A liquid accumulator for a propellant tank in a space vehicle

A technology for propellant storage tanks and space vehicles, which is applied to space vehicle propulsion system devices, aircraft, space navigation vehicles, etc., can solve the problems of easy pollution, complex structure, low reliability, etc., and achieve a wide range of applications, structural The effect of high strength and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

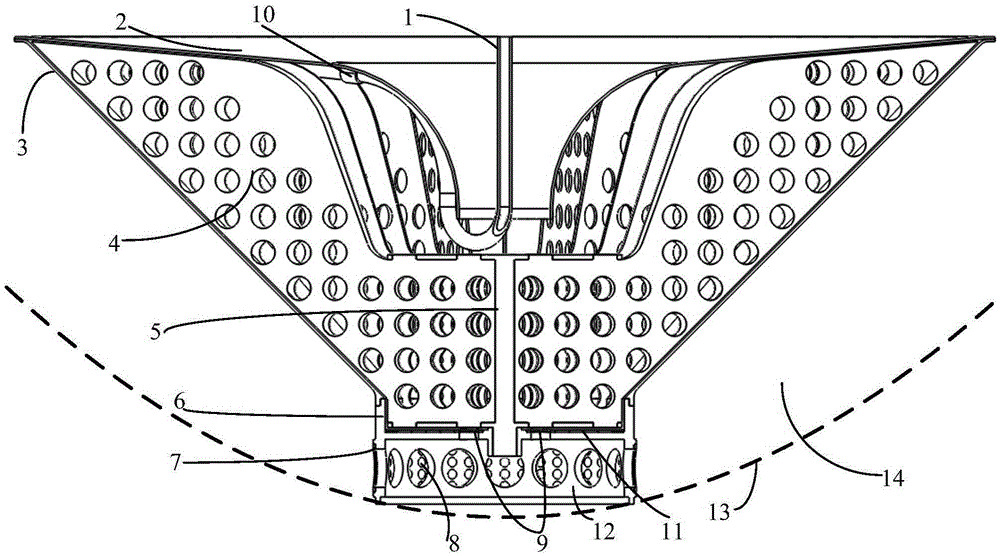

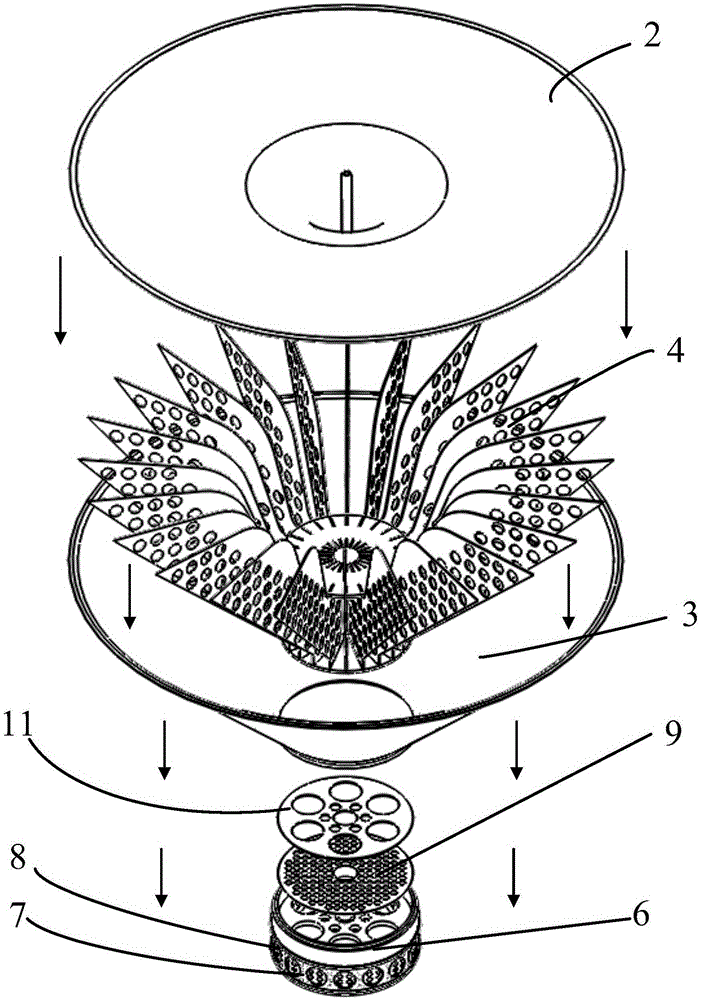

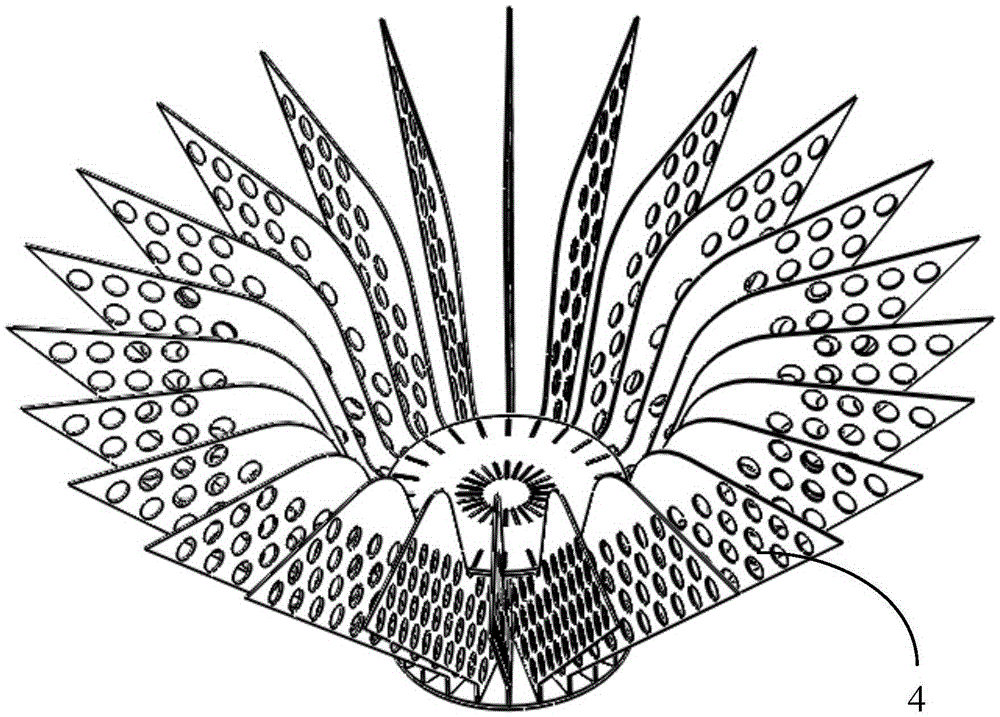

[0037] Such as figure 1 , 2 As shown, the present invention provides a liquid accumulator for a propellant storage tank in a space vehicle, comprising an air duct 1, a cover plate 2, a casing 3, a blade 4, a pillar 5, a base 6, a passage window pressure plate 7, a passage The window mesh 8, the liquid accumulator mesh 9, the fixed block 10 and the liquid accumulator mesh pressing plate 11; the channel window mesh 8 and the liquid accumulator mesh 9 are made of titanium alloy.

[0038] Such as Figure 6 As shown, the pillar 5 includes a center column 51, an upper support plate 52 and a lower support plate 53; the upper support plate 52 and the lower support plate 53 are coaxially connected by the center column 51, the upper support plate 52 is located at the top of the center column 51, and the lower support plate 52 is located at the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com