Emulsion polymerization reaction kettle

A technology of emulsion polymerization and reactor, which is applied in the field of emulsion polymerization, can solve the problems of unreachable product particle size and particle size distribution, low overall liquid phase flow rate, and small paddle liquid discharge, so as to reduce the amount of material crusting, Uniform distribution, enhanced axial flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

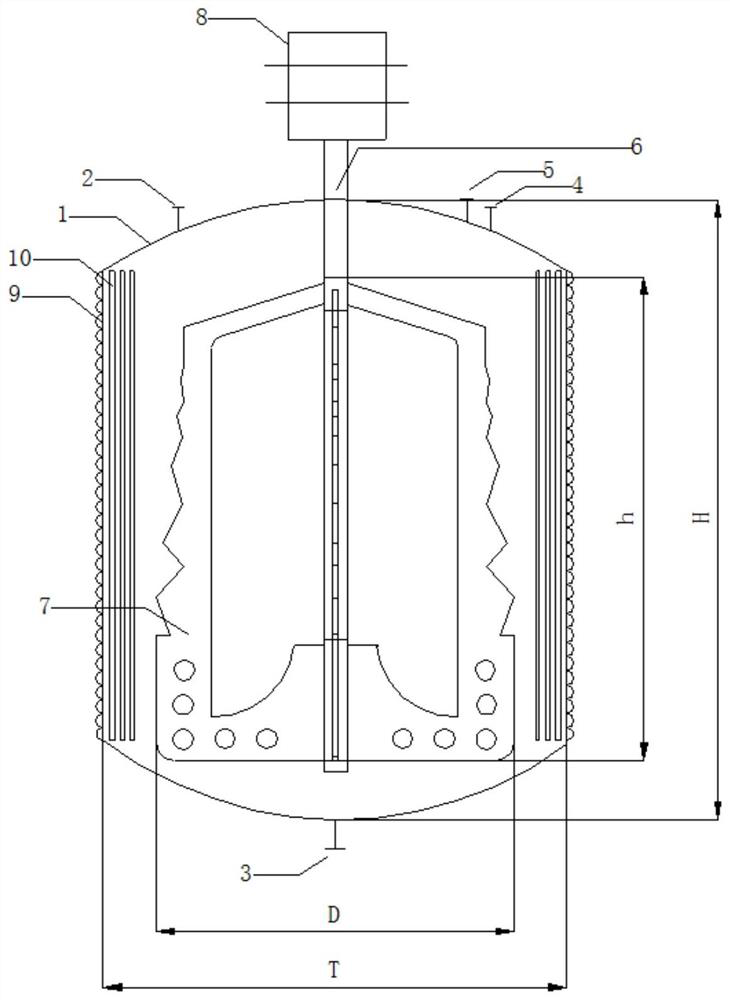

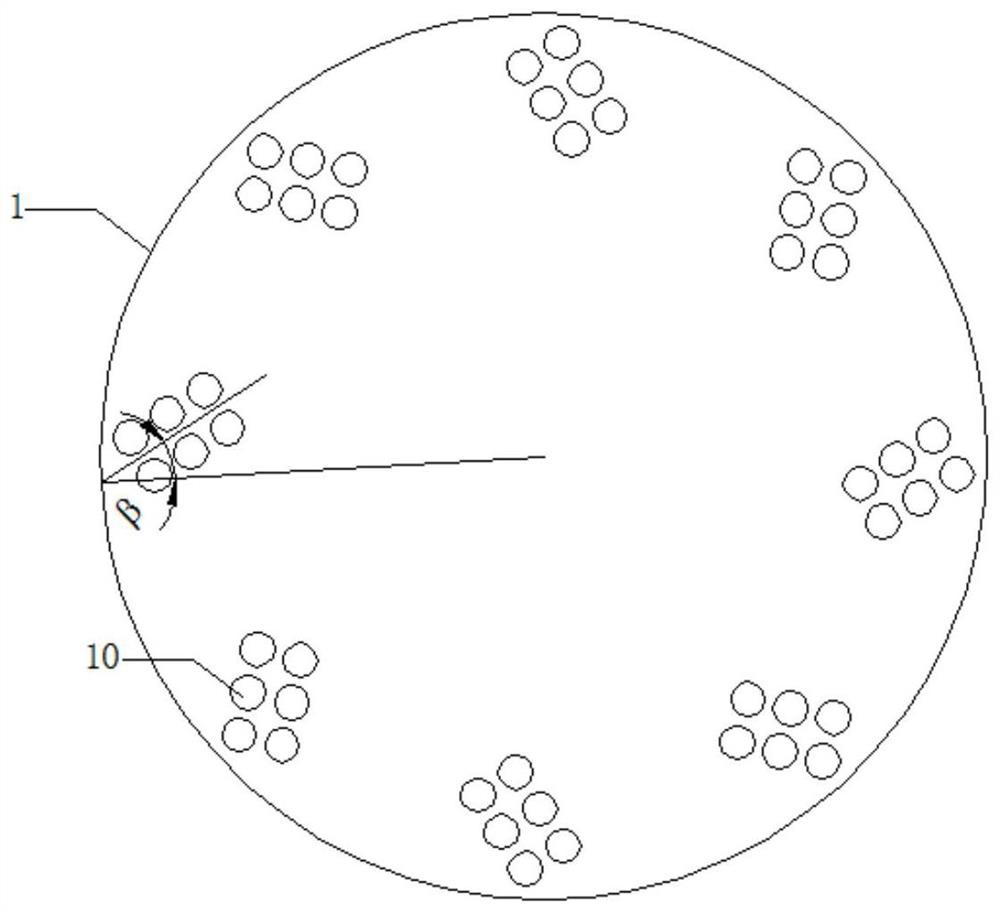

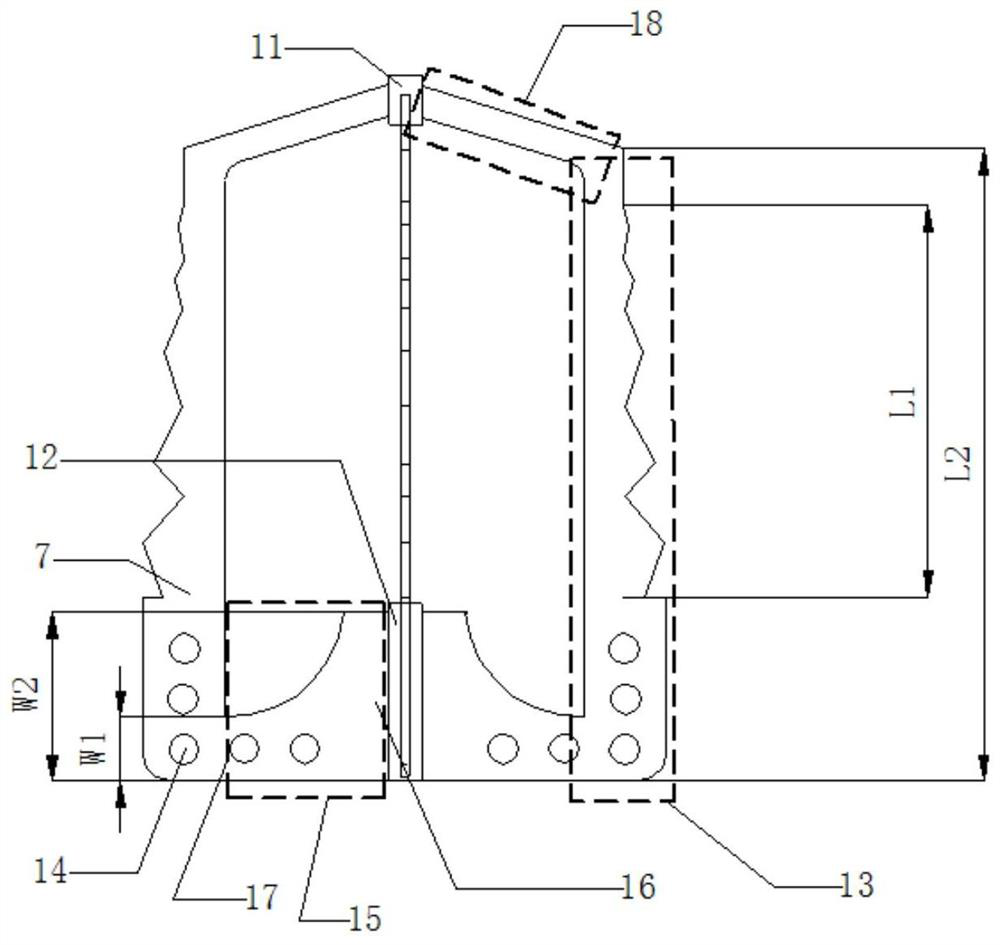

[0044] The emulsion polymerization reactor includes a vertical cylinder 1, the upper head of the cylinder 1 is provided with a material inlet 2, a gas inlet 4, a gas outlet 5, the gas outlet 5 is connected to a vacuum system, and the lower head is provided with a material outlet 3 The upper end of the cylinder body 1 is provided with a stirring shaft insertion port, one end of the stirring shaft is connected with the power unit 8, and the other end is connected with the four-leaf ring type stirrer 7, and the stirring shaft is connected with the cylinder body through a mechanical seal. The above-mentioned four-blade ring agitator 7 is composed of four blades, and the included angle between adjacent blades is 90 degrees. The wide blade 15 tapers from the blade root 16 to the blade end 17 at the hub. At the end 17 of the wide blade, there is a vertical narrow blade 13 connected to it, and the other end of the narrow blade 13 is connected to the upper hub 11 through a fixing membe...

Embodiment 3

[0063] Use the reaction kettle of Example 1. Add 50 ℃ of desalted water into the reaction kettle, start stirring, use a vacuum pump to evacuate from the gas outlet 5, feed nitrogen from the gas inlet 4, and replace the air in the kettle for many times. Under vacuum conditions, water-containing emulsifier, initiator aqueous solution, styrene and butadiene were added to the kettle in a ratio of 1:1:0.3:4. During the reaction, sampling and analysis were carried out. When the conversion rate reached 25%, additional raw materials were added. Butadiene, the ratio of butadiene supplementary amount to initial charging amount is 2:1, when the conversion rate is 50%, the raw material butadiene is supplemented for the second time, and the ratio of butadiene supplementary amount to initial charging amount is 1.5:1 , when the conversion rate is 75%, the raw material butadiene is added, and the ratio of the supplementary amount of butadiene to the initial addition amount is 1:1, and the pol...

Embodiment 4

[0065]Use the reaction kettle of Example 1. Add 50 ℃ of desalted water into the reaction kettle, start stirring, use a vacuum pump to evacuate from the gas outlet 5, feed nitrogen from the gas inlet 4, and replace the air in the kettle for many times. Under vacuum conditions, water-containing emulsifier, initiator aqueous solution, styrene and butadiene were added to the kettle in a ratio of 1.2:1:0.3:4. During the reaction, samples were taken for analysis. When the conversion rate reached 25%, additional raw materials were added. Butadiene, the ratio of butadiene supplementary amount to initial charging amount is 2:1, when the conversion rate is 50%, the raw material butadiene is supplemented for the second time, and the ratio of butadiene supplementary amount to initial charging amount is 1.5:1 , when the conversion rate is 75%, the raw material butadiene is added, and the ratio of the supplementary amount of butadiene to the initial addition amount is 1:1, and the polymeriz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com