Novel airproof oil well pump

An oil well pump and anti-gas technology, which is applied in the direction of pumps, pump components, variable capacity pump components, etc., can solve the problems of reducing the fullness of the pump chamber, the opening lag of the oil pump valve ball, and accelerated damage, so as to reduce the gas Influence, convenient use and maintenance, and the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

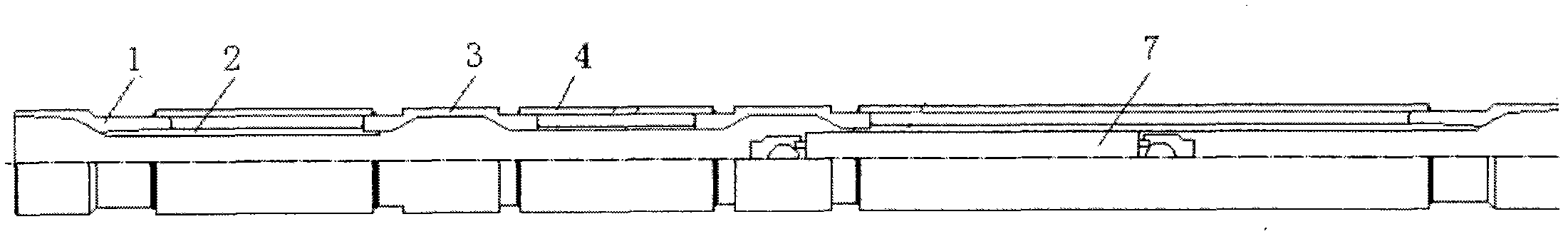

[0022] The novel air-proof oil well pump that the present invention relates to is as figure 1 As shown, it is mainly composed of a pump barrel assembly and a plunger assembly 7 arranged inside the pump barrel assembly. The pump barrel assembly is mainly composed of at least two pump barrels 2, and the two pump barrels 2 are connected. are sealed and connected to each other.

[0023] The pump barrel 2 is a thick-walled pump barrel.

[0024] The two adjacent pump barrels 2 are connected through a ventilation joint 3 .

[0025] One end of the pump barrel assembly is provided with a pump barrel collar 1 .

[0026] A reinforced outer tube 4 is arranged on the outer wall of the pump cylinder 2 .

[0027] The invention changes the function of the conventional oil well pump which can only produce liquid suction and liquid discharge at the beginning and end of the stroke, and can realize the removal of part of the gas during the stroke, greatly reducing the influence of the gas, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com