Sucker-rod lifting whole-process liquid discharging oil well pump

A kind of oil pump, whole process technology, applied in the field of oil pump with rod lifting and whole outlet, can solve the problems of energy loss, large application limitation, rising supporting cost, etc., to save energy, improve oil output efficiency, and reduce downward resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The detailed description and technical content of the present invention are described below with the drawings, but the drawings are only for reference and description, and are not used to limit the present invention.

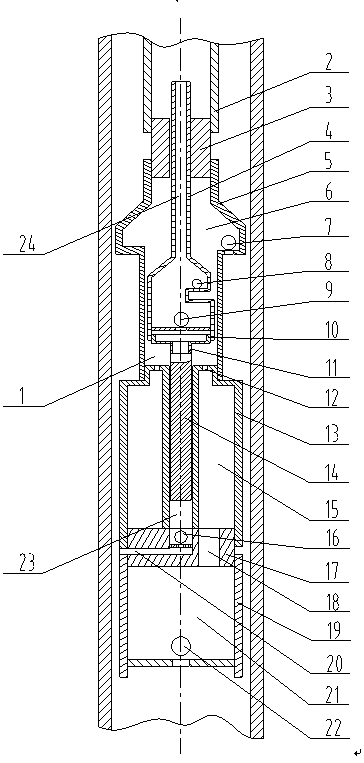

[0021] as attached figure 1 As shown in the figure, the oil well pump with rod lifting in the whole process includes the small pump cylinder 3, the large pump cylinder 5, the upper outer pipe 13, and the double-way joint 17 connected sequentially from top to bottom, and also includes the sequentially connected from top to bottom The upper plunger 4 and the downward booster plunger 14, the upper plunger includes an upper small-diameter section and a lower large-diameter section, wherein the upper small-diameter section runs in the small pump barrel 3, and wherein the lower large-diameter section runs in the large pump barrel 5 , the upper outer tube is provided with an axial central through hole and an eccentric through cavity 15, the downward booster plun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com