Piston pump for brake

A piston pump and brake technology, which is applied to components, pumps, and multi-cylinder pumps for elastic fluid pumping devices, can solve the problems of reduced engine durability, increased weight, and increased engine prices, and achieves increased displacement. The effect of fluid volume and load reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

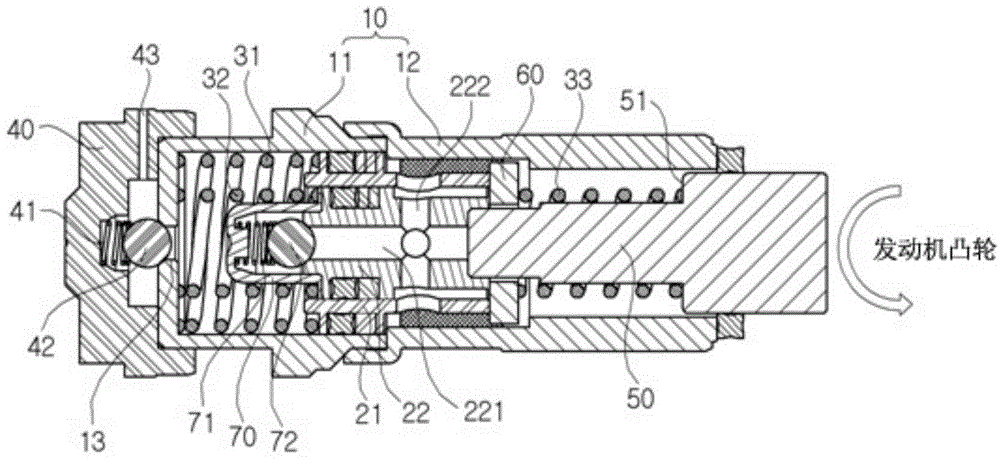

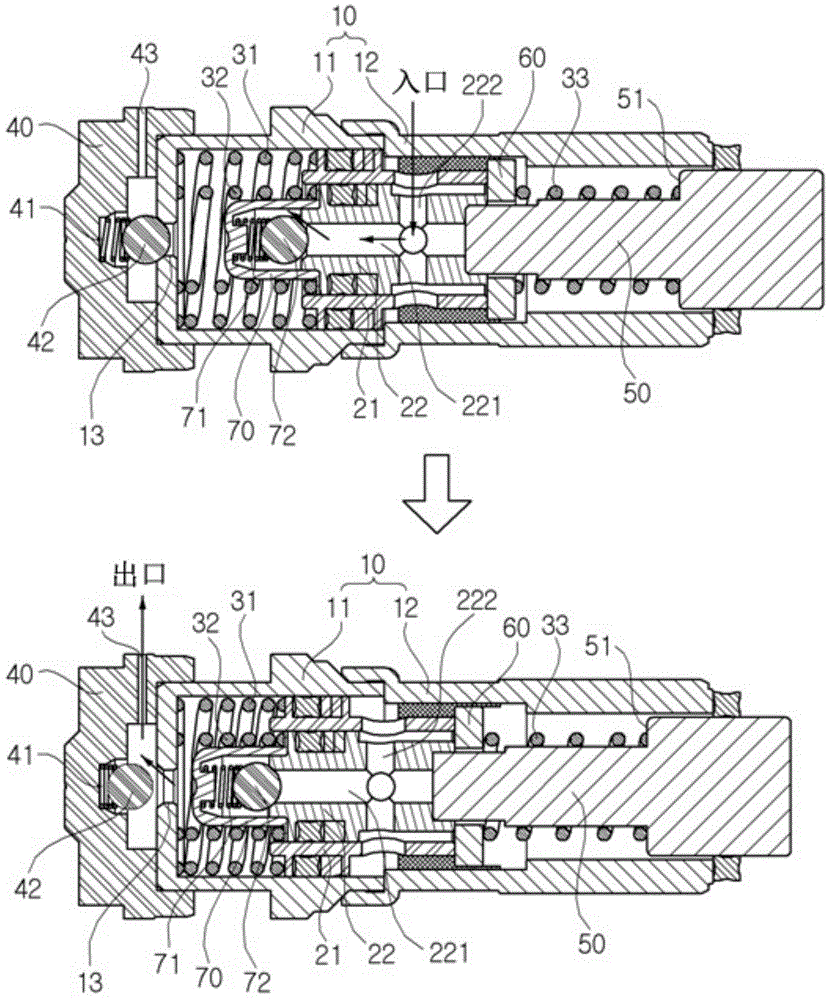

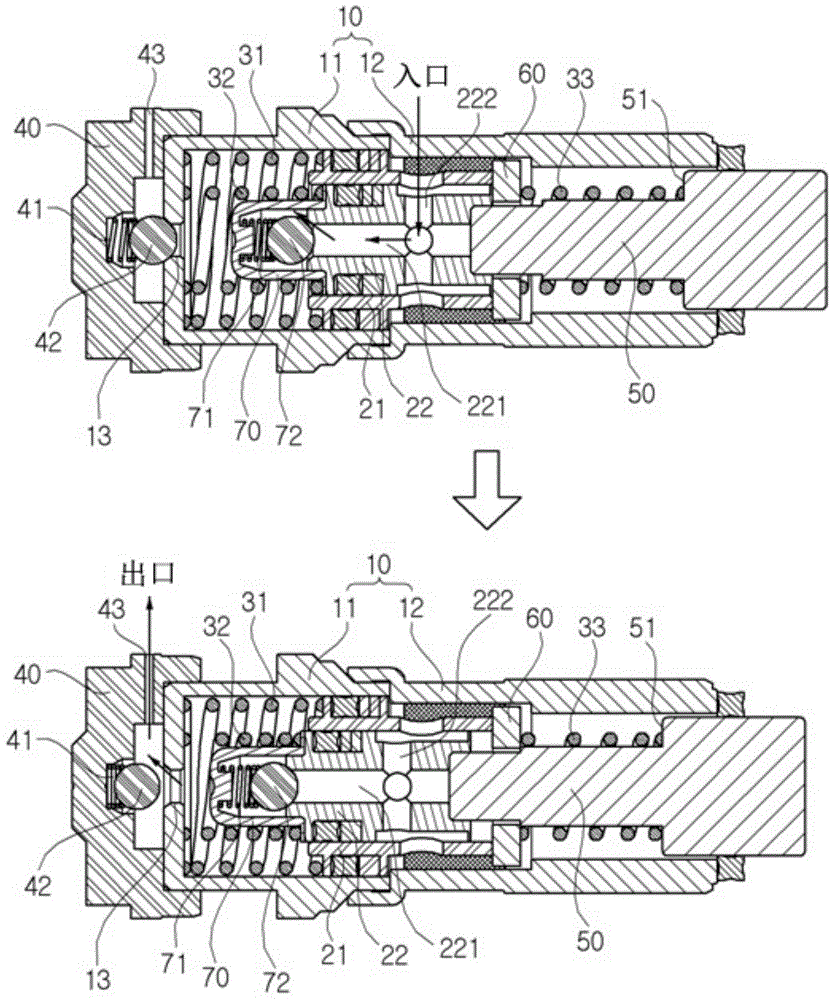

[0039] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. First, reference symbols are attached to each drawing, and care should be taken to have the same reference symbols as much as possible even though the same components are shown in other drawings. In addition, preferred embodiments of the present invention will be described below, but the technical idea of the present invention is not limited thereto, and can be variously implemented by those skilled in the art.

[0040] First, the configuration of a piston pump for a brake according to an embodiment of the present invention will be described.

[0041] Such as figure 1 As shown, the piston pump for the brake according to the embodiment of the present invention includes: a piston housing 10; an outer piston 21, which performs linear reciprocating motion inside the piston housing 10; and an inner piston 22, which is combined inside the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com