A kind of preparation device and method of 1,3-propanediol crude product solution

A preparation device and a technology for propylene glycol, applied in 1 field, can solve the problems of difficult refining process, affecting product yield separation, many side reactions, etc., and achieve high reaction efficiency, reduce the formation of liquid phase dead zone, and high production stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

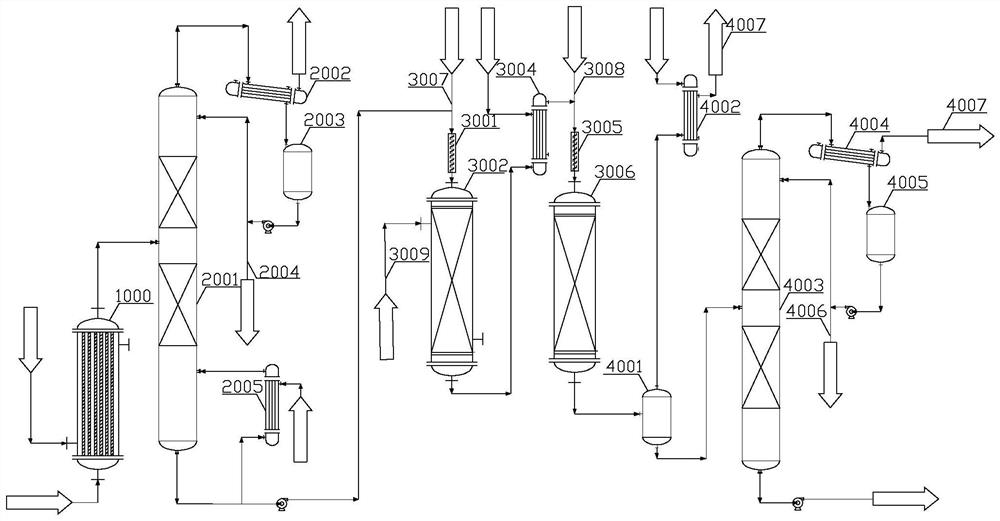

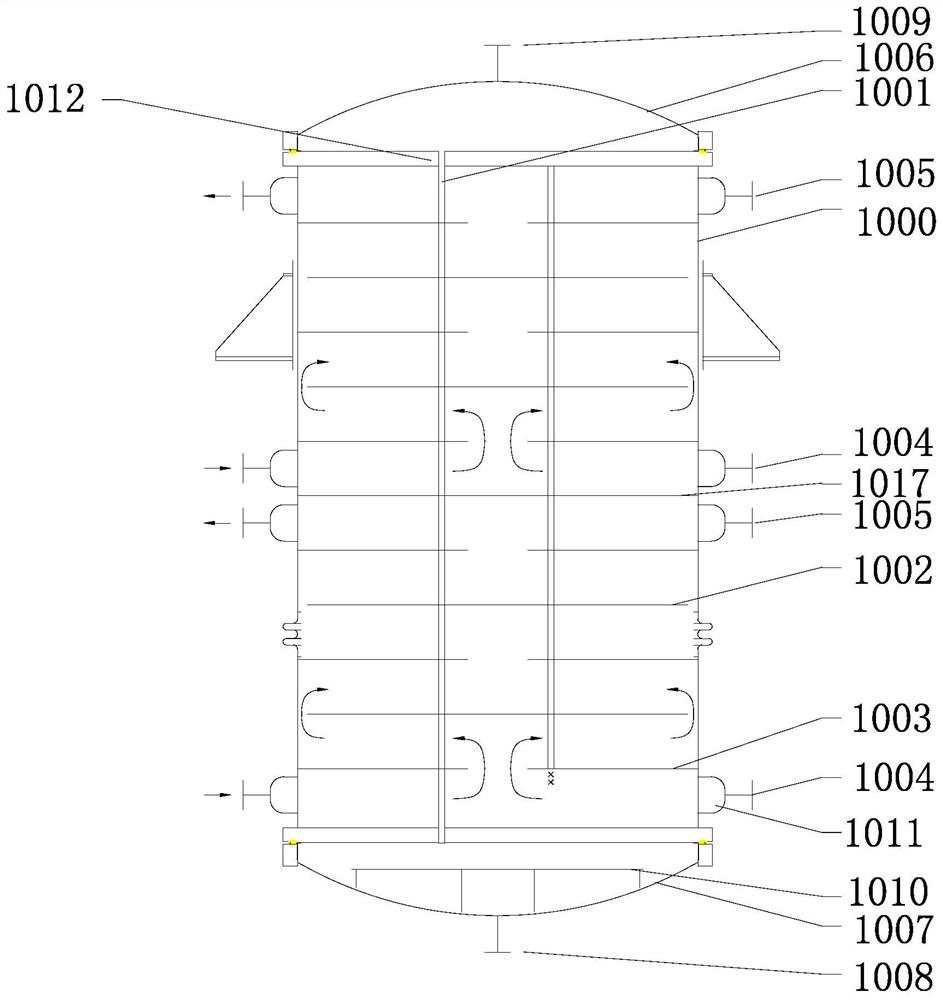

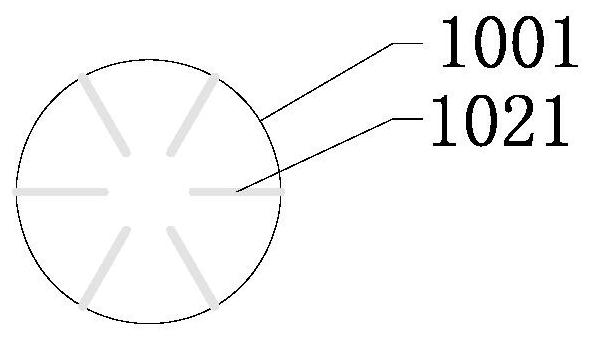

[0132] like figure 1 As shown, a preparation device for 1,3-propanediol crude product solution includes a hydration reactor 1000, an acrolein separation unit, a two-stage hydrogenation unit and a gas-liquid separation unit which are connected in sequence.

[0133] The acrolein separation unit includes an acrolein separation column 2001, a first condenser 2002 and a first reflux tank 2003; the hydration reactor is communicated with the acrolein separation column, and the top of the acrolein separation column, the first condenser, The first return tanks are connected in sequence to form a circuit. The first reflux tank is also connected with a reflux pipe 2004 for preparing the raw materials of the reaction liquid; a steam heat exchanger 2005 is provided at the bottom of the acrolein separation tower.

[0134] The two-stage hydrogenation unit includes a first mixer 3001, a first-stage hydrogenation reactor 3002, a preheater 3004, a second mixer 3005, and a second-stage hydroge...

Embodiment 2

[0162] use figure 1 As shown in the process flow, the concentration of the acrolein raw material solution is 15%, the operating conditions are adjusted, and the specific parameters are shown in Table 2 (for other processes, refer to Example 1).

[0163] Table 2 - Operating conditions for each stage of the process flow

[0164]

[0165]

[0166] In this production process, the temperature and pressure of the hydration reaction are reduced, and the conversion rate of acrolein is reduced; at the same time, the temperature and pressure of the first-stage hydrogenation and the second-stage hydrogenation reaction are reduced, resulting in the conversion of 3-hydroxypropionaldehyde in the first-stage hydrogenation reaction The rate decreased, and after the secondary hydrogenation reaction was completed, a small amount of 3-hydroxypropanal was not completely converted. The reaction was completed, the conversion of acrolein was 99.8%, and the selectivity of the total reaction w...

Embodiment 3

[0168] use figure 1 As shown in the process flow, the concentration of the acrolein raw material solution is 15%, the operating conditions are adjusted, and the specific parameters are shown in Table 3 (for other processes, refer to Example 1).

[0169] Table 3 - Operating conditions for each stage of the process flow

[0170]

[0171] In this production process, the conversion rate of 3-hydroxypropionaldehyde in the first-stage hydrogenation reaction is reduced due to the reduction of the first-stage hydrogenation temperature and pressure. When the reaction temperature is increased, the selectivity of acrolein is reduced, the reaction is completely completed, the conversion rate of acrolein is 99.8%, and the selectivity of the total reaction is 86%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com