Multi-plunger cooperative gas-lift liquid drainage technology

A multi-plunger, gas lift technology, which is applied in liquid fuel engines, liquid variable capacity machinery, and production fluids, etc. Small ratio, the effect of reducing the gas-liquid ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

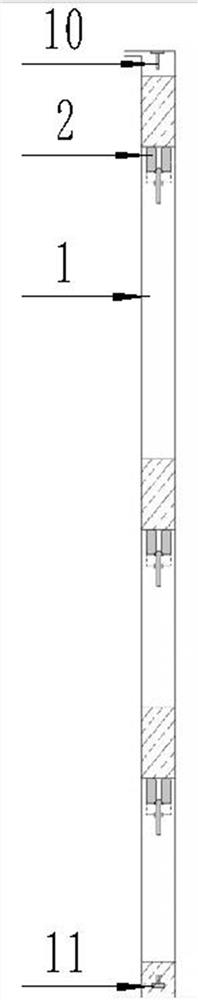

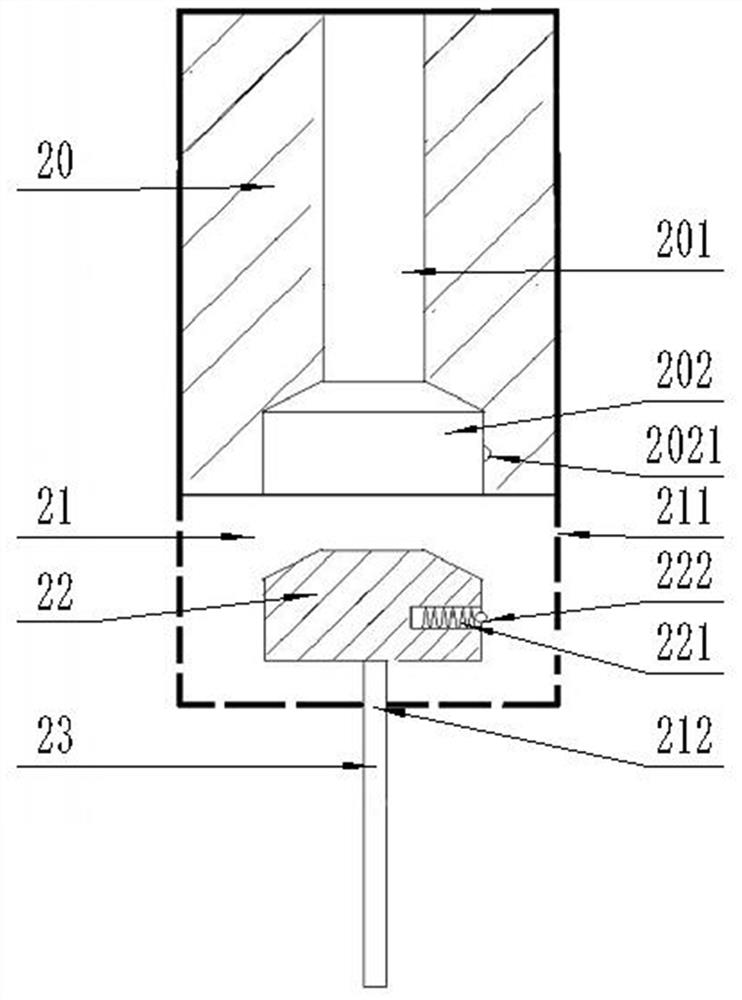

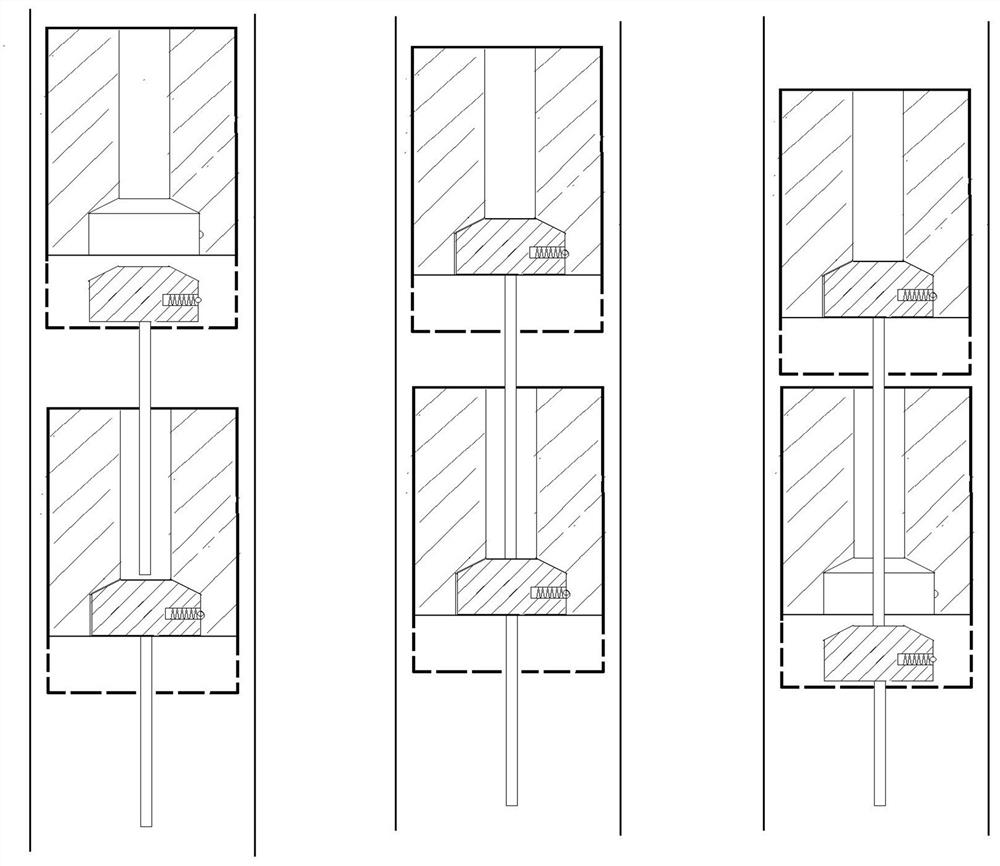

[0033] Such as Figure 1~Figure 5 As shown, a multi-plunger cooperative gas lift drainage technology is applied in the multi-plunger cooperative gas lift drainage system. There are several plungers 2 inside, the top of the tubing 1 is provided with a wellhead poking rod 10, the bottom of the tubing 1 is provided with a retainer 11, the plunger 2 includes a valve body 20, and a cavity 21 connected to the lower part of the valve body 20 is arranged in the cavity. The valve body 22 in the chamber 21 is fixedly connected to the valve rod 23 at the lower part of the valve body 22 and passes through the bottom of the cavity 21. The valve body 20 is provided with a through hole 201 that runs through the upper end surface of the valve body 20, and the lower part of the through hole 201 communicates with a The valve seat hole 202 runs through the lower end surface of the valve body 20 , and a plurality of mesh holes 211 are arranged on the surface of the cavity 21 .

[0034] Multi-plu...

Embodiment 2

[0046] Based on Embodiment 1, an anti-falling spring 221 is provided on the outer surface of valve 22 through the blind hole opened, and an anti-falling boss 222 is provided at the end of the anti-falling spring 221, and an anti-falling boss 222 is provided on the inner surface of the valve seat hole 202. 222 cooperates with the anti-falling hole 2021 to prevent the valve body 22 from falling off. The design of the structure here can improve the stability of the system operation and the fault tolerance rate. In the absence of this structure, the valve body 20 is combined with the valve body 22. Under the action of pressure, the structure is in a sealed state, which can better complete the draining work, but in the case of certain defects in the structure, the anti-falling spring 221 can bear part of the pressure to ensure the stability of the entire draining system.

[0047] The number of anti-falling springs 221 can be multiple, and evenly distributed on the outer surface of t...

Embodiment 3

[0049] Based on the first embodiment, the gas at the bottom of the oil pipe can be continuously injected from the ground through the casing to the bottom of the oil pipe. In this case, the application of the multi-stage plunger is even more important. The multi-stage plunger makes the gas column expand step by step. At the same time, the upward movement of the plunger and the liquid column above it is accelerated, the required gas-liquid ratio is reduced, and the liquid discharge volume is increased. In the case of the same liquid discharge volume, the gas volume required by the liquid discharge system is greatly reduced, which can save more manpower. and physical costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com