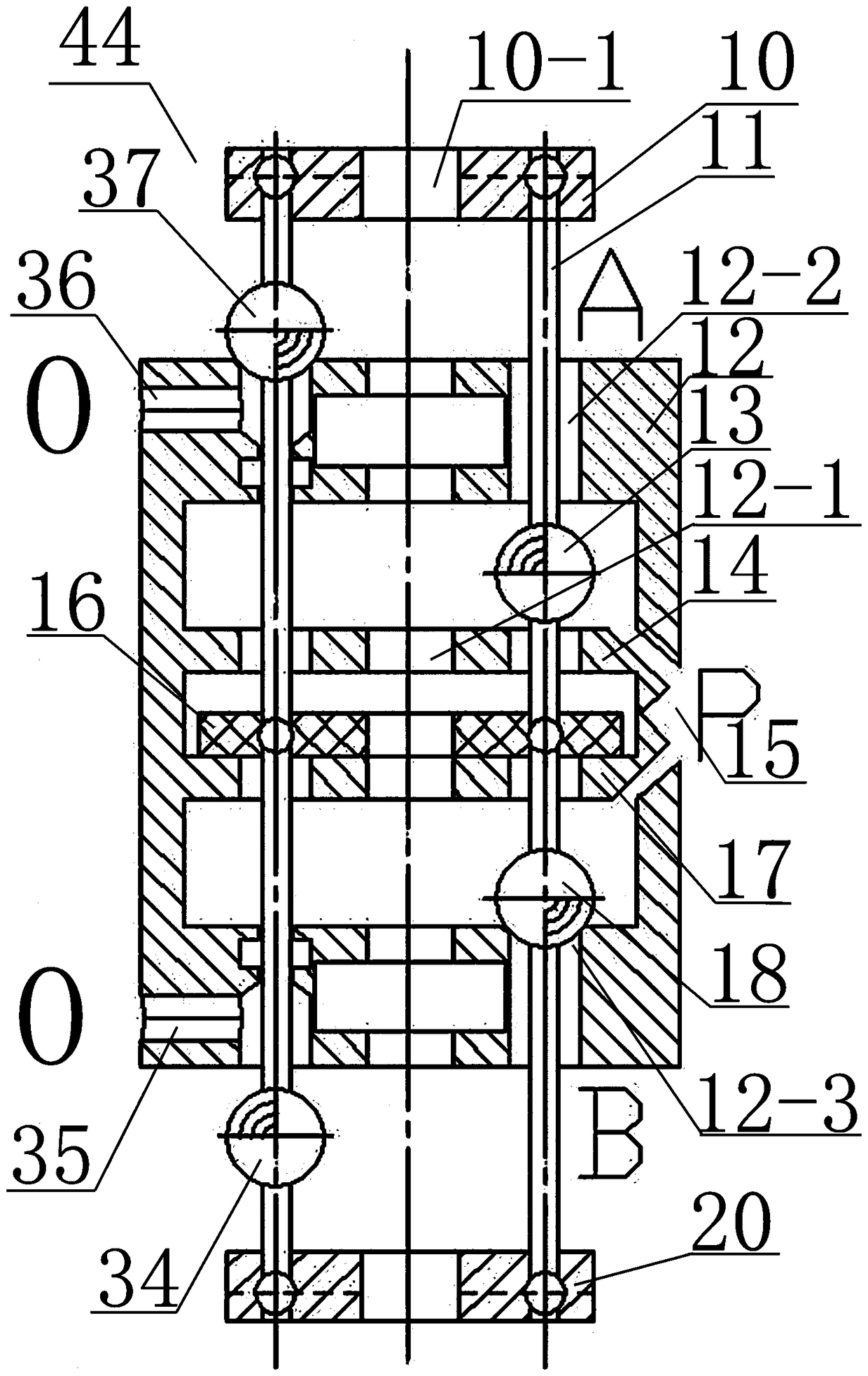

Double-acting impeller pump

ActiveCN103727028AReduce speedLarge adjustment rangeRotary piston pumpsRotary piston liquid enginesImpellerMechanical engineering technology

The invention provides a double-acting impeller pump, and belongs to the technical field of mechanical engineering. The problems of high noise and large pump body vibration of the traditional double-acting impeller pump are solved. The double-acting impeller pump comprises a front shell, a back cover, a stator, an oil outlet distribution disc, an oil inlet distribution disc and a rotating shaft, wherein a rotor which is installed on the rotating shaft is arranged in the stator; the cavity between the front shell and one side of the oil outlet distribution disc is formed into an oil inlet chamber, and the cavity between the back cover and the other side of the oil outlet oil distribution disc is formed into an oil outlet chamber; a plurality of guide grooves and blades formed in the guide grooves in a sliding mode are formed in the stator, every guide groove comprises a guide surface and a groove bottom which are mutually parallel, oil supply holes which are communicated with the groove bottoms are all formed in the oil inlet oil distribution disc and the oil outlet oil distribution disc, a pressure groove which intersects the guide grooves is arranged on the rotor, a plurality of through holes are formed in the oil outlet oil distribution disc, the through holes penetrate the oil outlet chamber, and the pressure groove and the through holes are placed on the same shaft diameter. The double-acting impeller pump has the advantages of small noise and low rotating speed.

Owner:NINGBO YINZHOU JINBEN MACHINERY

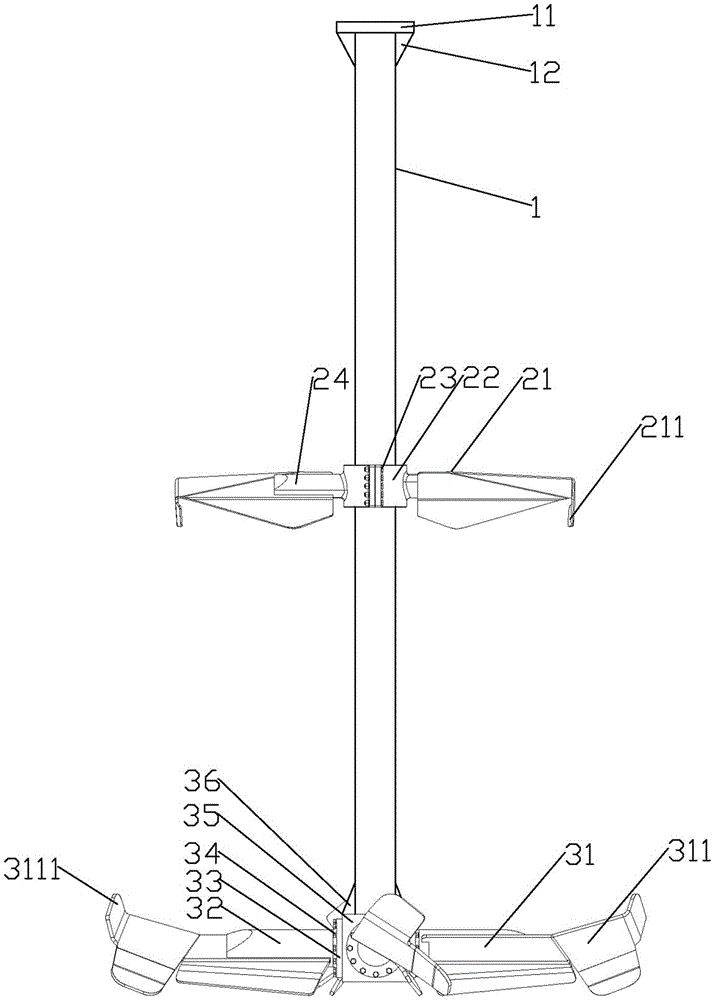

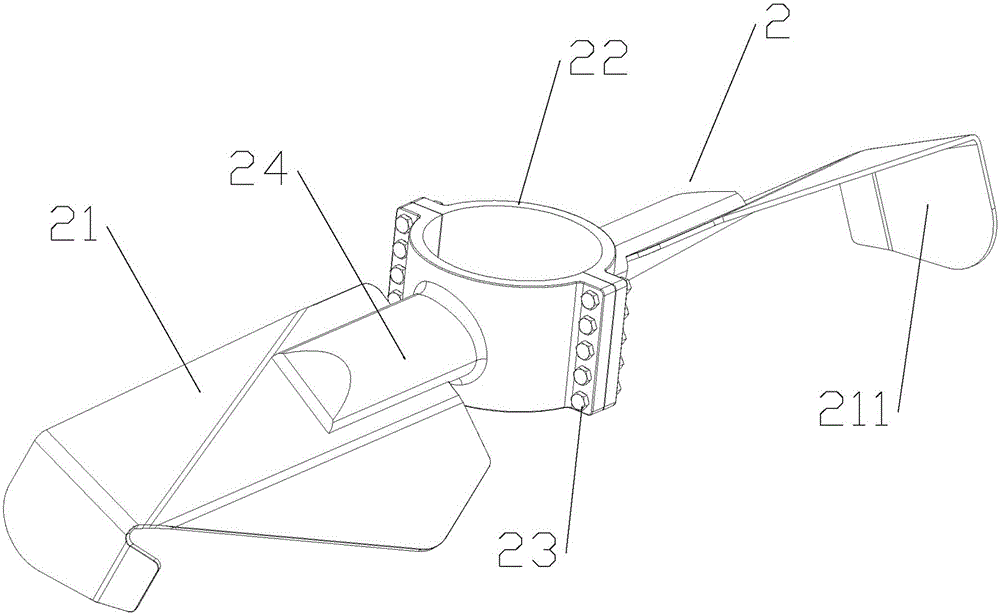

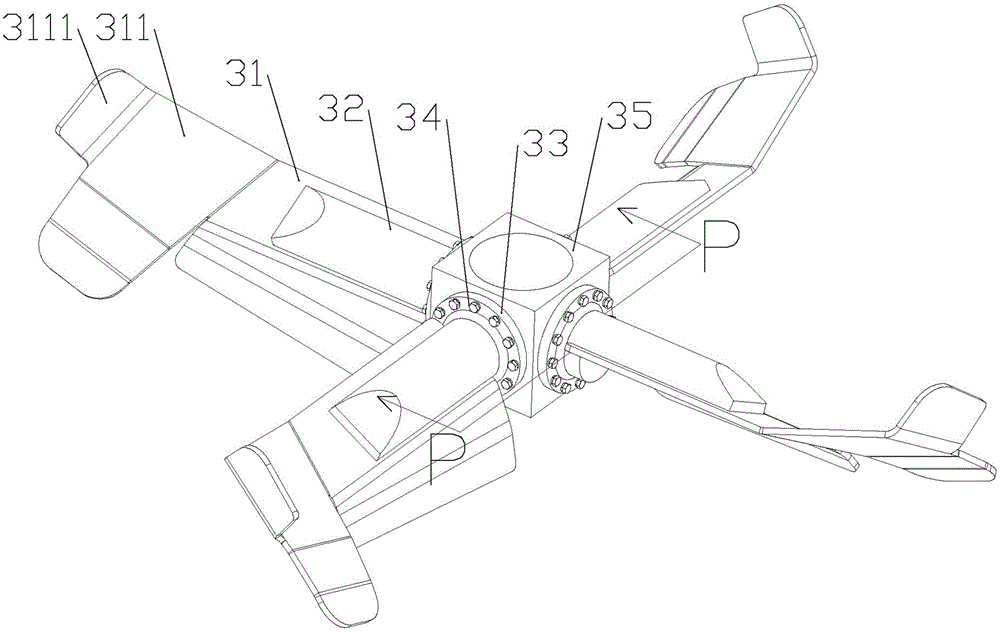

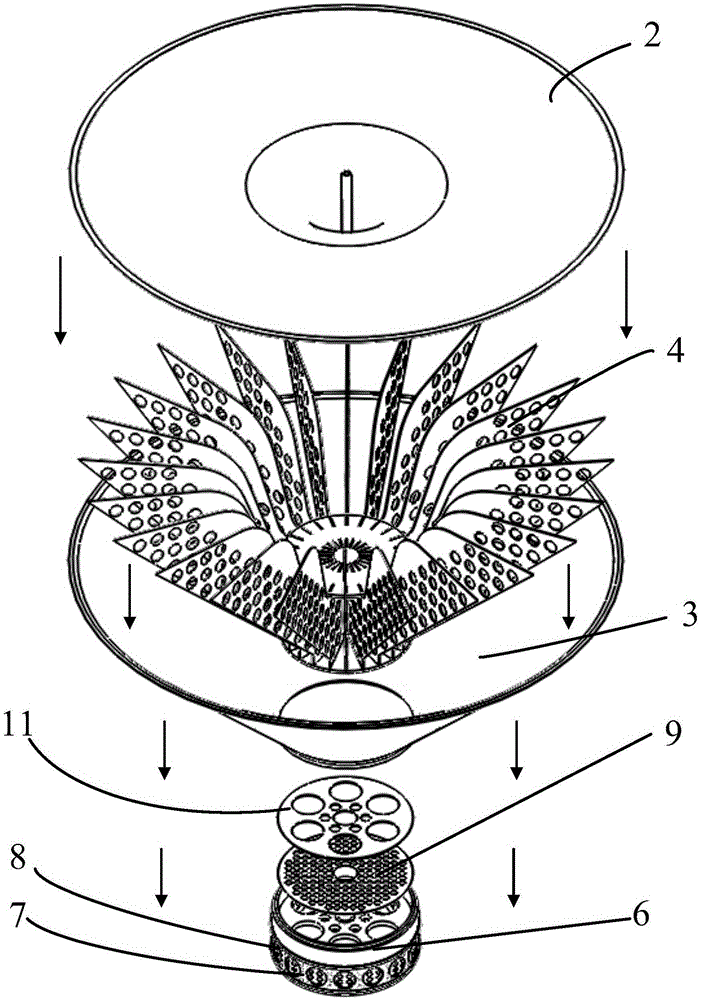

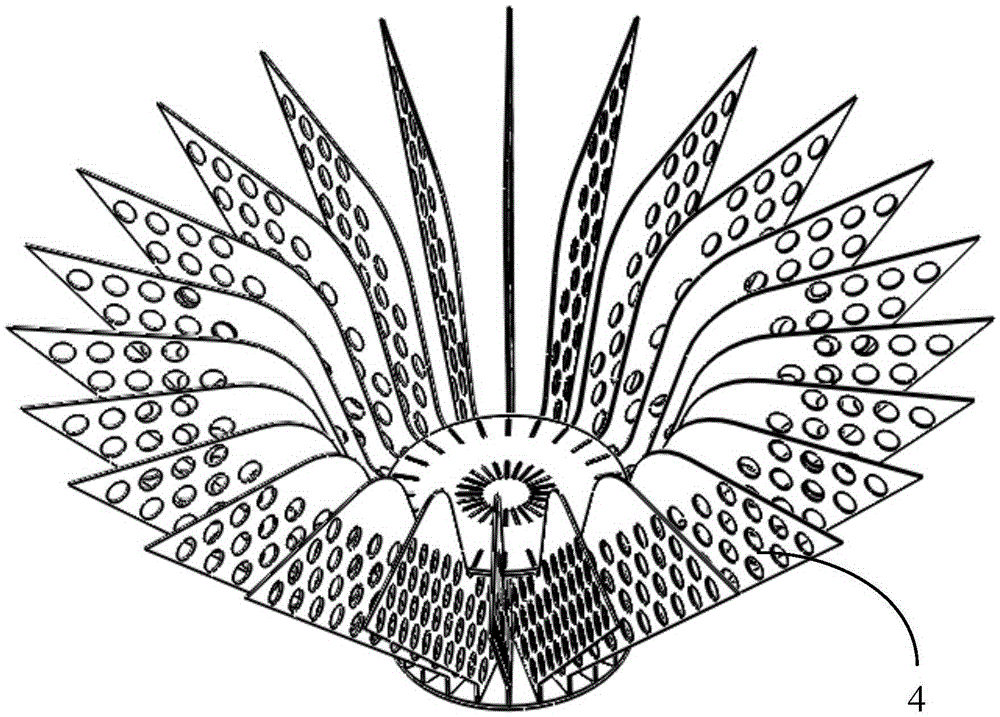

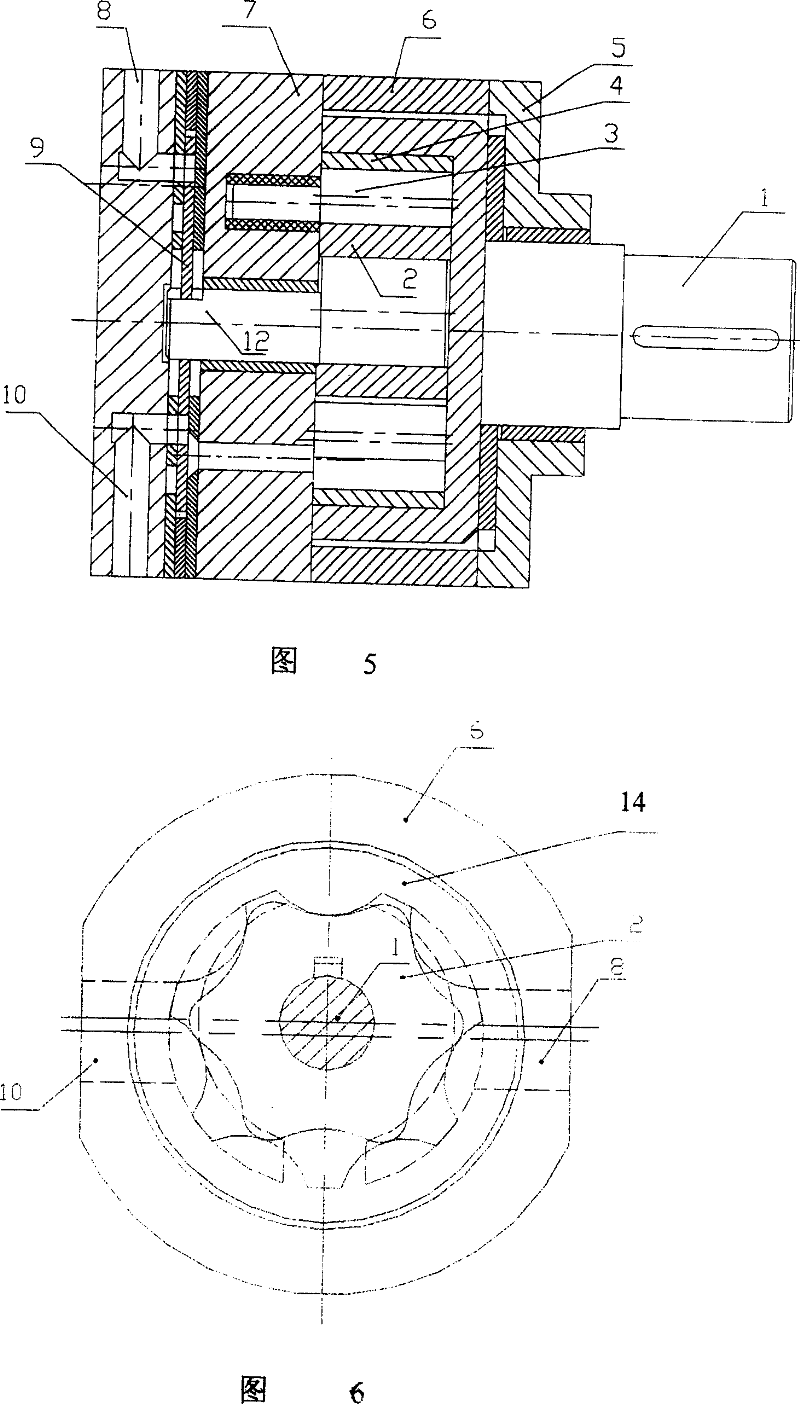

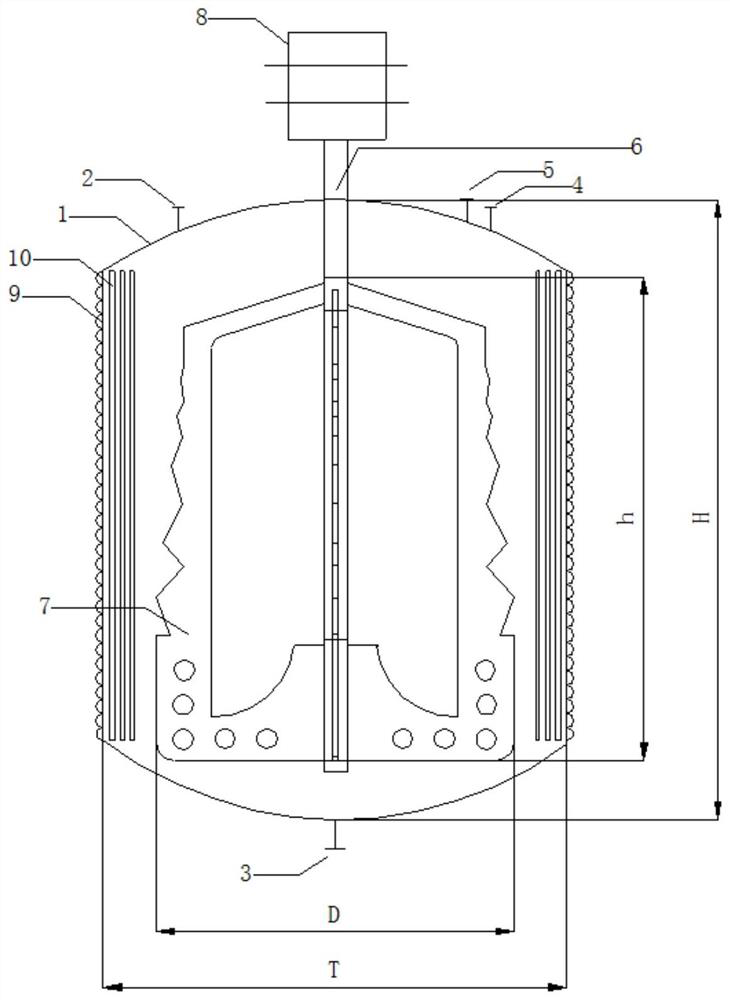

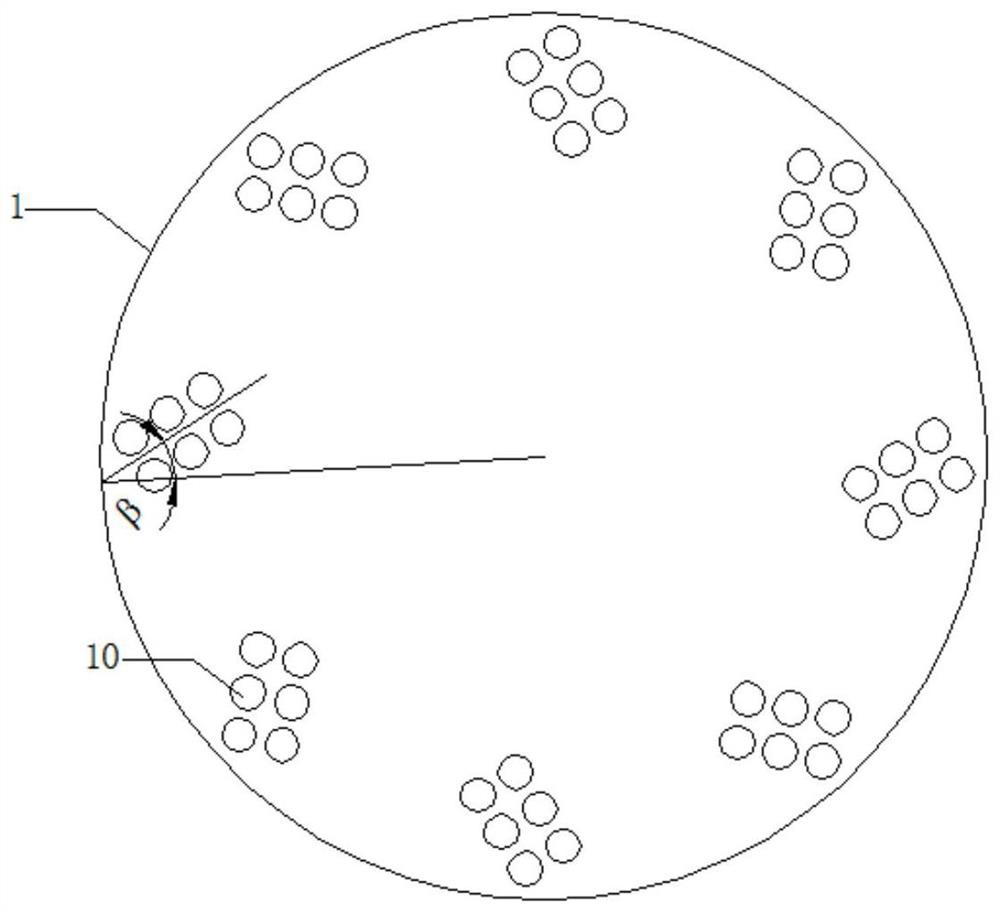

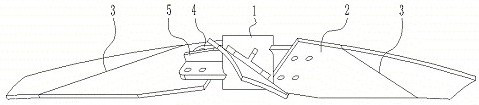

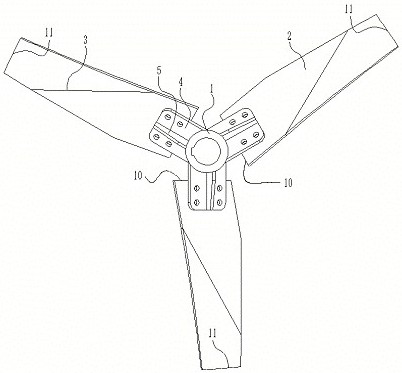

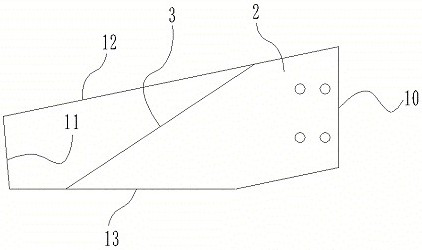

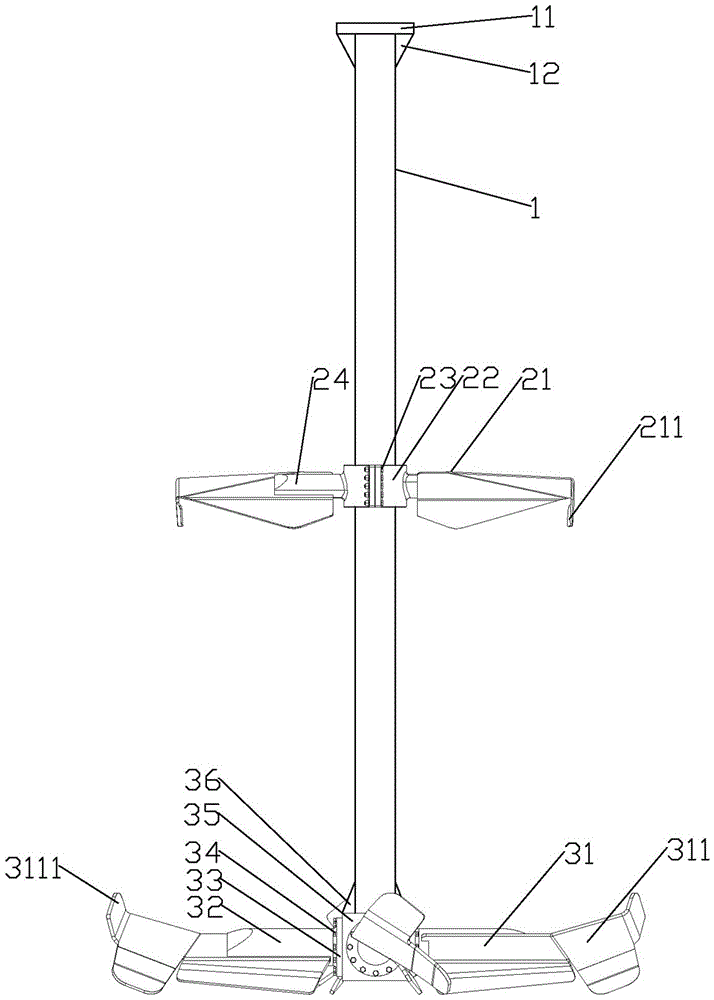

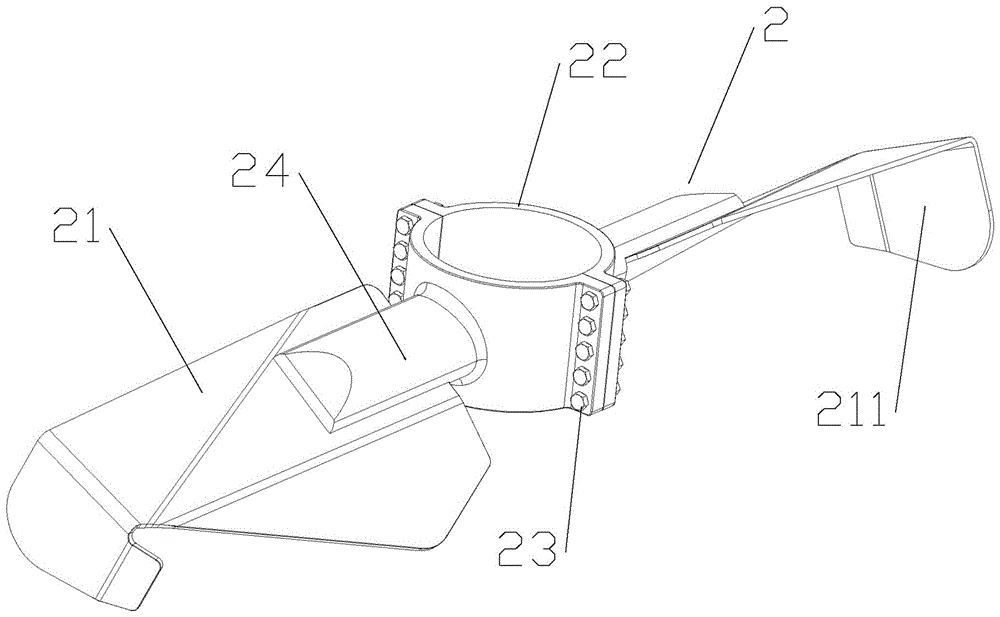

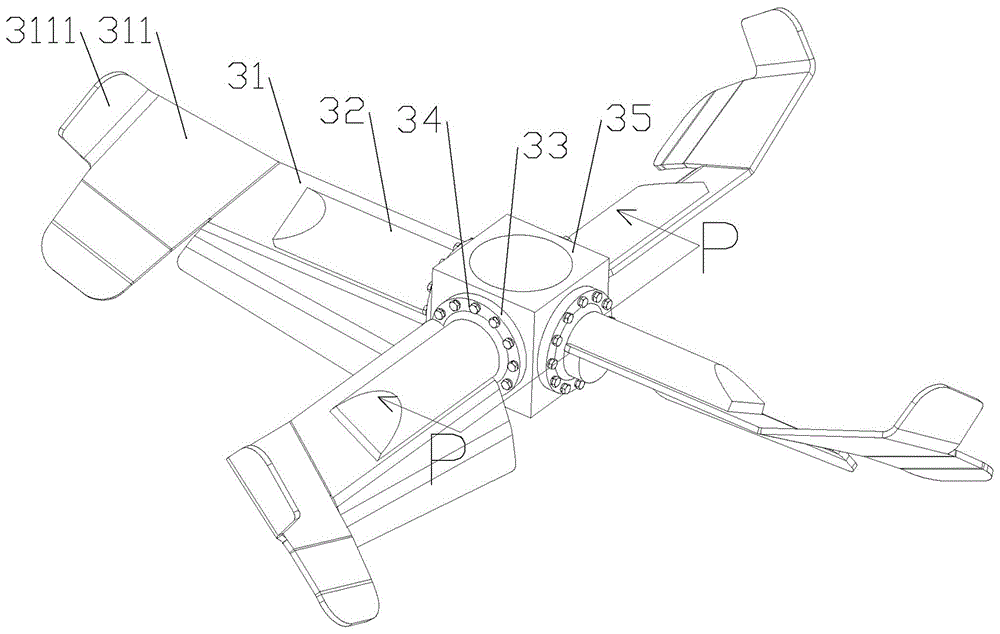

Pulp tank agitator

ActiveCN104998580AImprove the mixing effectReduce deflectionMixer accessoriesPropellerPulp and paper industry

The invention discloses a pulp tank agitator. The pulp tank agitator comprises an agitating shaft (1), a second vane wheel (3) is fixedly arranged at the bottom end of the agitating shaft (1), and a first vane wheel (2) fixed on the agitating shaft (1) is arranged over the second vane wheel (3); the water attaining surfaces of the propeller surfaces of first vanes (21) adopted by the first vane wheel (2) bend downwards, and the tails of the first vanes (21) are provided with first flow stabilizing rings(211) which bend downwards; the water attaining surfaces of the propeller surfaces of second vanes (31) adopted by the second vane wheel (3) bend downwards, the tails of the second vanes (31) are provided with upward-bending sections (311) to push materials to move downwards in the axial direction of the agitating shaft (1) and move downwards and outwards in the radial direction of the agitating shaft (1), and meanwhile the outermost ends of the upward-bending sections (311) are provided with upward-bending second flow stabilizing rings (3111). According to the pulp tank agitator, agitating is stable and efficient, part replacing is convenient, the angle of the vanes can be regulated, and therefore the pulp tank agitator is suitable for use and popularization.

Owner:江苏胜开尔工业技术有限公司

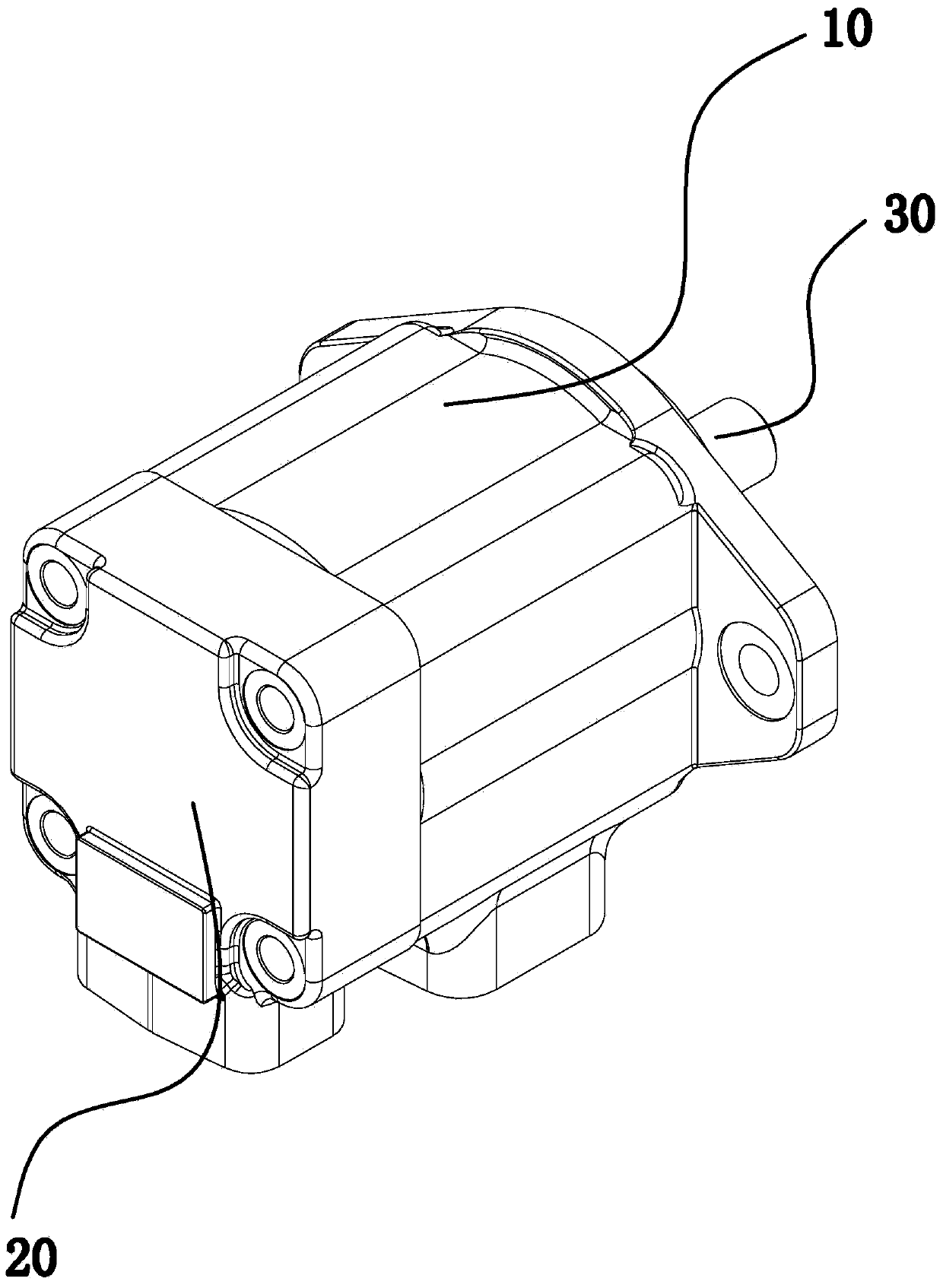

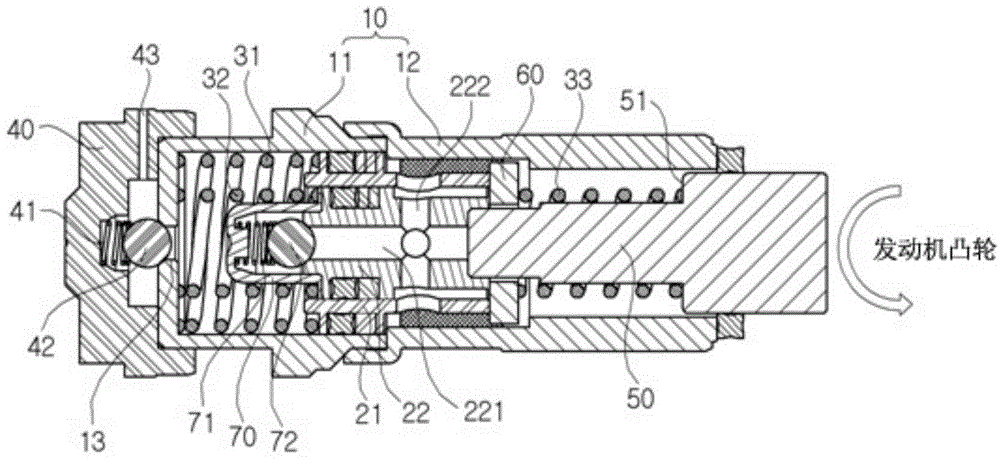

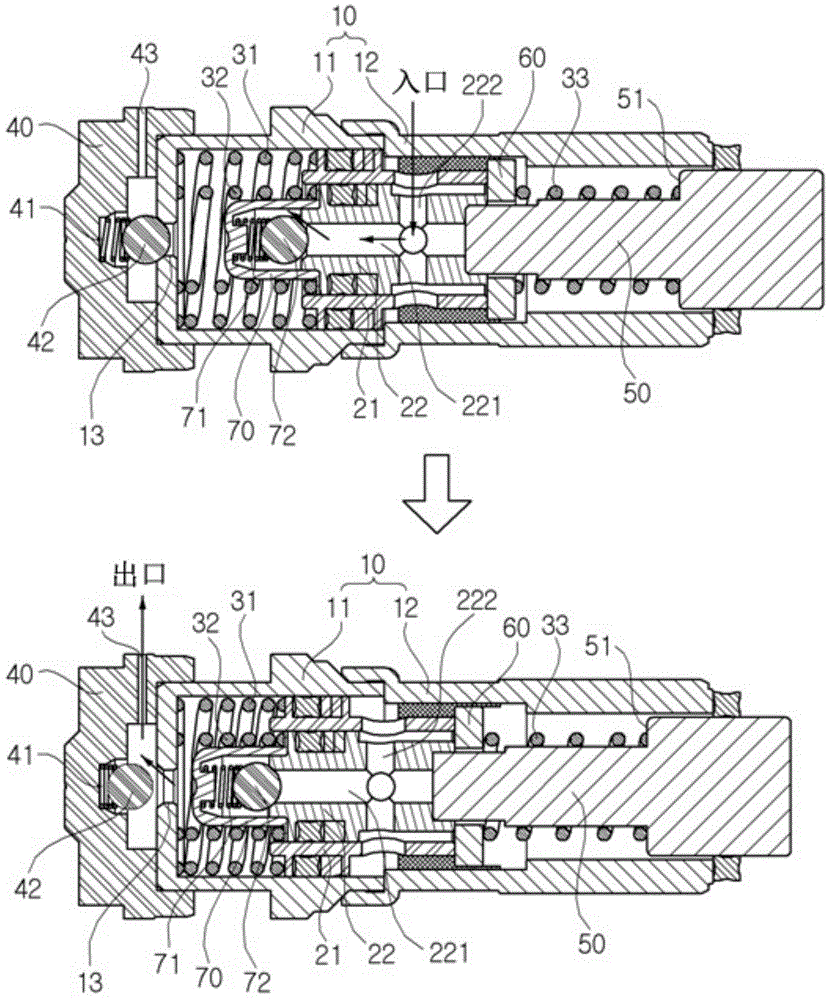

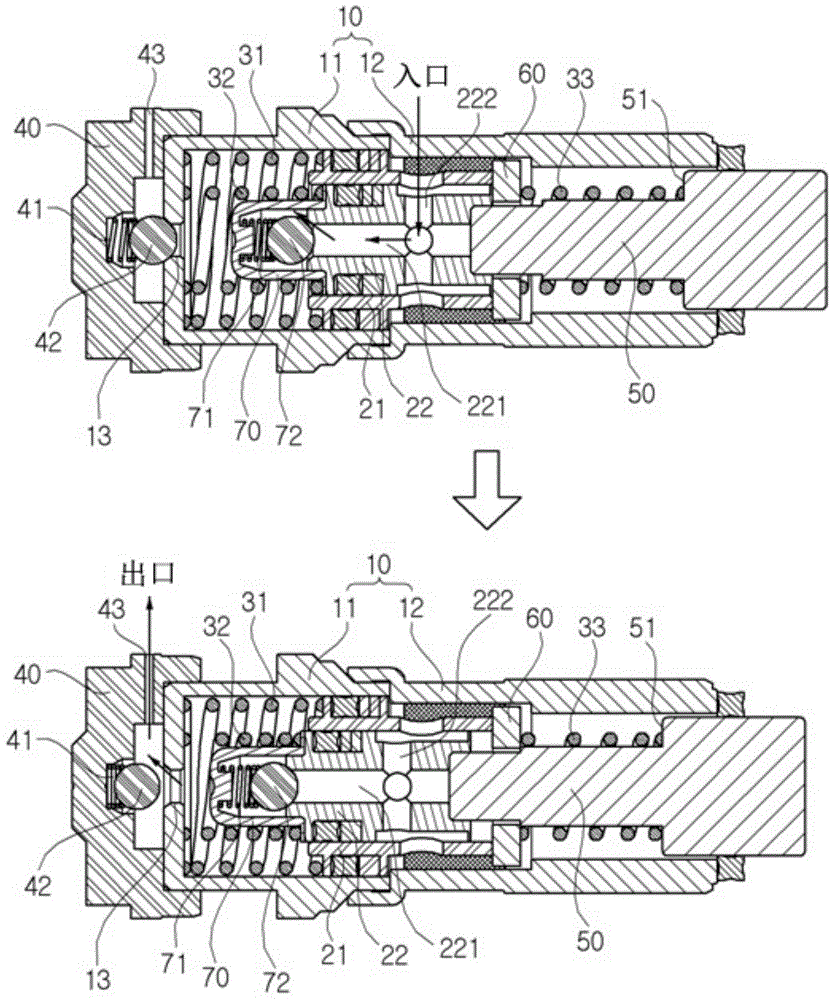

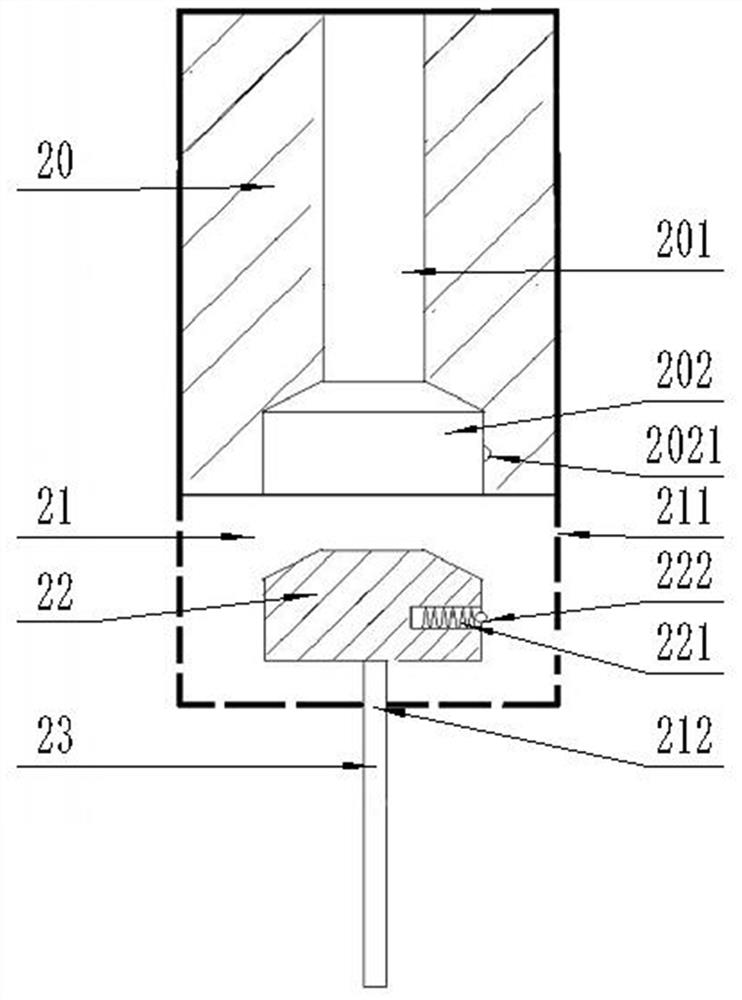

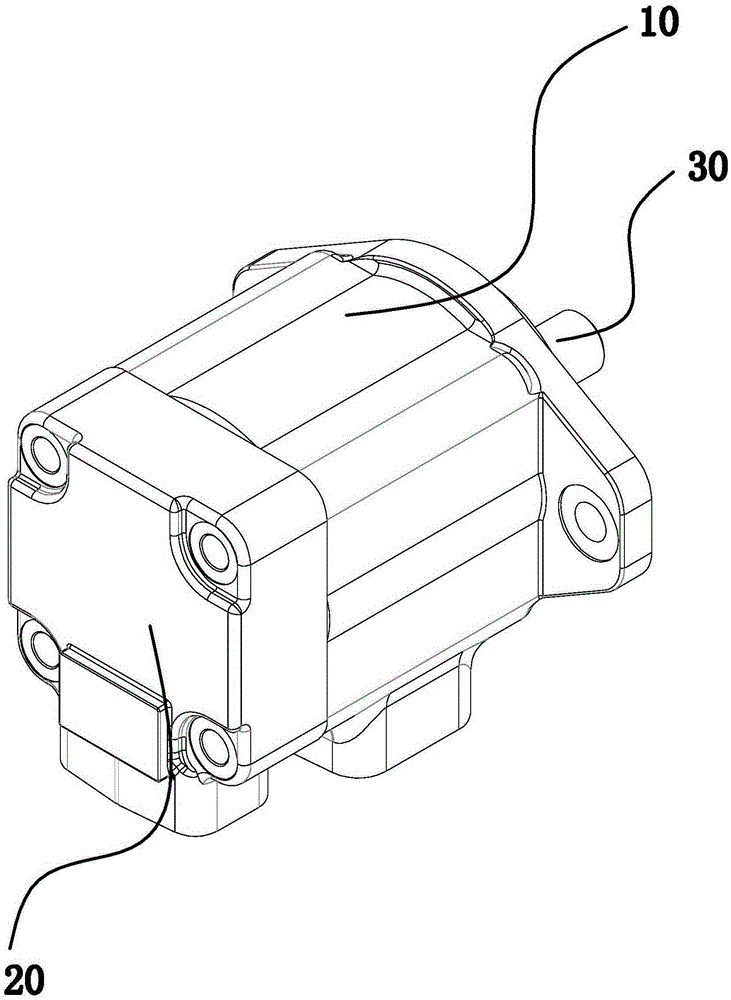

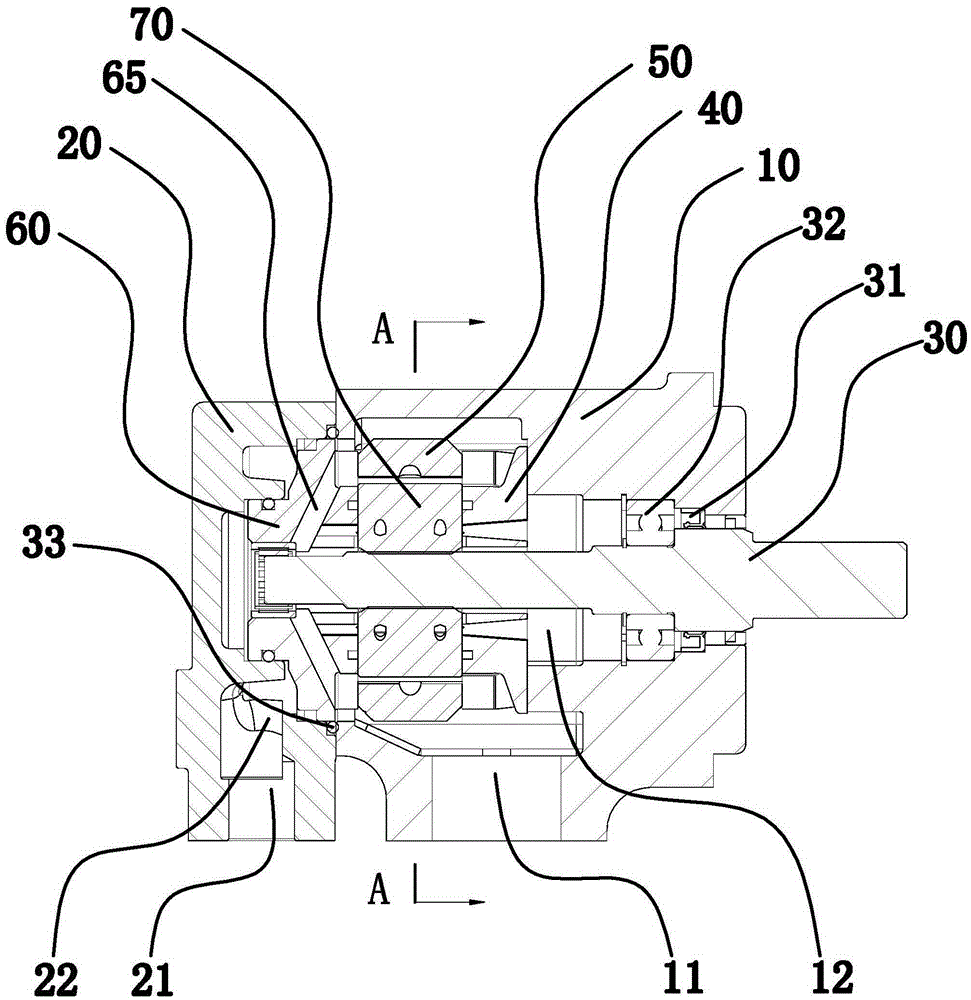

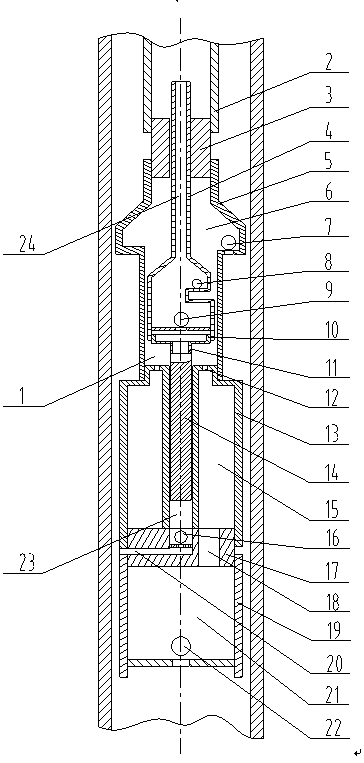

Piston pump for brake

ActiveCN105863987ALarge amount of liquidReduce loadPositive displacement pump componentsPump installationsMechanical engineeringPiston rod

A piston pump for a brake includes: a piston housing; an outer piston which rectilinearly reciprocates in the piston housing; an inner piston which is coupled to an inner portion of the outer piston, and rectilinearly reciprocates together with the outer piston in a state in which the inner piston is coupled to the inner portion of the outer piston, or rectilinearly reciprocates alone in a state in which the outer piston is stopped; an outer return spring which supports a tip portion of the outer piston; an inner return spring which supports a tip portion of the inner piston; and a piston rod spring which supports rear end portions of the outer piston and the inner piston.

Owner:HYUNDAI MOBIS CO LTD

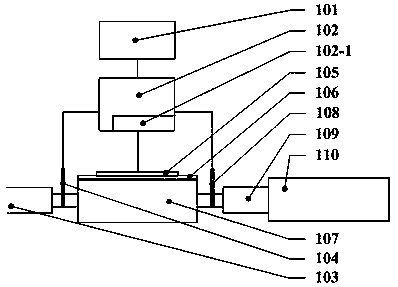

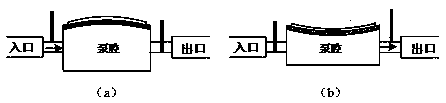

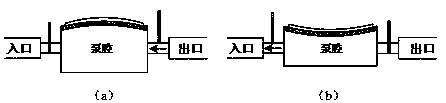

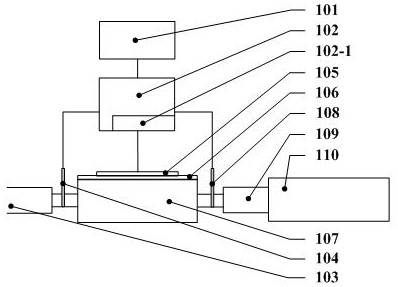

Microfluidic liquid automatic photochromic spectacles charging device based on piezoelectric driving

ActiveCN110454367ASolve the problem of slow color changeLarge amount of liquidPositive displacement pump componentsFlexible member pumpsElectricityEngineering

The invention provides a microfluidic liquid automatic photochromic spectacles charging device based on piezoelectric driving. The device comprises a microprocessor which is connected with a power supply module, wherein the power supply module is connected with a piezoelectric element which is connected with a pump membrane, the pump membrane is arranged on a pump cavity, one end of the pump cavity is communicated with an inlet, the inlet is communicated with a liquid storage cavity, an inlet microvalve is arranged between the inlet and the pump cavity and connected with the power supply module, the other end of the pump cavity is communicated with an outlet, the outlet is communicated with a fluid flow pulse reducing element which is communicated with a photochromic spectacle lens, and anoutlet microvalve is arranged between the outlet and the pump cavity and connected with the power supply module. The device is simple in structure, small in size, comfortable to wear and long in service life, can realize circulation of a colored liquid between the photochromic spectacle lens and the liquid storage cavity, and completes the automatic, fast and uniform color changing function.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

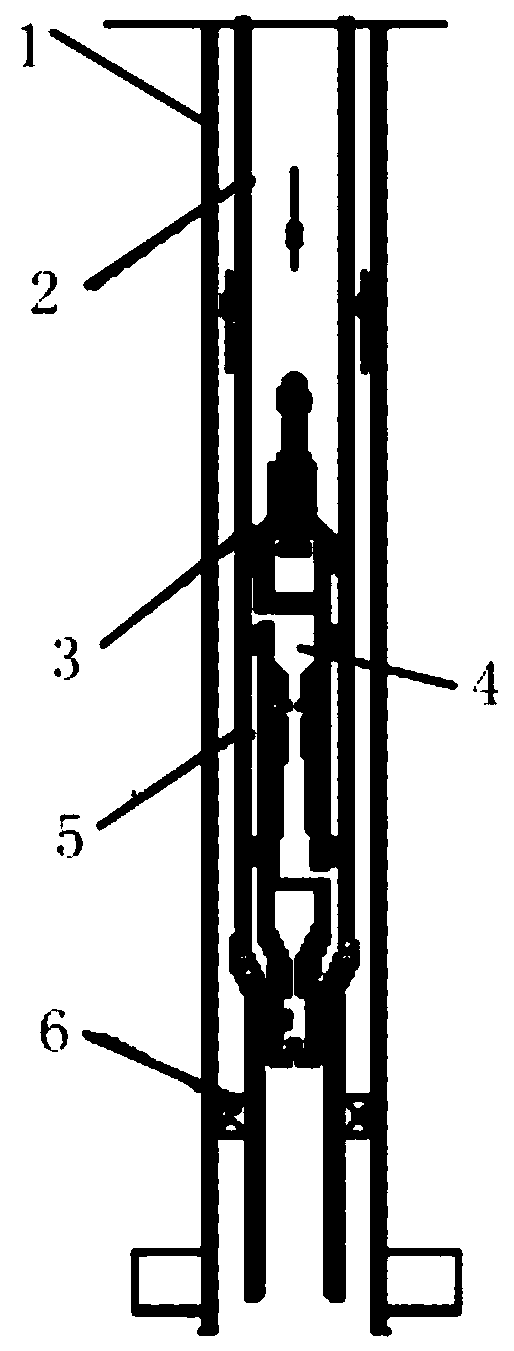

Single-tube jet pump liquor drainage technology method for normal-pressure shale gas well

InactiveCN108868698ALarge amount of liquidDrain fastFluid removalPulp and paper industryPressure shale

The invention discloses a single-tube jet pump liquor drainage technology method for a normal-pressure shale gas well. In the method, firstly, a packer assembly and a jet pump cylinder are lowered into the well through an oil tube; then a jet pump core is put into the oil tube and pushed into the jet pump cylinder through well flushing, direct-cycle well flushing production is performed, and a single-tube jet pump liquor drainage device is formed. With the oil tube being a power liquor injecting tube, an annulus is formed between the oil tube and a production casing to be used as a mixed liquor discharging tube; in this way, rapid liquor drainage is realized for the normal-pressure shale gas well.

Owner:中国石油化工股份有限公司华东油气分公司采油气工程服务中心

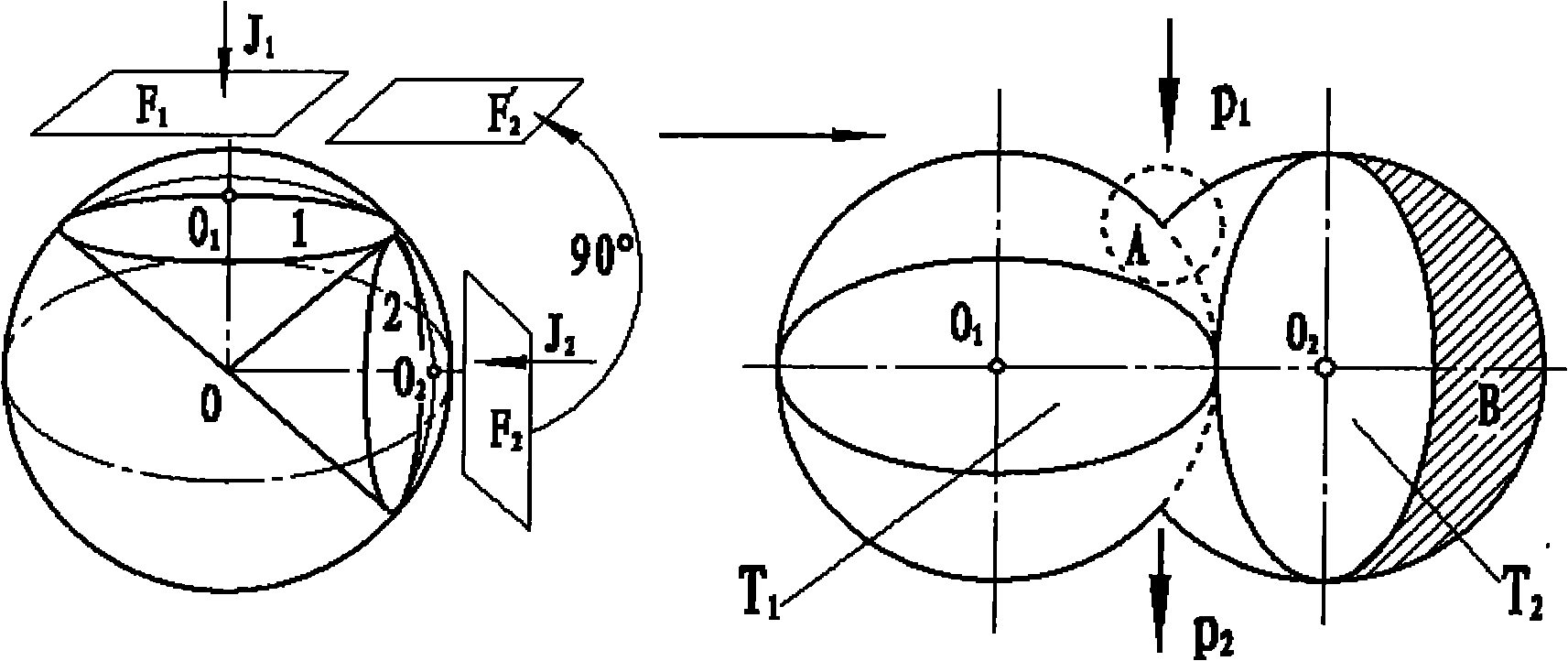

Egg shape conical gear pump

ActiveCN101846072AImprove efficiencyExtend working lifeRotary piston pumpsRotary piston liquid enginesGear pumpWorking life

The invention discloses an egg shape conical gear pump, comprising a pump case as well as a driving gear and a driven gear which are arranged in the pump case and are mutually meshed; wherein the driving gear and the driven gear are all egg shape conical gears and vertically intersected and meshed with the axis, the spherical large end face pitch curves of the driving gear and the driven gear are in egg shape. Compared with the existing gear pump, under the conditions of the same volume, the same rotating speed and the same working condition, the egg shape conical gear pump is greatly higher than the same type cylindrical gear pump and non-cylindrical gear pump in the aspects of average flow, instant flow and variable range thereof, the problem that radial force of gear pump is larger is overcome, pulse amplitude of force is reduced, transmission stationarity is good, vibration and noise are less, the working life of gear pump can be effectively prolonged, efficiency of pump is improved, and driving energy source is saved. The invention is applicable to application occasion with large delivery volume and large variable range.

Owner:CHONGQING UNIV

Method for fermentative production of n-acetyl-d-glucosamine by microorganism

InactiveUS20100055746A1Low yieldLarge amount of liquidFungiMicroorganism based processesBiotechnologyMicroorganism

N-Acetyl-D-glucosamine can be produced by cultivating a fungus capable of producing N-acetyl-D-glucosamine, such as Trichoderma hamatum AB10282 strain (FERM BP-10623) or Trichoderma harzianum AB10283 strain (FERM BP-10624), in a culture medium supplemented with a carbon source other than chitin and chitin oligosaccharide and a nitrogen source to produce and accumulate N-acetyl-D-glucosamine in the culture medium and then collecting N-acetyl-D-glucosamine from the culture medium.

Owner:HOKKO CHEM IND CO LTD (JP)

Building coating and preparation method thereof

The invention discloses a building coating and a preparation method thereof. The building coating comprises the following components in parts by weight: 100 parts of polyvinyl butyral (PVB) resin, 30-50 parts of ammonium polyphosphate, 20-35 parts of titanium dioxide, 15-40 parts of amino resin, 15-30 parts of nano calcium carbonate, 25-40 parts of etherified melamine resin, 6-20 parts of hydroxyethyl cellulose, 15-30 parts of pentaerythritol, 4-20 parts of chlorinated paraffin, 6-20 parts of ethylene glycol monobutyl ether and 5-10 parts of sodium tripolyphosphate; and the building coating further comprises 20-30 parts of a styrene-acrylate copolymer emulsion, 4-10 parts of aluminum silicate fibers and 10-15 parts of a defoaming agent. The coating is applied to wall surfaces of building pipelines. The beneficial effects are as the follows that the PVB resin is adopted in the components, so that compared with an existing coating applied to building pipelines, the coating has improved adhesion capability on a pipeline, and the problem that the coating falls off and is stripped from the pipeline is reduced. The foaming rate of the coating provided by the invention is reduced, and thefire resistance time is prolonged.

Owner:陈泽威

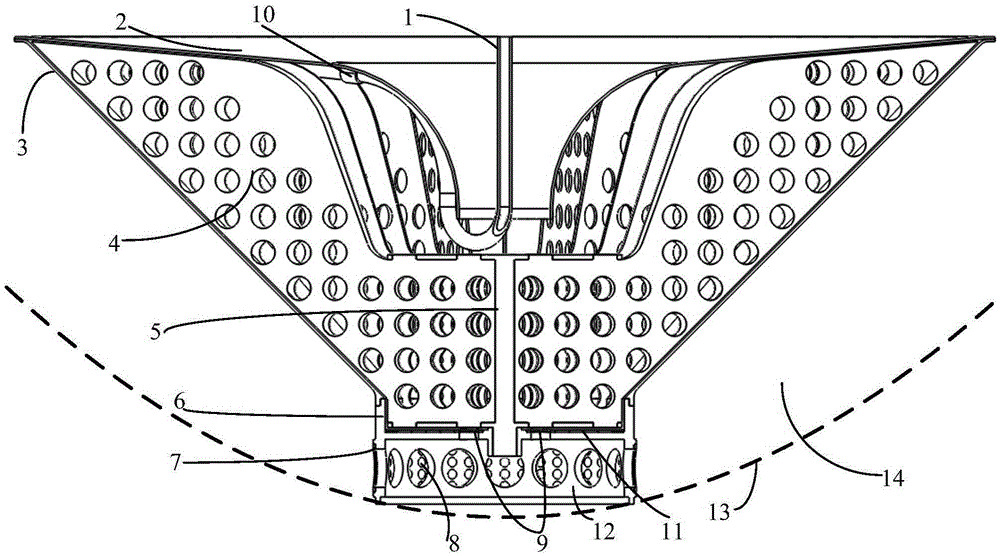

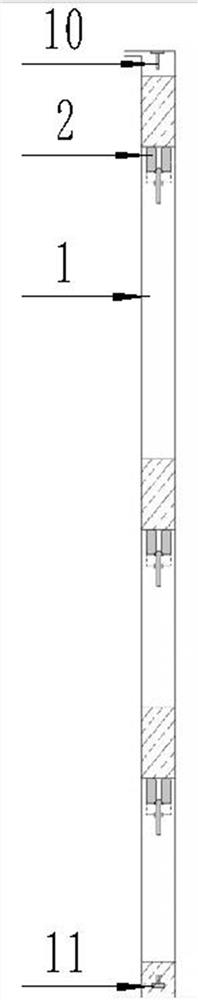

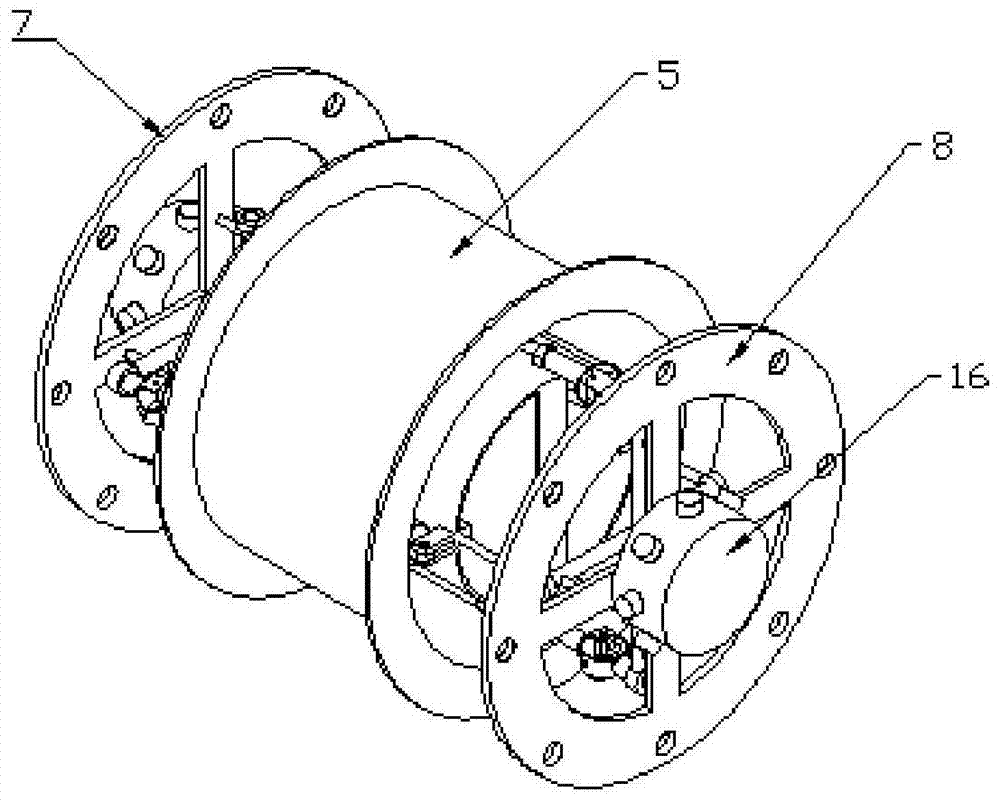

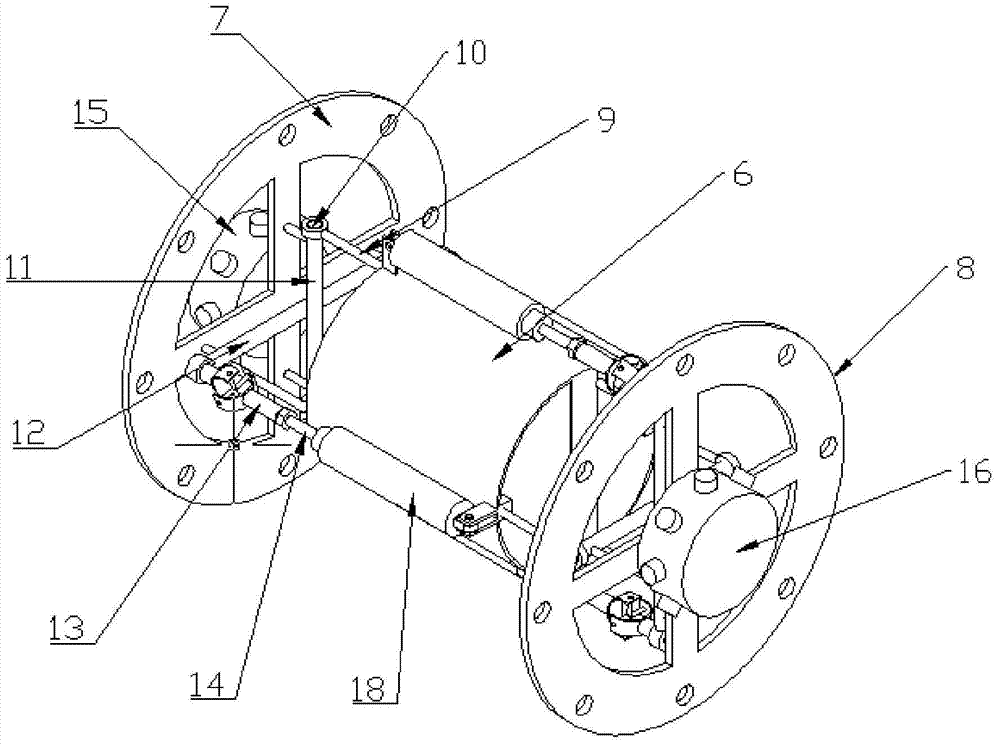

A liquid accumulator for a propellant tank in a space vehicle

ActiveCN103950557BImprove structural strengthImprove reliabilityCosmonautic vehiclesCosmonautic propulsion system apparatusPropellant tankGuide tube

A liquid accumulator used in a propellant tank in a space vehicle, including an air guide tube, a cover plate, a shell, a blade, a pillar, a base, a passage window pressure plate, a passage window mesh, an accumulator mesh, a fixing block and an accumulator. The liquid container mesh pressure plate; the blades are evenly distributed and fixed on the pillars in the radial direction to form an integral structure, which is installed and fixed on the circular partition plate in the base; the liquid accumulator mesh is pressed by the liquid accumulator mesh pressure plate It is fixed on the circular partition in the base; the channel window mesh is pressed on the outside of the base cylinder wall through the channel window pressure plate and then fixed; the shell is fixed on the top of the base, the cover plate is fixed on the shell, and the fixing block fixes the air guide tube on the cover on the board. The liquid accumulator of the present invention has a simple structure, high strength, high reliability, large liquid storage capacity, and a wide range of working applications. It has the function of repeatedly filling the liquid accumulator with liquid and expelling liquid from the liquid accumulator. The filling and discharging speed is high, and repeated filling on the ground can be achieved at the same time.

Owner:BEIJING INST OF CONTROL ENG

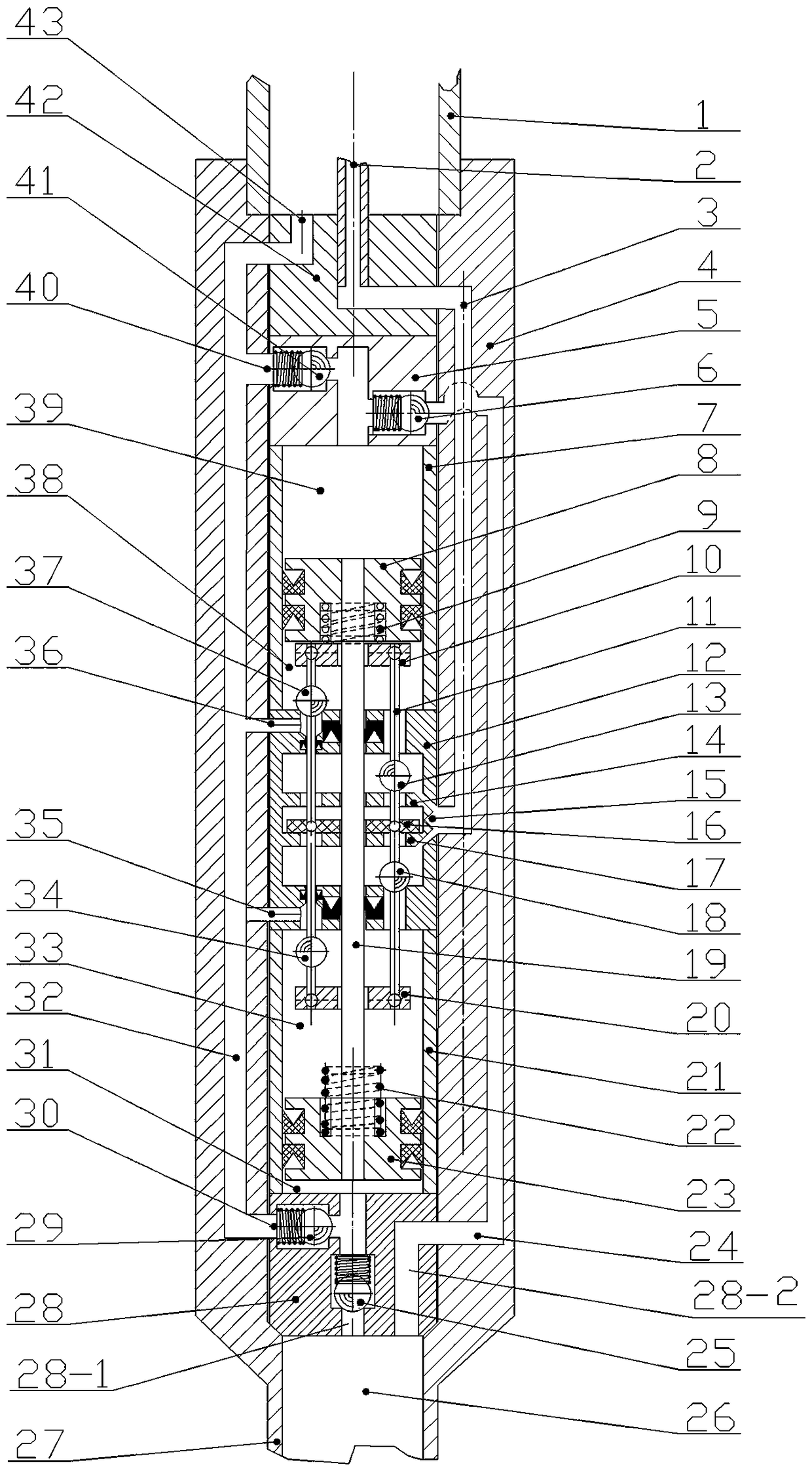

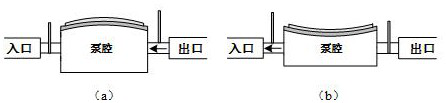

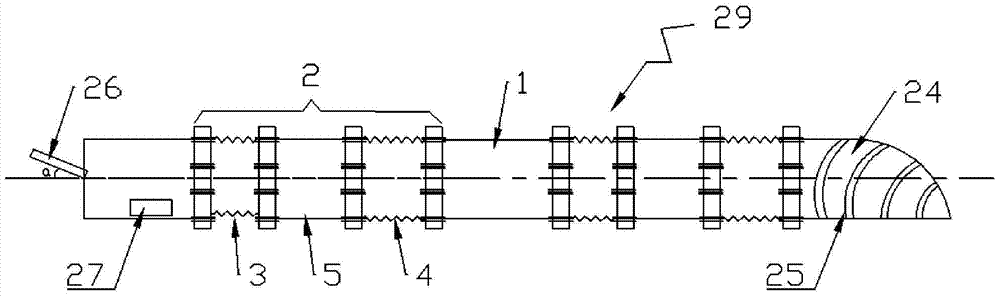

Oil well liquid-displacement reciprocating oil pumping system

PendingCN108506179ARealize free castingUniform workloadPositive displacement pump componentsFlexible member pumpsHydraulic cylinderFour-way valve

The invention relates to liquid-displacement rodless oil pumping systems in the technical field of artificial lift, in particular to an oil well liquid-displacement reciprocating oil pumping system. According to the oil well liquid-displacement reciprocating oil pumping system, high-pressure power liquid is generated through a ground power device and transferred to a downhole reversing oil pumpingunit through channels such as a power liquid pipe or an oil pipe in a wellbore so as to drive an oil-well pump to work. The oil well liquid-displacement reciprocating oil pumping system comprises a working cylinder, a first hydraulic cylinder, a first piston, a piston rod, a second hydraulic cylinder, a second piston, output liquid inlet valve balls, output liquid drainage valve balls and a two-position four-way reversing valve. The working cylinder is connected to the lower end of the oil pipe and put into an oil well along with the oil pipe. The output liquid inlet valve balls comprise theoutput liquid inlet valve ball A and the output liquid inlet valve ball B. The output liquid drainage valve balls comprise the output liquid drainage valve ball A and the output liquid drainage valveball B. The two-position four-way reversing valve comprises a two-position four-way reversing valve element and a two-position four-way reversing valve seat. The two-position four-way reversing valveelement comprises two sliding rods, a reversing push plate A, a reversing push plate B, a permanent magnet ring, a liquid inlet valve ball A, a liquid inlet valve ball B, a reversing liquid drainage valve ball A and a reversing liquid drainage valve ball B.

Owner:南京聚源隆能源科技有限公司

Cycloidal pin gear hydraulic pump

InactiveCN100357605CFlow without fluctuationEliminate the effects of pressure smoothnessRotary piston pumpsRotary piston liquid enginesDrive shaftHydraulic pump

The pin gear-cycloid gear hydraulic pump has driving shaft, pump core and valve inside the pump body. The pump core is rotated with the driving shaft, and has drawing cavity connected to conveying pipeline via valve. The pump core is one pin gear-cycloid gear mechanism comprising inner rotor, pin gear, and inner cycloid gear; the inner rotor is set eccentrically relative to the inner cycloid gear and meshed with the pin gear and the inner cycloid gear successively. The inner rotor and the inner cycloid gear and two adjacent pin gears constitute one drawing cavity. The pin gear is eccentric and has fixed rotating shaft and rotating axis distributed on one cylindrical surface with the rotating shaft of the inner cycloid gear as the axis. The hydraulic pump of the present invention has the advantages of several drawing cavities, no fluctuation in flow rate, less liquid pressure impact, less noise, less energy loss, less wear, long service life, etc.

Owner:SHANGHAI NORMAL UNIVERSITY

Multi-plunger cooperative gas-lift liquid drainage technology

ActiveCN111997571ADecrease the gas-liquid ratioLarge amount of liquidPositive displacement pump componentsFlexible member pumpsGas liftMechanical engineering

The invention relates to a multi-plunger cooperative gas-lift liquid drainage technology. The technology is applied to a multi-plunger cooperative gas-lift liquid drainage system, the liquid drainagesystem operates circularly in a reciprocating mode, a plurality of plungers divide a large-section liquid column and a gas column in an oil pipe into multiple sections of liquid columns, the plungersand the gas columns are connected in series, and the plungers are connected in the oil pipe vertically and mutually to achieve liquid load cooperative work. Liquid is drained from a shaft step by step, pressure formed by a small section of liquid column disappears when each small section of liquid column is drained, the pressure of each stage of gas column below the small section of liquid columnis reduced, the volume is expanded, the gas columns are expanded step by step, and meanwhile, gas expansion can be fully utilized to accelerate the plungers and the liquid columns above the plungers to ascend, the needed gas-liquid ratio is reduced, and liquid drainage mount is increased. Under the condition of the same gas amount, more liquid can be drained, or under the condition of the same liquid drainage amount, the gas amount required by the liquid drainage system is greatly reduced.

Owner:贺信

Composite lining paper coating, printing processing technology

The invention discloses a composite lining paper coating, printing and processing technology. The technology comprises the following specific steps of: (1) unwinding: respectively inserting an aluminum foil roll and lining paper into two unwinding devices, simultaneously unwinding the aluminum foil and lining paper, enabling the unwound aluminum foil and lining paper to be parallel to each other,enabling the aluminum foil to be positioned right above the lining paper, and (2) compounding: coating the opposite surfaces of the aluminum foil and the lining paper with an adhesive through an adhesive coating roller, and then simultaneously pressing and forming the aluminum foil and the lining paper coated with the adhesive through a composite pressing roller to obtain the composite lining paper. The printing roller is set to be a micro-concave screen roller; the paper feeding direction of the composite lining paper is opposite to the rotating direction of the micro-concave screen roller; the composite lining paper and the micro-concave screen roller are coated reversely, certain relative friction is generated, so that uniform spreading of coating liquid on the composite lining paper isfacilitated; the liquid transfer amount of the micro-concave screen roller is further large, ink can fully fill fiber gaps and subsurface concave-convex areas of the composite lining paper, and the coating effect of the composite lining paper is guaranteed.

Owner:YUXI DAYING STREET ALUMINUM FOIL PAPER

A microfluidic liquid automatic color-changing glasses liquid filling device based on piezoelectric drive

ActiveCN110454367BSolve the problem of slow color changeLarge amount of liquidPositive displacement pump componentsFlexible member pumpsMicrofluidicsEyewear

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Novel airproof oil pumping technology

InactiveCN103133308AExtended service lifeLarge amount of liquidFlexible member pumpsPositive-displacement liquid enginesTop dead centerAir exchange

The invention discloses a novel airproof oil pumping technology which comprises the following steps: (a) a plunger piston is located in the bottom dead center, a fixing ball valve and a floating ball valve are both closed; (b) the plunger piston continues to go up, the lower portion of the plunger piston leaves an air exchange cavity, and the upper portion of the plunger piston enters into a sealed cavity; (c) the plunger piston reaches the top dead center of a pump; (d) the plunger piston begins to stroke downward, the floating ball valve of the plunger piston is closed at present, and air in the air exchange cavity enters an oil pipe after the plunger piston passes through the air exchange cavity; and (e) the plunger piston continues to go down, the floating ball valve is opened, and the air gathered in the air exchange cavity enters the oil pipe when the plunger piston passes through the air exchange cavity. The novel airproof oil pumping technology achieves discharging of some gas in the process of stroke, influence of the gas is greatly reduced, and the amount of discharging liquid is increased. Due to the fact that reinforcement outer tubes are arranged between the air exchange cavities, when the oil well pump works normally, influence of axial alternating load on dangerous sections of pump barrels of the oil well pump is enabled to be greatly reduced, service life of the oil well pump is prolonged, and processing difficulty is lowered. The novel airproof oil well pump has the advantages of being low in cost, long in service life, convenient to use and maintain and suitable for popularization and quantity production.

Owner:欧阳才伟

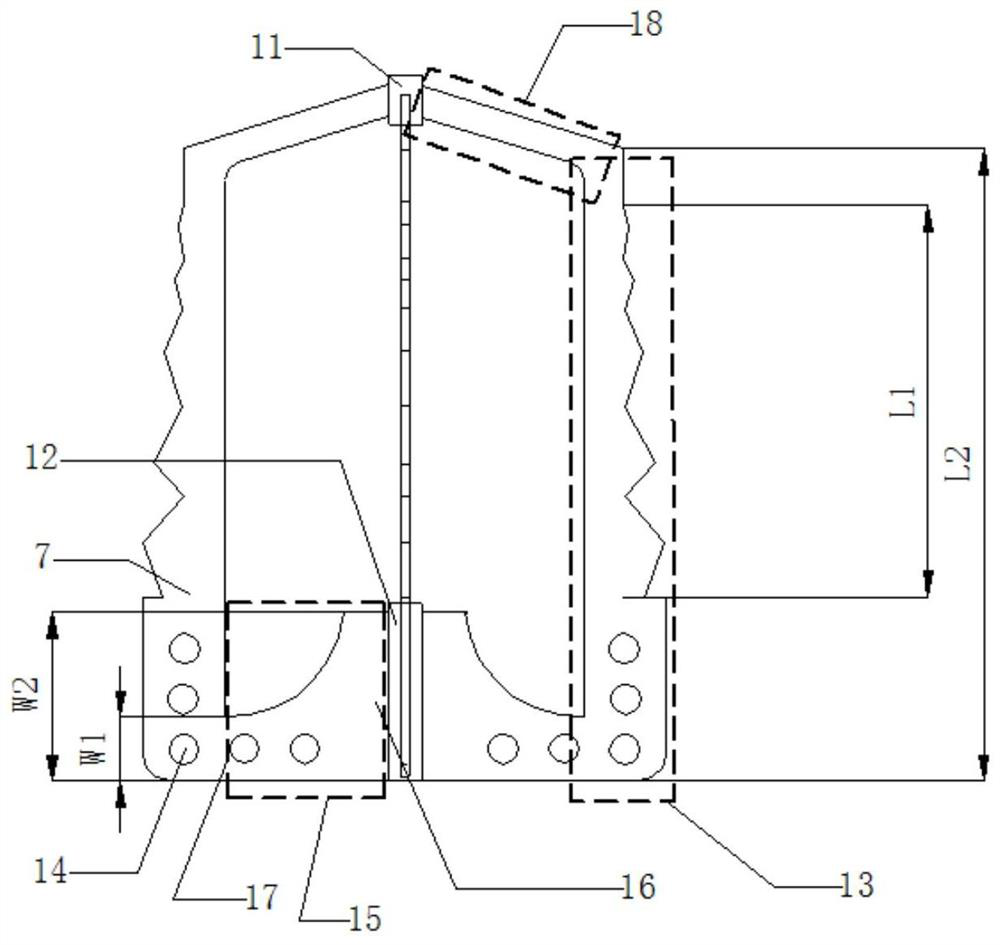

Emulsion polymerization reaction kettle

PendingCN114797715AEnhanced Axial FlowEvenly distributedChemical/physical/physico-chemical stationary reactorsChemistryRing type

The invention discloses an emulsion polymerization reaction kettle. The reaction kettle comprises a vertical cylinder, an upper sealing head of the cylinder is provided with a material inlet, a gas inlet and a gas outlet, the gas outlet is connected with the vacuum system, and a lower sealing head of the cylinder is provided with a material outlet; a stirring shaft insertion opening is formed in an upper sealing head of the barrel, one end of the stirring shaft is connected with the power device, the other end of the stirring shaft is connected with the four-blade ring type stirrer, and the stirring shaft is connected with the barrel through a mechanical seal. Blades on the lower portion of the four-blade ring type stirrer are large in size, the liquid discharging capacity of the blades can be improved, the axial flow effect in the reaction kettle can be enhanced, blades on the upper portion of the four-blade ring type stirrer are arranged to be in a sawtooth shape, the shearing capacity of the blades to fluid can be improved, in addition, the height of the blades of the four-blade ring type stirrer is larger than that of the reaction kettle, and therefore the stirring efficiency is improved. And various load working conditions can be adapted. The method is used for producing polybutadiene latex, the axial temperature difference is small, the particle size is reduced to 180-500 nm, the consumption of an emulsifier in an oil phase is increased, and the consumption of a refrigerant is reduced.

Owner:WANHUA CHEM (SICHUAN) CO LTD +1

Floating device for wave energy harvesting

The invention creatively discloses a floatation device for wave energy collection. The device is provided with a plurality of hard cylindrical connection units, and a collection unit is arranged between the adjacent hard cylindrical connection units; a liquid inlet and outlet main pipeline communicated with an outer water tank is arranged in the hard cylindrical connection units, and the collection unit is provided with a hose outer shell I, a hose outer shell II and a hard round floating cylinder arranged between the hose outer shell I and the hose outer shell II; a reinforcing sleeve is arranged in the hard round floating cylinder, and a plurality of piston cylinder units are arranged on the outer wall of the reinforcing sleeve in the circumferential direction of the reinforcing sleeve; liquid inlets in the piston cylinder units are connected with a converging device I through branch pipelines, and liquid outlets in the piston cylinder units are connected with a converging device II through branch pipelines; and the converging device I and the converging device II are connected with the main pipeline through the branch pipelines. The floatation device has the beneficial effects of being high in wave energy collection efficiency, low in cost, energy-saving, environment-friendly, flexible in application, convenient to widely popularize and apply and the like.

Owner:盖争

Novel energy-saving stirrer

PendingCN113244809AReduce shearSimple structureRotary stirring mixersTransportation and packagingEngineeringAgitator

The invention discloses a novel energy-saving stirrer. A variable angle is arranged for each blade tip, and each blade is composed of a blade tip, a blade root and an shaped arc, so that a fluid is less sheared. In order to achieve a uniform shaft suction effect along the whole length and obtain the optimal speed effect at each point on the stirring blades, the dip angle and the curved surface chord width along the length direction of the stirring blades are variable, the blade root with lower linear speed is wide and has large dip angle, and the blade tip with higher linear speed is narrow and has small dip angle. The rear sides of the blades are in smooth arc transition, so that the whole stirring blades are streamlined, the curved surfaces of the stirring blades face downwards, an efficient downward suction effect is generated with the minimum pushing force, and finally, smooth motion of a fluid medium is obtained. Meanwhile, separation of a boundary layer with energy loss is prevented, the flow pattern of fluid is in a W shape, and the power consumption is reduced while the flow is maximized. The stirrer has the advantages of high efficiency, energy conservation, consumption reduction, large liquid discharge amount, good circulation effect and simple structure.

Owner:ZHEJIANG HENGFENGTAI REDUCER MFG +1

A double acting impeller pump

ActiveCN103727028BReduced centrifugal force requirementsLight in massRotary piston pumpsRotary piston liquid enginesImpellerMechanical engineering technology

The invention provides a double-acting impeller pump, and belongs to the technical field of mechanical engineering. The problems of high noise and large pump body vibration of the traditional double-acting impeller pump are solved. The double-acting impeller pump comprises a front shell, a back cover, a stator, an oil outlet distribution disc, an oil inlet distribution disc and a rotating shaft, wherein a rotor which is installed on the rotating shaft is arranged in the stator; the cavity between the front shell and one side of the oil outlet distribution disc is formed into an oil inlet chamber, and the cavity between the back cover and the other side of the oil outlet oil distribution disc is formed into an oil outlet chamber; a plurality of guide grooves and blades formed in the guide grooves in a sliding mode are formed in the stator, every guide groove comprises a guide surface and a groove bottom which are mutually parallel, oil supply holes which are communicated with the groove bottoms are all formed in the oil inlet oil distribution disc and the oil outlet oil distribution disc, a pressure groove which intersects the guide grooves is arranged on the rotor, a plurality of through holes are formed in the oil outlet oil distribution disc, the through holes penetrate the oil outlet chamber, and the pressure groove and the through holes are placed on the same shaft diameter. The double-acting impeller pump has the advantages of small noise and low rotating speed.

Owner:NINGBO YINZHOU JINBEN MACHINERY

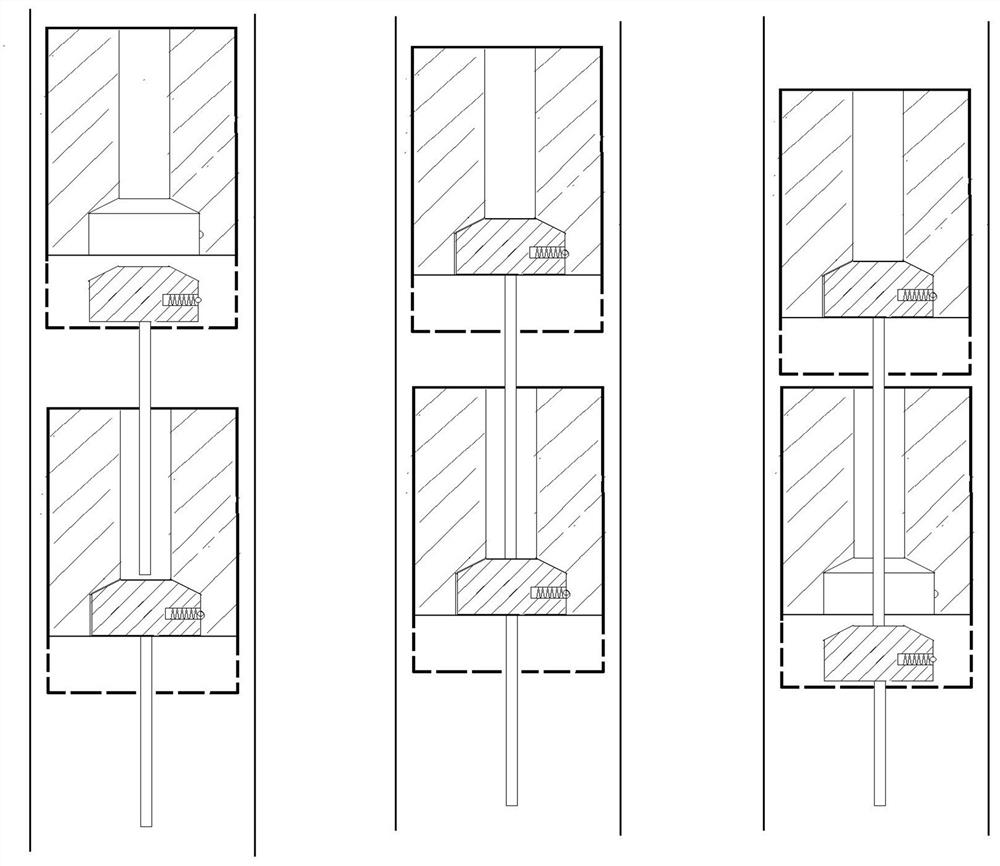

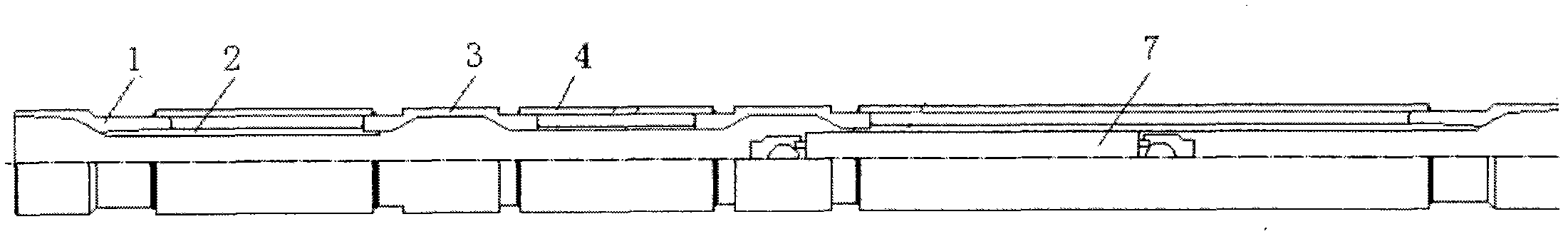

Novel airproof oil well pump

InactiveCN103133338AExtended service lifeReduce the impactPositive displacement pump componentsFlexible member pumpsEngineeringAir exchange

The invention discloses a novel airproof oil well pump which is mainly composed of a pump barrel assembly and a plunger piston assembly (7) which is arranged inside the pump barrel assembly. The pump barrel assembly is composed of at least two pump barrels (2) and two adjacent pump barrels (2) are communicated with each other in a sealing mode. The novel airproof oil well pump changes the fact that the traditional oil well pump can only perform the functions of absorbing liquid and discharging liquid when a stroke begins and ends, discharging some gas in the process of stroke is achieved, influence of the gas is greatly reduced, and the amount of discharging liquid is increased. Due to the fact that reinforcement outer tubes are arranged between air exchange cavities, when the oil well pump works normally, influence of axial alternating load on dangerous sections of pump barrels of the oil well pump is enabled to be greatly reduced, service life of the oil well pump is prolonged, and processing difficulty is lowered. The novel airproof oil well pump has the advantages of being low in cost, long in service life, convenient to use and maintain and suitable for popularization and quantity production.

Owner:欧阳才伟

A slurry tank agitator

The invention discloses a pulp tank agitator. The pulp tank agitator comprises an agitating shaft (1), a second vane wheel (3) is fixedly arranged at the bottom end of the agitating shaft (1), and a first vane wheel (2) fixed on the agitating shaft (1) is arranged over the second vane wheel (3); the water attaining surfaces of the propeller surfaces of first vanes (21) adopted by the first vane wheel (2) bend downwards, and the tails of the first vanes (21) are provided with first flow stabilizing rings(211) which bend downwards; the water attaining surfaces of the propeller surfaces of second vanes (31) adopted by the second vane wheel (3) bend downwards, the tails of the second vanes (31) are provided with upward-bending sections (311) to push materials to move downwards in the axial direction of the agitating shaft (1) and move downwards and outwards in the radial direction of the agitating shaft (1), and meanwhile the outermost ends of the upward-bending sections (311) are provided with upward-bending second flow stabilizing rings (3111). According to the pulp tank agitator, agitating is stable and efficient, part replacing is convenient, the angle of the vanes can be regulated, and therefore the pulp tank agitator is suitable for use and popularization.

Owner:江苏胜开尔工业技术有限公司

Sucker-rod lifting whole-process liquid discharging oil well pump

PendingCN109424529ASave energyImprove oil output efficiencyPositive displacement pump componentsFlexible member pumpsOil wellPlunger

The invention discloses a sucker-rod lifting whole-process liquid discharging oil well pump. The sucker-rod lifting whole-process liquid discharging oil well pump comprises a small pump cylinder, a large pump cylinder, an upper outer pipe, a two-way joint, an upper plunger and a descending assisting plunger, wherein the small pump cylinder, the large pump cylinder, the upper outer pipe and the two-way joint are sequentially connected from top to bottom; the upper plunger and the descending assisting plunger are sequentially connected from top to bottom; the upper plunger comprises an upper small-diameter section and a lower large-diameter section, wherein the upper small-diameter section runs inside the small pump cylinder; the lower large-diameter section runs inside the large pump cylinder; the upper outer pipe is provided with an axial center through hole and an eccentric through chamber; the descending assisting plunger runs inside the center through hole of the upper outer pipe; the two-way joint is provided with an axial flow channel and a radial flow channel which do not communicate with each other; the lower end of the center through hole of the upper outer pipe is connected with the radial flow channel; and the lower end of the eccentric through chamber of the upper outer pipe is connected with the axial flow channel. The sucker-rod lifting whole-process liquid discharging oil well pump disclosed by the invention can realize liquid discharging in a whole lifting process of a sucker-rod pump, saves energy and improves the oil output efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com