Feed liquid stirring equipment for reaction kettle

A technology of stirrer and stirring shaft, which is applied in chemical/physical/physical chemical fixed reactors, mixers with rotating stirring devices, chemical instruments and methods, etc., can solve the problems of small range of axial flow, etc., and achieve Enhanced turbulence, improved efficiency and uniformity, good circulation and mixing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

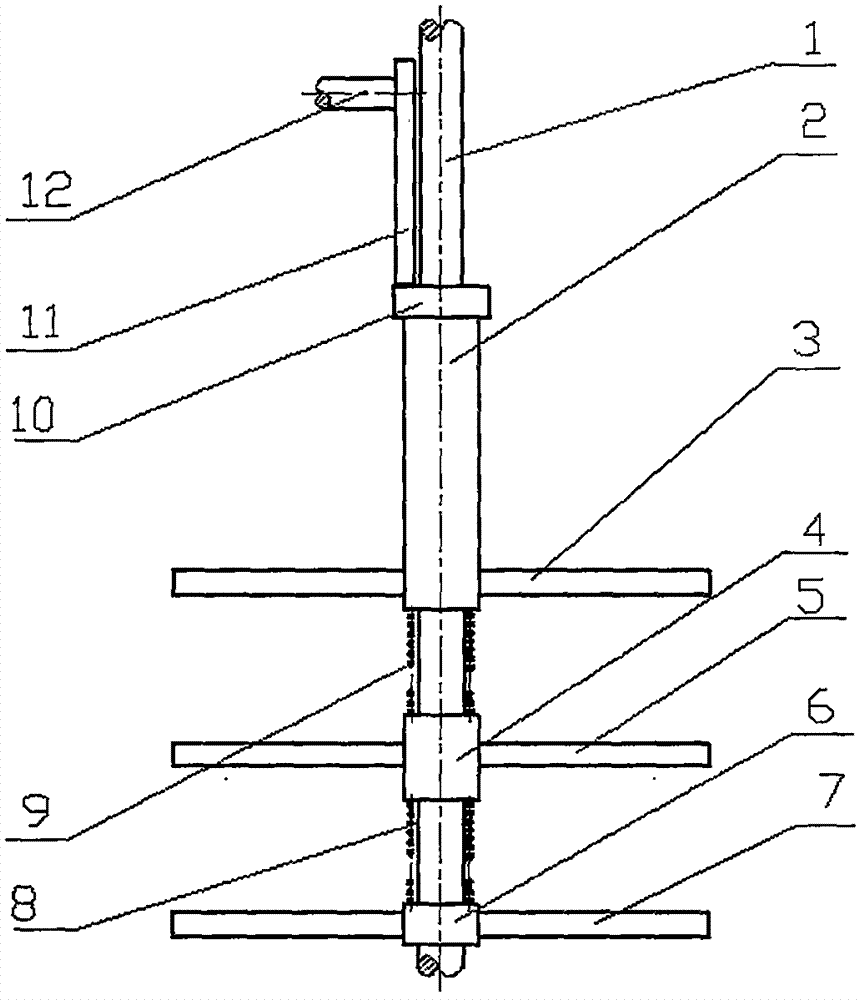

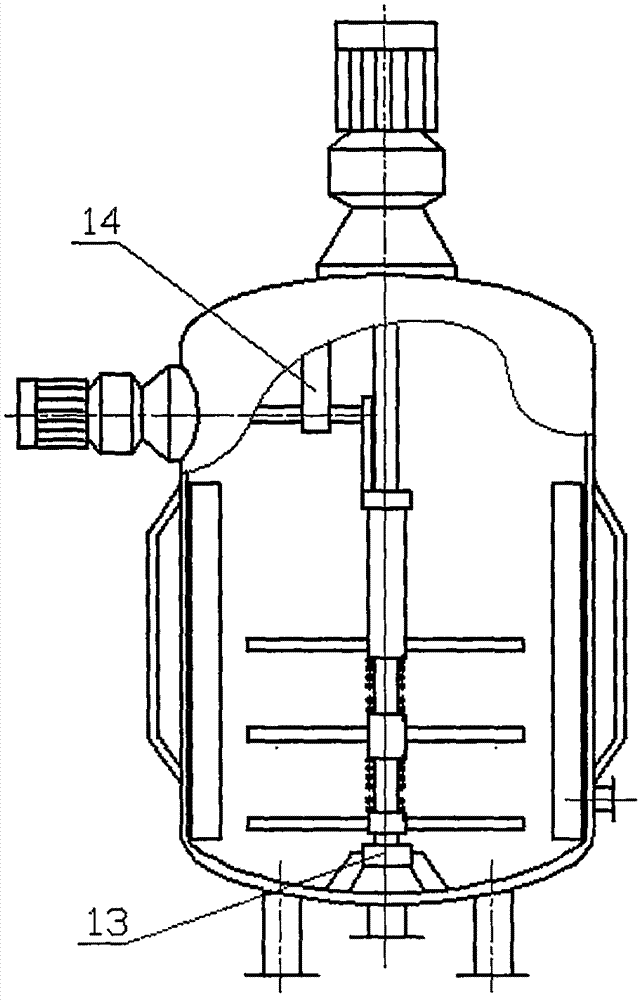

[0011] as attached figure 1 , 2 As shown, the present invention structurally comprises a stirring shaft 1, an upper shaft sleeve 2, an upper paddle 3, an intermediate shaft sleeve 4, an intermediate paddle 5, a lower shaft sleeve 6, a lower paddle 7, a lower spring 8, and an upper spring 9 , Cam 11 and camshaft 12. Wherein, the upper bushing 2 and the upper paddle 3, the middle bushing 4 and the middle paddle 5, the lower bushing 6 and the lower paddle 7 are respectively fixedly connected together by welding or bolting. The stirring shaft 1 is provided with a long feather key, and the inner hole of the upper shaft sleeve 2 and the inner hole of the intermediate shaft sleeve 4 are respectively provided with key grooves. Install the upper shaft sleeve 2, the upper spring 9, the intermediate shaft sleeve 4, the lower spring 8, and the lower shaft sleeve 6 sequentially from top to bottom on the stirring shaft 1. Wherein, the inner hole of the upper shaft sleeve 2 and the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com