Novel energy-saving stirrer

An agitator and a new type of technology are applied in mixers with rotary stirring devices, chemical instruments and methods, dissolution and other directions, which can solve the problems of low blade strength, high investment cost, and many molds, and reduce investment costs and production costs. , good circulation effect, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

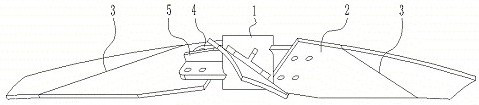

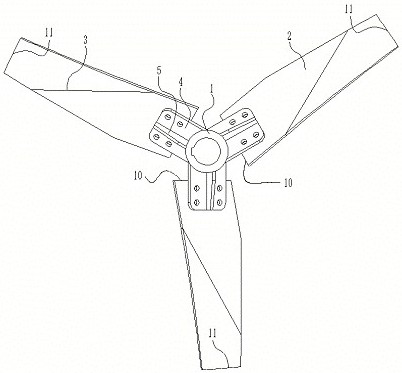

[0028] Embodiment 1: The stirring blade is welded and fixed on the side wall of the hub, that is, the hub and the stirring blade are integrated.

Embodiment 2

[0029] Embodiment 2: A connecting plate is welded and fixed on the side wall of the hub, and the stirring paddle is detachably fixed on the connecting plate.

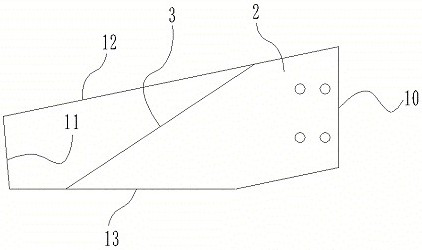

[0030] A bending starting line is provided from the front end of the front side of the blade to the rear end of the rear side of the blade, and the stirring paddle is bent along the starting line of bending, and the starting line of bending is in front of the blade The starting point of the side is located at the rear side of the blade end, and the distance is 0 to 0.1 times the diameter of the agitator. Less than the outer end of the connecting plate 4 as a benchmark.

[0031] A reinforcing rib is provided on the non-liquid-facing surface of the connecting plate, and the reinforcing rib is welded on the hub to improve the overall strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com