Oil well liquid-displacement reciprocating oil pumping system

An oil well and liquid flooding technology, applied in the field of liquid flooding rodless pumping system, can solve the problem of inability to adapt to non-oily working medium, etc., and achieve the effects of high power utilization rate, timely commutation response, and uniform working load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

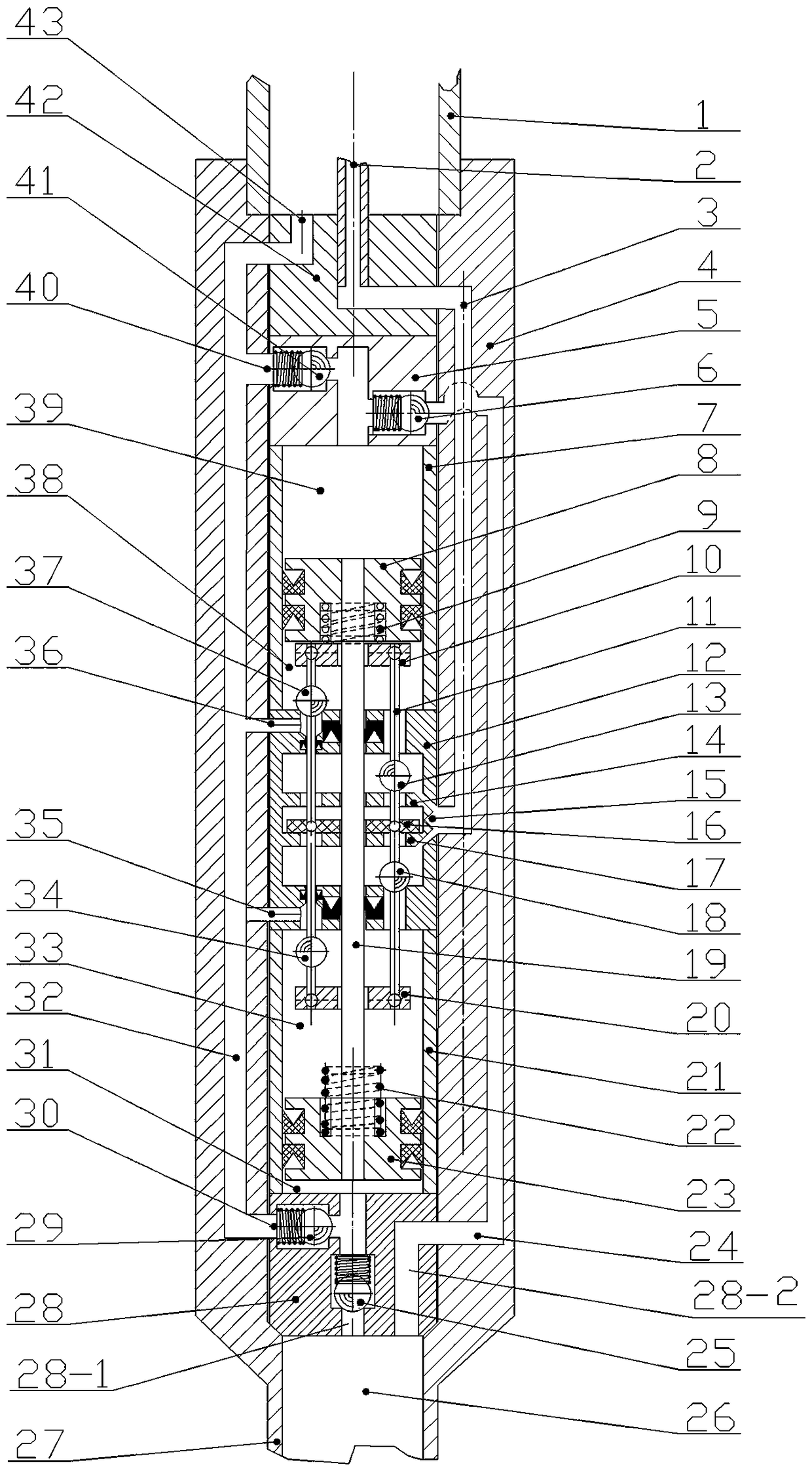

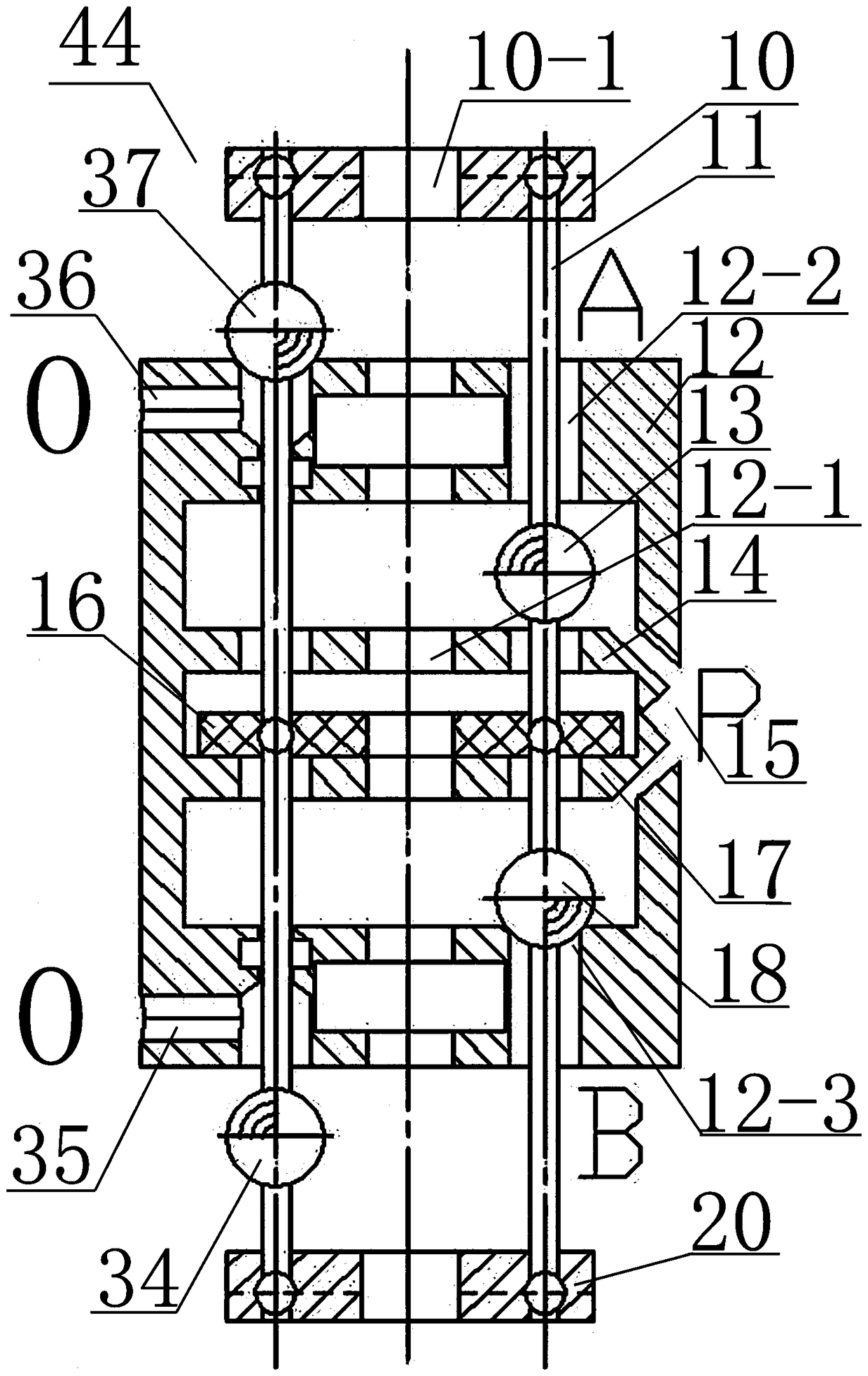

[0027] Reference attached figure 1 , 2 , An oil well fluid flooding reciprocating pumping system includes a working cylinder (4), a hydraulic cylinder A (7), a piston A (8), a produced fluid inlet valve ball A (6), and a produced fluid drain valve ball A (41), piston rod (19), cylinder B (21), piston B (23), produced fluid inlet valve ball B (25), produced fluid drain valve ball B (29), and two-position four Through the reversing valve (44). The working cylinder (4) is connected to the lower end of the tubing (1) and goes down into the oil well along with the tubing (1). The working cylinder (4) is assembled into a whole by the connection of the multi-layer tubing string, and goes down in the oil well with the tubing (1) , The working cylinder is provided with a power fluid channel 3, a formation fluid channel 24, and a produced fluid and depleted power fluid channel 32, which can provide multiple fluid channels such as a power fluid channel, a formation fluid channel, and a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com