Patents

Literature

56results about How to "Large wall thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

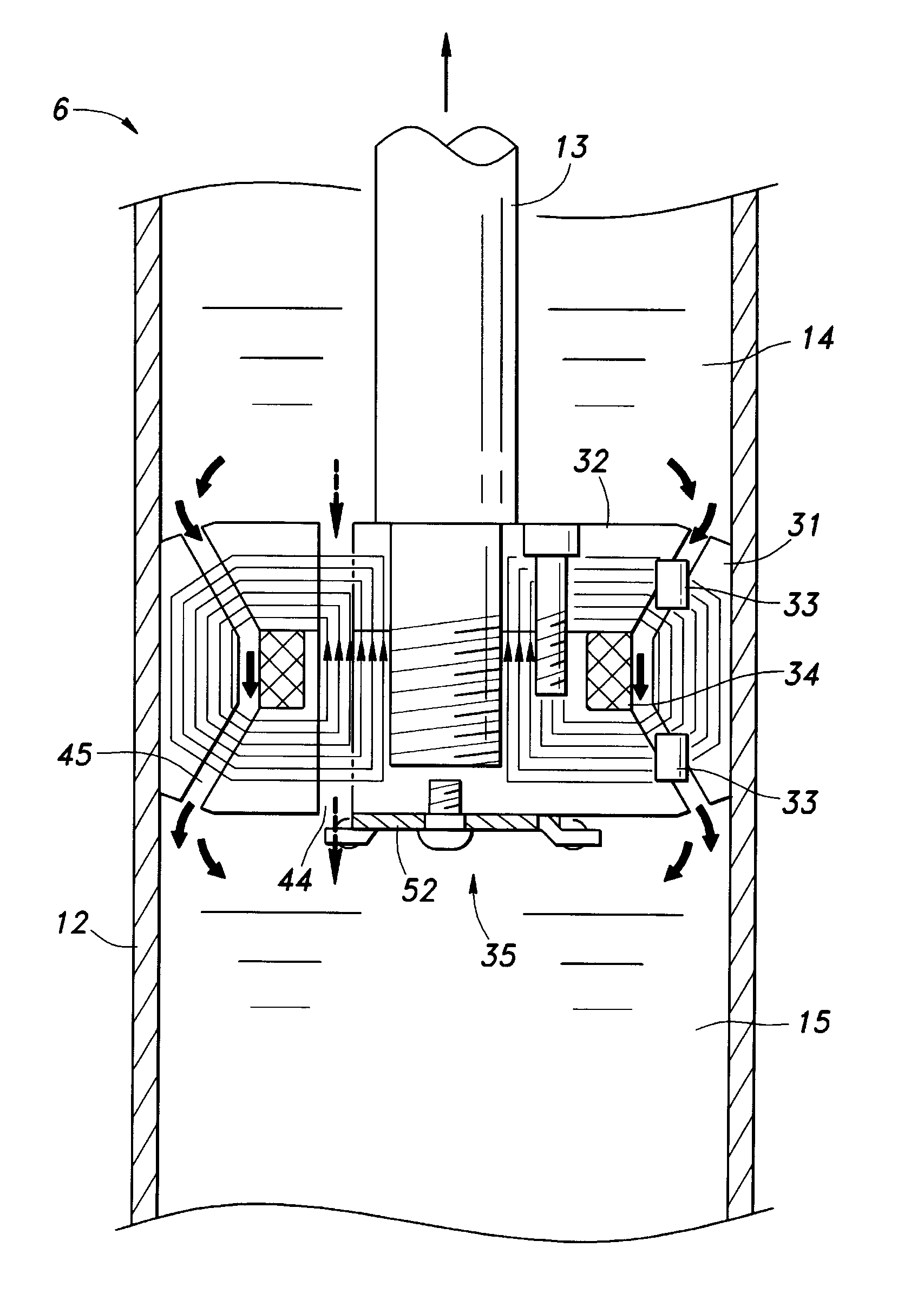

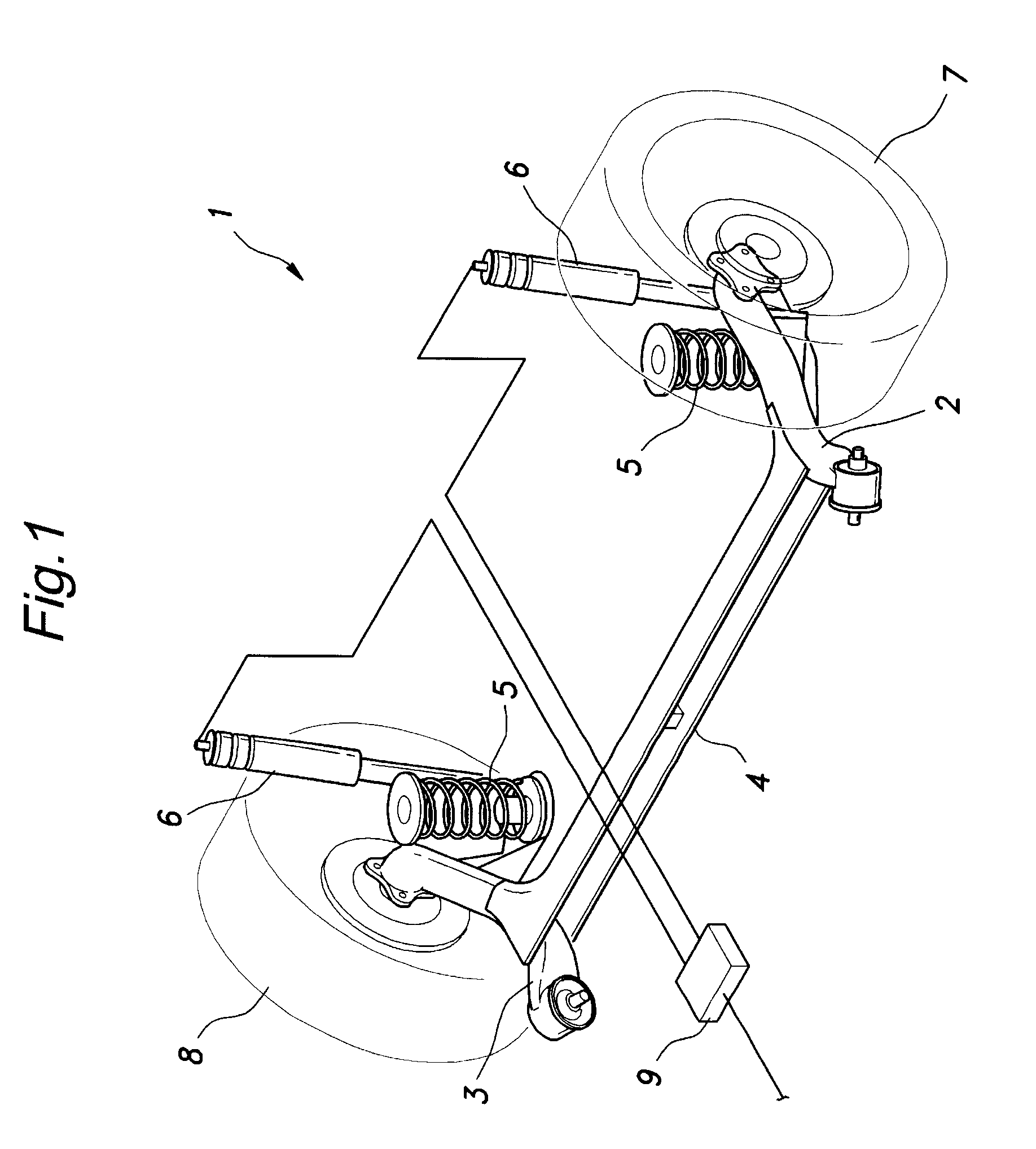

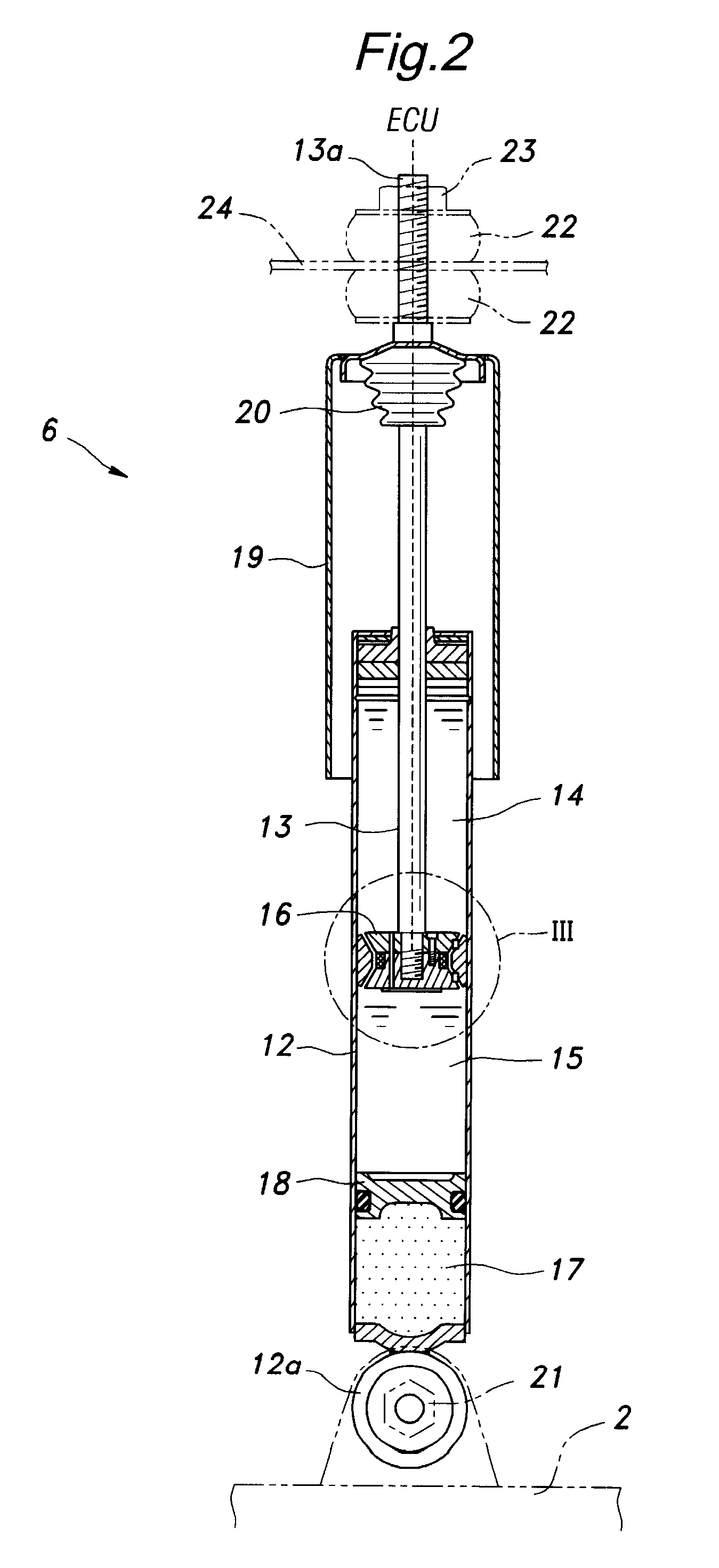

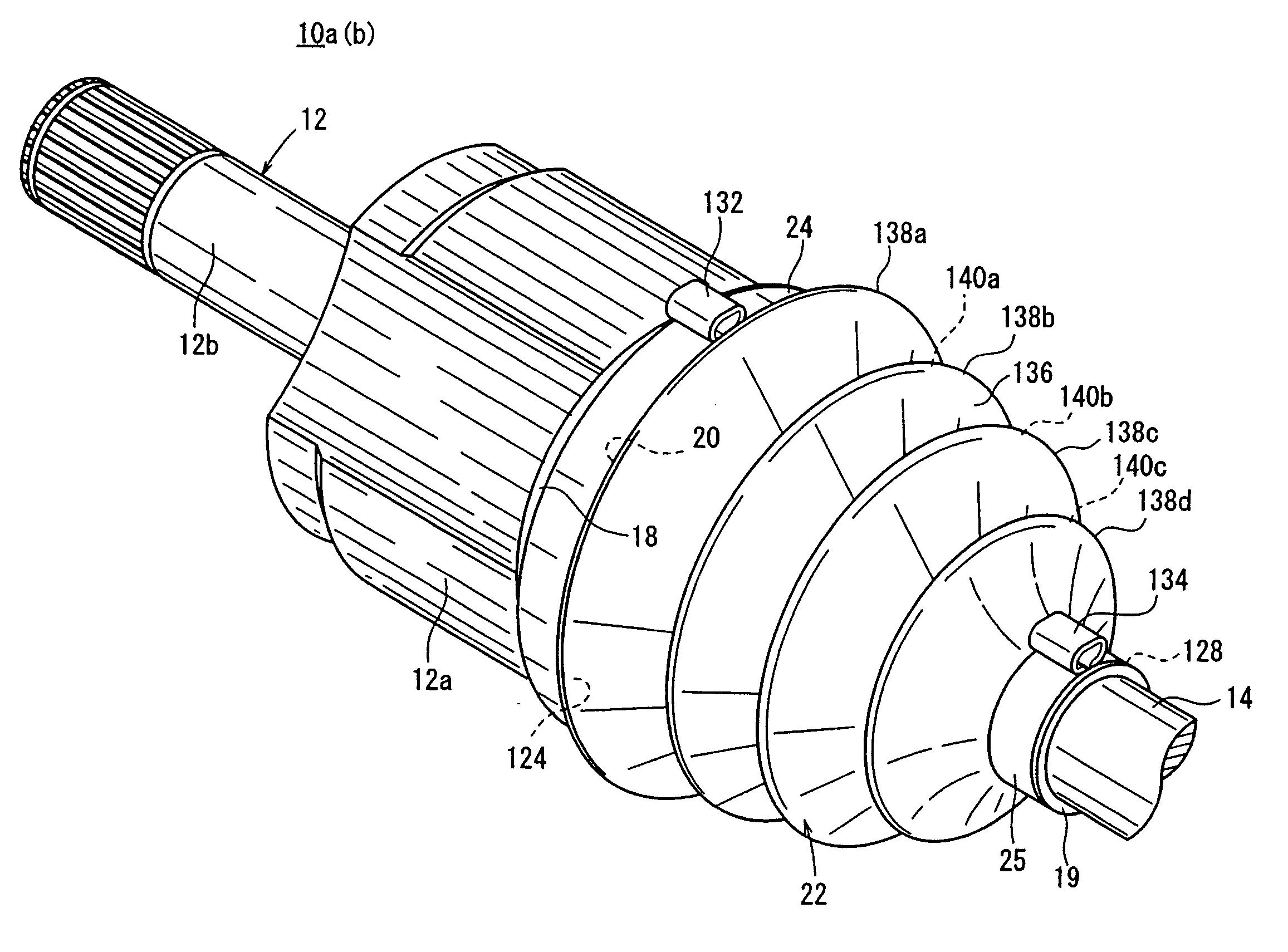

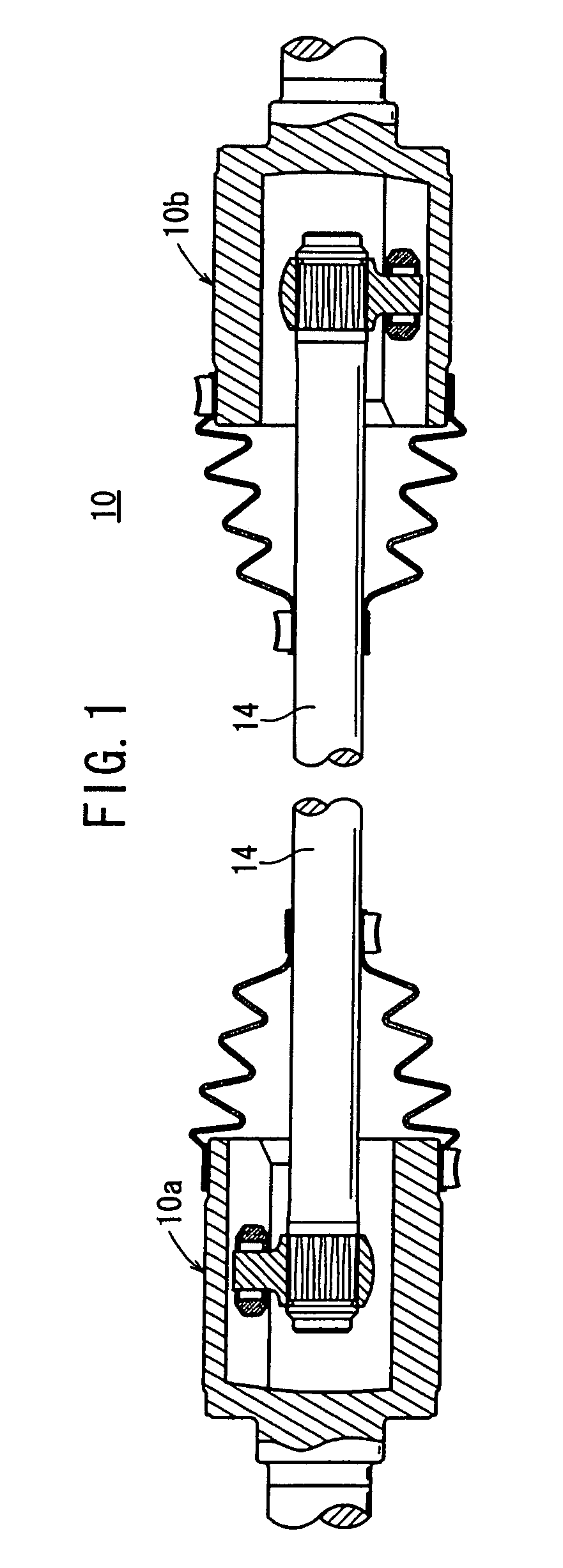

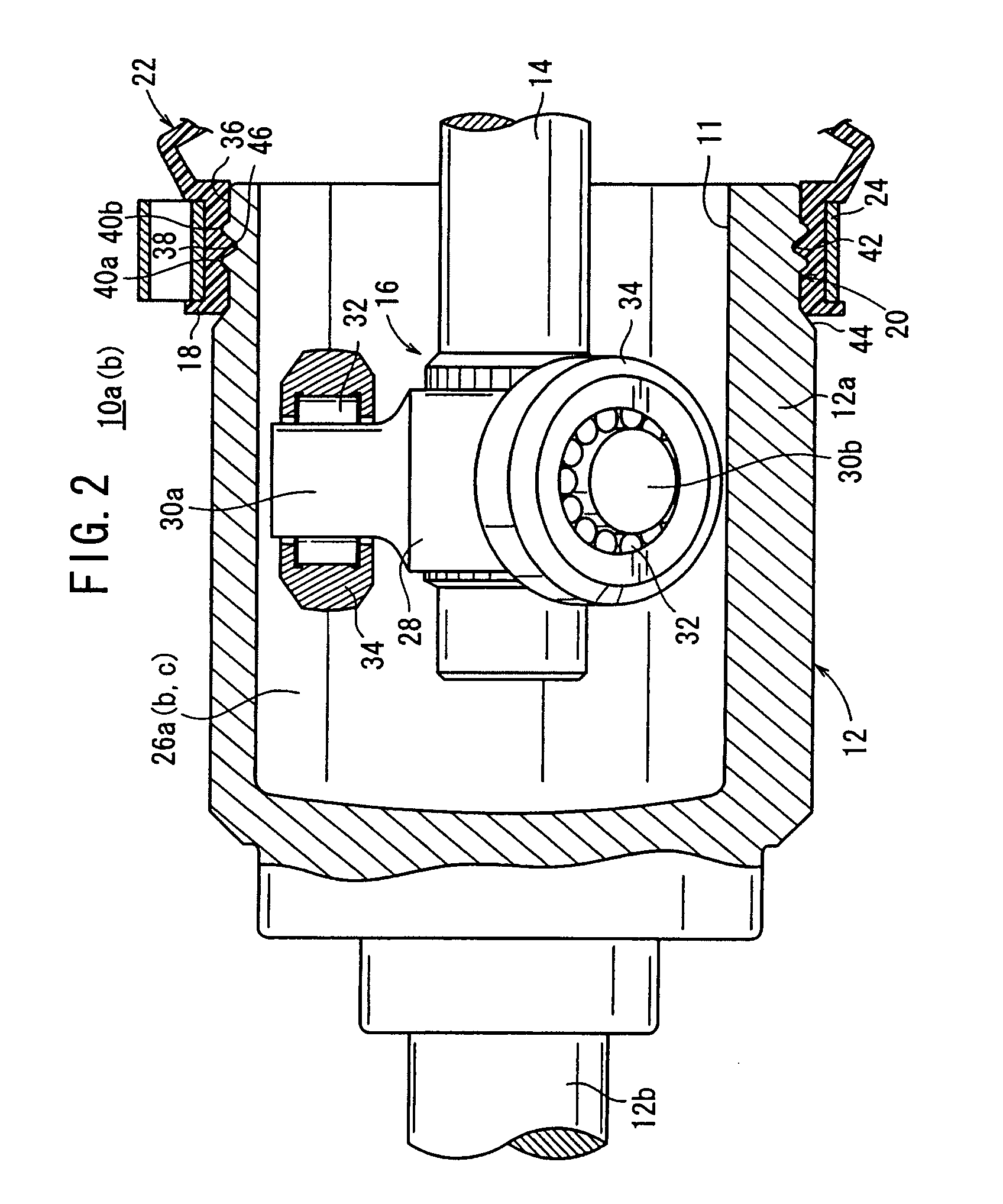

Variable damper

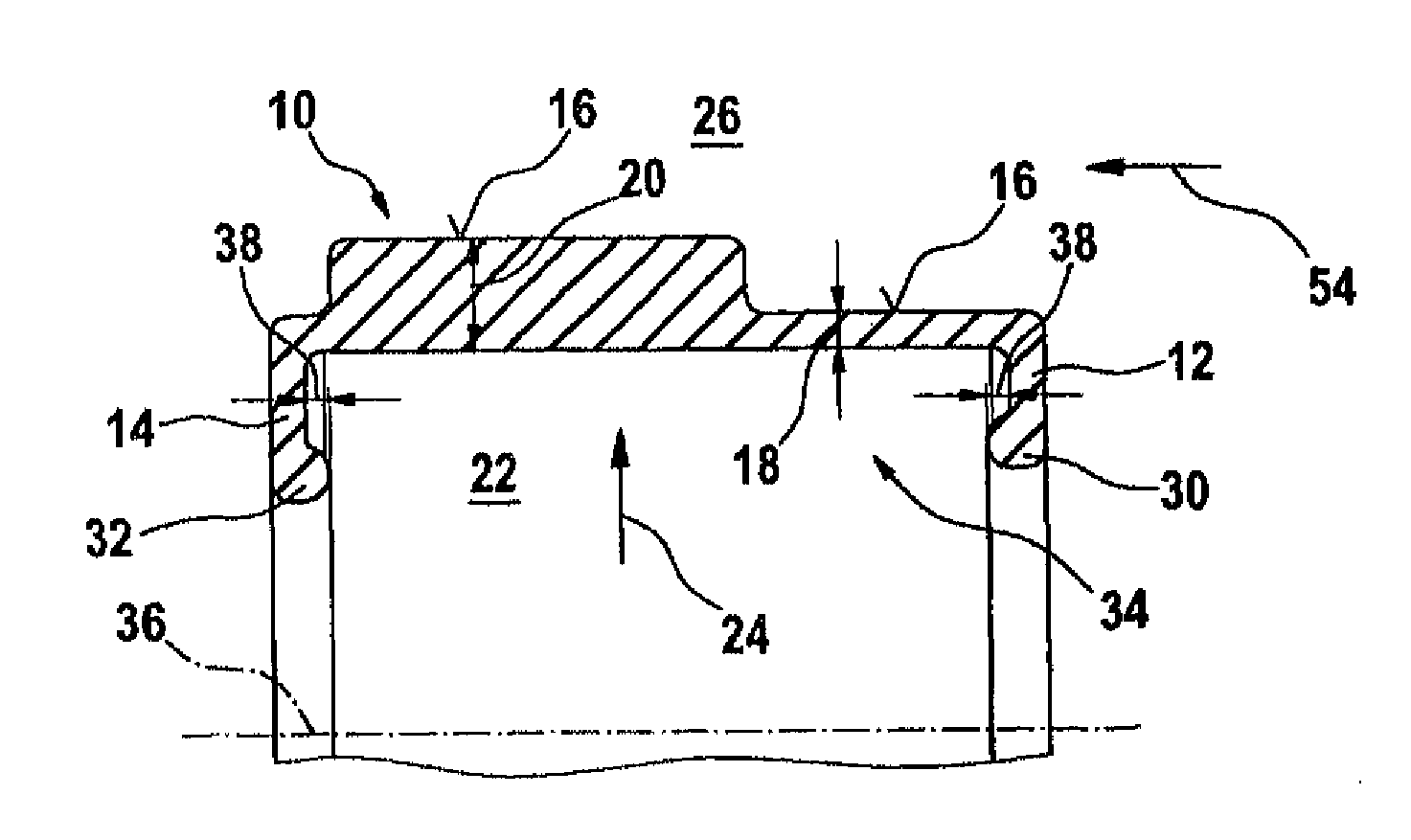

InactiveUS20080251982A1Compact designImprove damping performanceMachine framesNon-rotating vibration suppressionMagnetic valveControl theory

In a variable damper using magneto-rheological fluid that comprises a cylinder (12) filled with the fluid, a piston (16) slidably received in the cylinder and including an inner yoke (32; 62; 126), an outer yoke (31; 64, 65; 140) and a coil (34; 130), a piston rod (13) having an inner end attached to the piston and an outer end extending out of the cylinder and a magnetic valve formed in a gap between the inner and outer yokes, at least one of the outer yoke and inner yoke consisting of at least two parts that are joined to each other in an axial direction. The two piece arrangement of the inner yoke or outer yoke allows the end plates to be omitted because the gap spacer can be installed without requiring end plates, and this contributes to a compact design and a favorable damping property. Also, the manufacturing and servicing of the damper can be simplified. When end plates (134) are used, the freedom in the positioning of the coil is increased.

Owner:HONDA MOTOR CO LTD

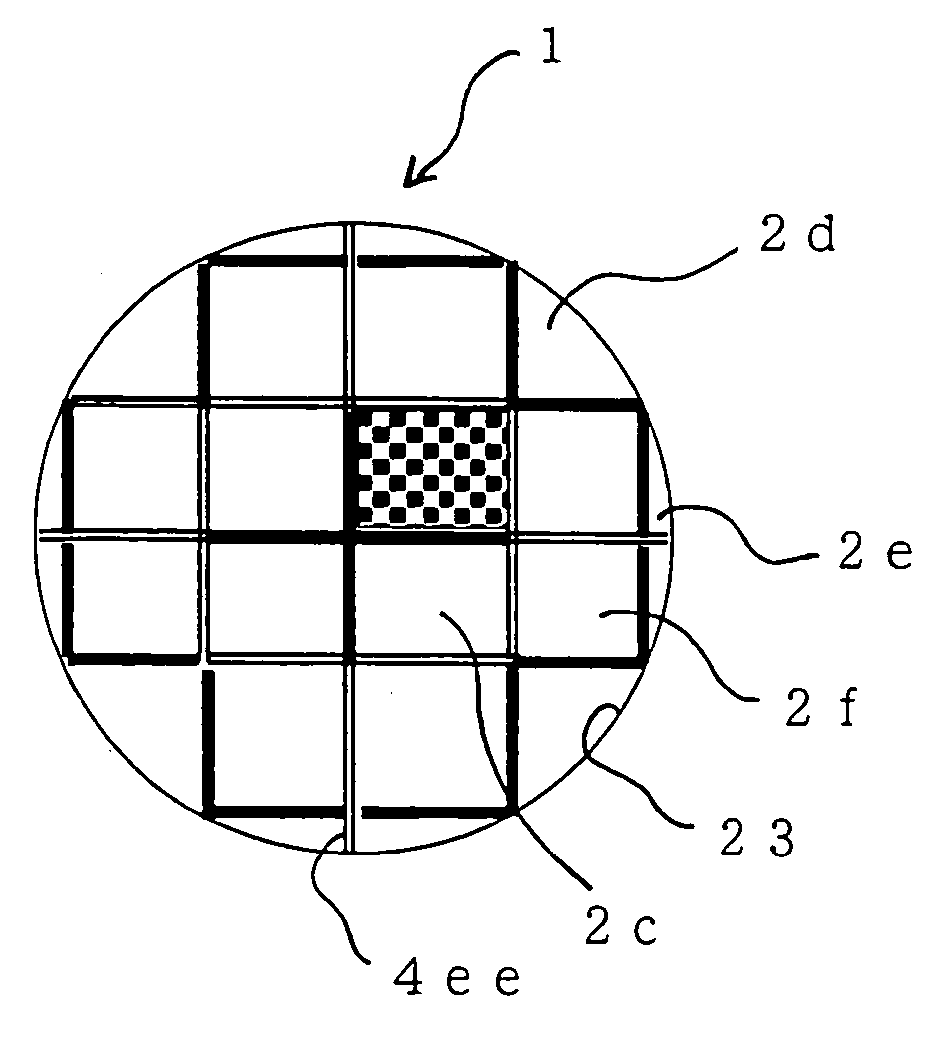

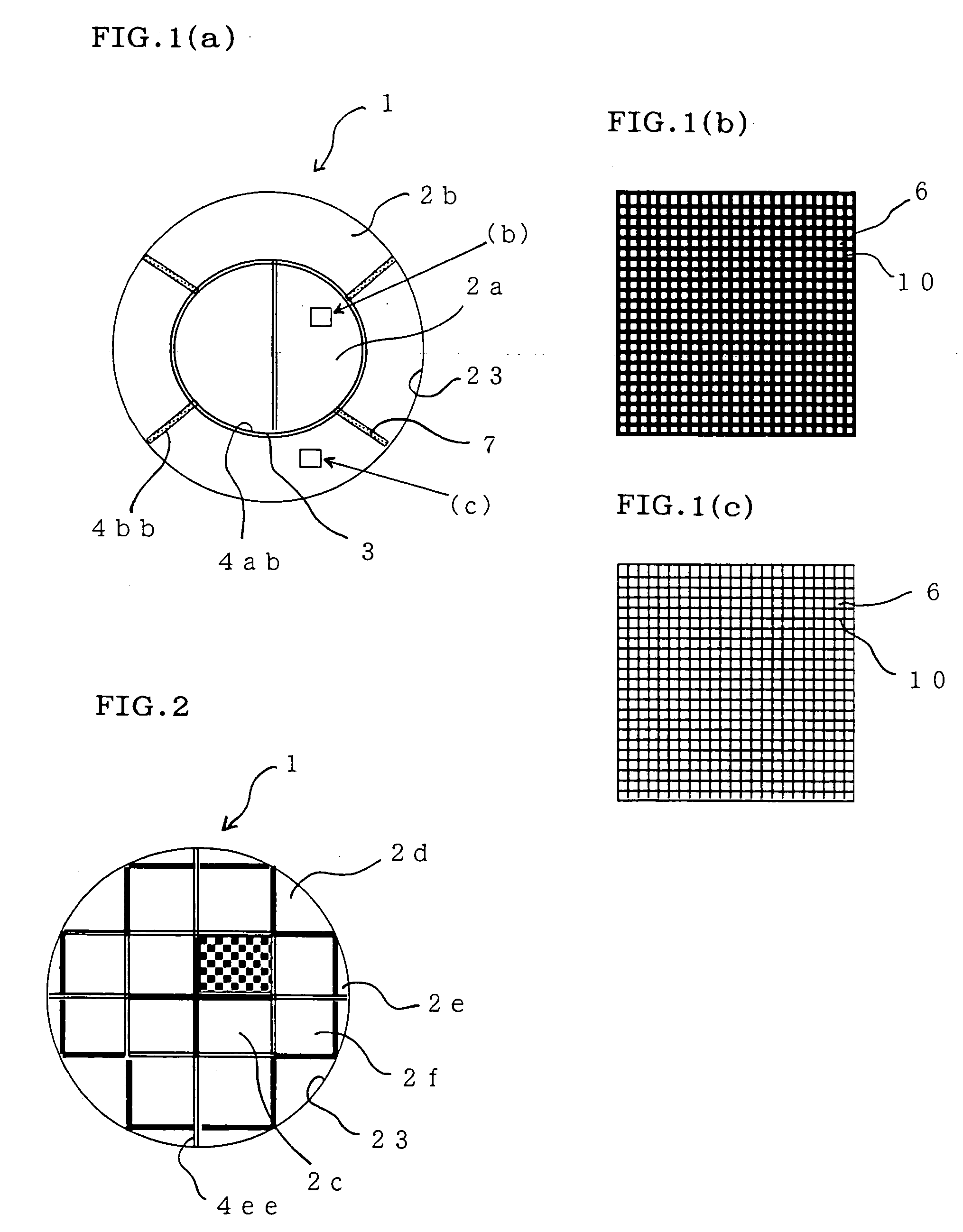

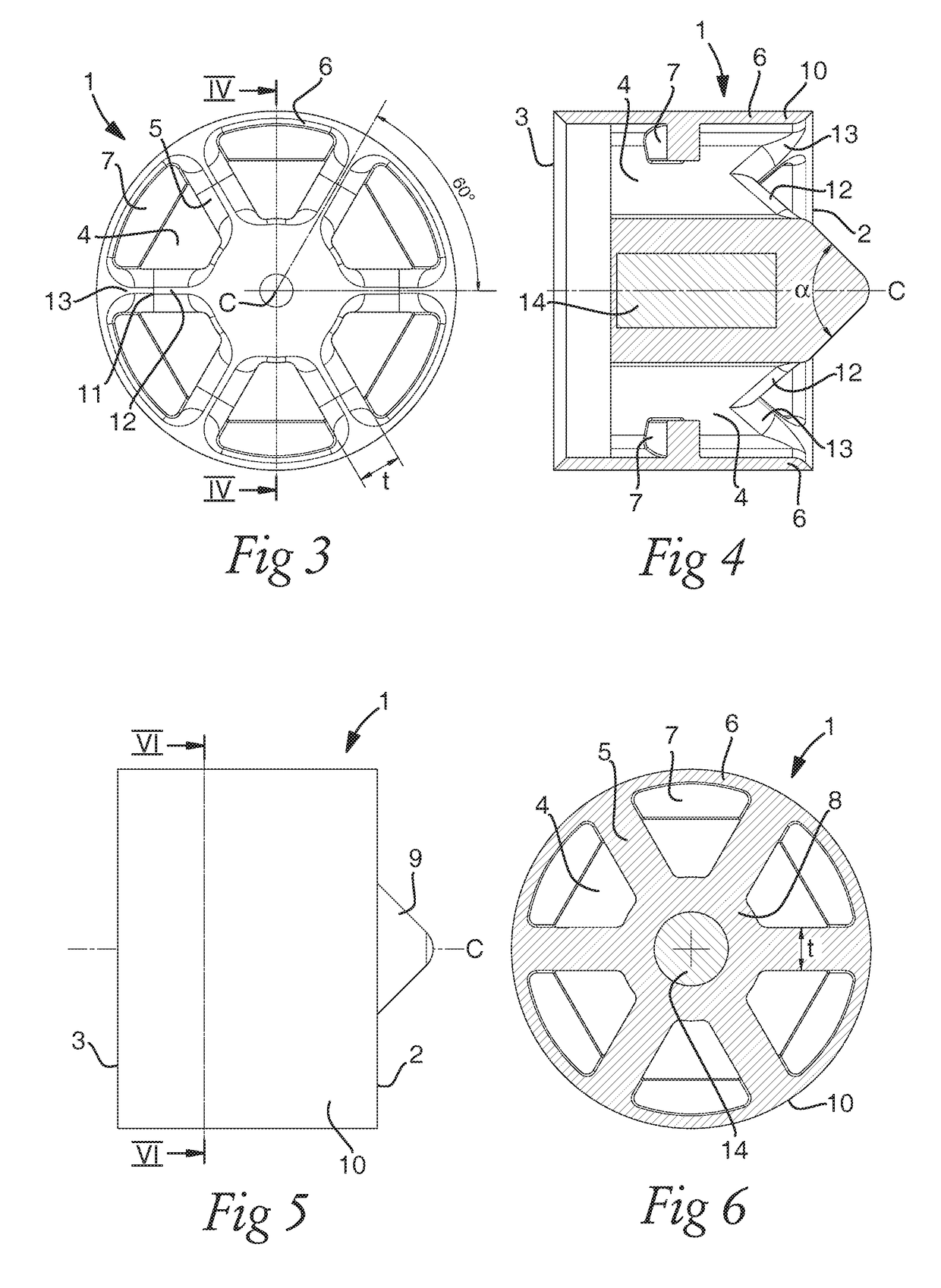

Honeycomb structural body and assembly thereof

InactiveUS20040076794A1Low efficiencySuppressing temperature increaseCombination devicesCatalyst protectionHoneycomb structureMetal

A honeycomb structural body (1) is obtained by bonding, into one piece, a plurality of honeycomb segments (2a, 2b) having a large number of through-holes (6) surrounded by partition walls (10) and extending in the axial direction. An average wall thickness of at least one honeycomb segment (2a) not constituting the outermost peripheral surface (23) of the honeycomb structural body is larger than an average wall thickness of at least one honeycomb segment (2b) constituting the outermost peripheral surface (23) of the honeycomb structural body. A honeycomb structural assembly is obtained by providing a material B having compressive elasticity on the outermost peripheral surface (23) of the honeycomb structural body (1) in a compressed state and thereby compression-holding the honeycomb structural body (1) in a metallic container. The honeycomb structural body and assembly are low in reductions in the conversion rate, purification efficiency, regeneration efficiency, etc. during the use and superior in durability against the breakage caused by thermal stress.

Owner:NGK INSULATORS LTD

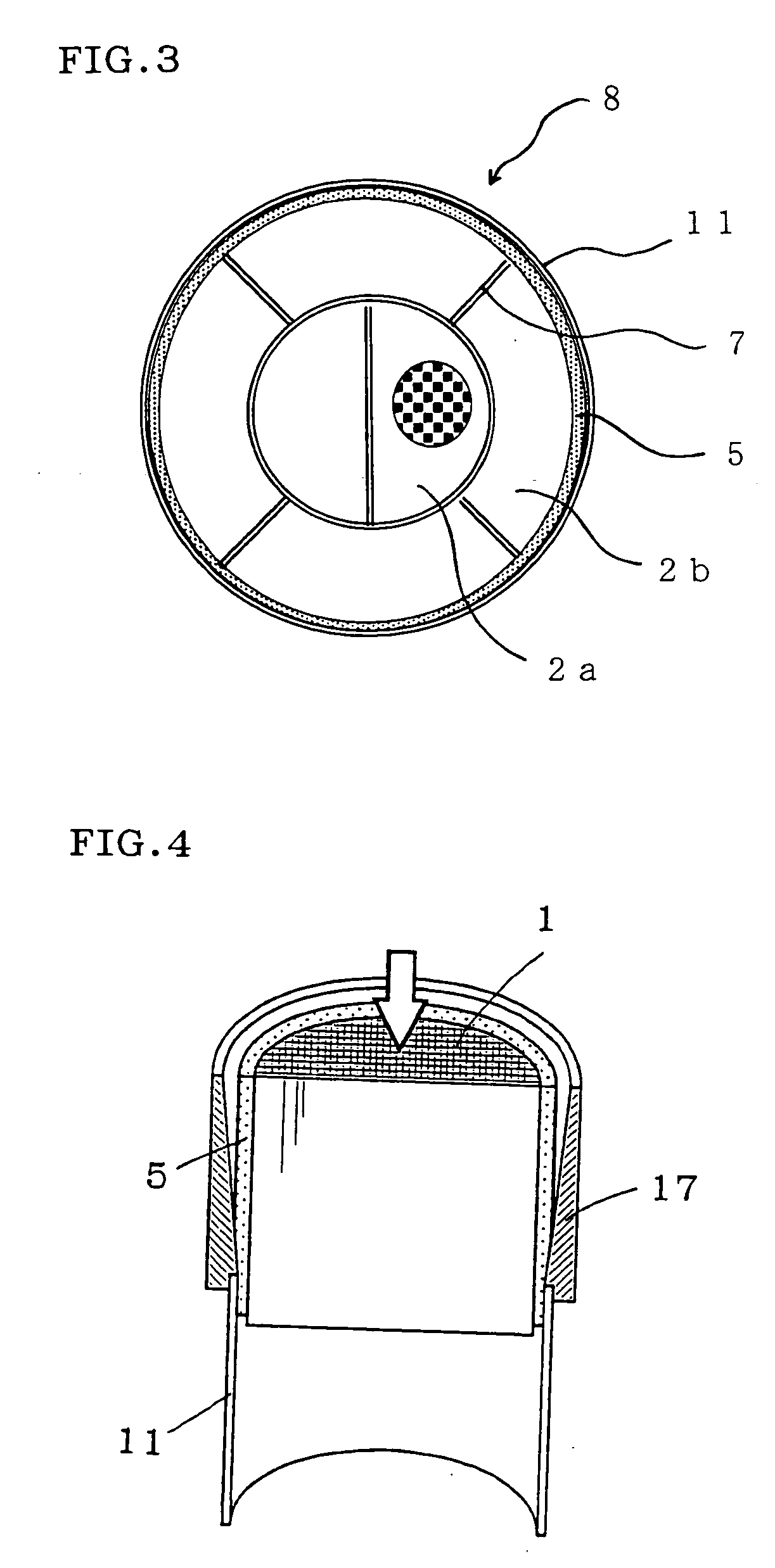

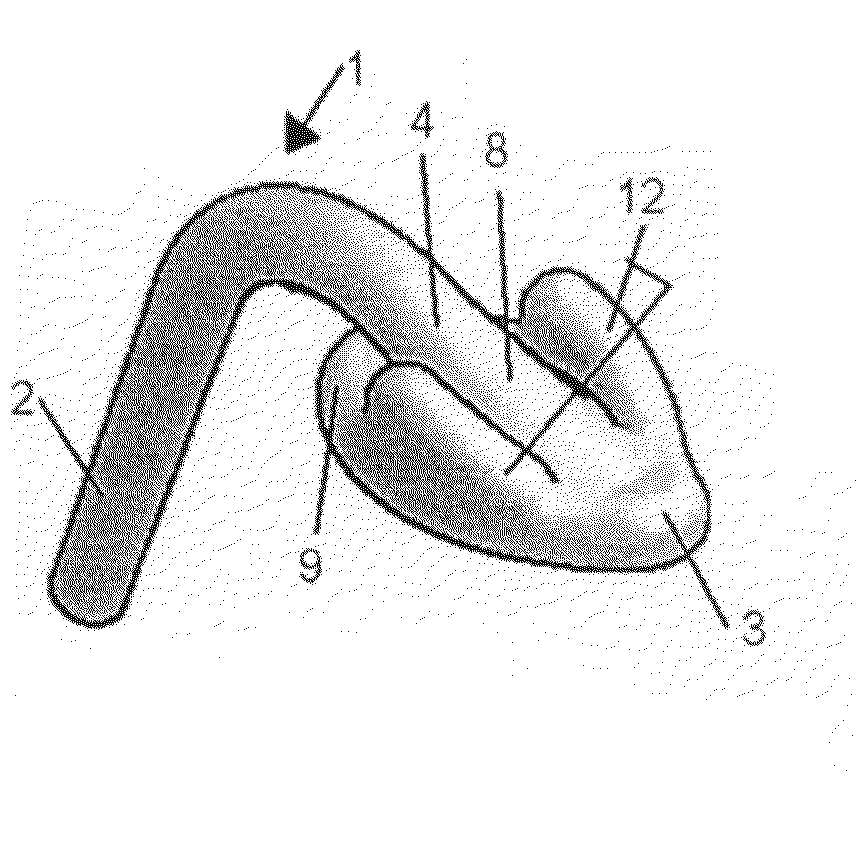

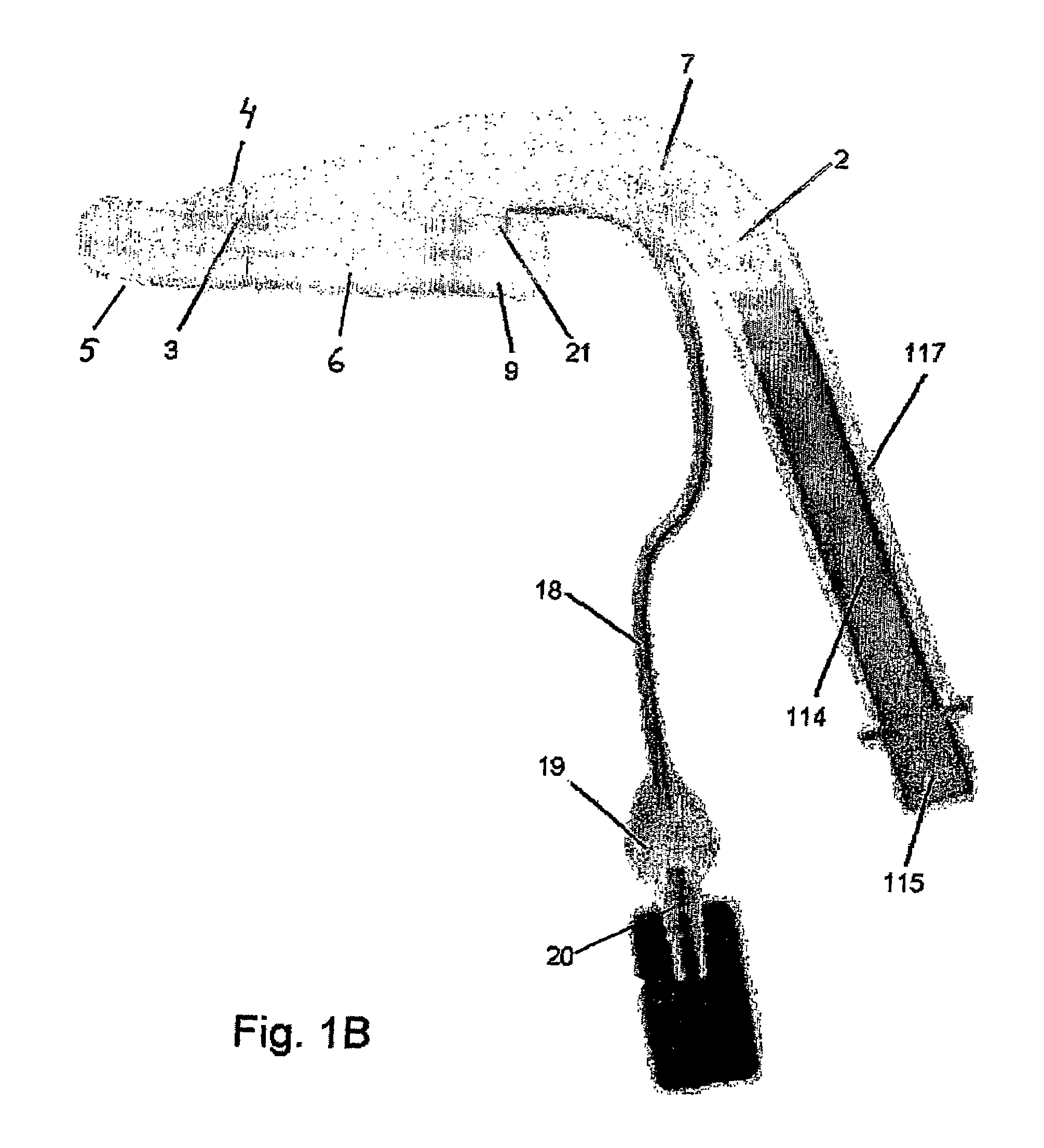

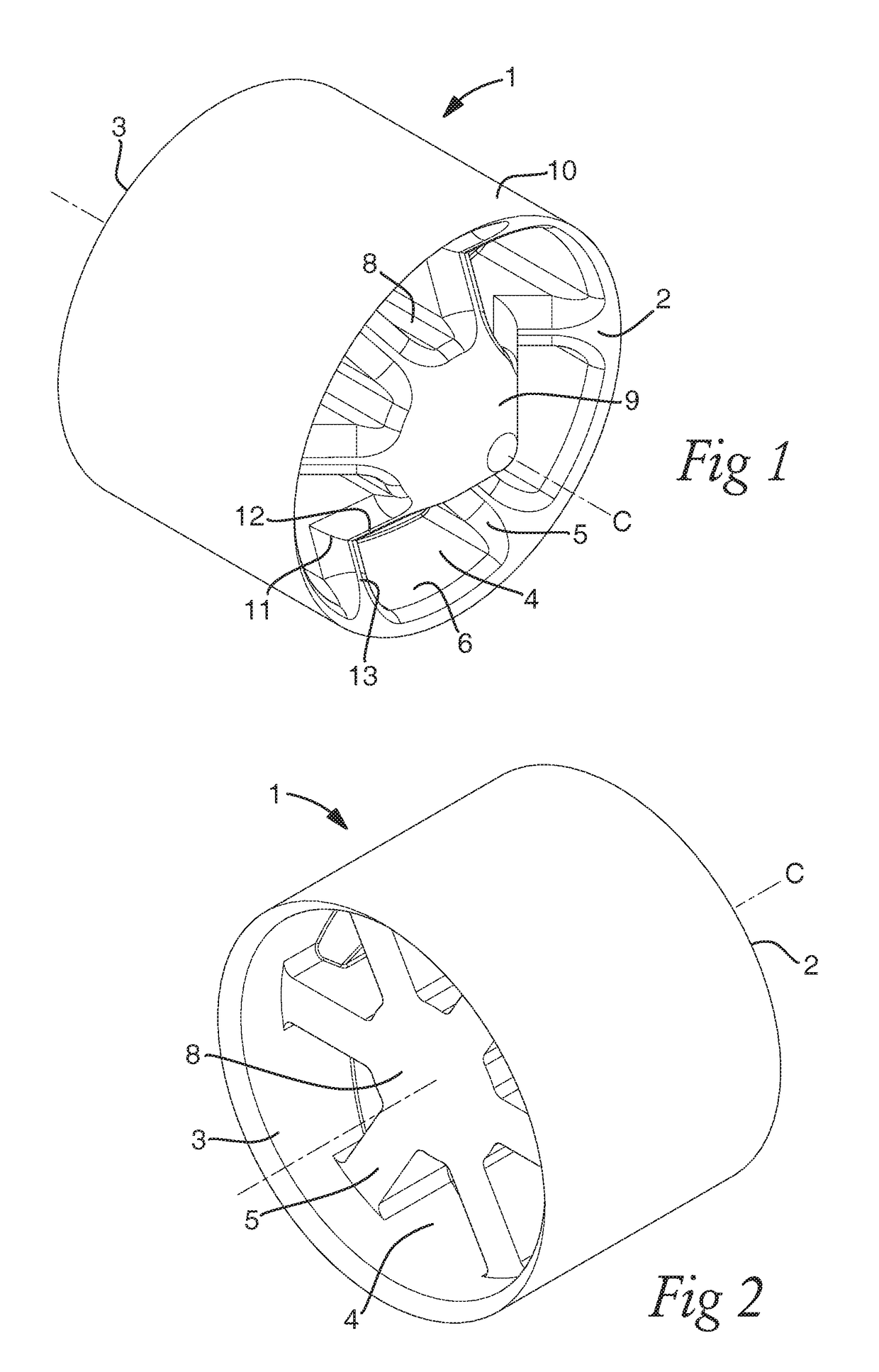

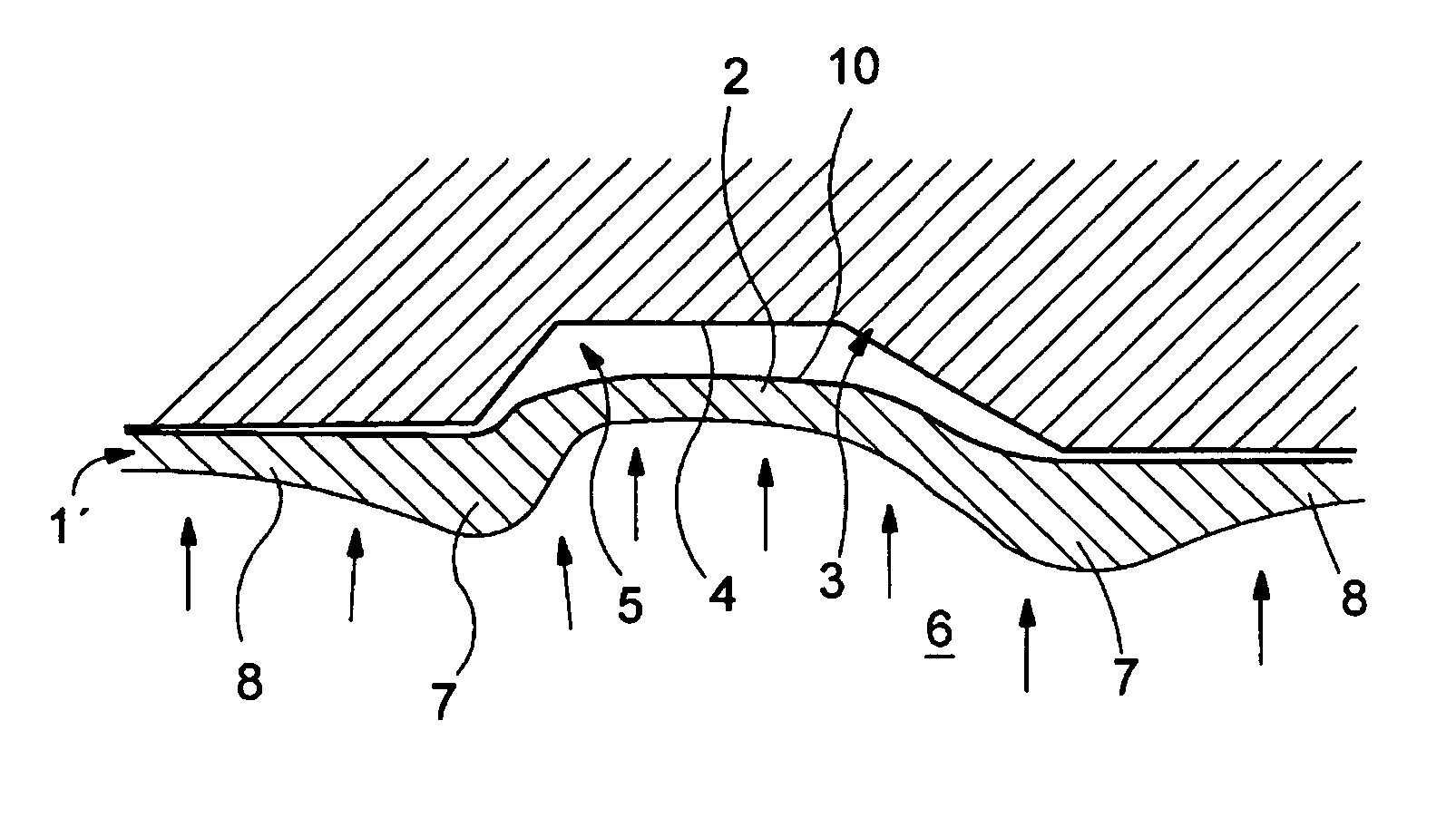

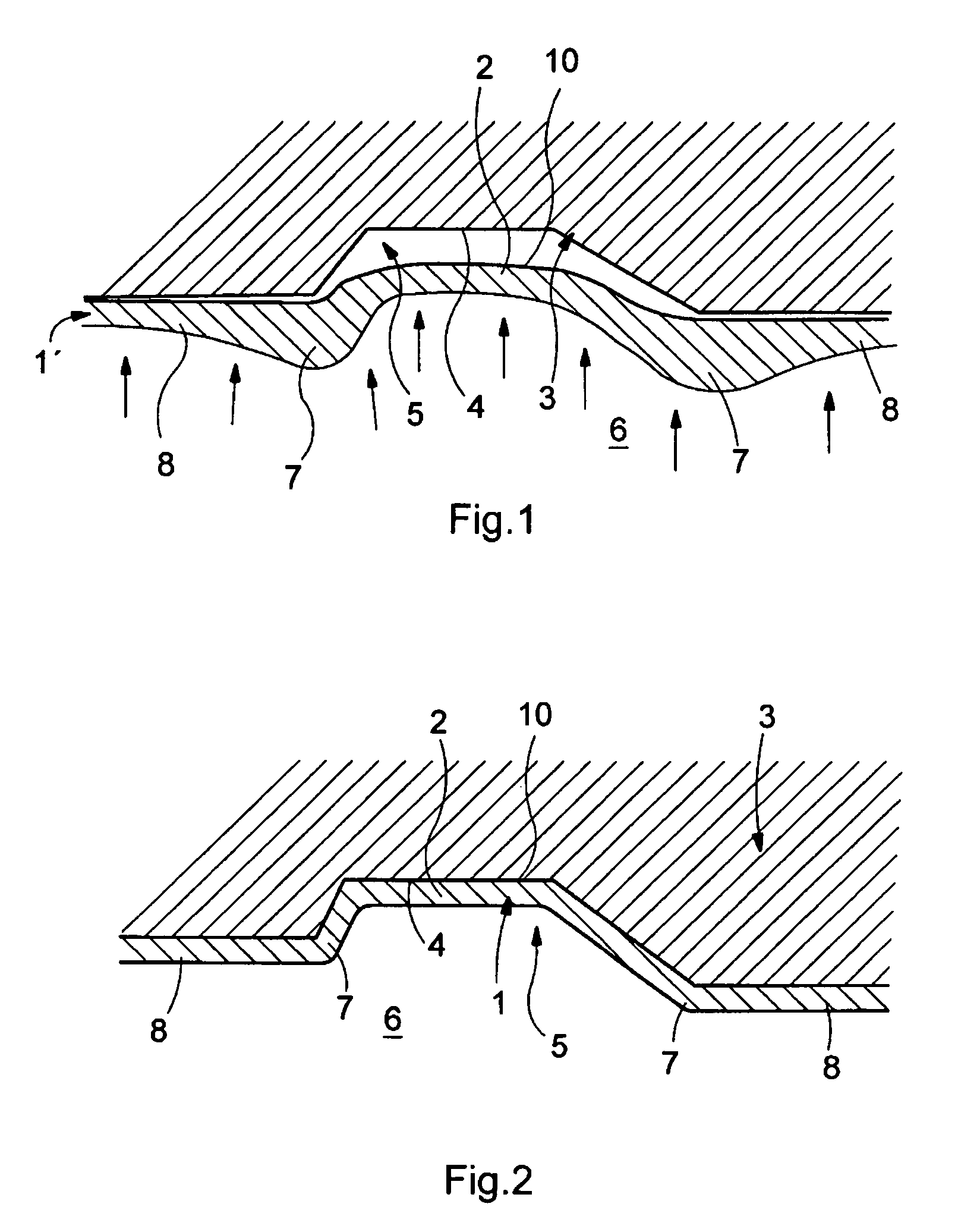

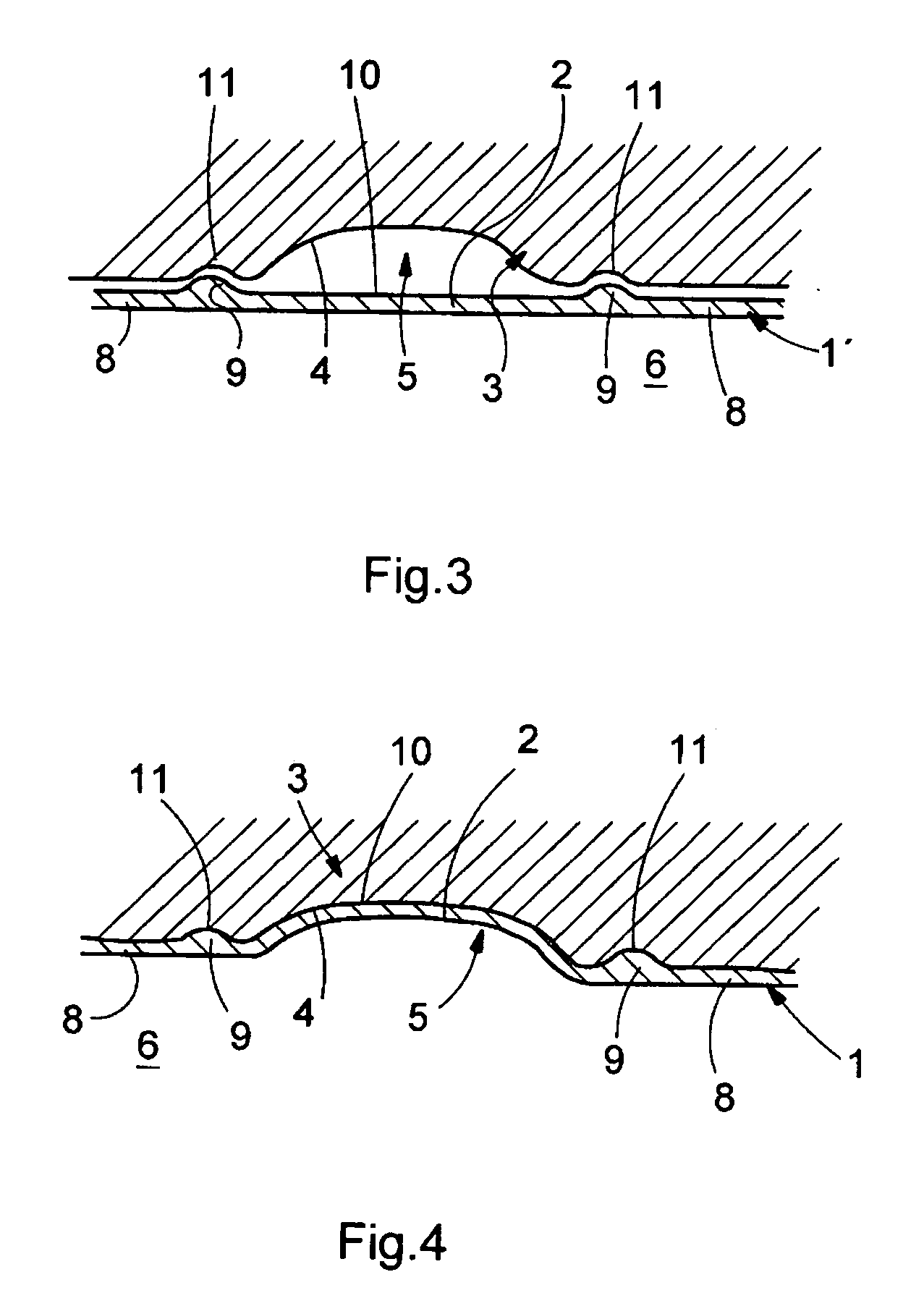

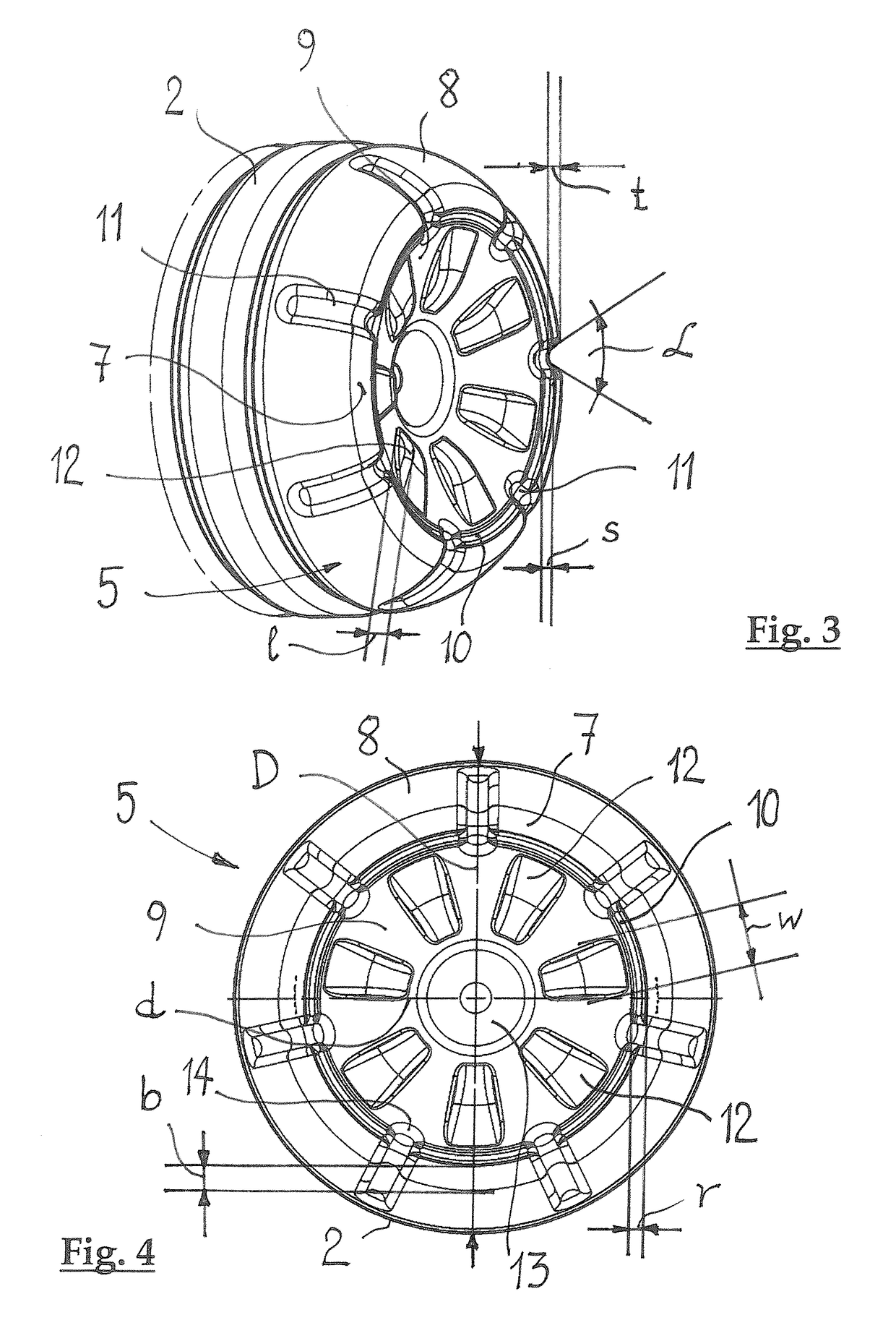

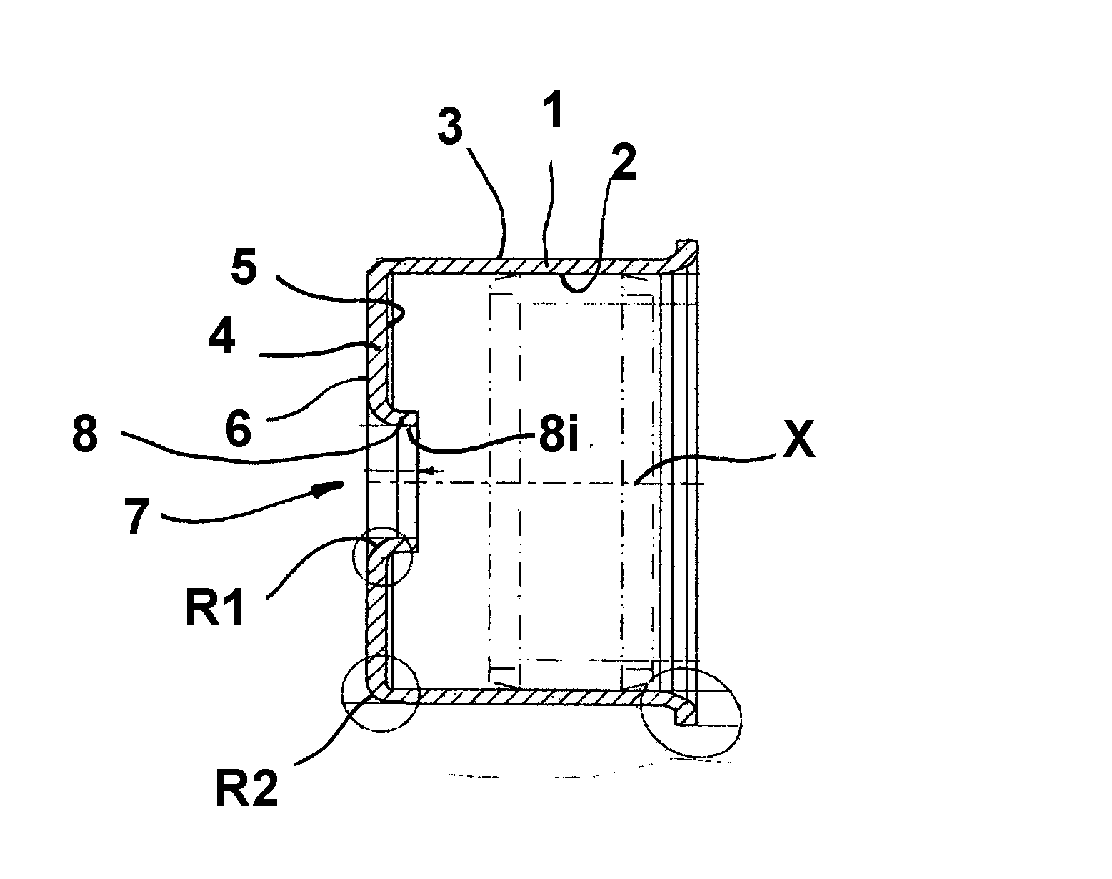

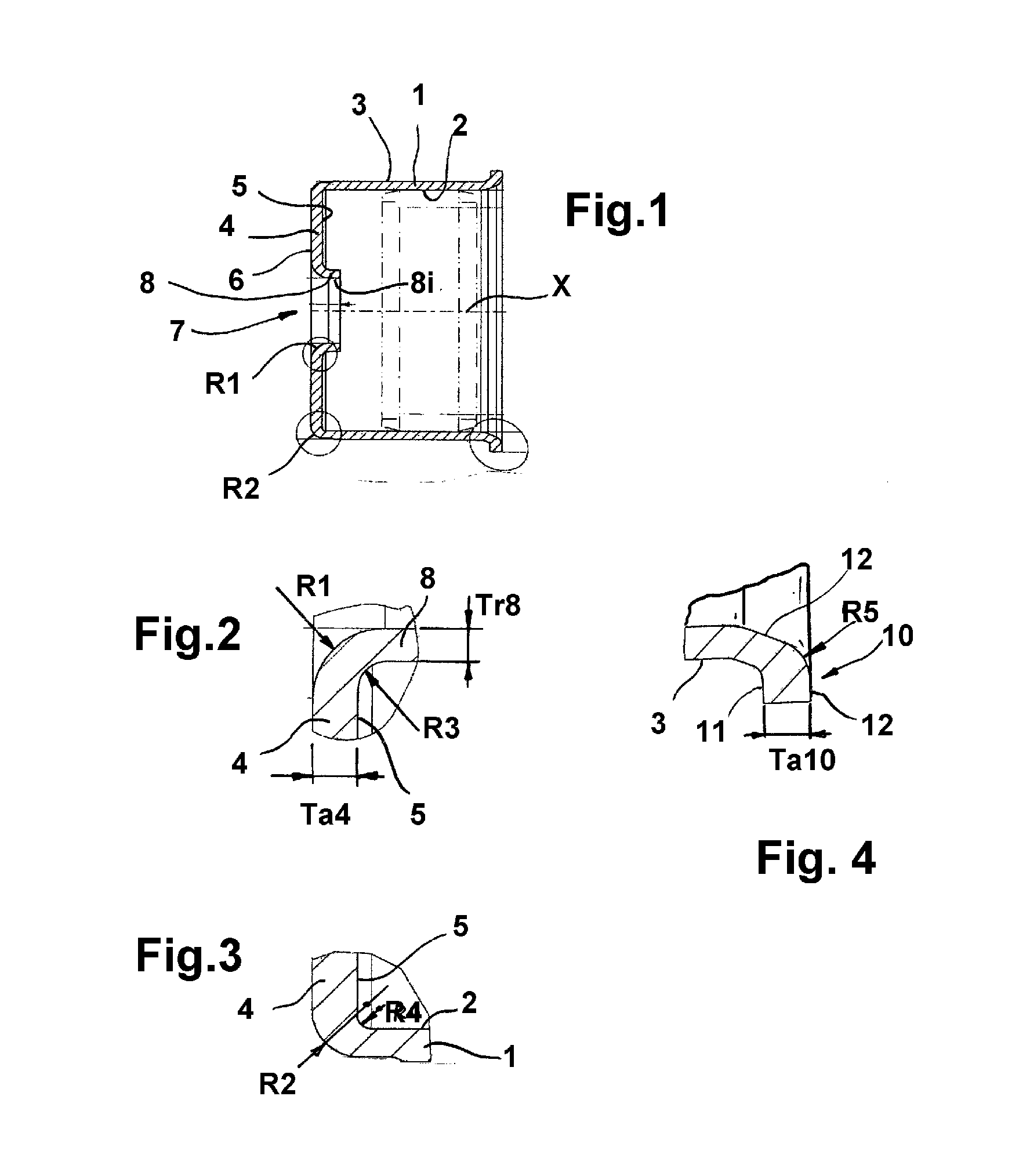

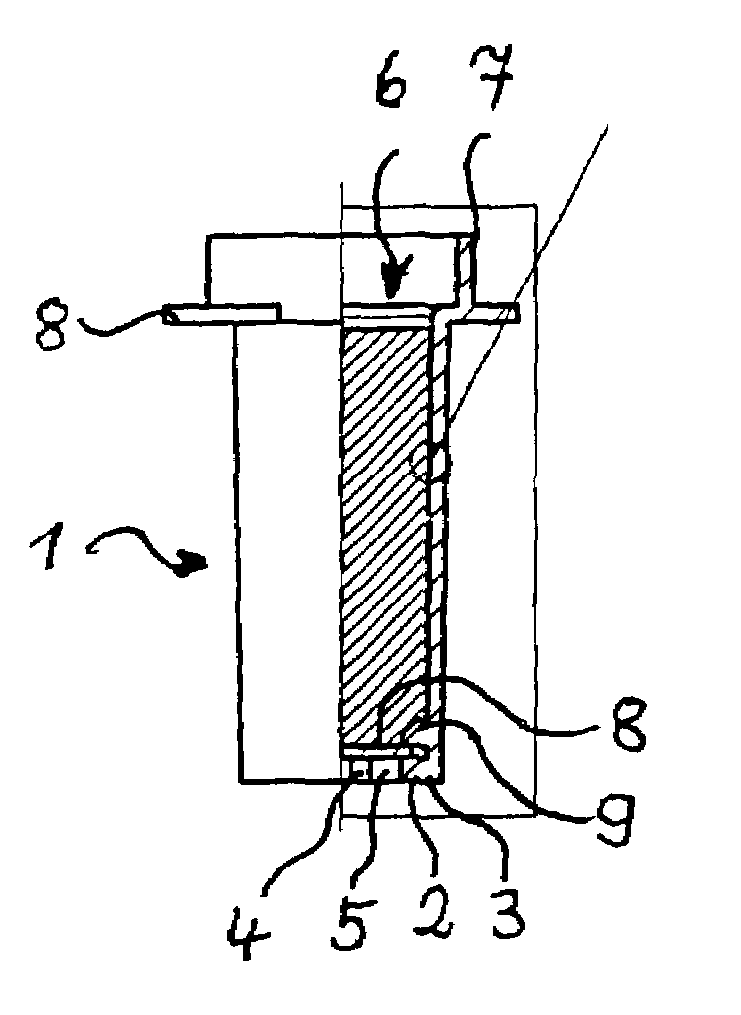

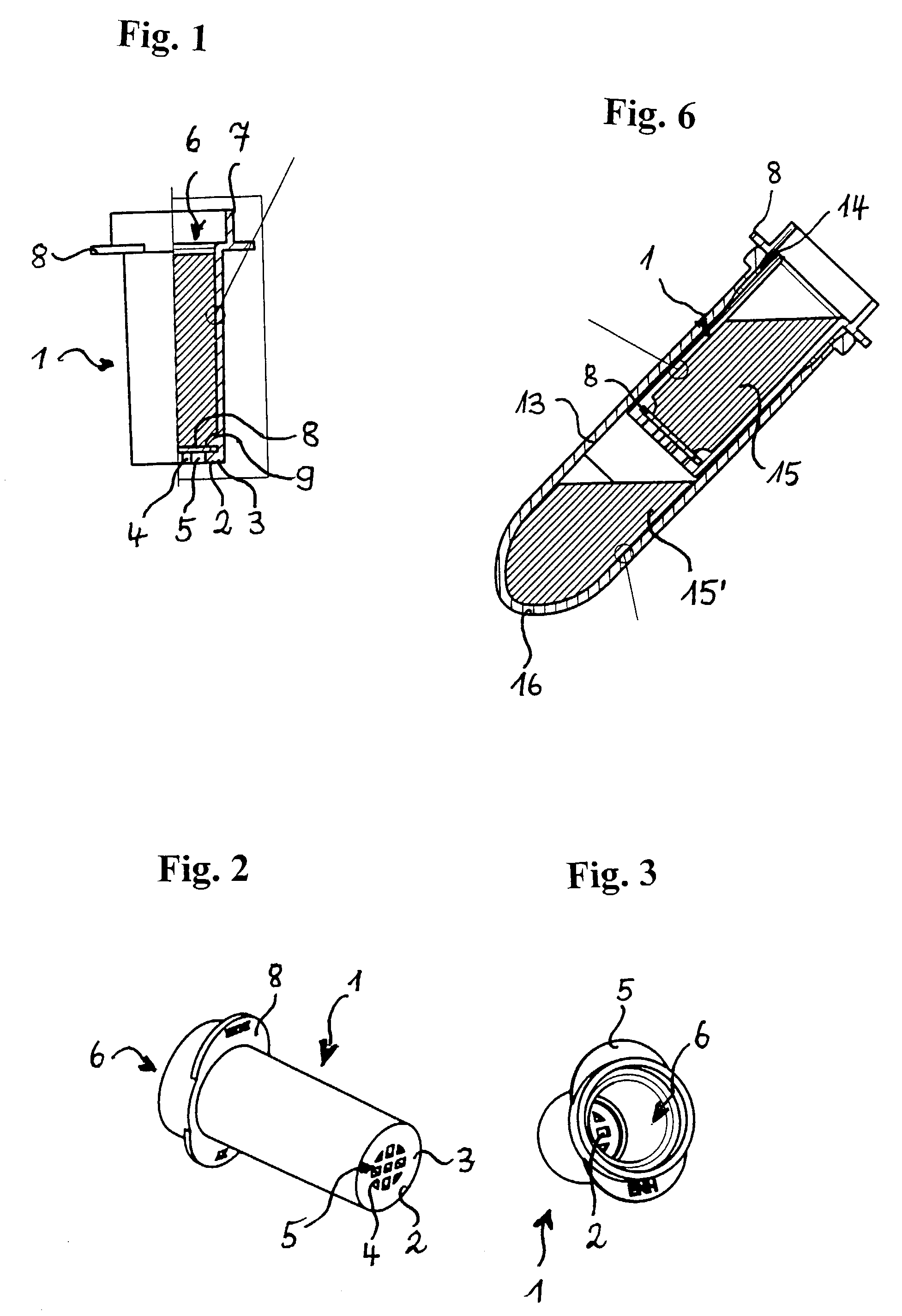

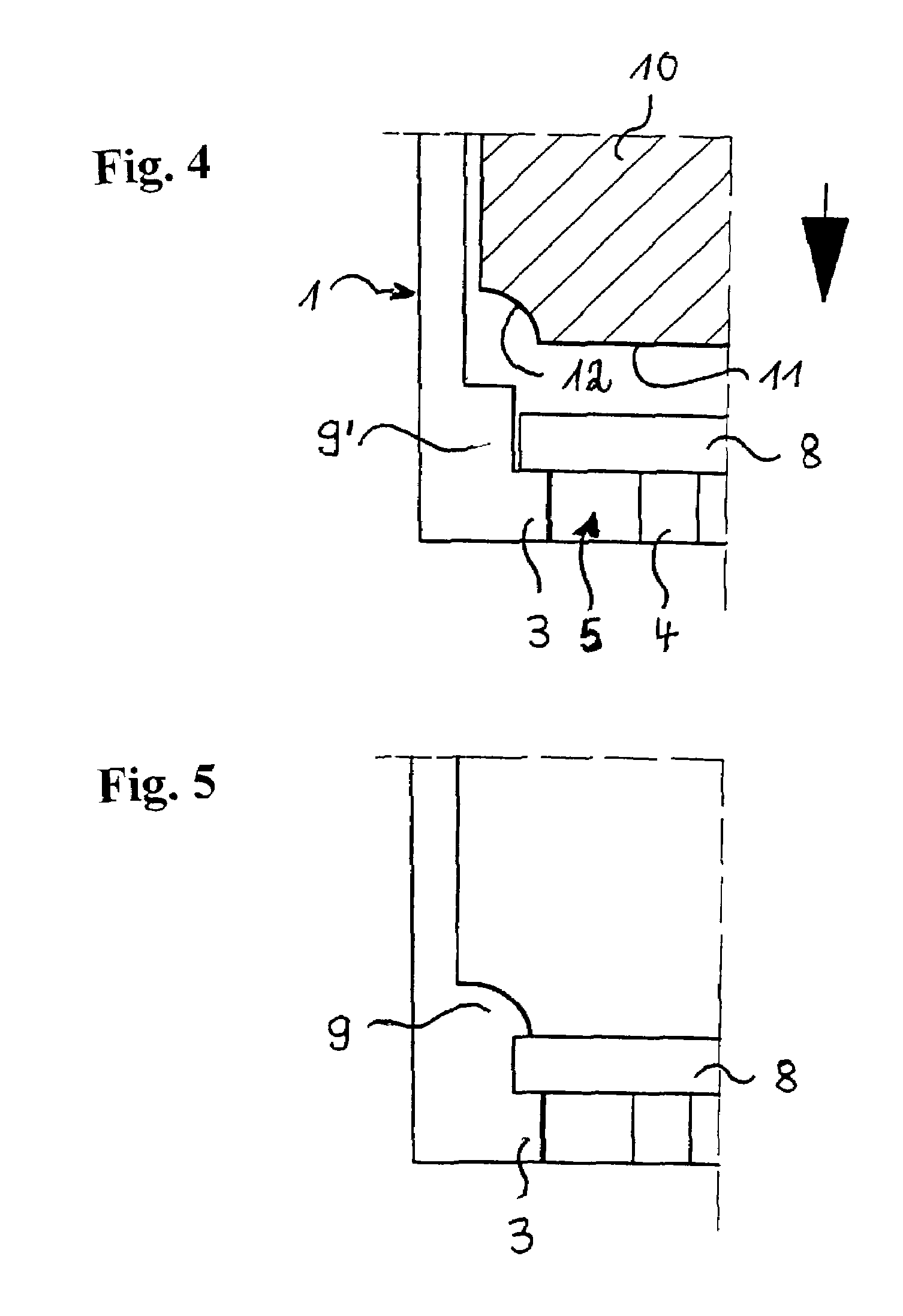

Laryngeal mask and a method manufacturing same

ActiveUS7694682B2Increasing the thicknessThin wallTracheal tubesBreathing masksLaryngeal MasksEngineering

The invention relates to a laryngeal mask (1) comprising at least one airway tube (2) and a mask portion (3), which mask portion (3) comprises a top face (4) and a bottom face (5), said bottom face (5) comprising a lumen (6) that communicates with the tube (2) interior (7), and said top face (4) comprising a closed transition face (8), and said mask portion (3) being at least on the bottom face in the periphery delimited by an inflatable cuff (9), and said mask portion (3) comprising a joint throughout the entire internal circumference of the cuff (9), facing towards the lumen (6) and for providing a closed cuff. Hereby a product is provided which is formed integrally with regard to mask portion and airway tube portion thereby eliminating the risk that the two parts are separated in use.

Owner:AMBU AS

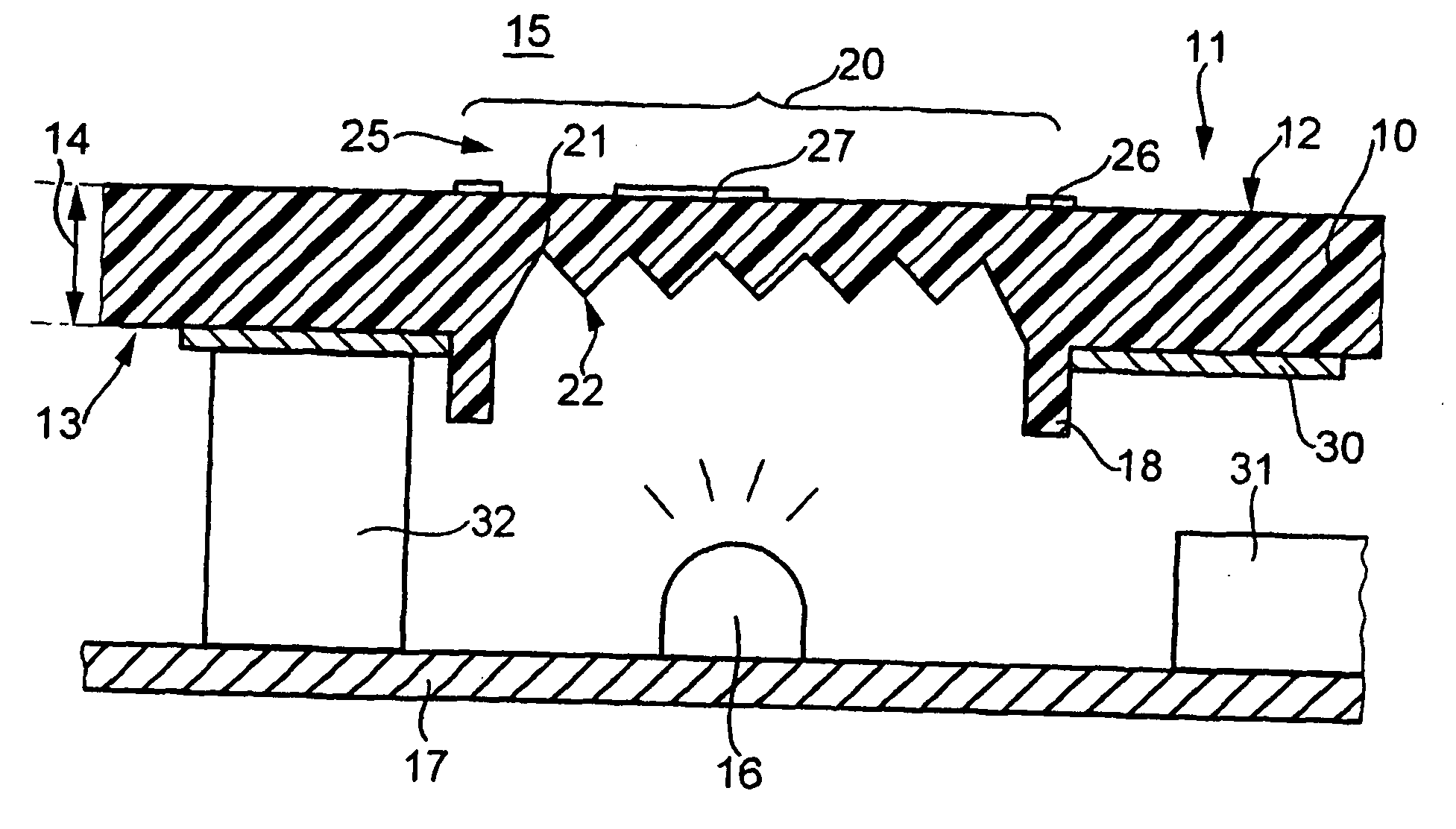

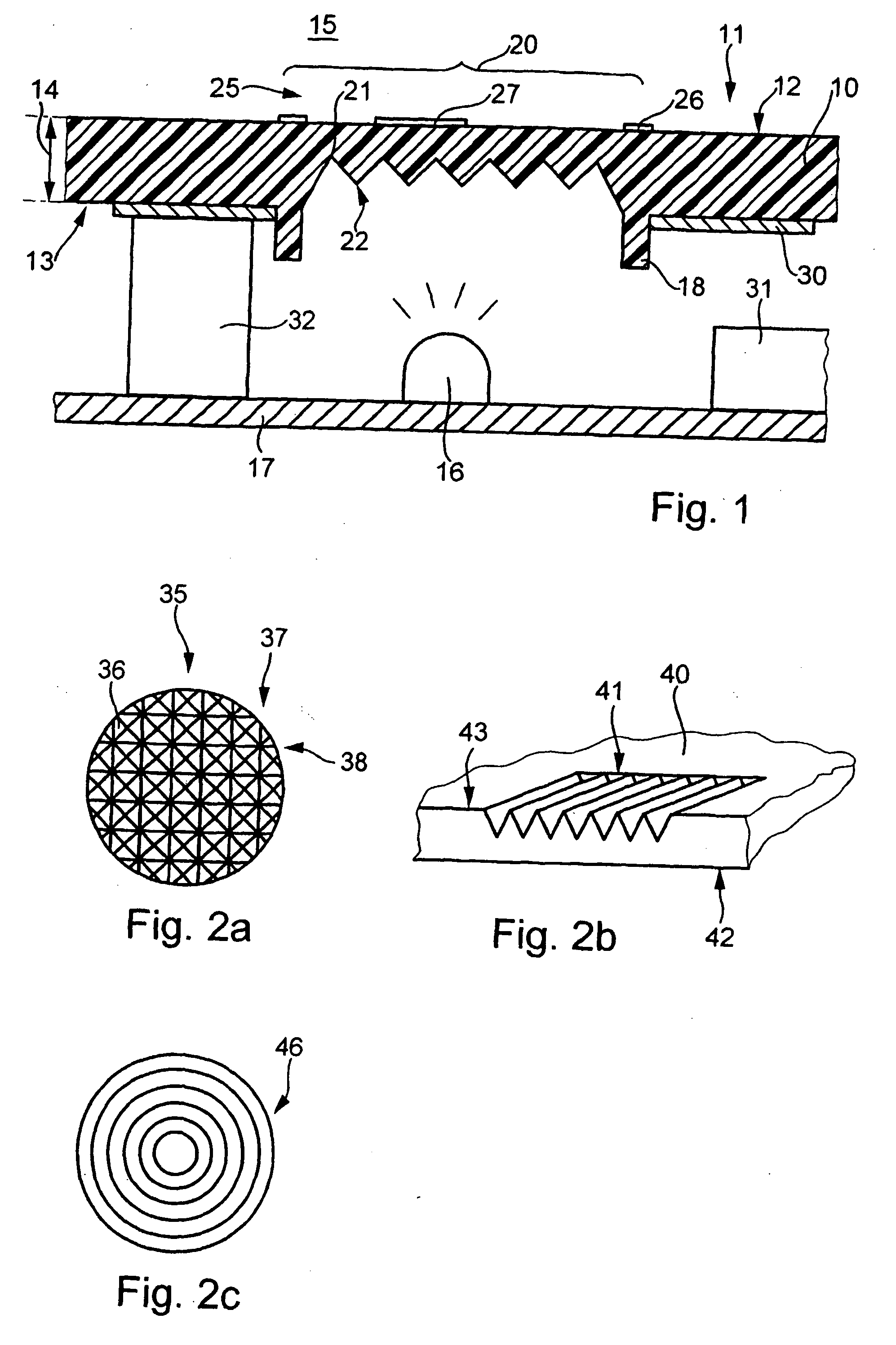

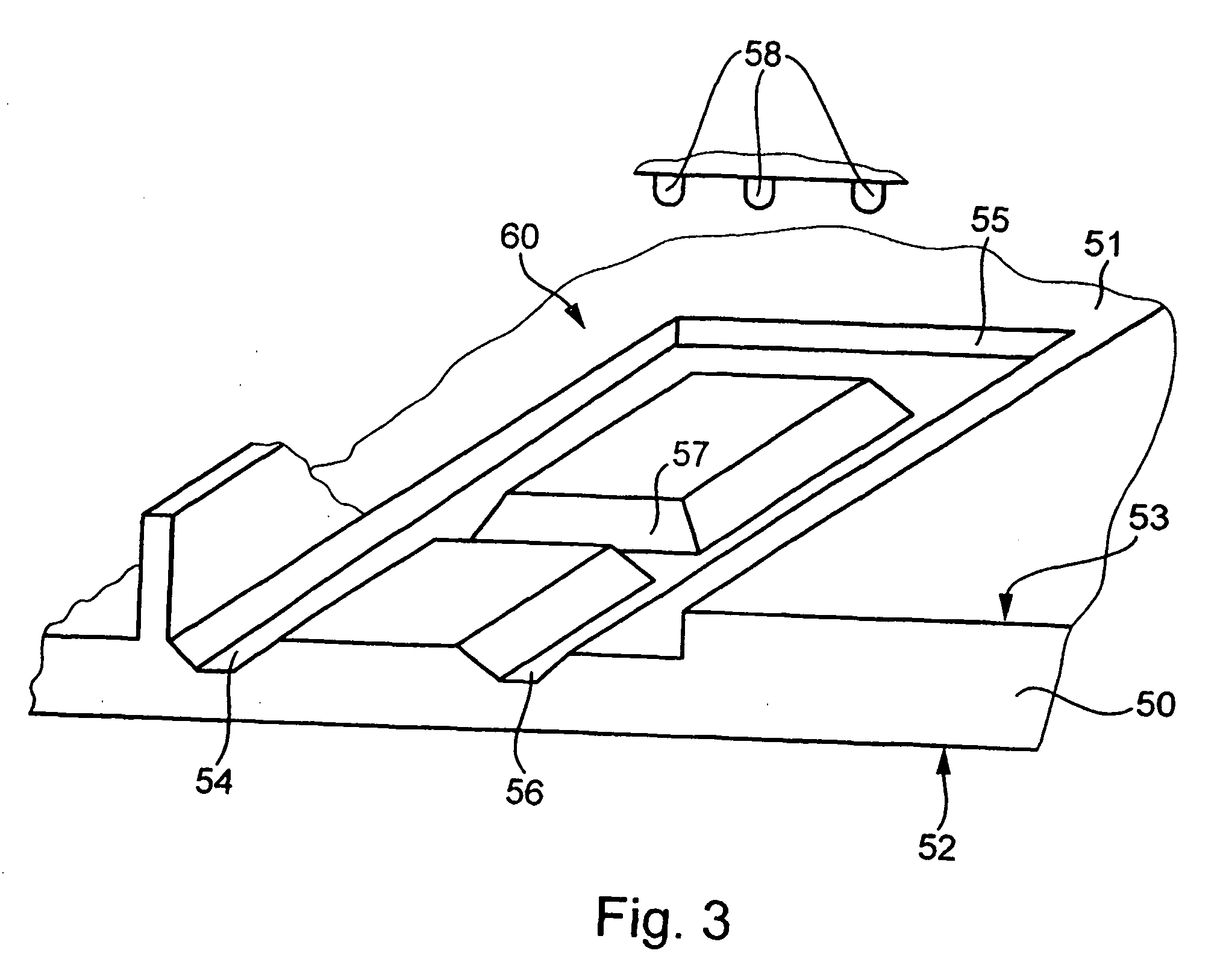

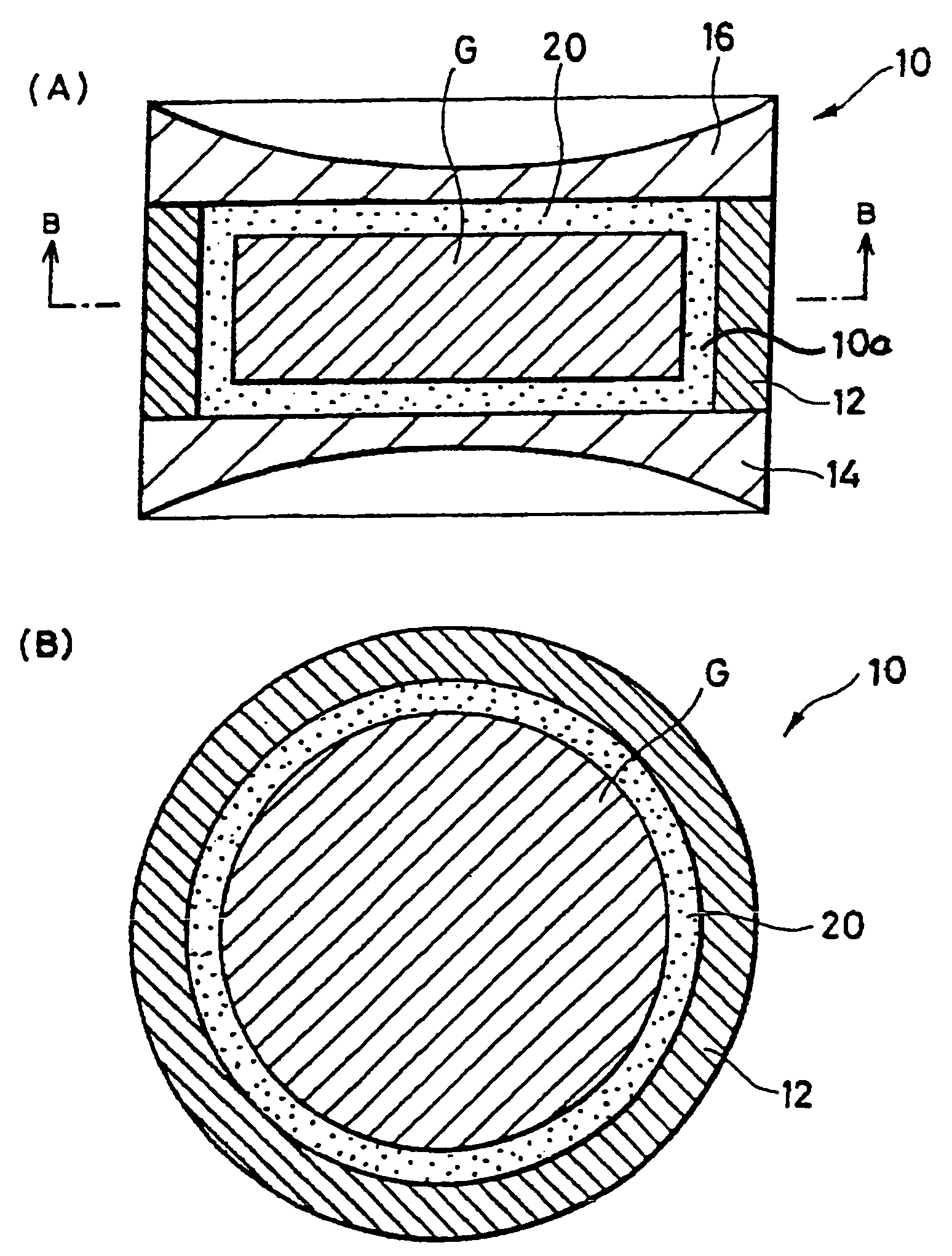

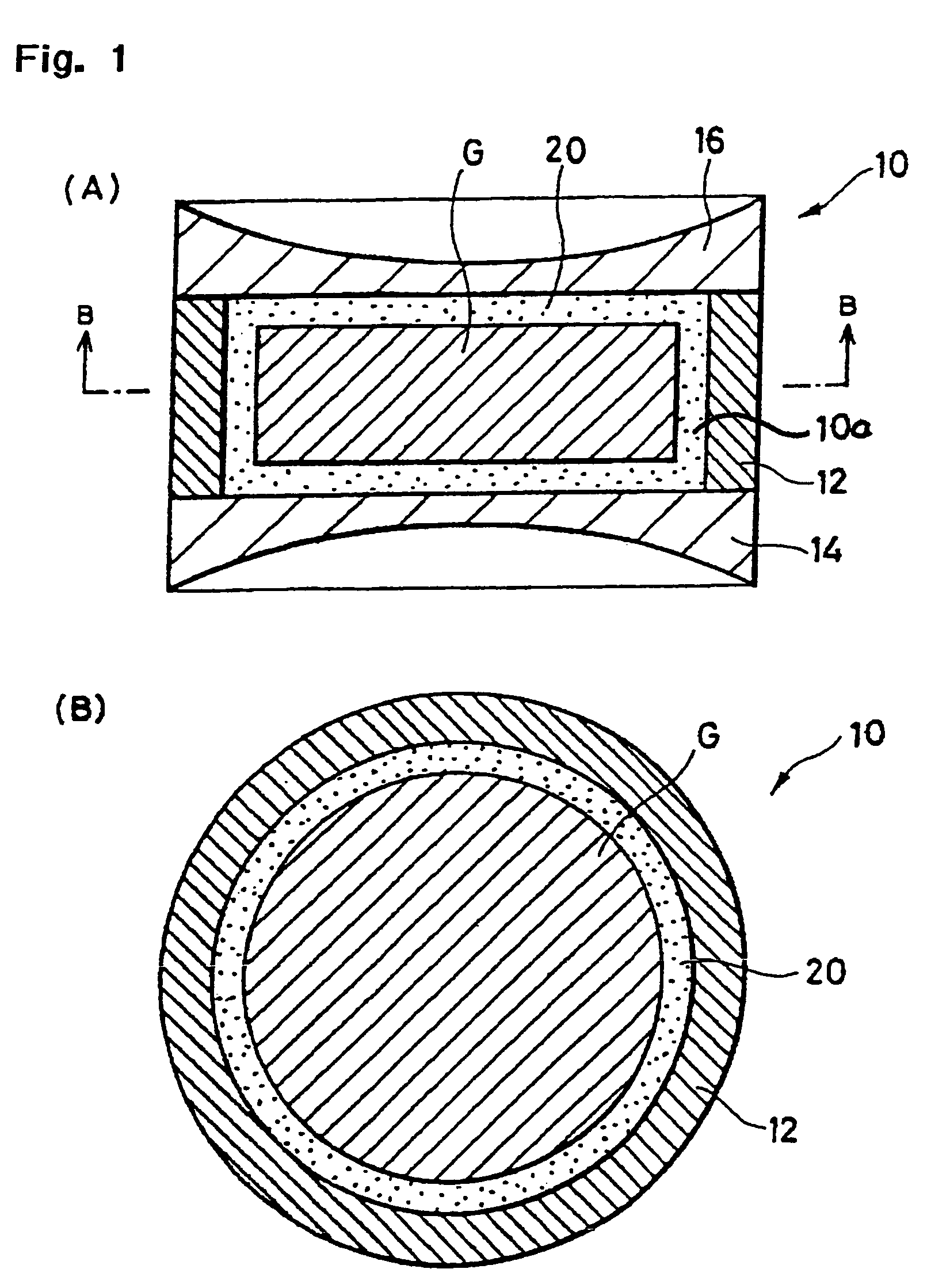

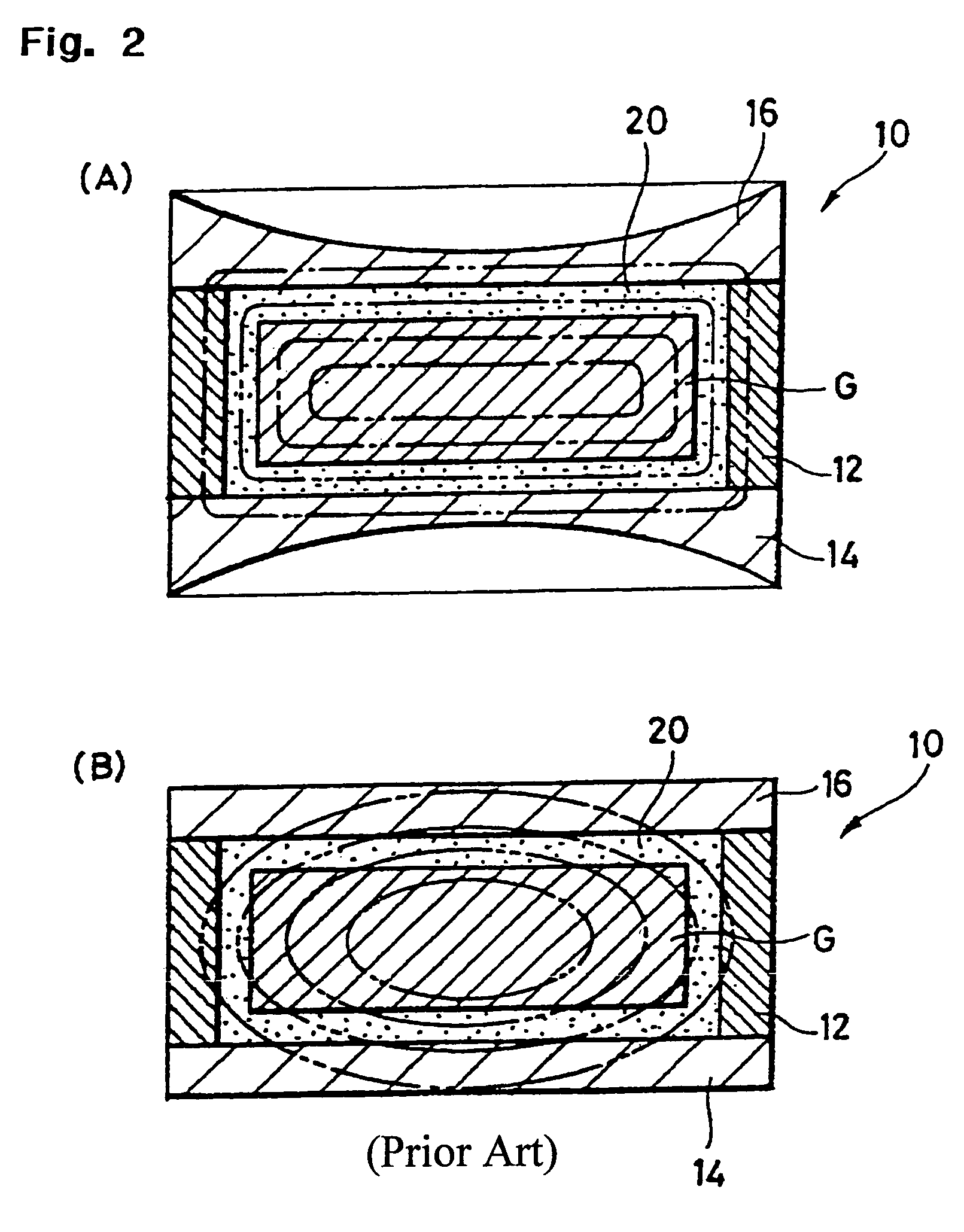

Electrical household appliance equipped with a control device and a display device

InactiveUS20060089732A1Large wall thicknessImprove stabilityDomestic stoves or rangesTableware washing/rinsing machine detailsDisplay deviceLight-emitting diode

One embodiment of the invention concerns an electrical household apparatus, for example a washing machine, equipped with a control device in the form of a panel, said panel comprising a display device for providing visual data to the user. Said panel (10) is made of a material which is substantially opaque when it has a normal thickness (14). One area specific to the display device (15) comprises at least one transparency zone (20) wherein the thickness of the panel material is reduced relative to the thickness of the material outside said transparency zone such that light from a light source (16), for example a light-emitting diode, located behind the panel may pass through said transparency zone. Such a configuration provides backlighted panels having a closed surface. In another embodiment, the control device is in the form of a turning knob (70, 80).

Owner:E G O CONTROL SYST

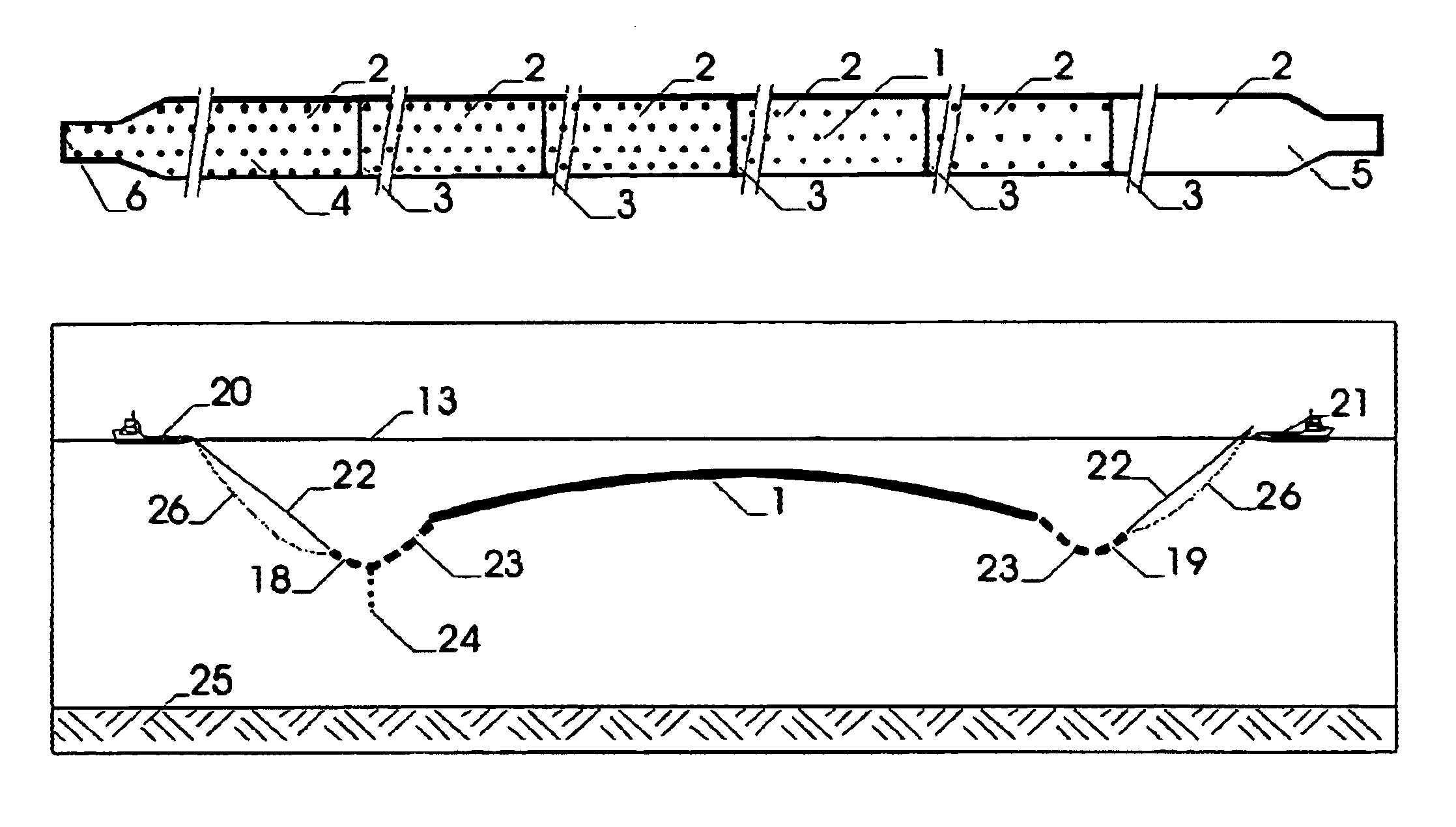

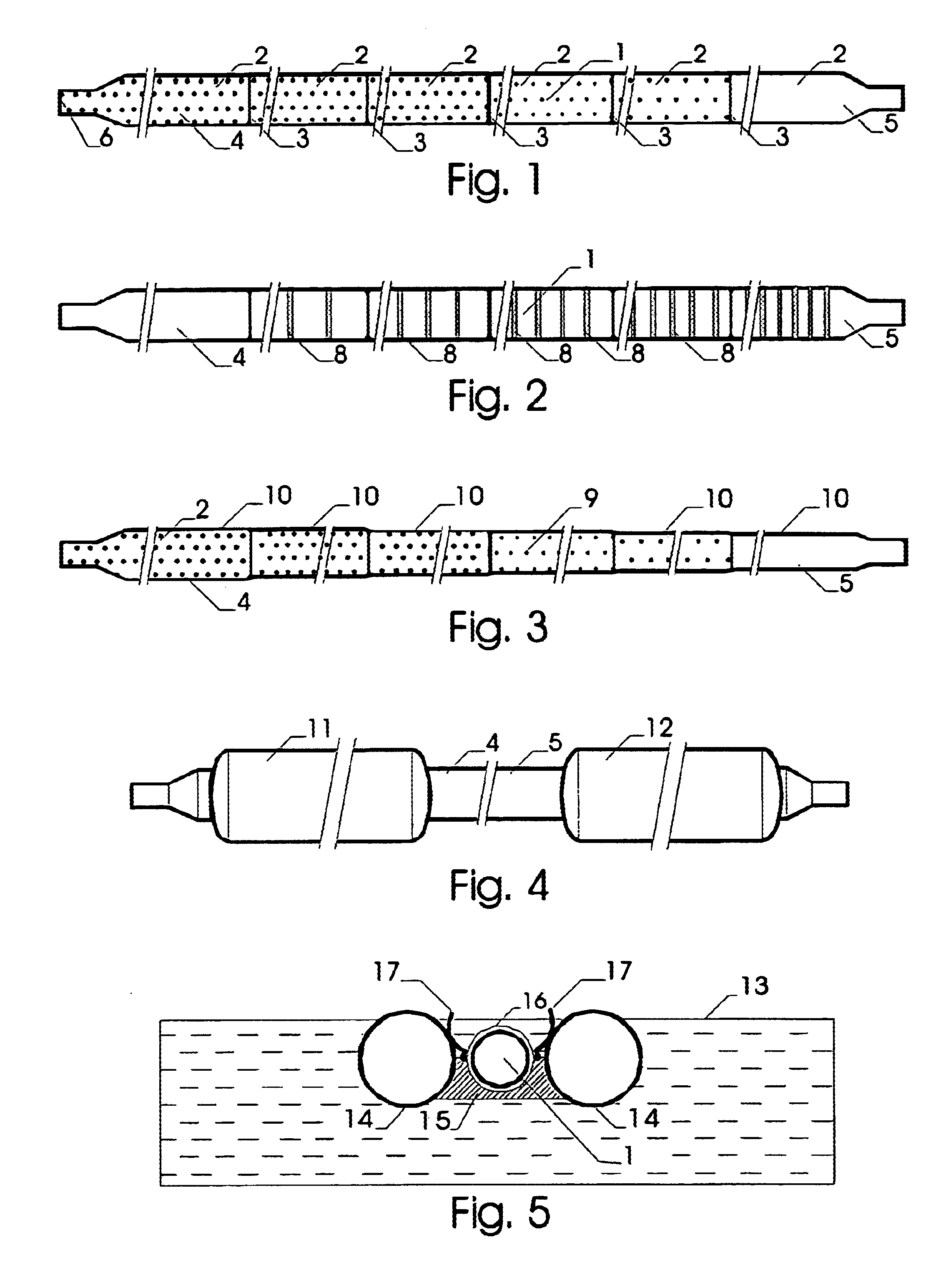

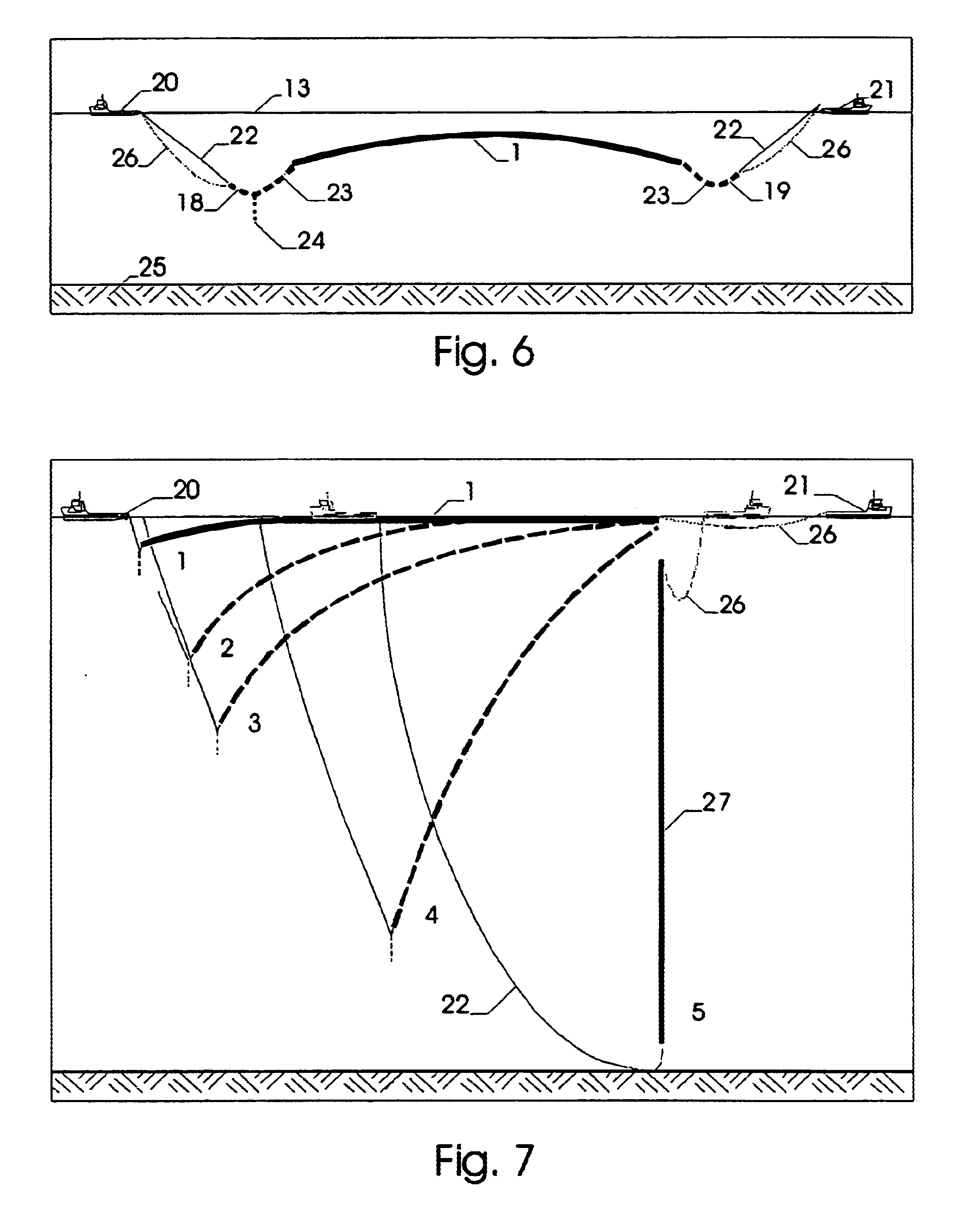

Tension leg and method for transport, installation and removal of tension legs pipelines and slender bodies

InactiveUS6682266B2Increase the diameterLarge wall thicknessPipe laying and repairDrilling rodsRiver bedEngineering

A tendon which is divided into compartments enclosing therein pressurized gas. A method for transporting a fluid containing tubular body or assembly of bodies above a sea / river bed floor and within a body of water. In addition to the method for transporting the tendon a method of installing and removing an internal pressurized tendon or assembly of tendons in a vertical position in a body of water.

Owner:ANCHOR CONTRACTING

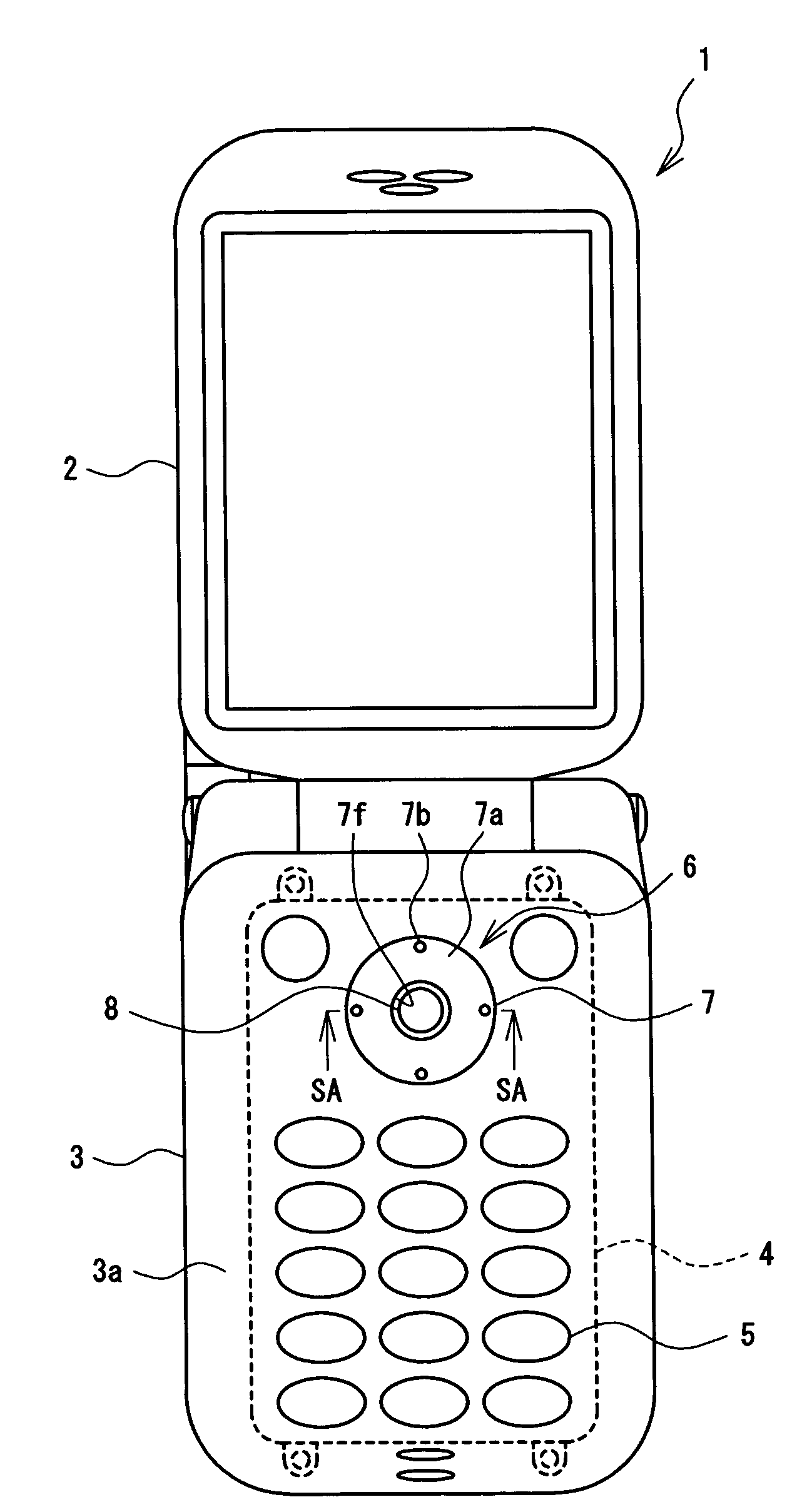

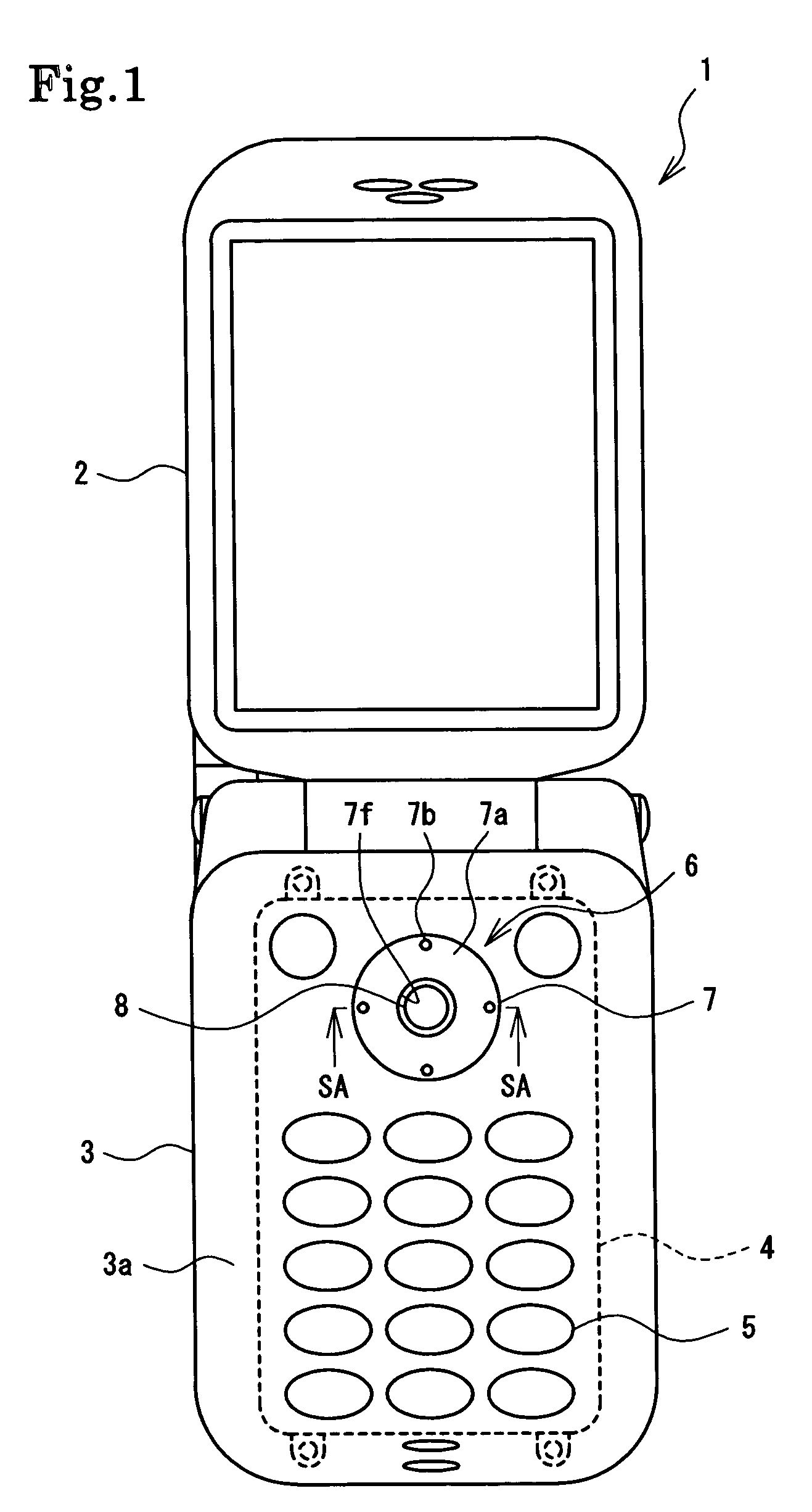

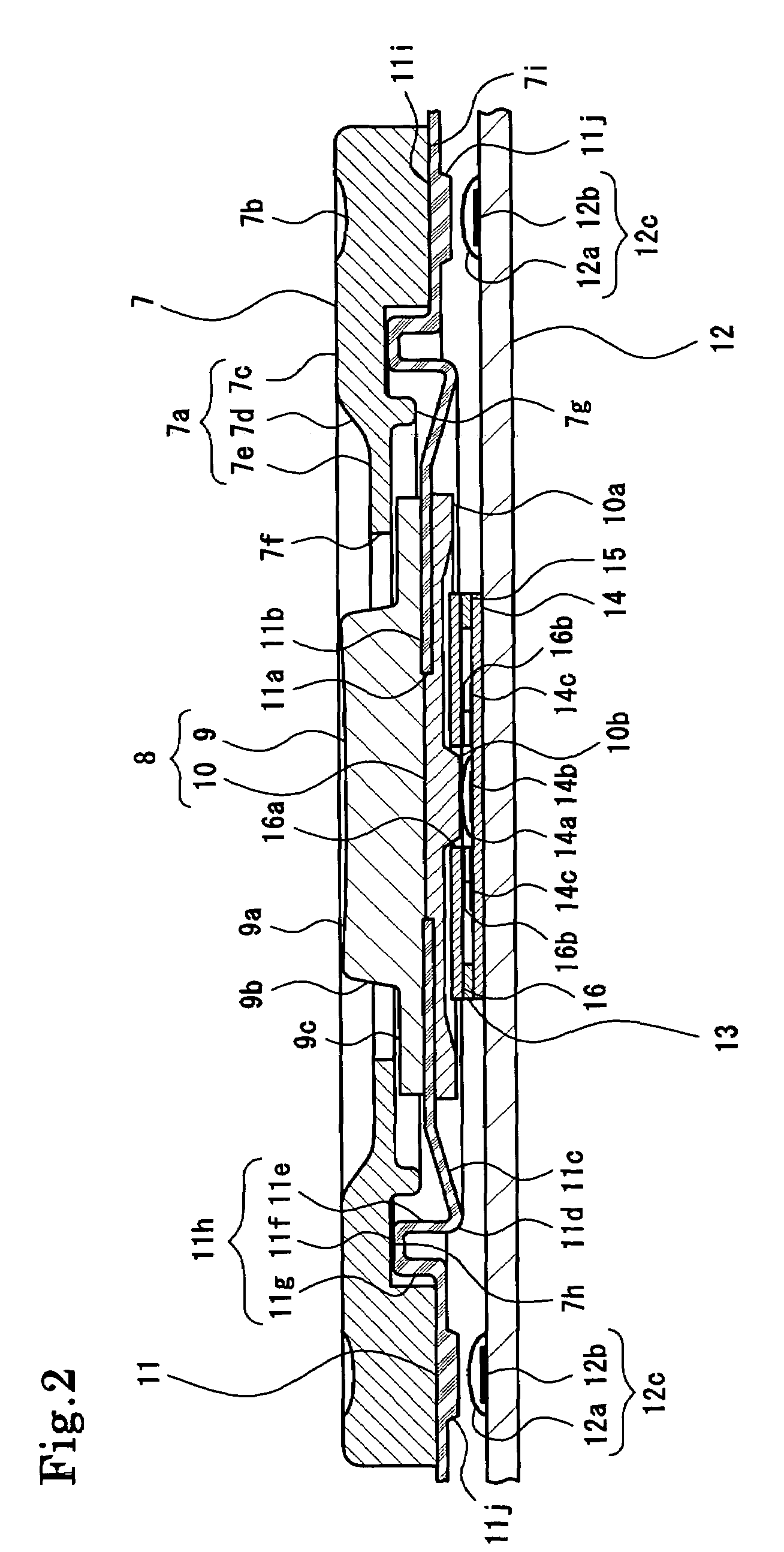

Slide-type multi-directional input key

InactiveUS7269439B2Little fatigueReliably effect both input sliding and return slidingInput/output for user-computer interactionChemical analysis using catalysisMembrane switchMechanical engineering

A multi-directional input key is capable of plural inputs through multi-directional operation, wherein the plural inputs are realized by a novel multi-directional operation, instead of the conventional operation in which force is applied to the operation surface so as to push it in deeply. There is provided a central key top equipped with an upper key top protruding from an insertion hole of an outer-ring key top and a lower key top having a pushing member protruding downwardly therefrom. This central key top is supported on a key sheet so as to be slidable in the direction of the hole inner surface of the insertion hole. And, when the central key top is caused to slide, an upper contact and a lower contact of a membrane switch are brought into contact with each other to effect input under the pressure from the pushing member.

Owner:POLYMATECH CO LTD

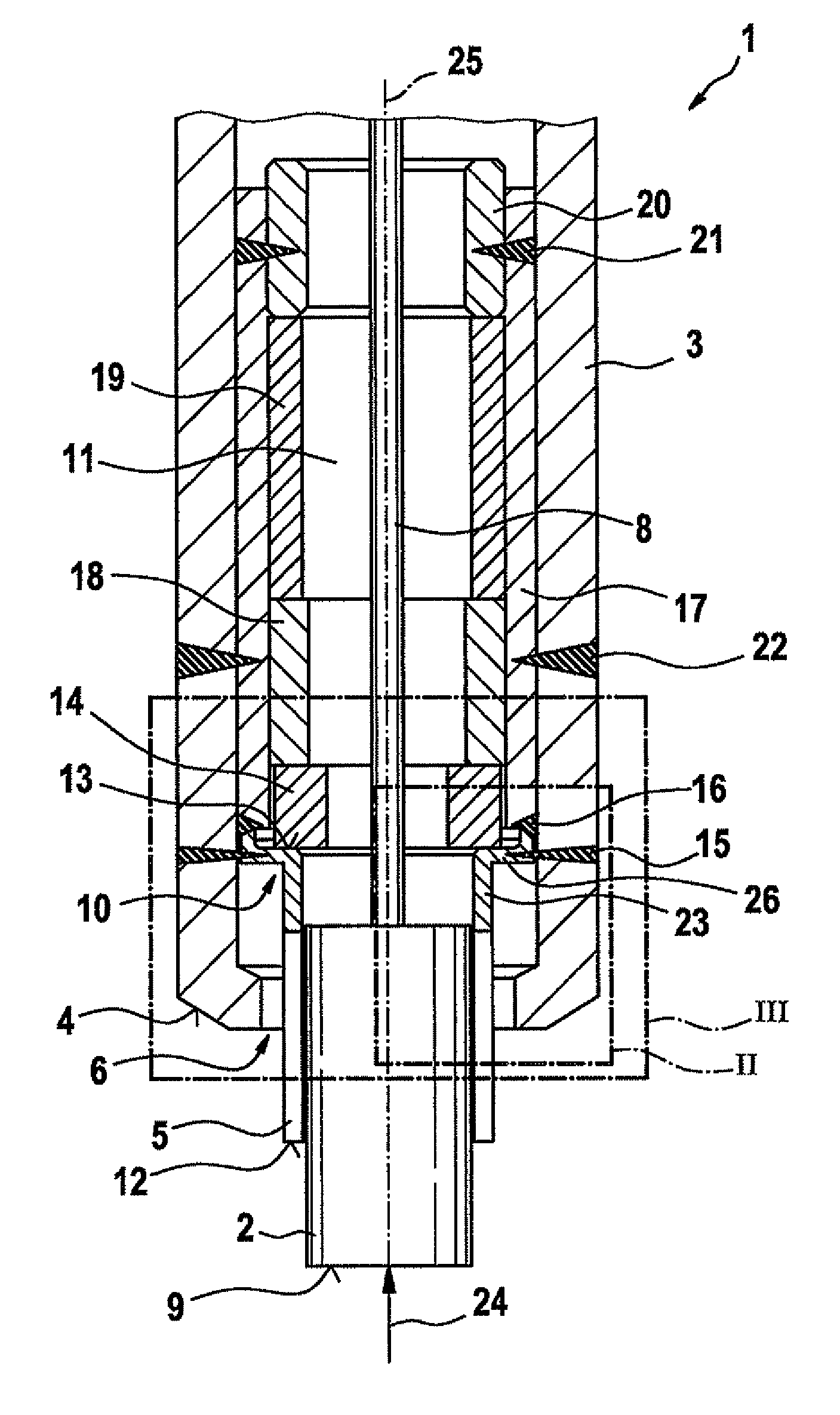

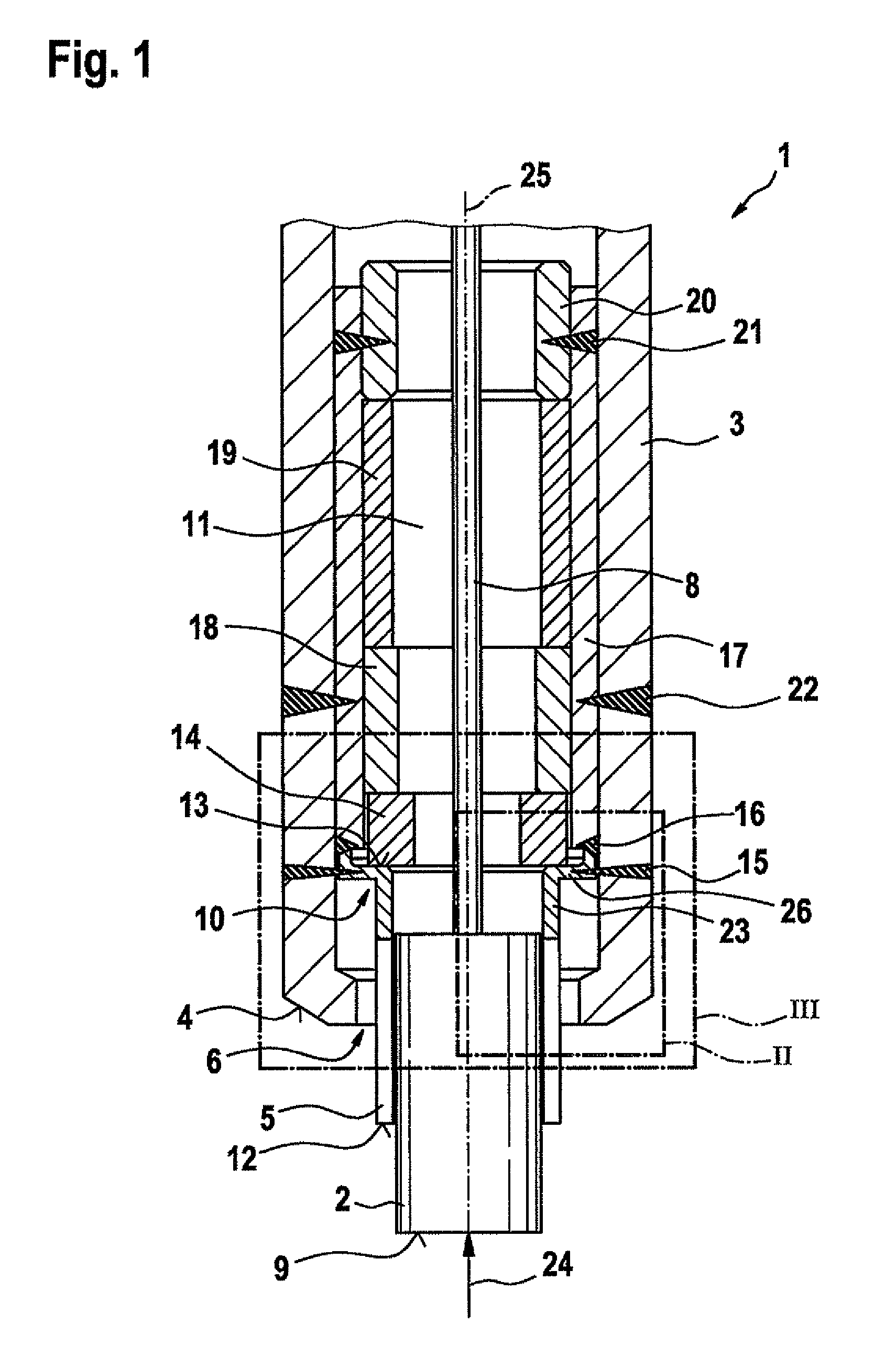

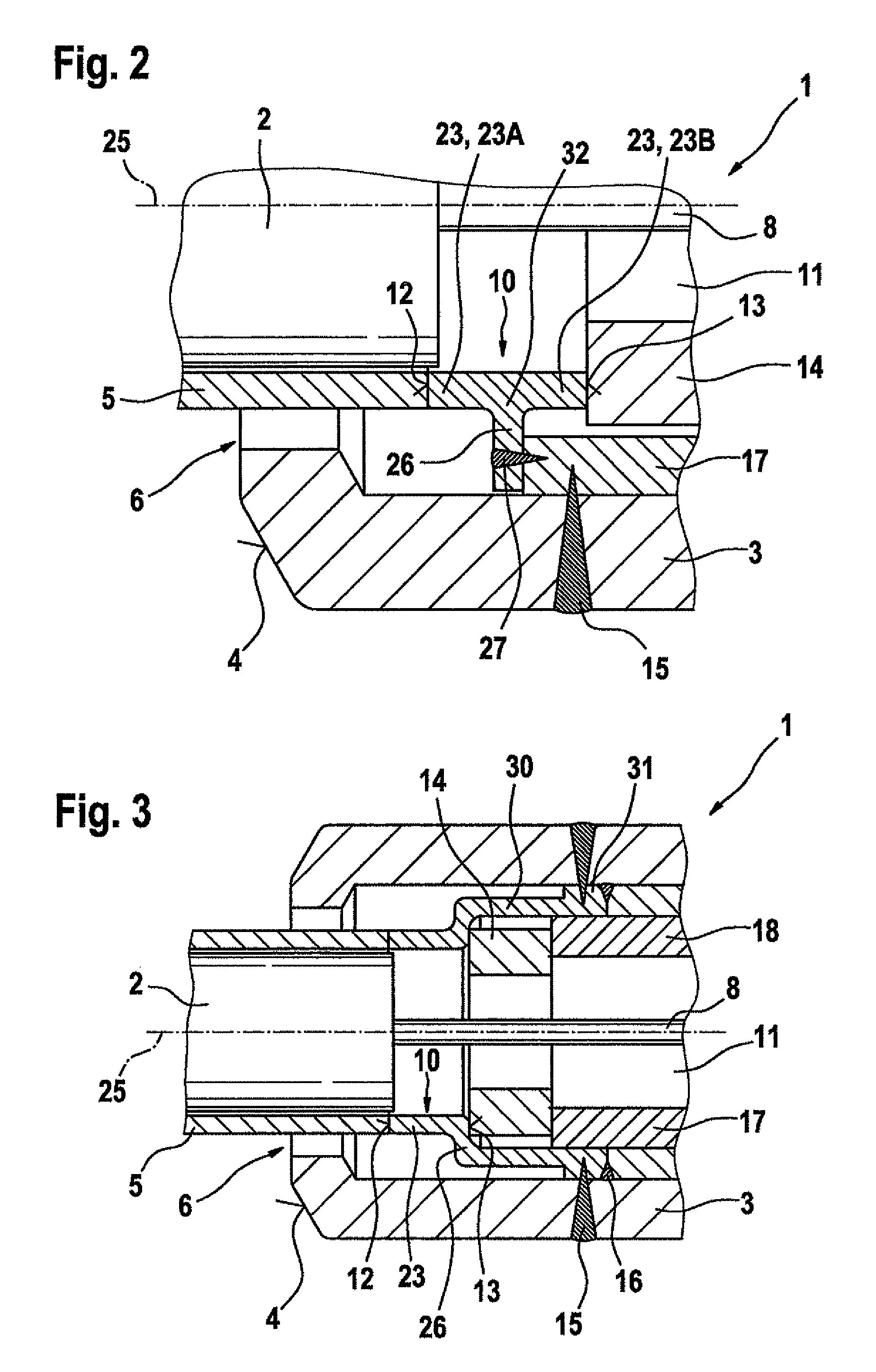

Pressure-measuring device

InactiveUS7954382B2Increase pressureReduce outputIncandescent ignitionFluid pressure measurement using elastically-deformable gaugesInterior spaceCombustion

A pressure-measuring device is situated in a chamber of an internal combustion engine. The pressure-measuring device has a housing, a force-transmitting element that protrudes partly from the housing at a chamber-side opening of the housing, and a pressure sensor that is situated in an interior space of the housing. The pressure sensor stands in effective connection to the force-transmitting element. In addition, a diaphragm is provided that seals the interior space of the housing, in which the pressure sensor is situated, against the chamber-side opening. The diaphragm, which is preferably fashioned as a metal diaphragm, has a force-transmitting segment that is oriented in an axial direction of the force-transmitting element. Moreover, the pressure sensor stands in effective connection with the force-transmitting element via the force-transmitting segment of the diaphragm. In this way, there takes place at least a partial compensation of thermally caused changes in length of the diaphragm, caused for example by hot combustion gases, and resulting in periodic impairments of the pressure measurement made by the pressure sensor.

Owner:ROBERT BOSCH GMBH

Mixing module and steam heater

InactiveUS20170291151A1Improve life expectancyIncrease resistanceFlow mixersTransportation and packagingEngineering

Owner:SANDVIK INTELLECTUAL PROPERTY AB

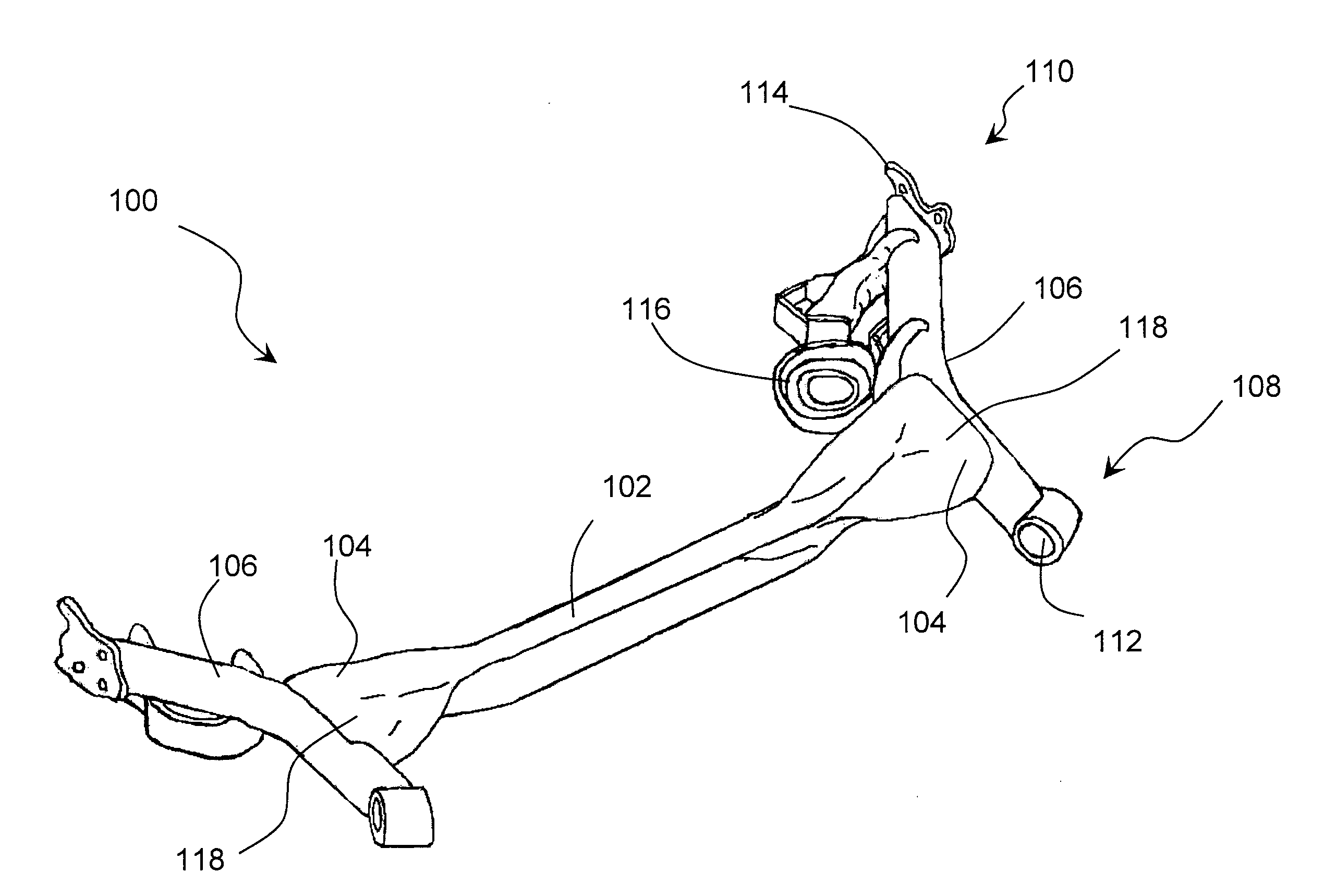

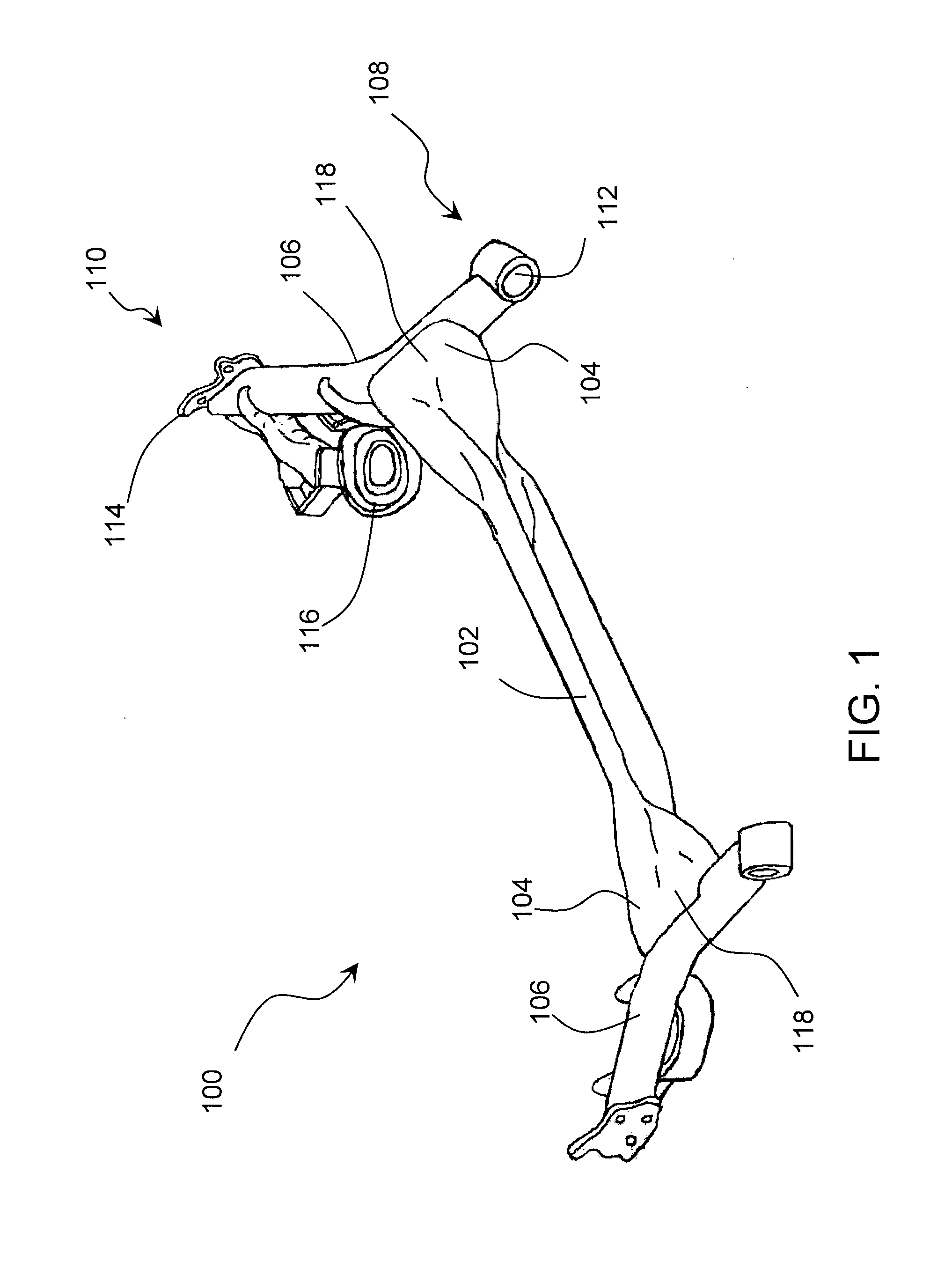

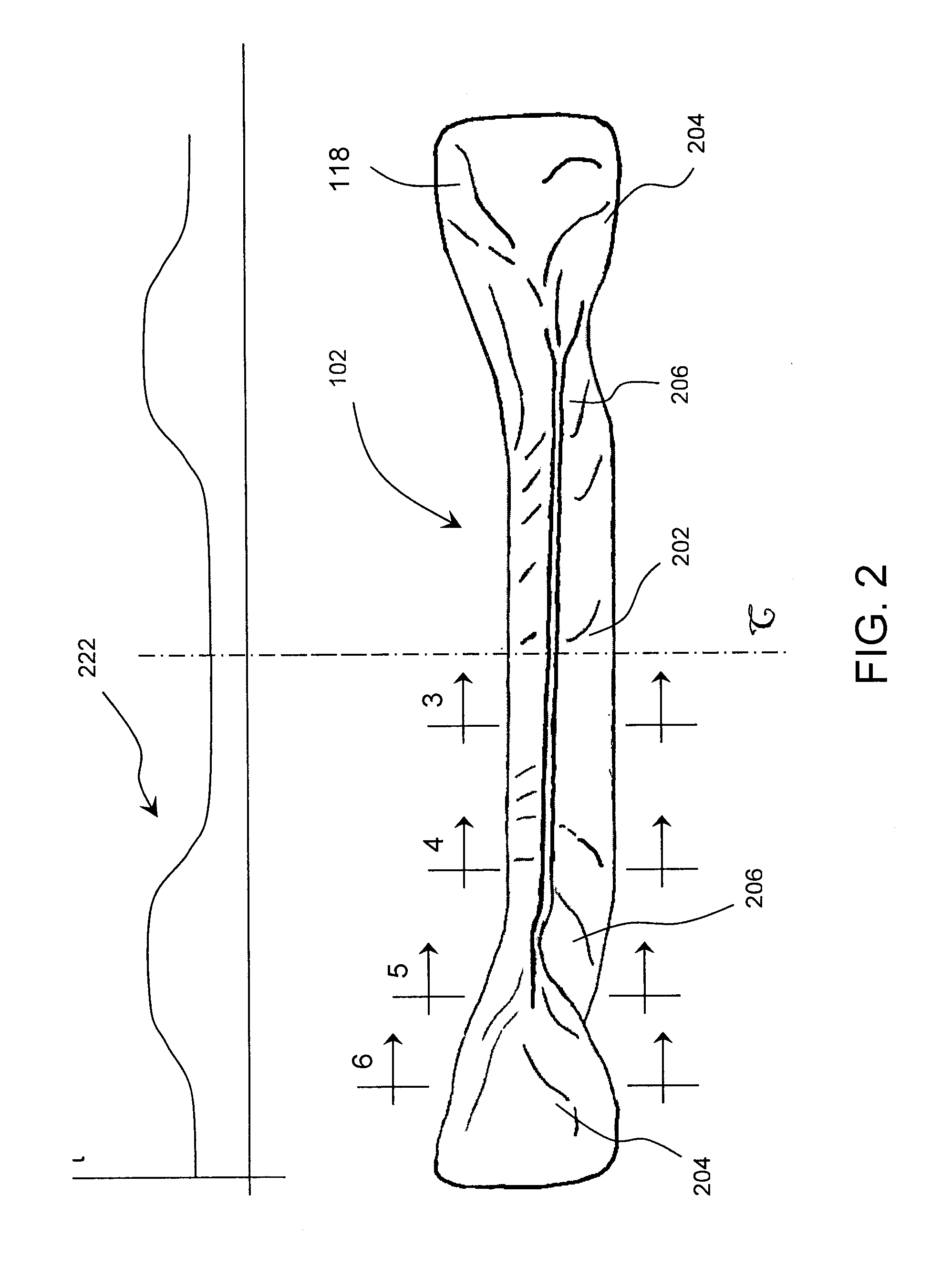

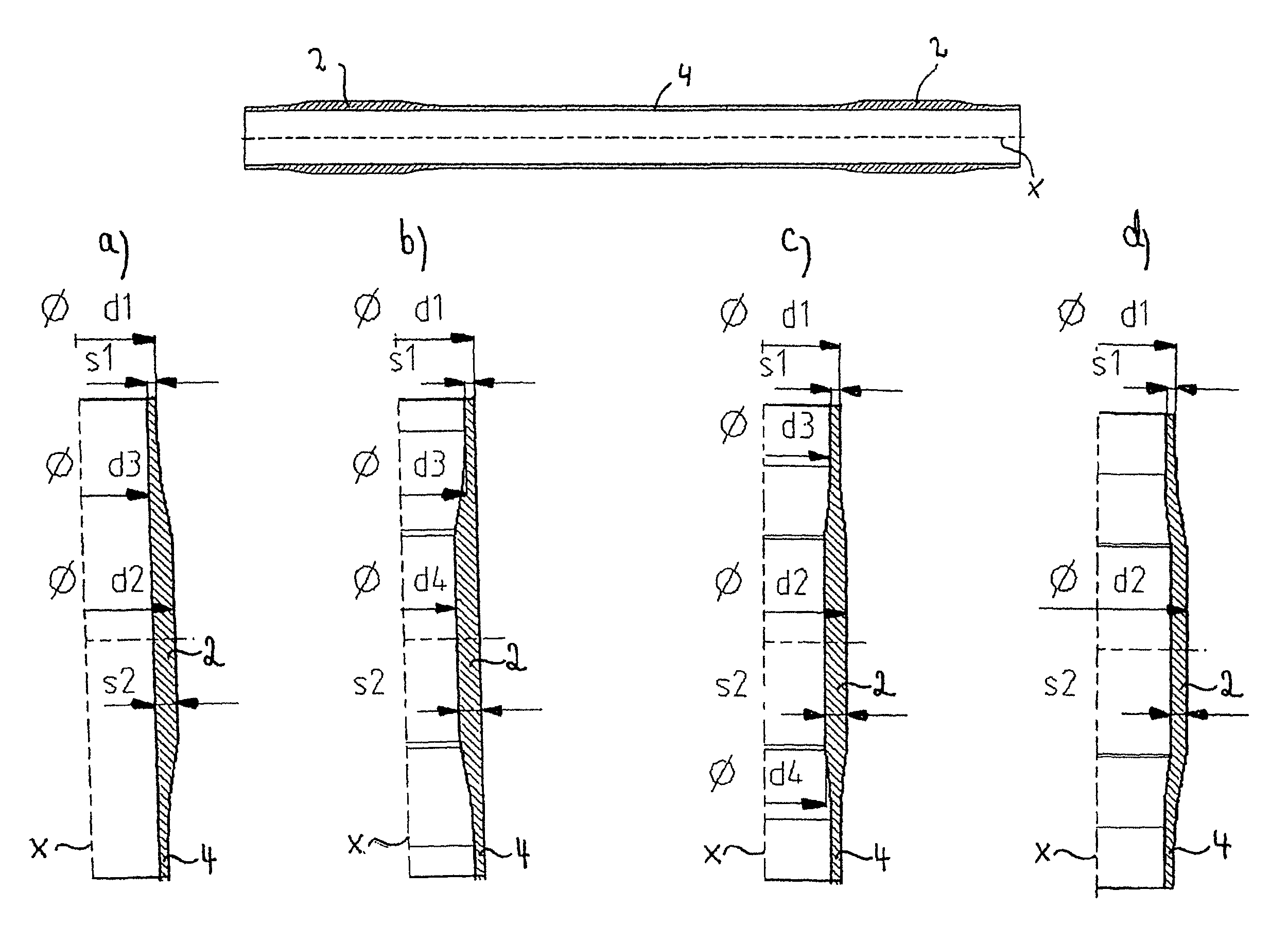

Twist-axle with longitudinally-varying wall thickness

ActiveUS20110260423A1Large wall thicknessStable changeTorsion springsMetal-working apparatusTrailing armEngineering

The invention relates to a twist-axle that includes a cross-beam member and two trailing arms, each trailing arm rigidly secured to the cross-beam member in one of two connection regions of the cross-beam member or formed integrally with and extending from one of the two connection regions. The cross-beam member is formed from a tubular blank and has a torsionally elastic central portion and two torsionally stiff connection regions. The cross-beam member has a wall thickness that varies longitudinally along the length of the cross-beam member from the torsionally elastic central portion to each of the torsionally stiff connection regions.

Owner:ARCELORMITTAL TUBULAR PRODS CANADA

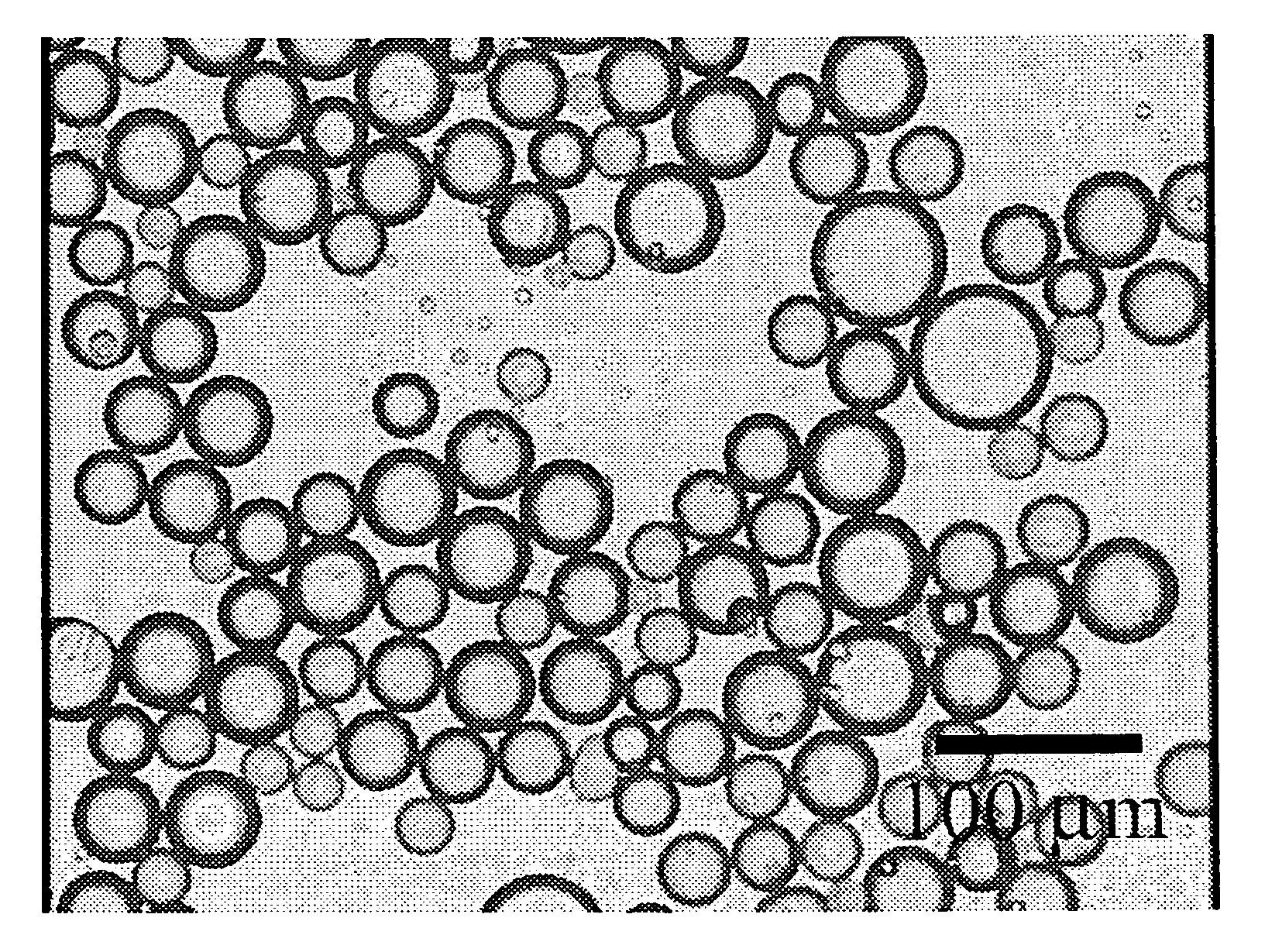

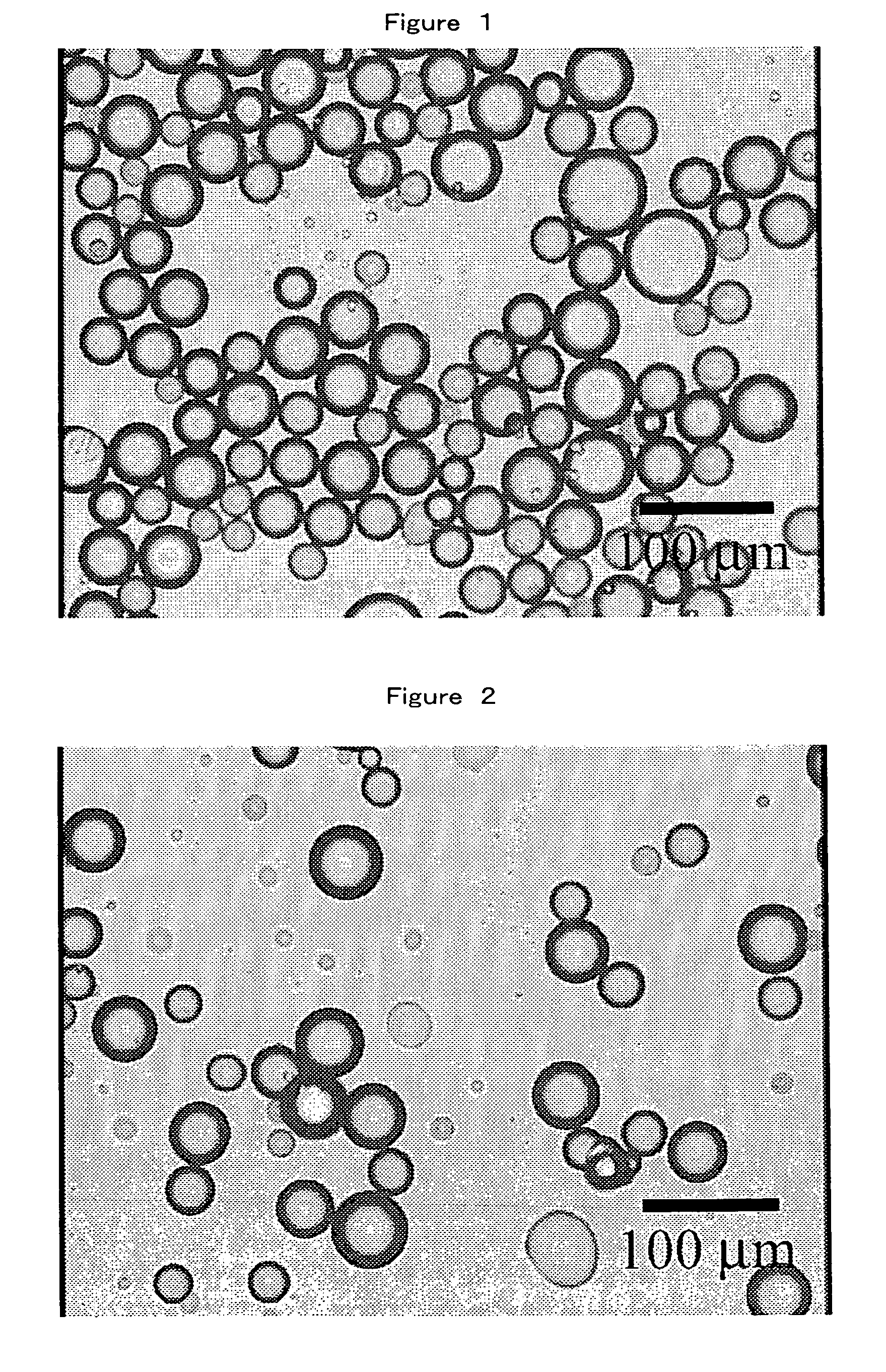

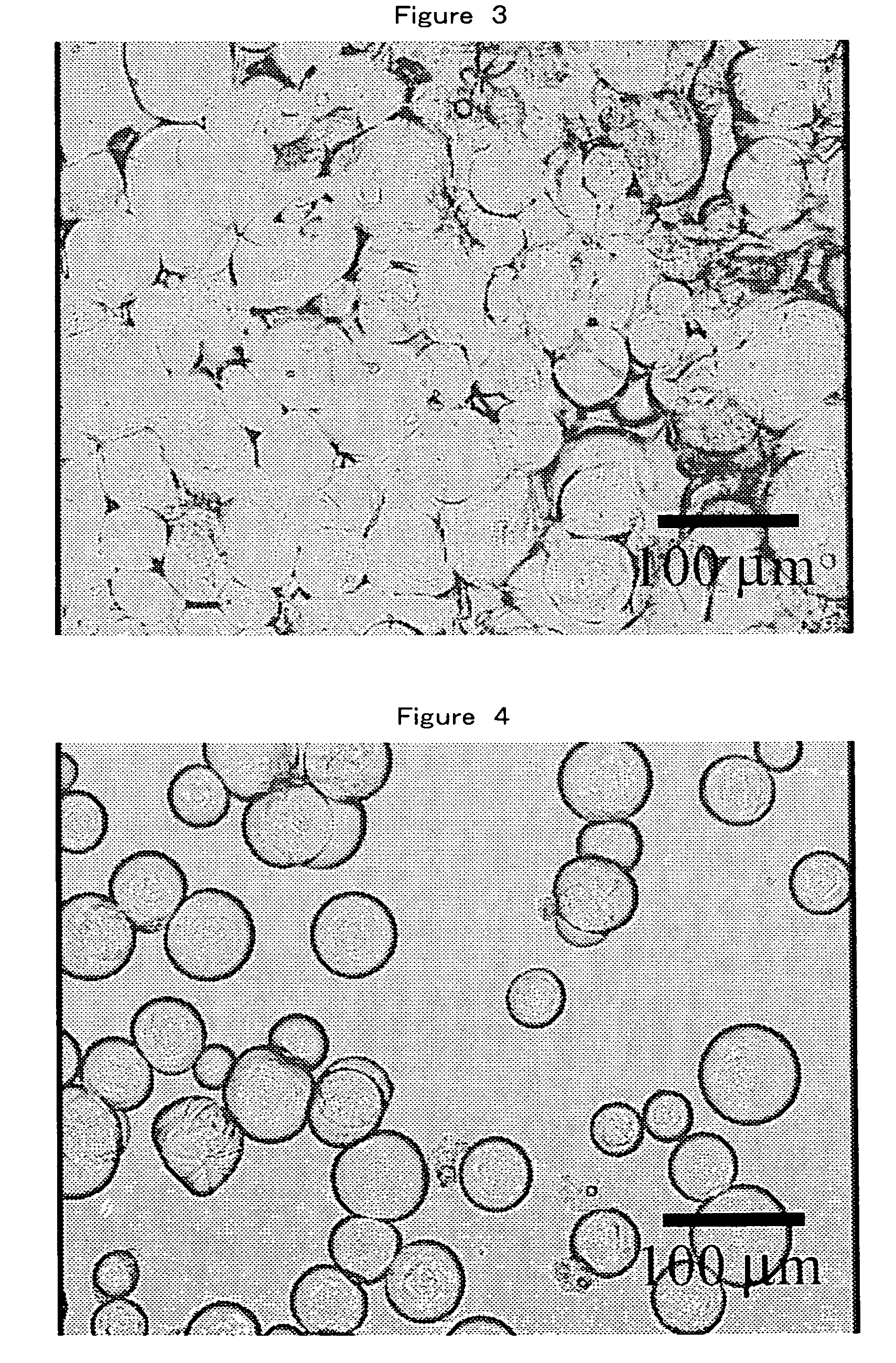

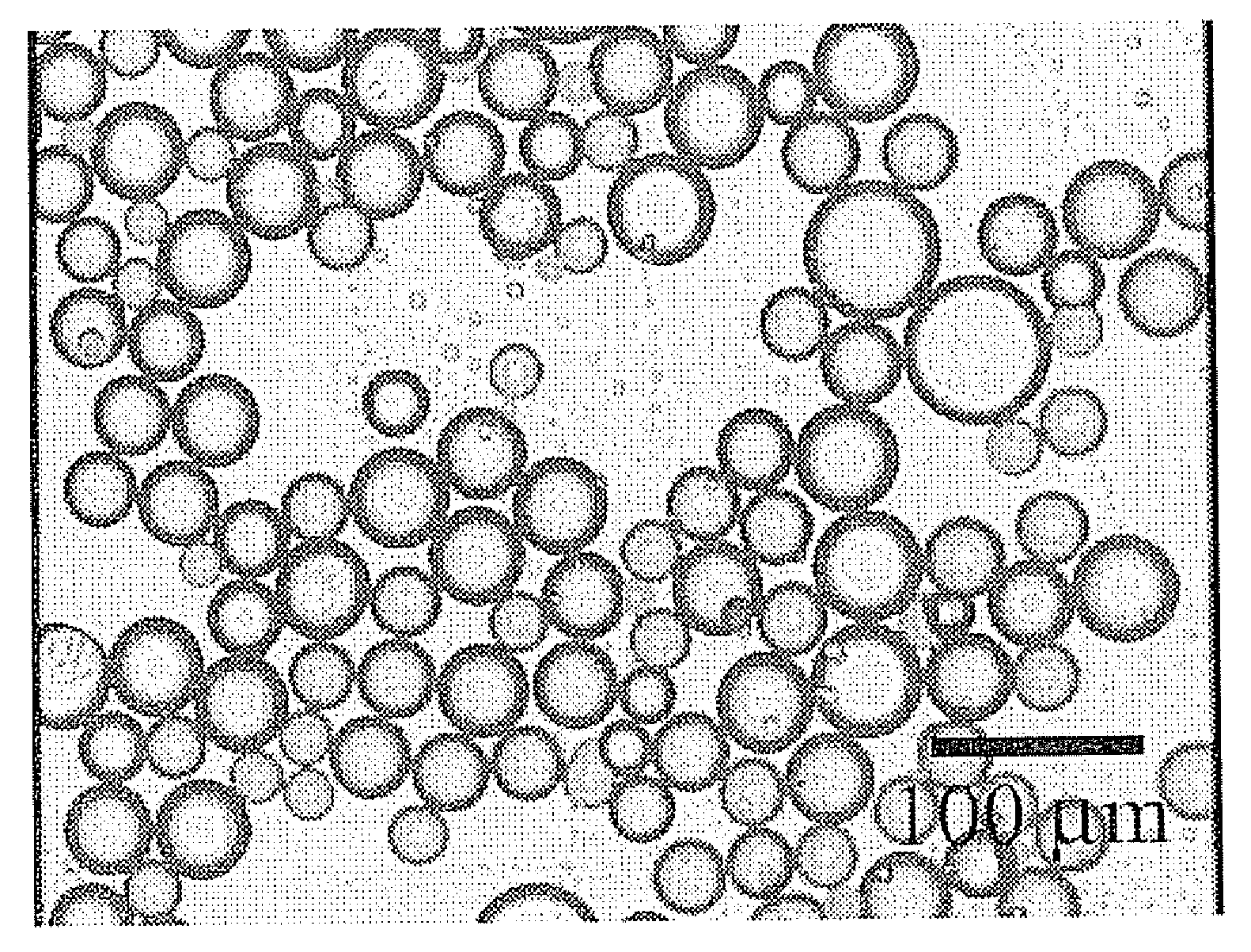

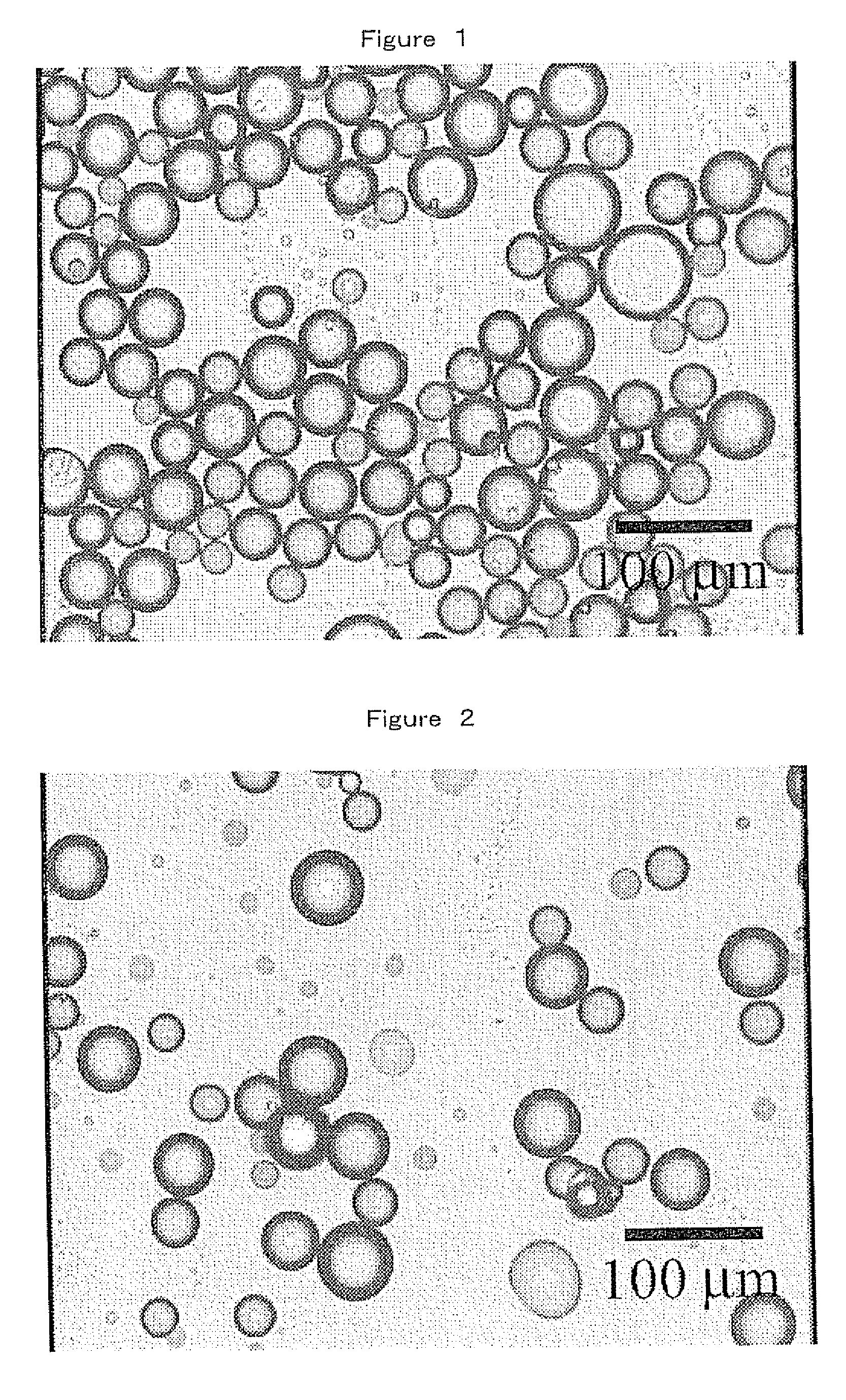

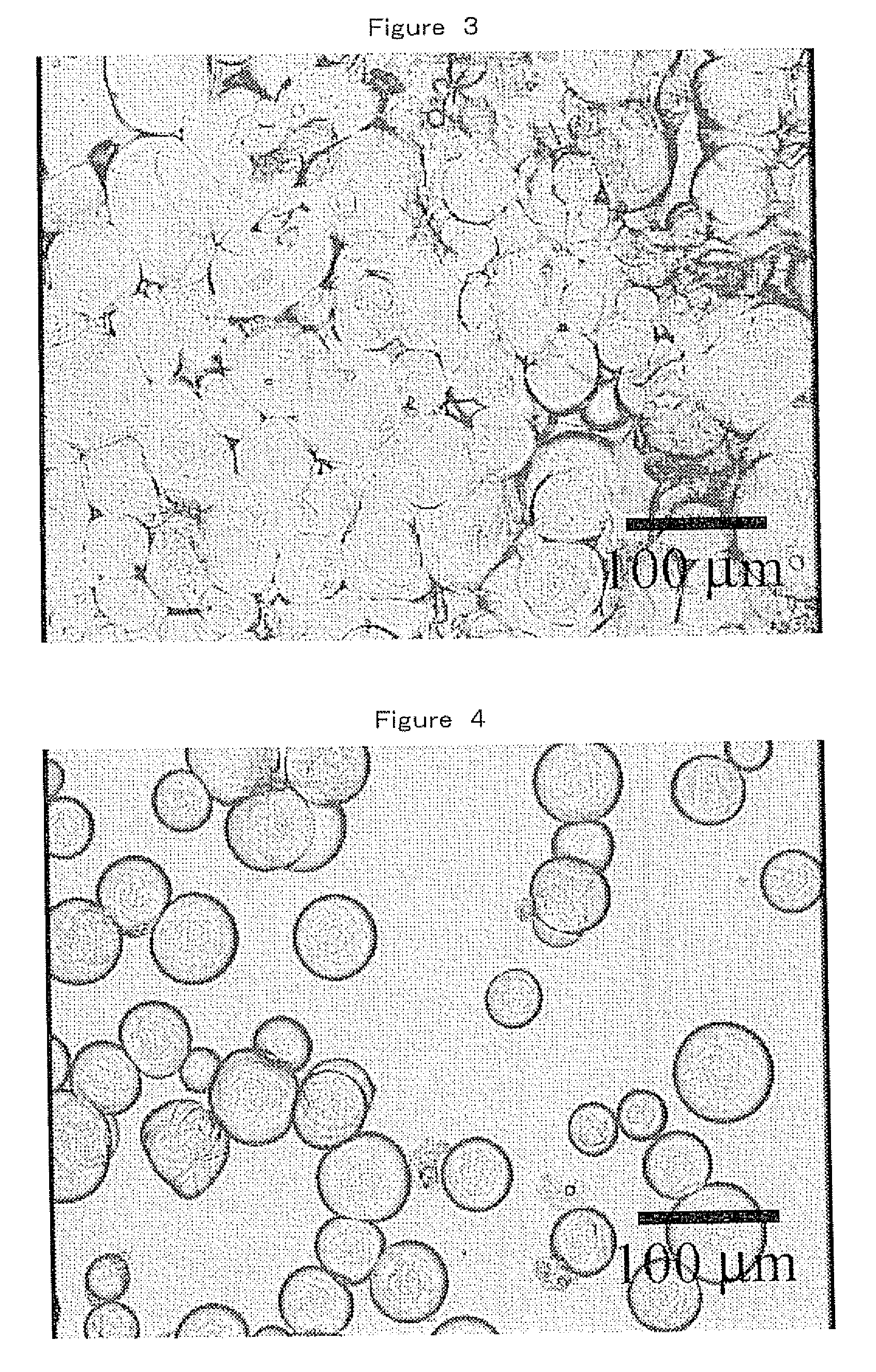

Process for producing electrophoretic microcapsules

InactiveUS7279121B2Excellent in stability and durabilityLarge wall thicknessDiffusion transfer processesGlass/slag layered productsElectrophoresesPolymer science

A microcapsule is produced by dispersing a liquid organic dispersion in an aqueous medium to form a capsule particle in the aqueous medium, the liquid organic dispersion containing an acid group-containing resin, a colored particle and an organic solvent, and the capsule particle comprising a disperse system containing the liquid organic dispersion, and a wall encapsulating the disperse system, wherein the acid group of the resin has been at least partly neutralized with an alkanolamine. The wall comprises the resin, and the resin may be crosslinked or cured with a crosslinking agent. Moreover, the process may comprise crosslinking or curing the resin constituting the wall with the crosslinking agent, and further crosslinking or curing the residual crosslinking agent with a polyfunctional compound. Such a process can produce a microcapsule has a small and uniform particle size while encapsulating a disperse system dispersed a colored particle in an oil phase.

Owner:DAICEL CHEM IND LTD

Microcapsules and processes for producing the same

InactiveUS20070298337A1Excellent in stability and durabilityLarge wall thicknessDiffusion transfer processesLayered productsOrganic solventOil phase

A microcapsule is produced by dispersing a liquid organic dispersion in an aqueous medium to form a capsule particle in the aqueous medium, the liquid organic dispersion containing an acid group-containing resin, a colored particle and an organic solvent, and the capsule particle comprising a disperse system containing the liquid organic dispersion, and a wall encapsulating the disperse system, wherein the acid group of the resin has been at least partly neutralized with an alkanolamine. The wall comprises the resin, and the resin may be crosslinked or cured with a crosslinking agent. Moreover, the process may comprise crosslinking or curing the resin constituting the wall with the crosslinking agent, and further crosslinking or curing the residual crosslinking agent with a polyfunctional compound. Such a process can produce a microcapsule has a small and uniform particle size while encapsulating a disperse system dispersed a colored particle in an oil phase.

Owner:HAYASHI MASAKI

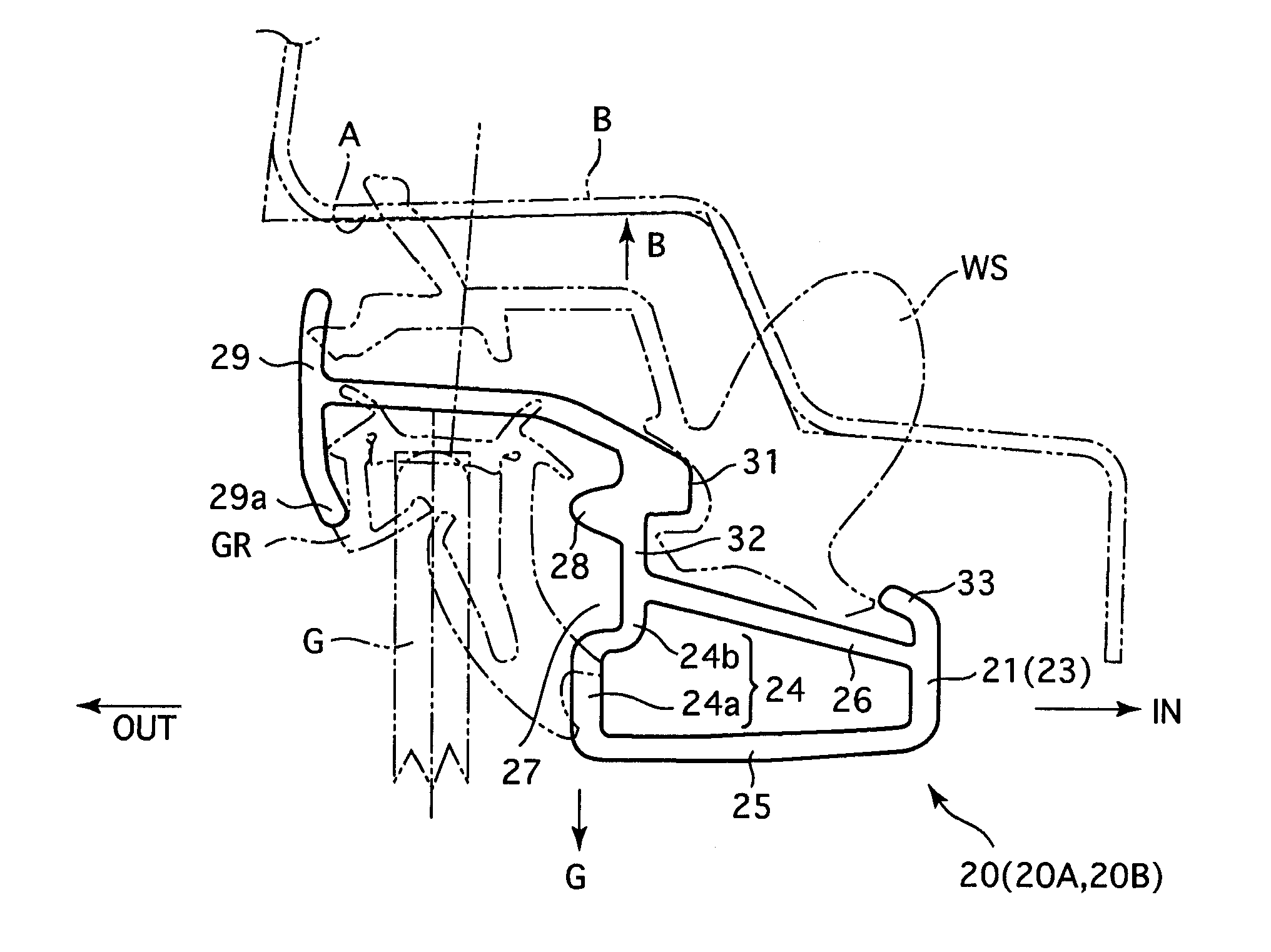

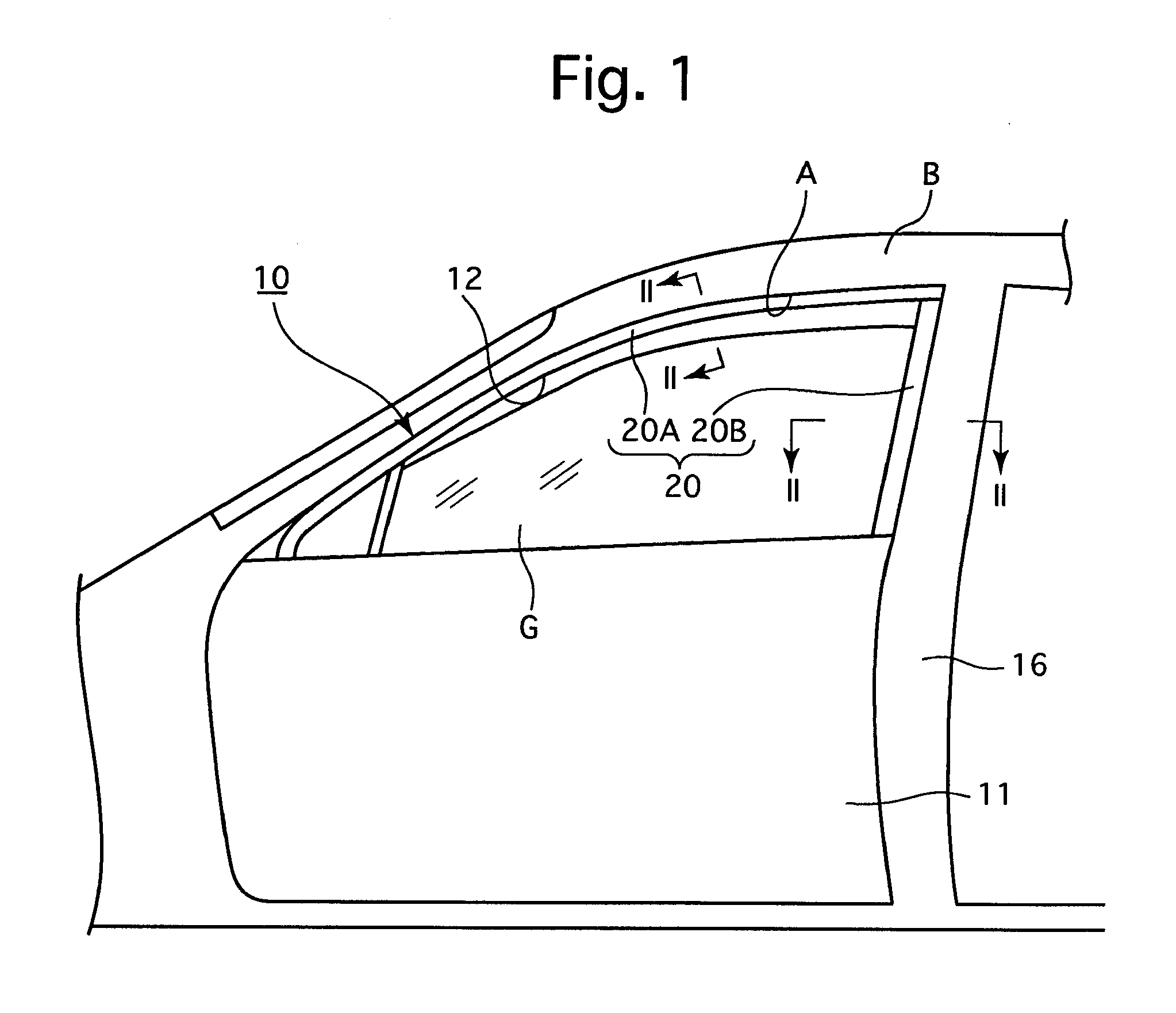

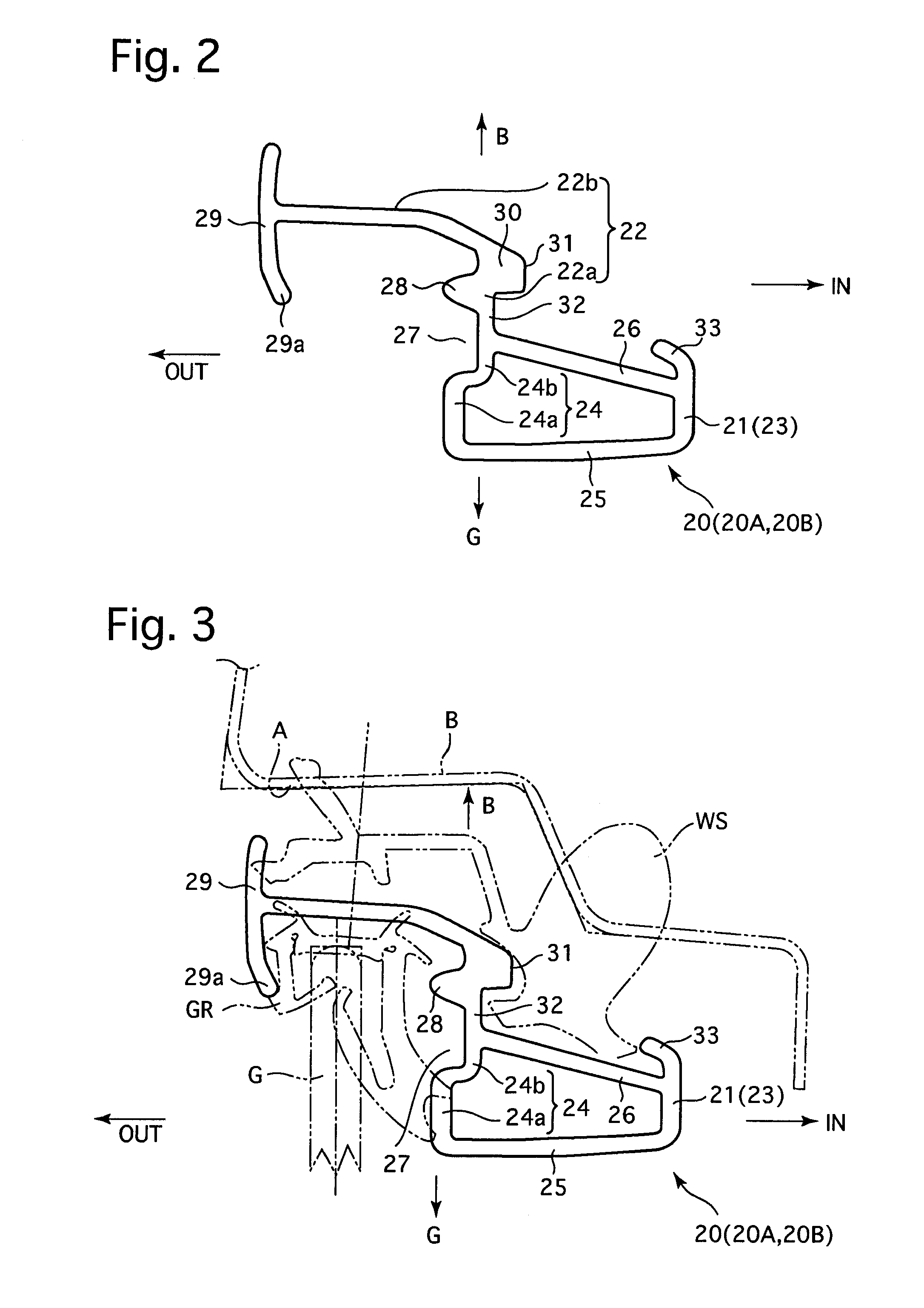

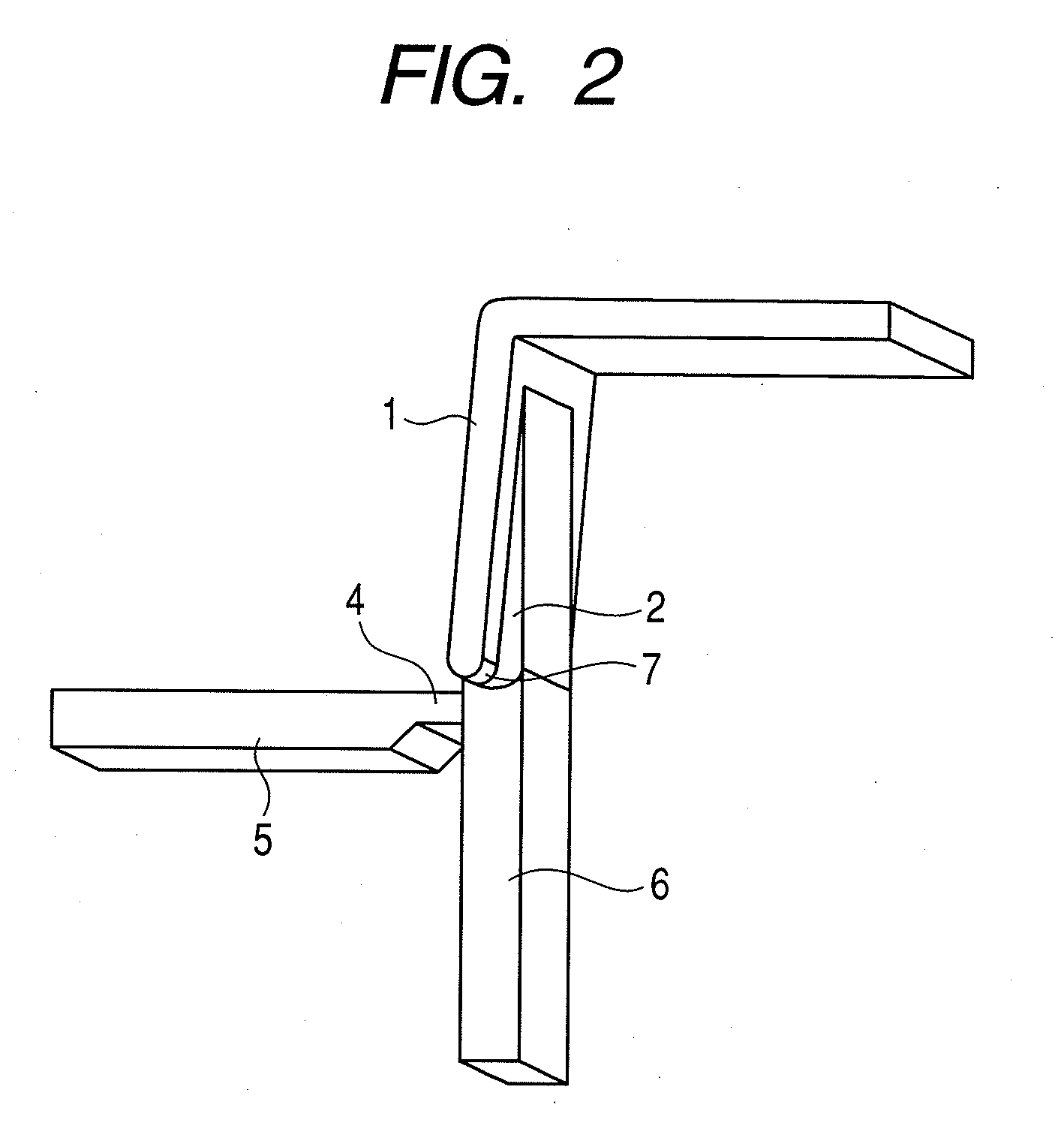

Extruded vehicle door sash

Owner:AISIN CORP

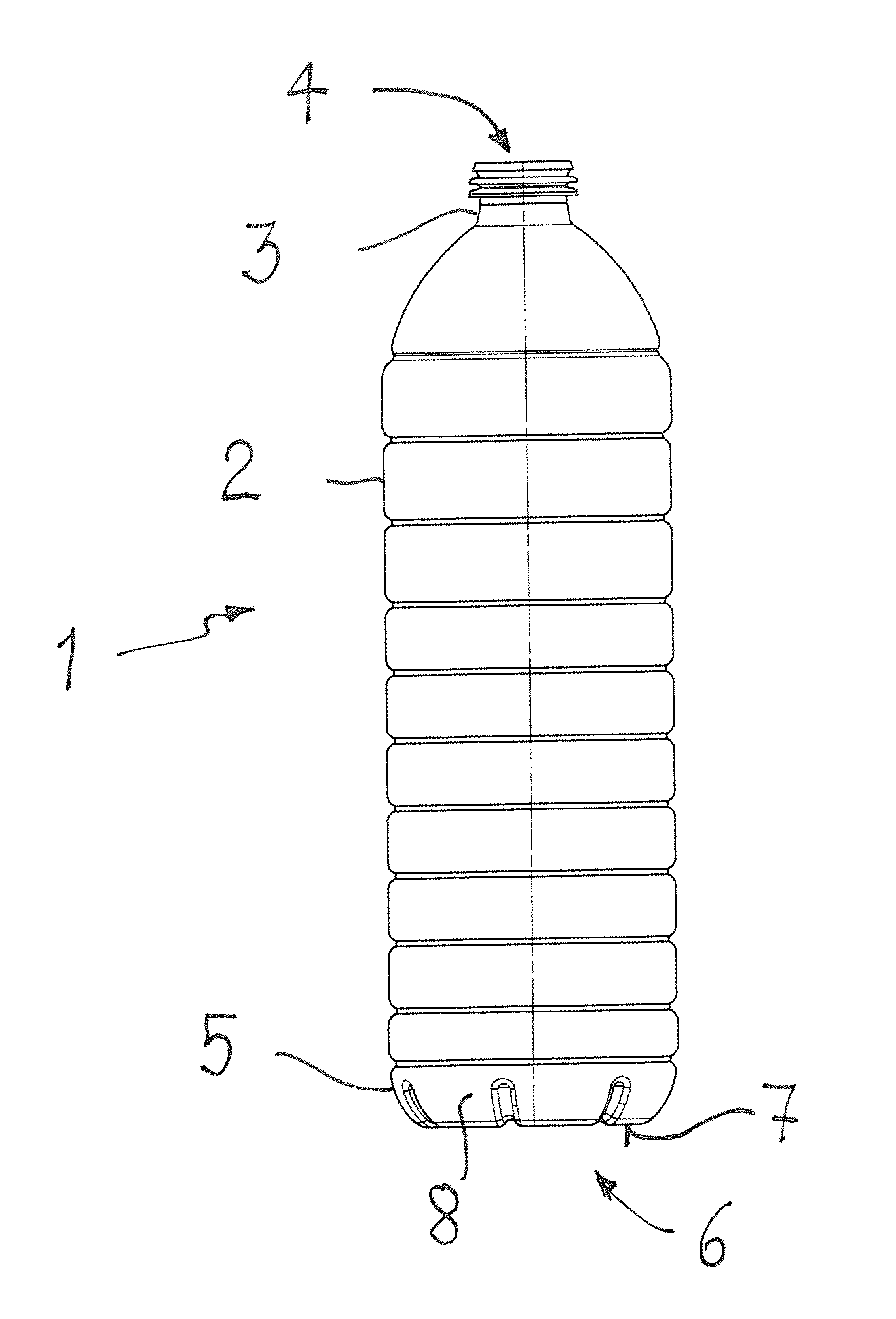

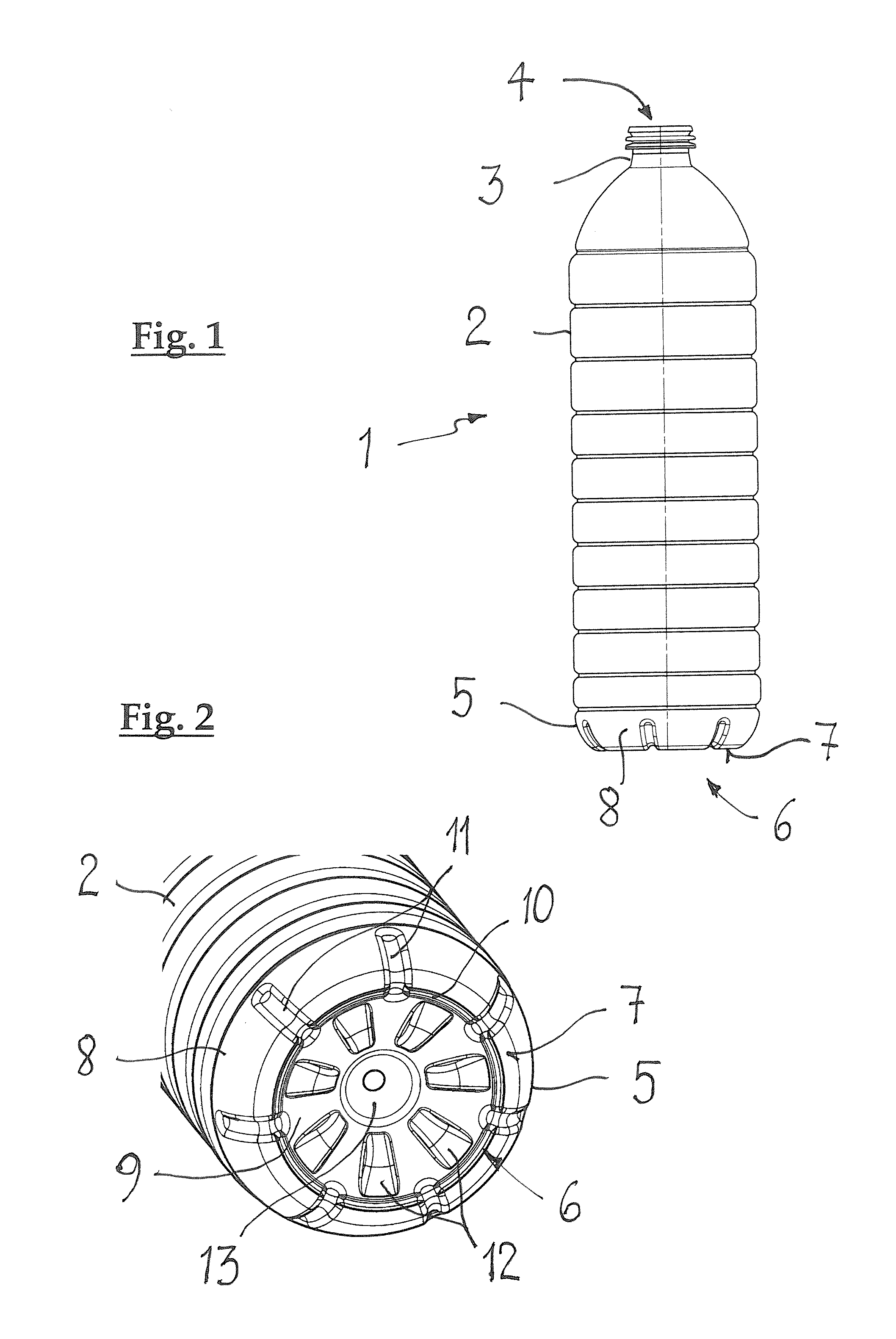

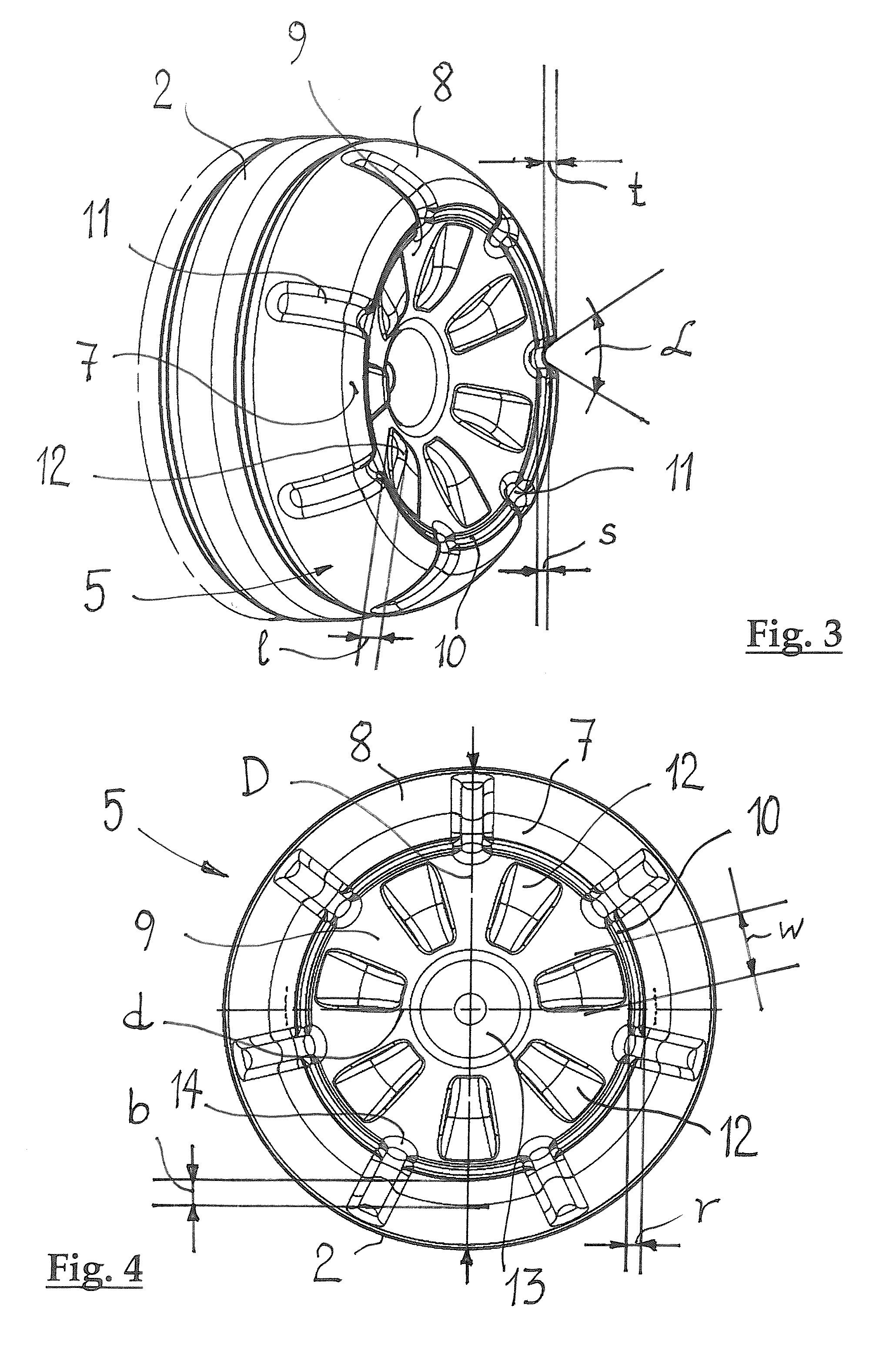

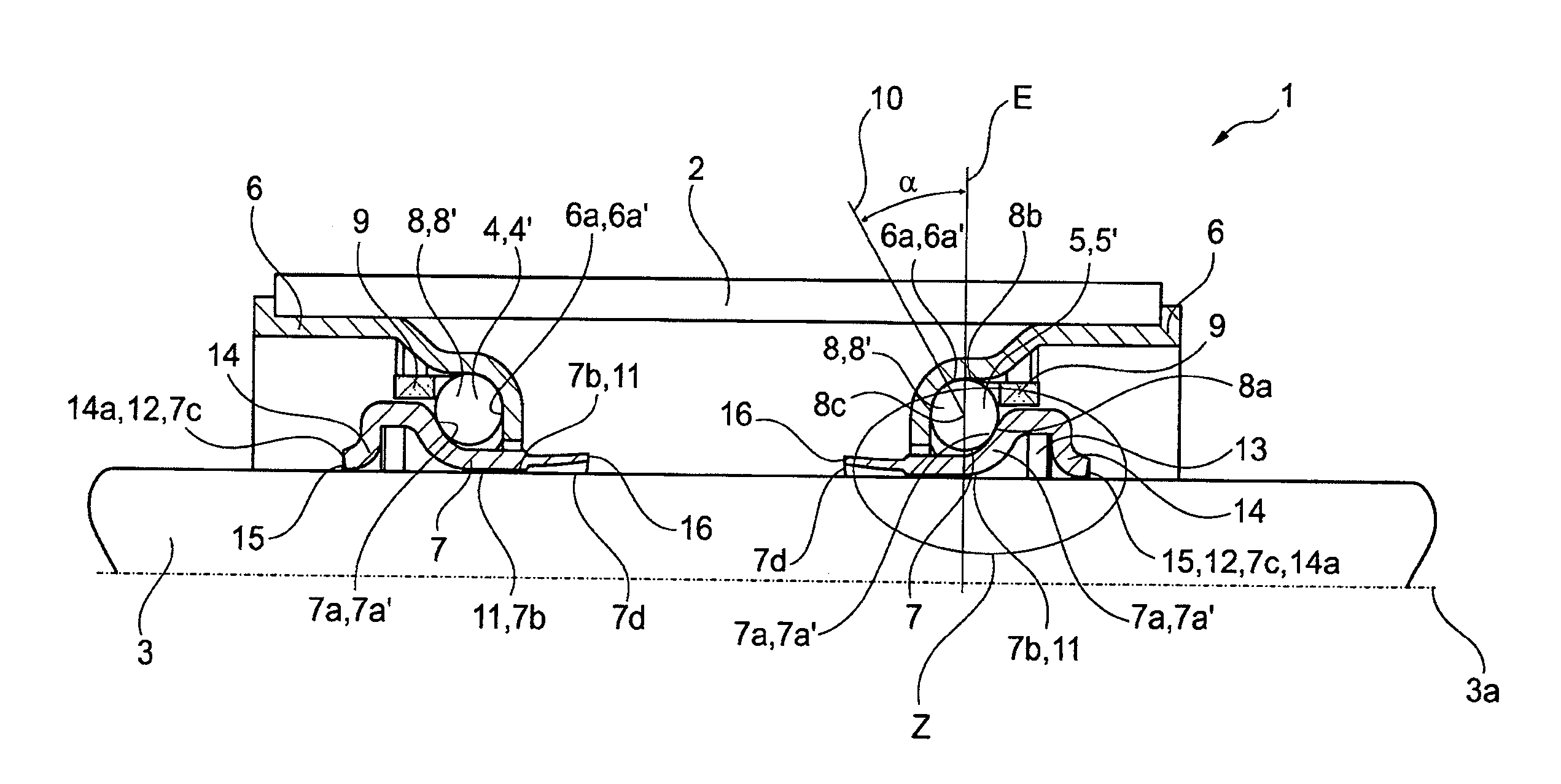

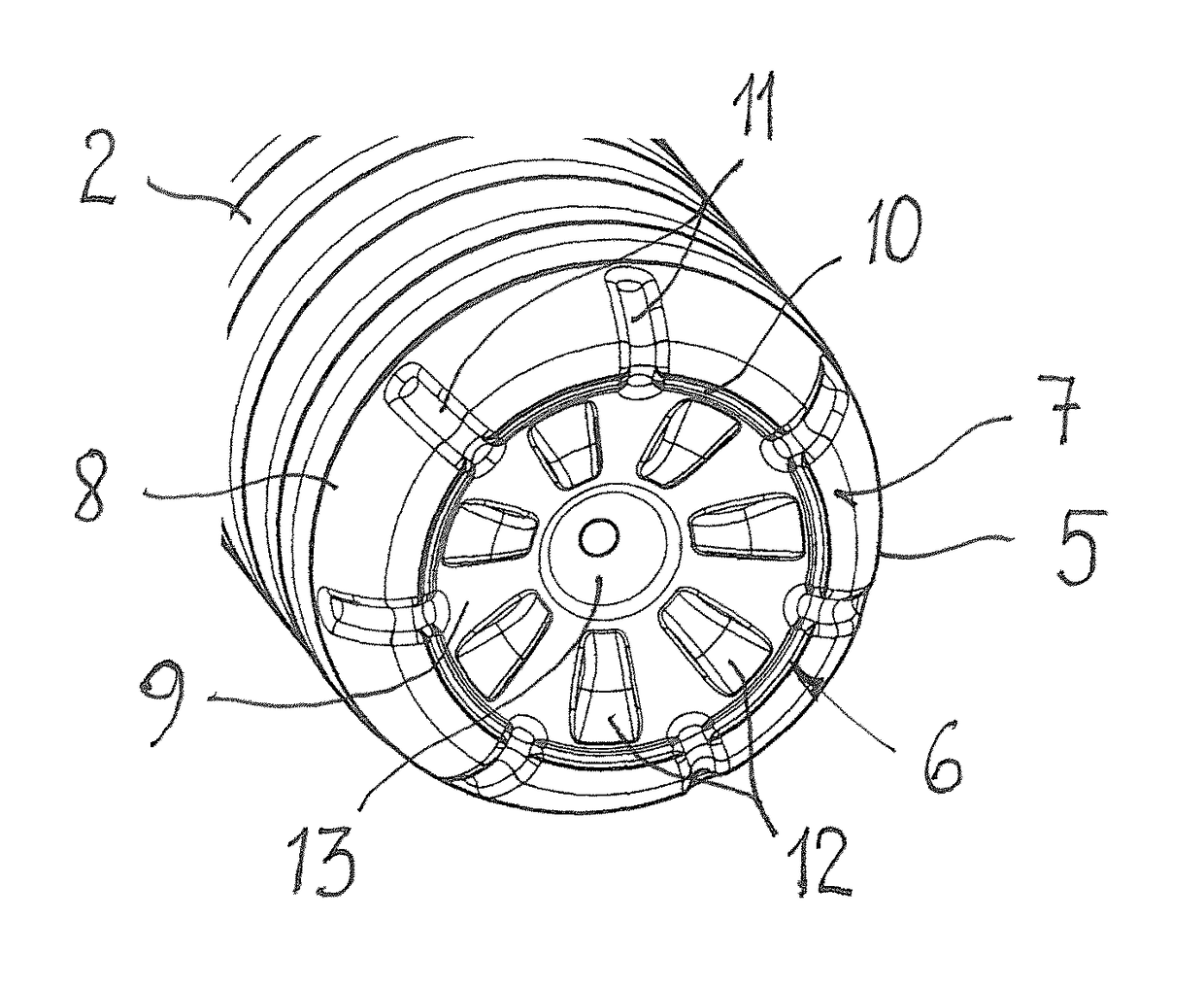

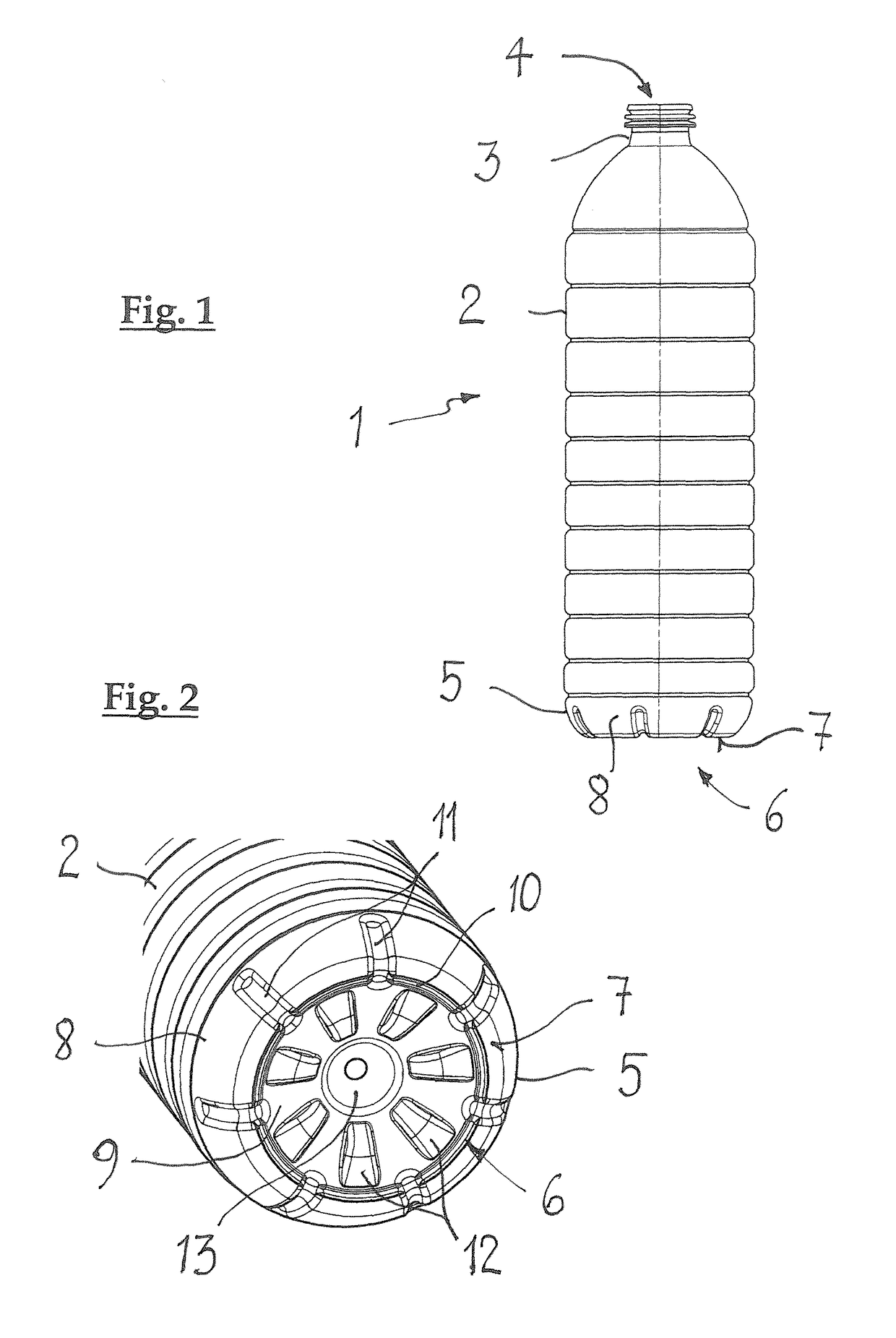

Plastic container

ActiveUS20150259090A1Reduced stabilityConvenient heightBottlesLarge containersEngineeringMechanical engineering

A plastic container for storing liquid under a low overpressure having a container body, to whose one longitudinal end a container neck is connected, which neck has a pour opening. A bottom section has a container bottom and an edge area pulled up on the sides and that turns into the container body, is connected to the other longitudinal end of the container body. The container bottom has a curved concave section, whose periphery is connected via an axially projecting, graduated transition area to a platform that runs into the edge area pulled up on the sides. The platform and at least one partial area of the graduated transition area are interrupted by a first number of grooves. In the concave section, a second number of panel-like projections are made, which essentially extend between the graduated transition area and the longitudinal axis and end before the graduated transition area.

Owner:ALPLA WERKE ALWIN LEHNER

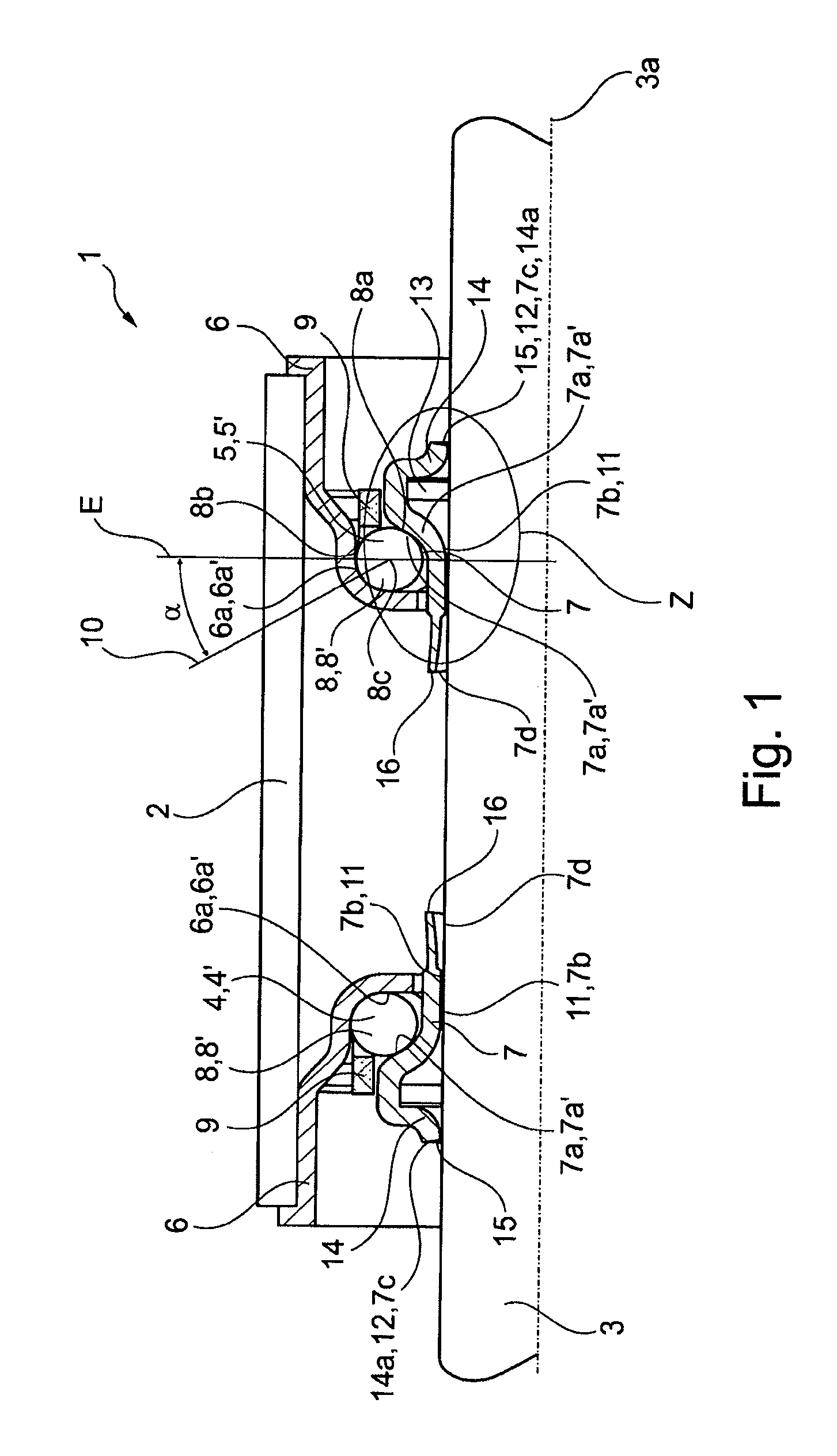

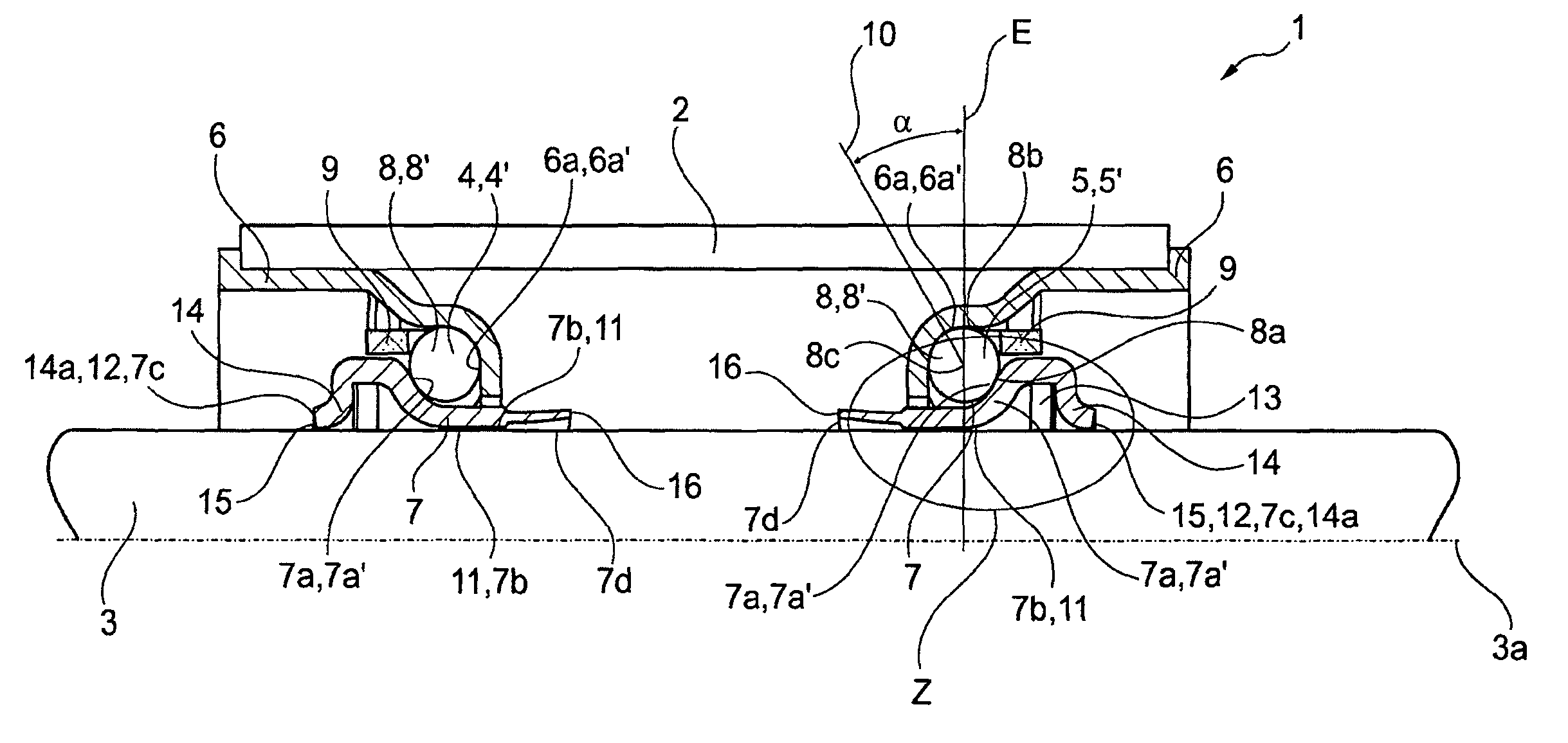

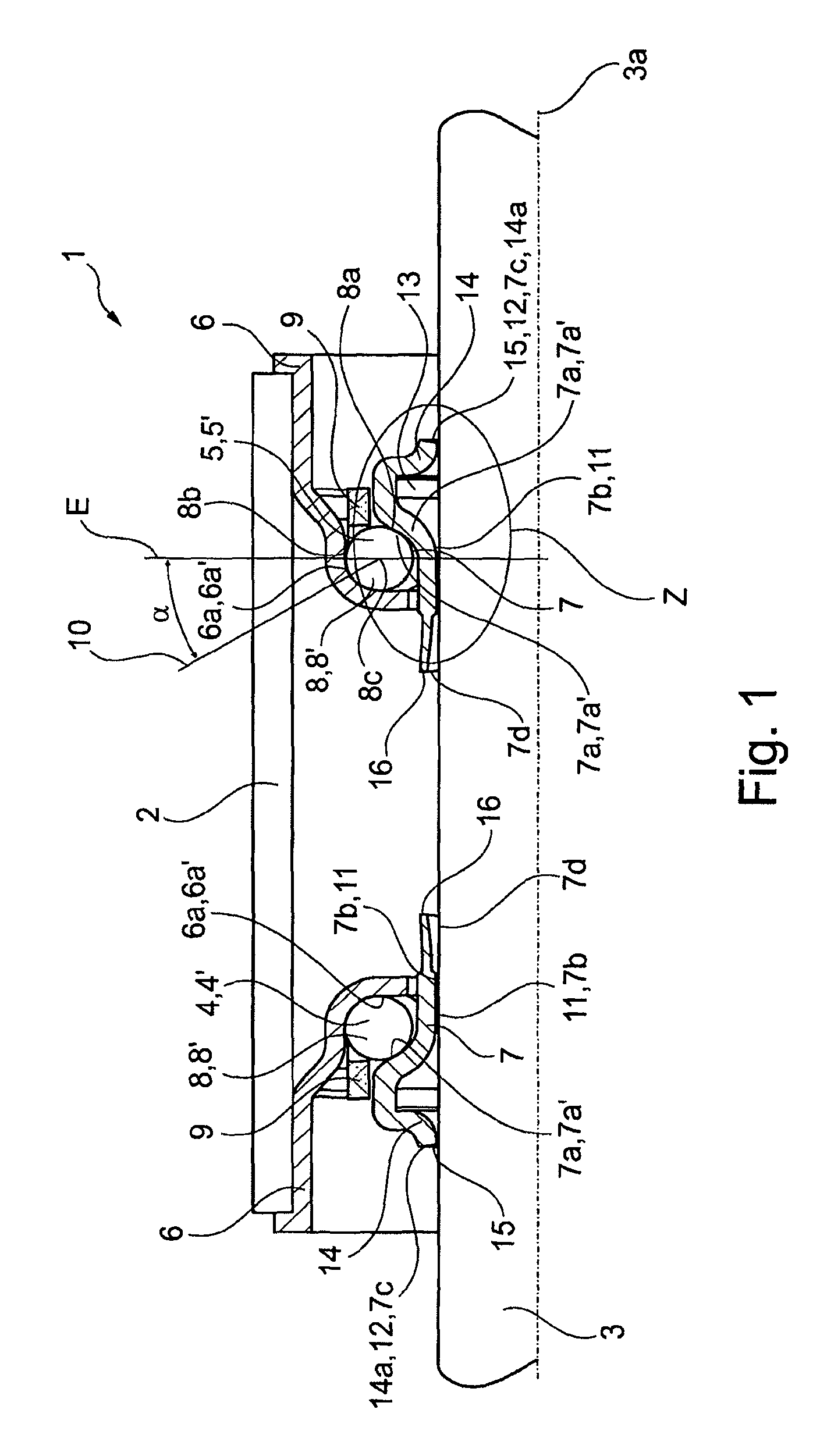

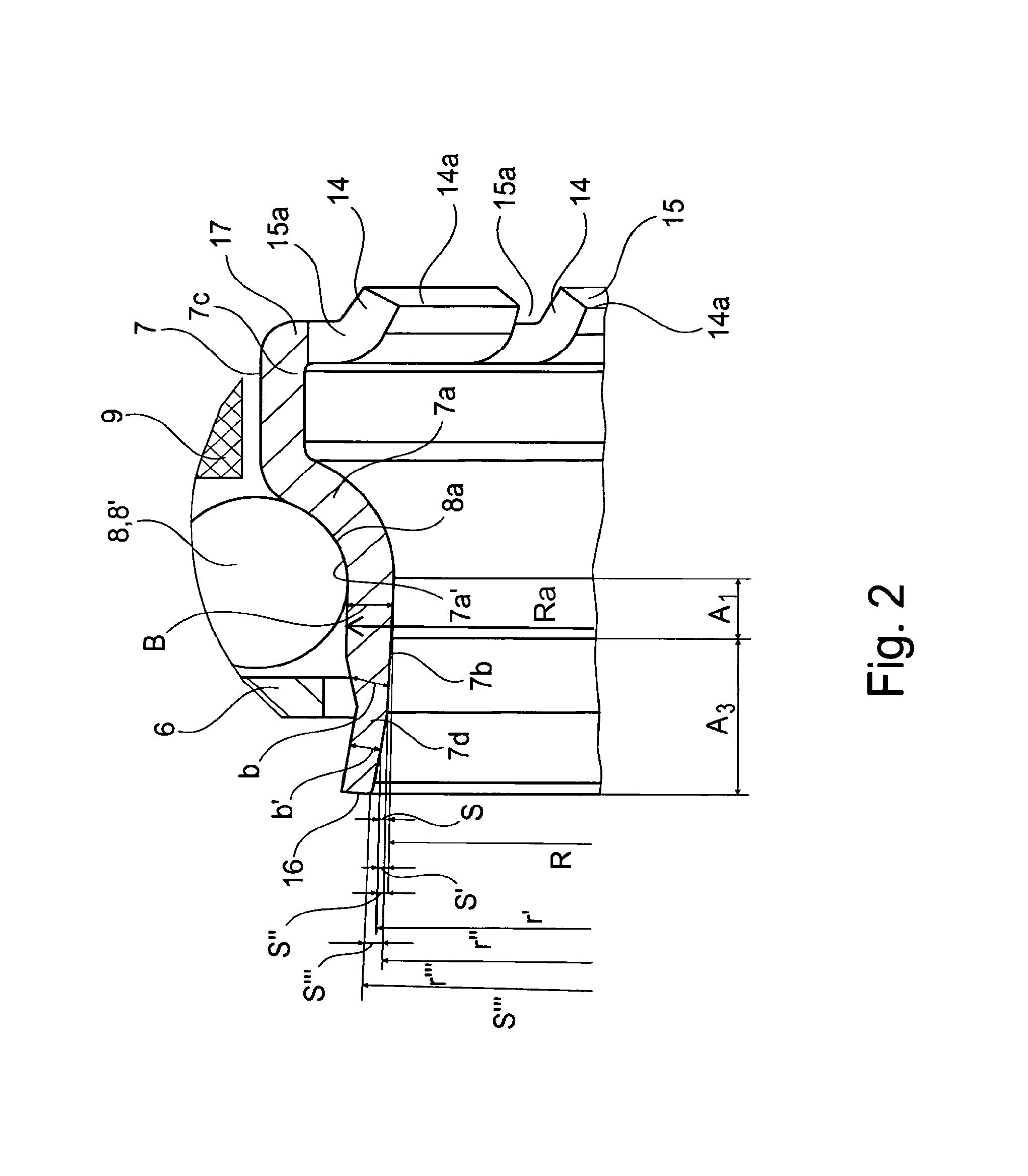

Steering column comprising a steering bearing, and a steering bearing of a steering column

InactiveUS20140157938A1Avoid contactPress firmlyBall bearingsSteering columnsSteering columnControl theory

A steering column with a steering-column tube, a steering spindle and at least one steering bearing for the rotatable mounting of the steering spindle in the steering-column tube, the steering bearing having an outer ring sitting in the steering-column tube, an inner ring and rolling bodies arranged between the outer ring and a track section of the inner ring, wherein the inner ring bears against the steering spindle at only two points and, for this purpose, has a first section which axially adjoins the track section and bears under prestress against the steering spindle at the first point, and a second section which is axially spaced apart from the first section, which axially adjoins the track section, and which has a first end of the inner ring in interaction with the steering spindle at the second point.

Owner:SCHAEFFLER TECH AG & CO KG

Device for connecting two electrical conductors

InactiveUS8267730B2Large wall thicknessProduce contact force be highCoupling device detailsScrewsBiomedical engineeringElectrical conductor

The invention relates to a device for connecting two electrical conductors (4, 5), comprising a metallic clamp (1) that is designed as a pipe section and that comprises in the wall thereof at least two through holes provided with a thread for receiving clamping screws (2) provided with an external thread. In the pipe section of the clamp (1), at least one central through hole provided with a thread is furnished between the two through holes in order to receive a fixing screw (3) provided with an external thread, wherein the fixing screw has a tapered, approximately wedge-shaped tip (11), which, in the assembled position, lies rigidly against the end faces of the two conductors (4, 5) inserted into the pipe section. The tip (11) provided with an external thread is screwed into a hole (10) of the fixing screw (3) provided with an internal thread, and the external thread of the tip (1) runs opposite to the external thread of the fixing screw (3).

Owner:NEXANS

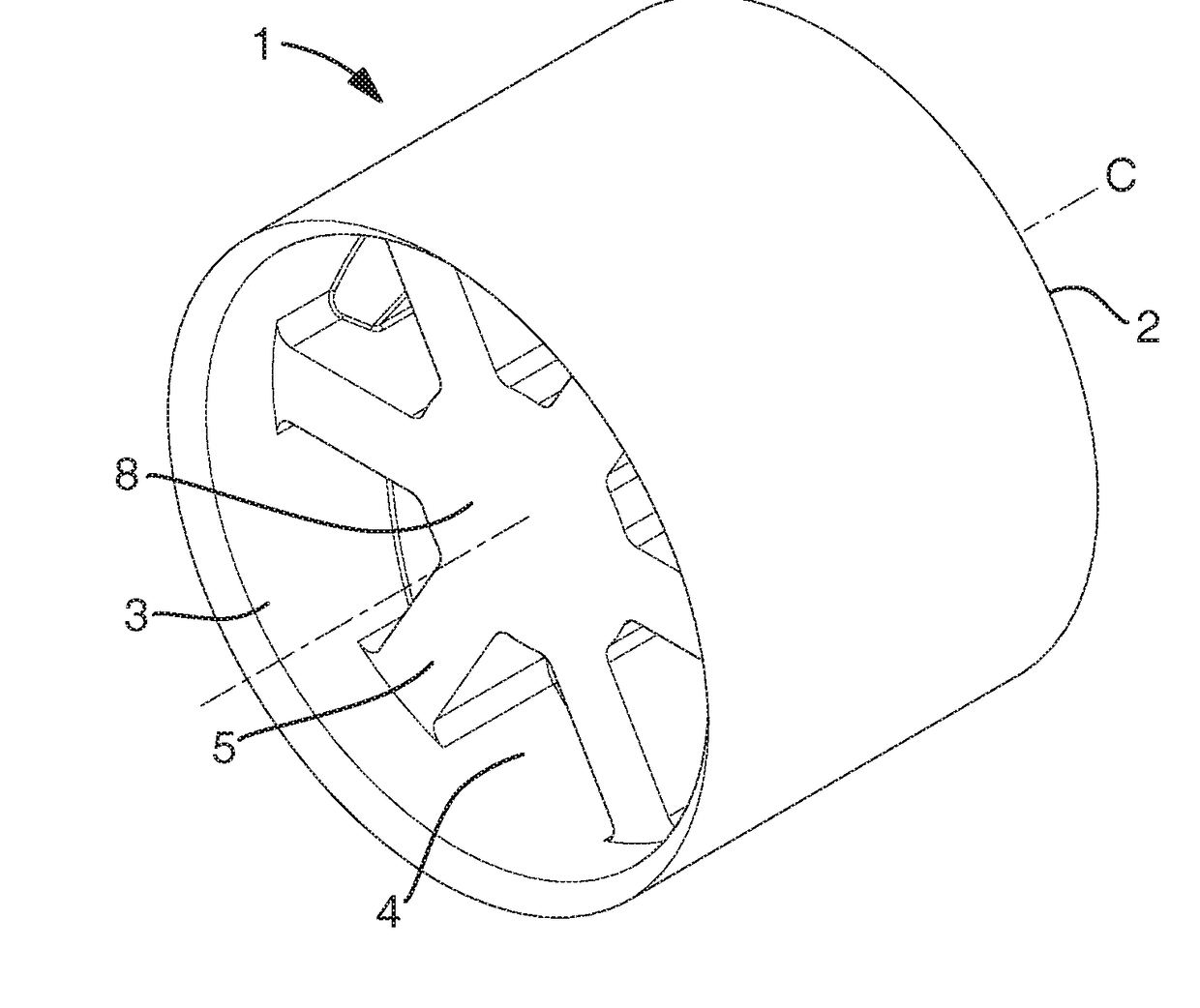

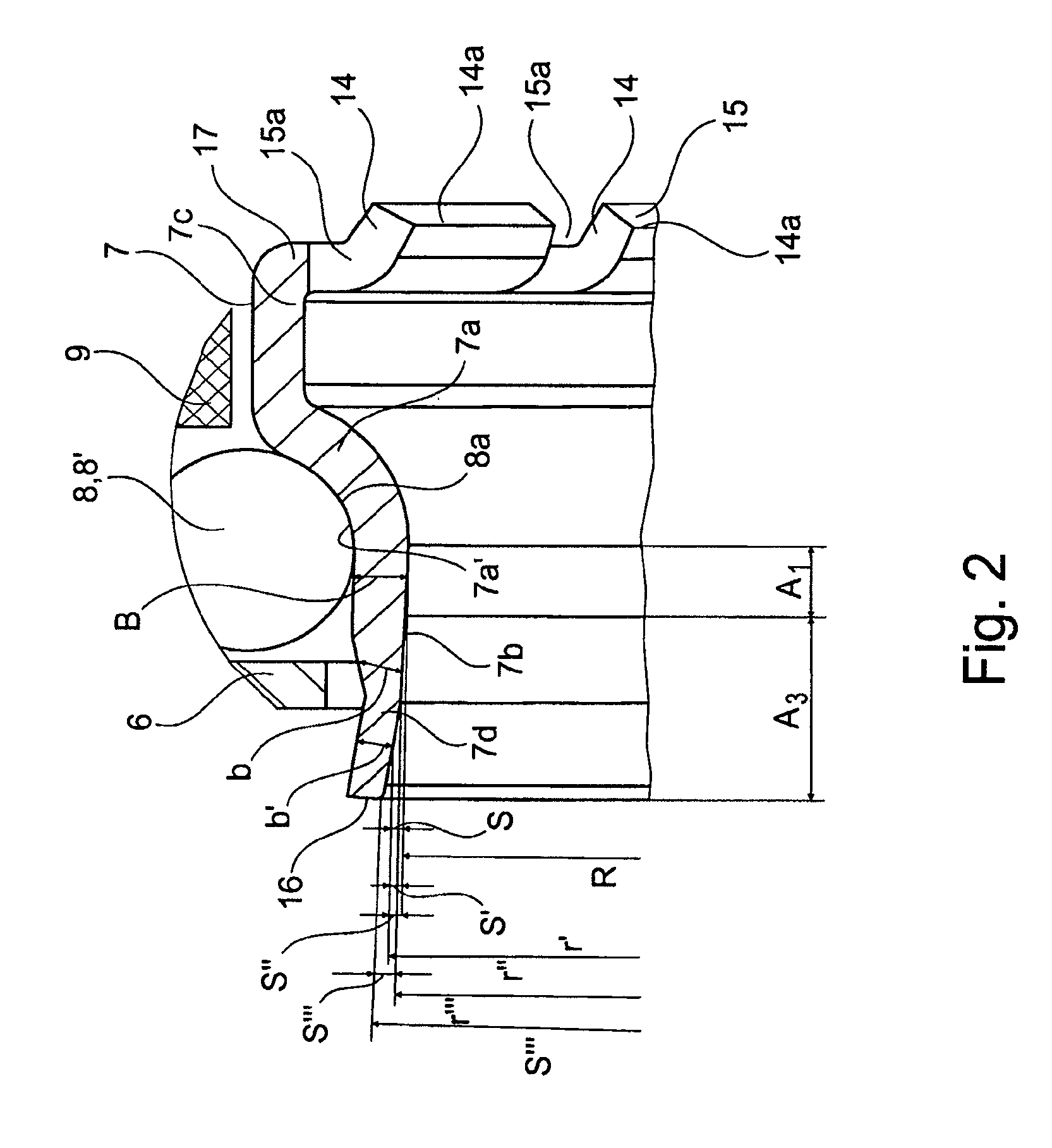

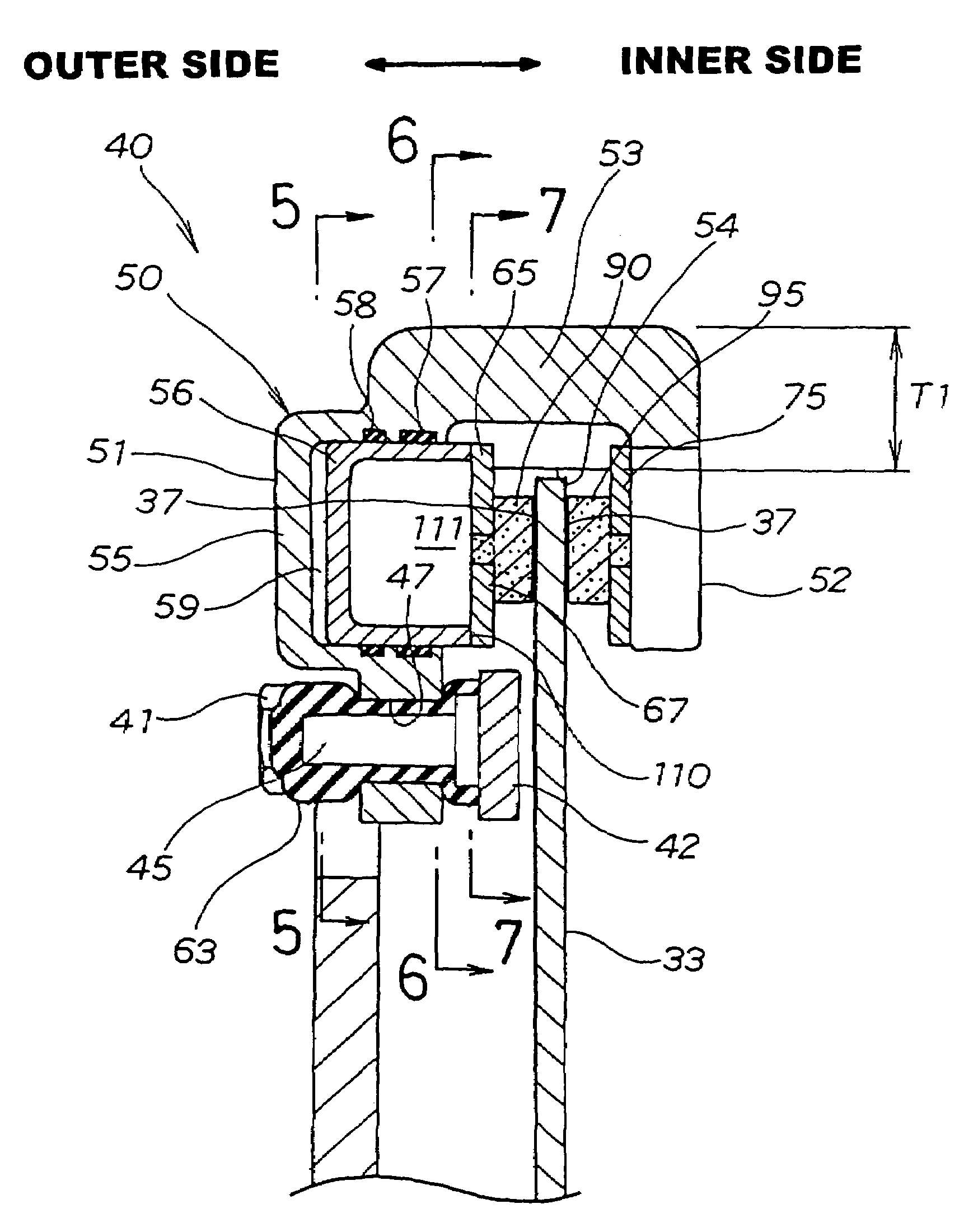

Rotation Drive Force Transmission Mechanism, Constant Velocity Universal Joint and Resin Joint Boot Constructing the Mechanism, and Method of Tightening Clamp Band for Constant Velocity Universal Joint

InactiveUS20090017923A1Control lengthEasy to set upYielding couplingMetal working apparatusUniversal jointEngineering

A rotation drive force transmission mechanism has tripod constant-velocity joints coupled to respective ends of a shaft in opposite phase. Outer members of the tripod constant-velocity joints and portions of the shaft are covered with boots. When the large-diameter tube of each of the boots is fastened to the corresponding outer member by a first fastening band, a band crimping ratio is managed so as to fall within a predetermined range. Each of the outer members has a boot mount whose shape is selected to satisfy predetermined equations.

Owner:HONDA MOTOR CO LTD

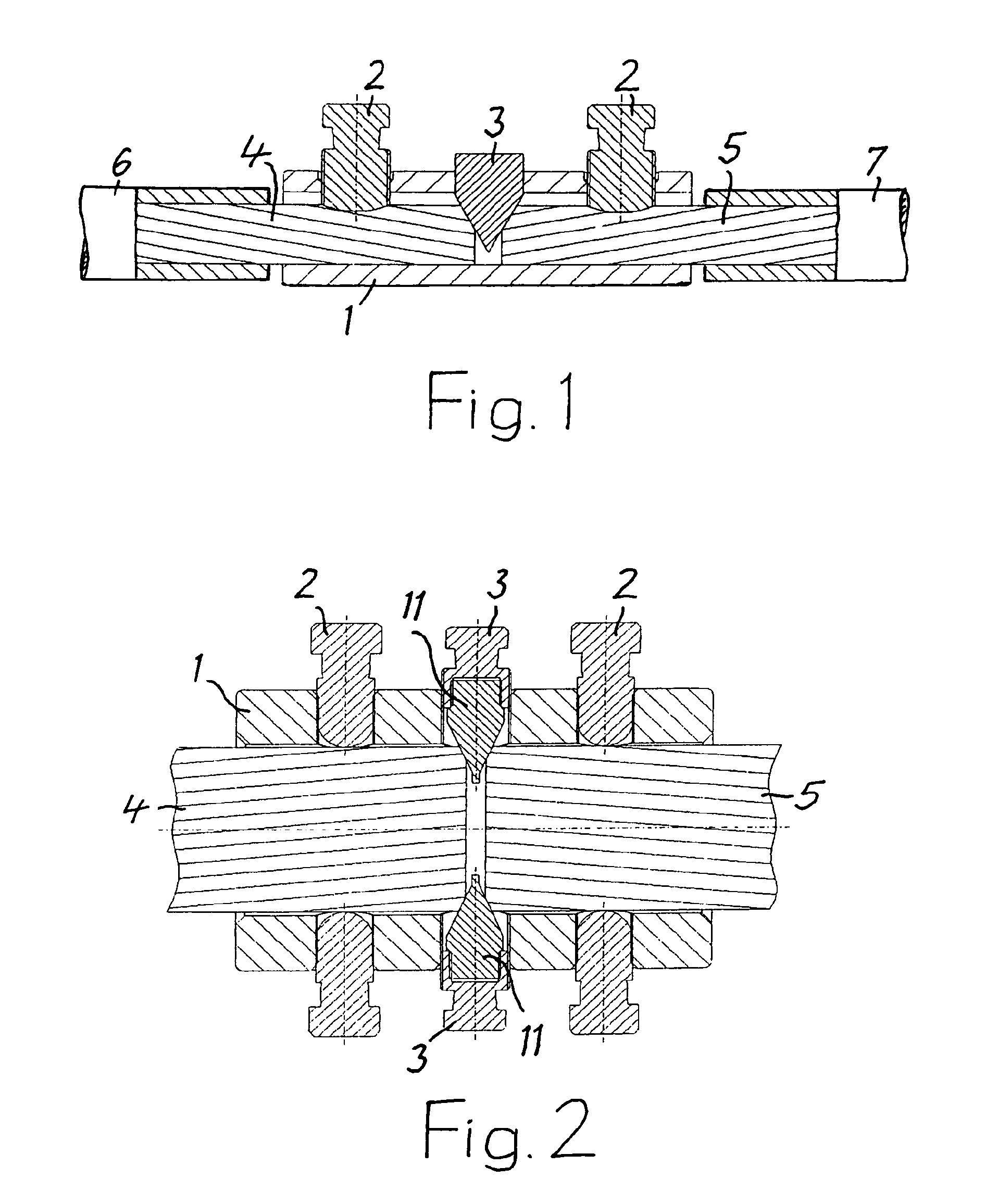

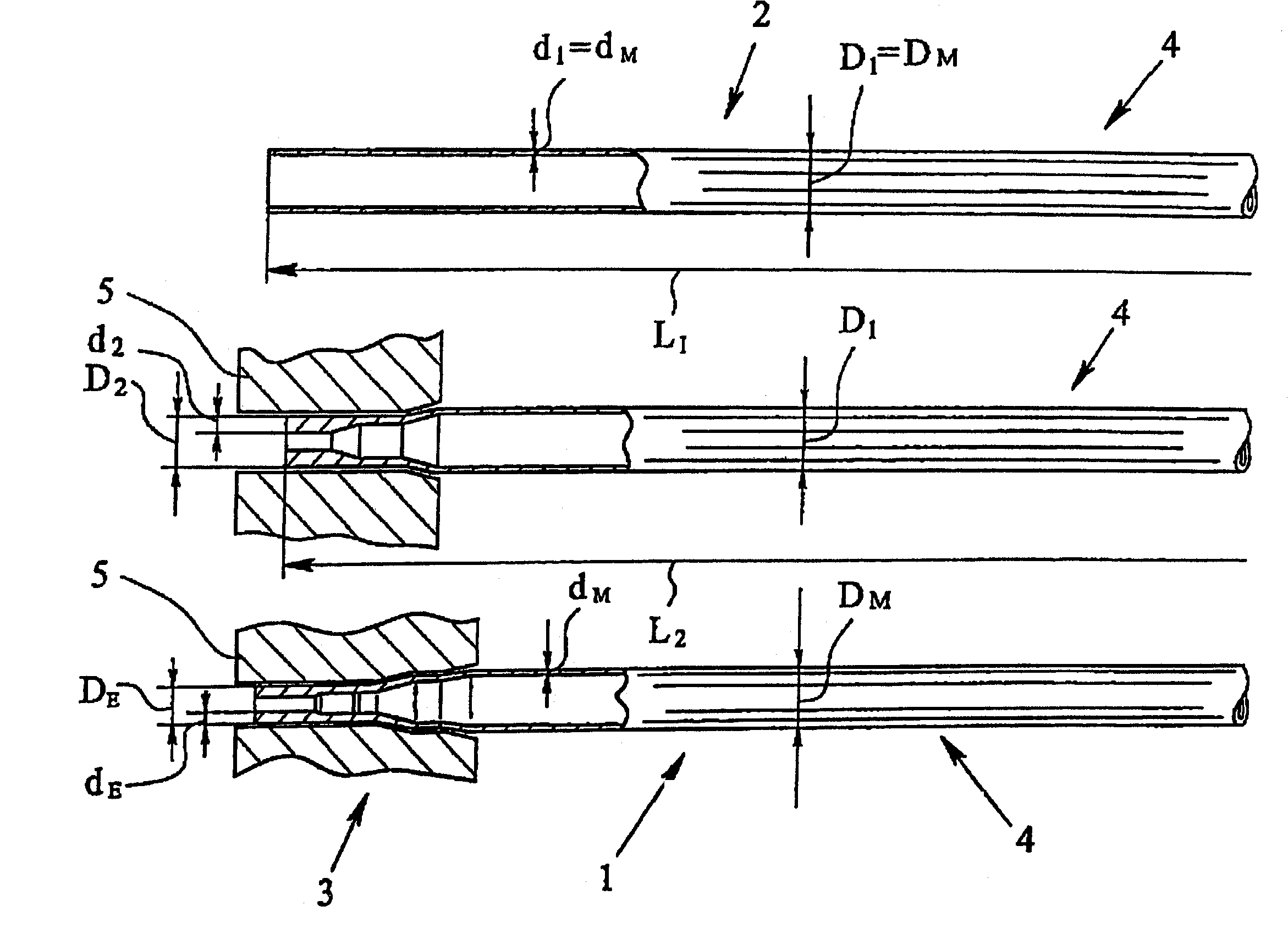

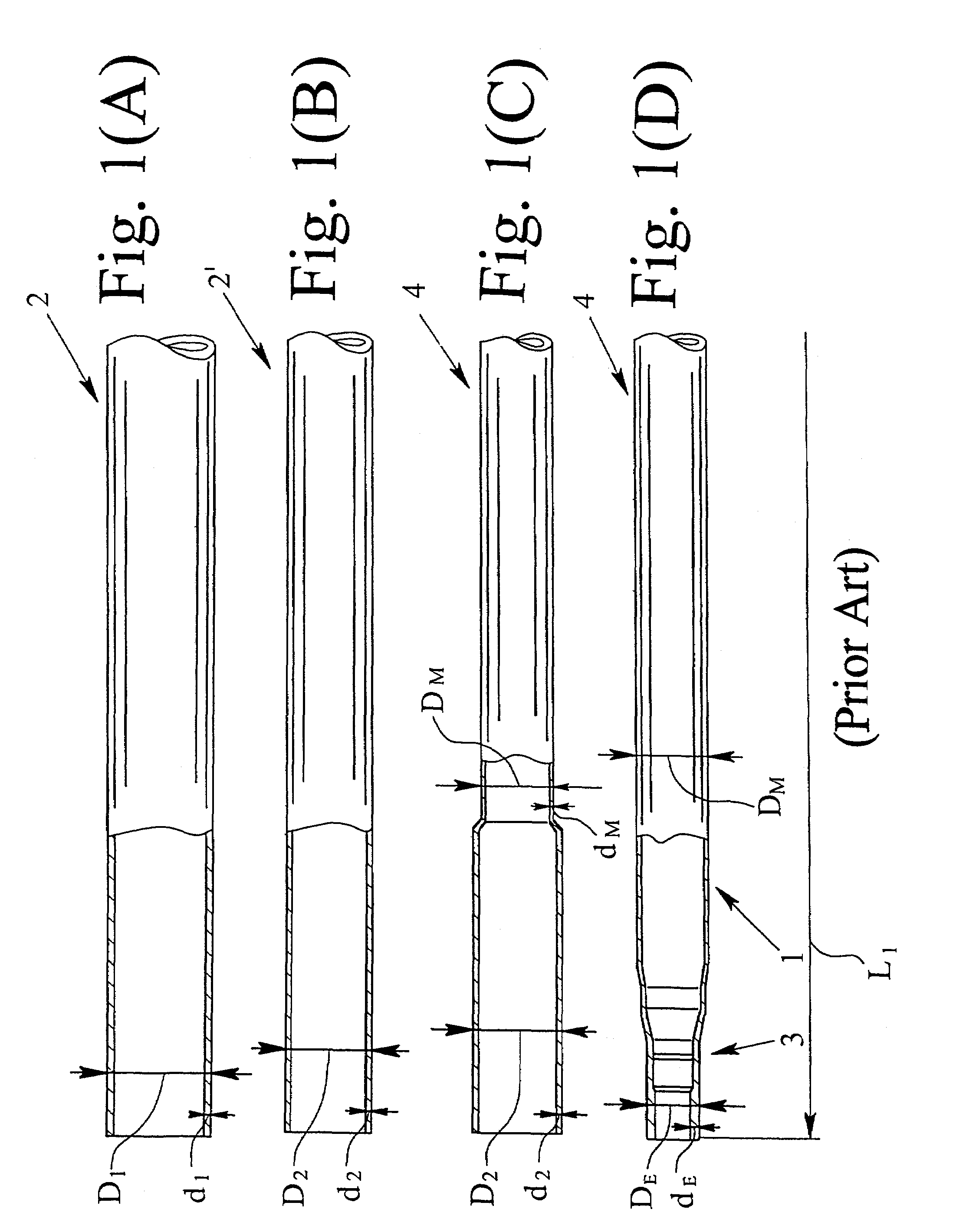

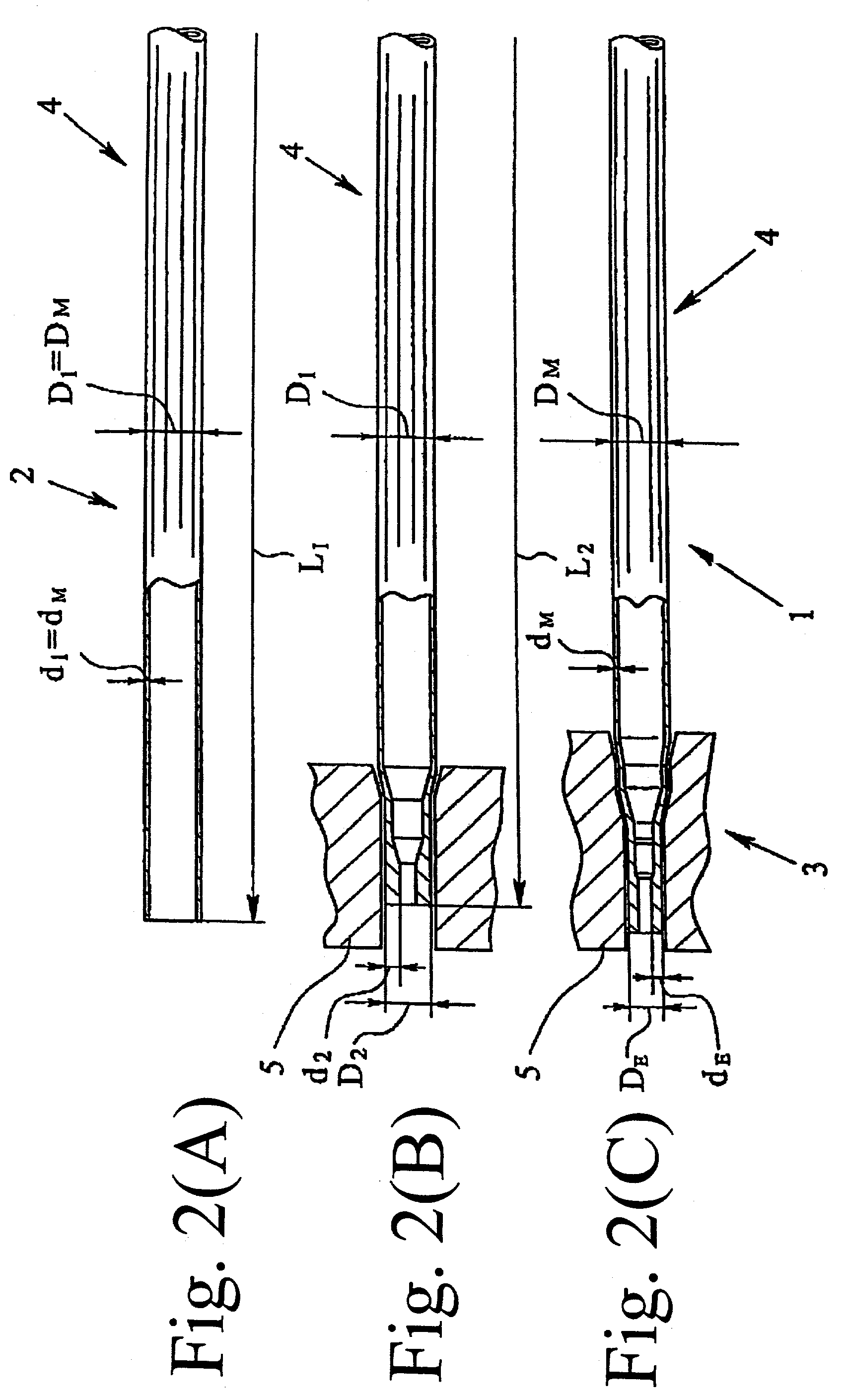

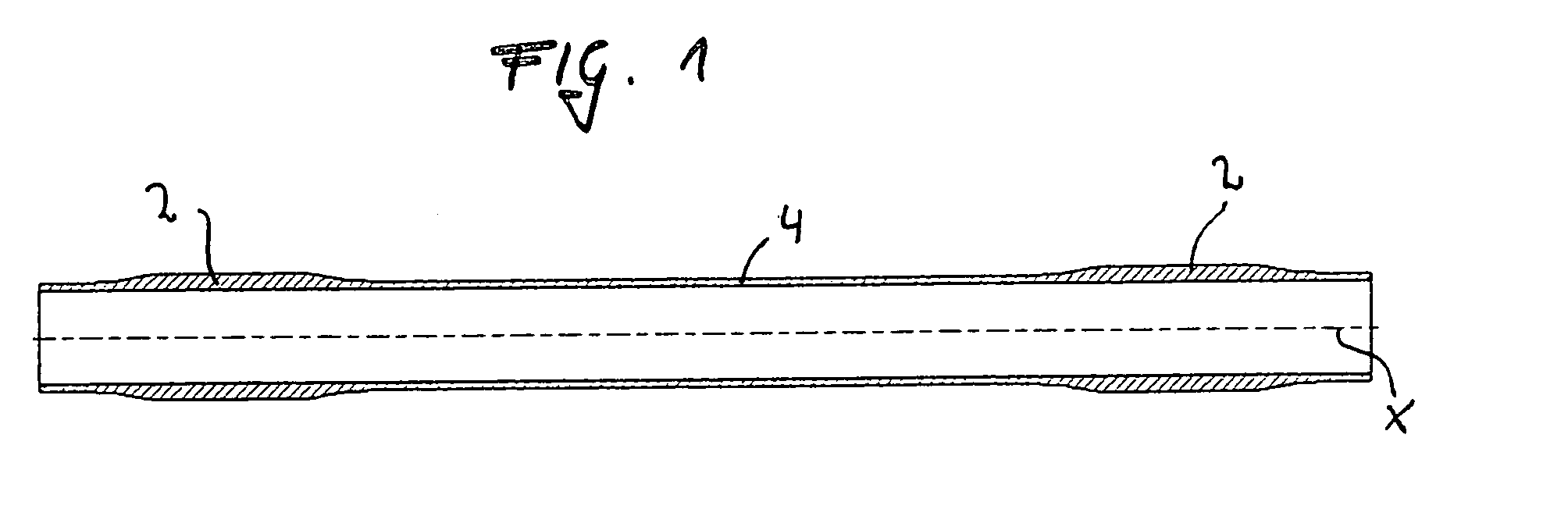

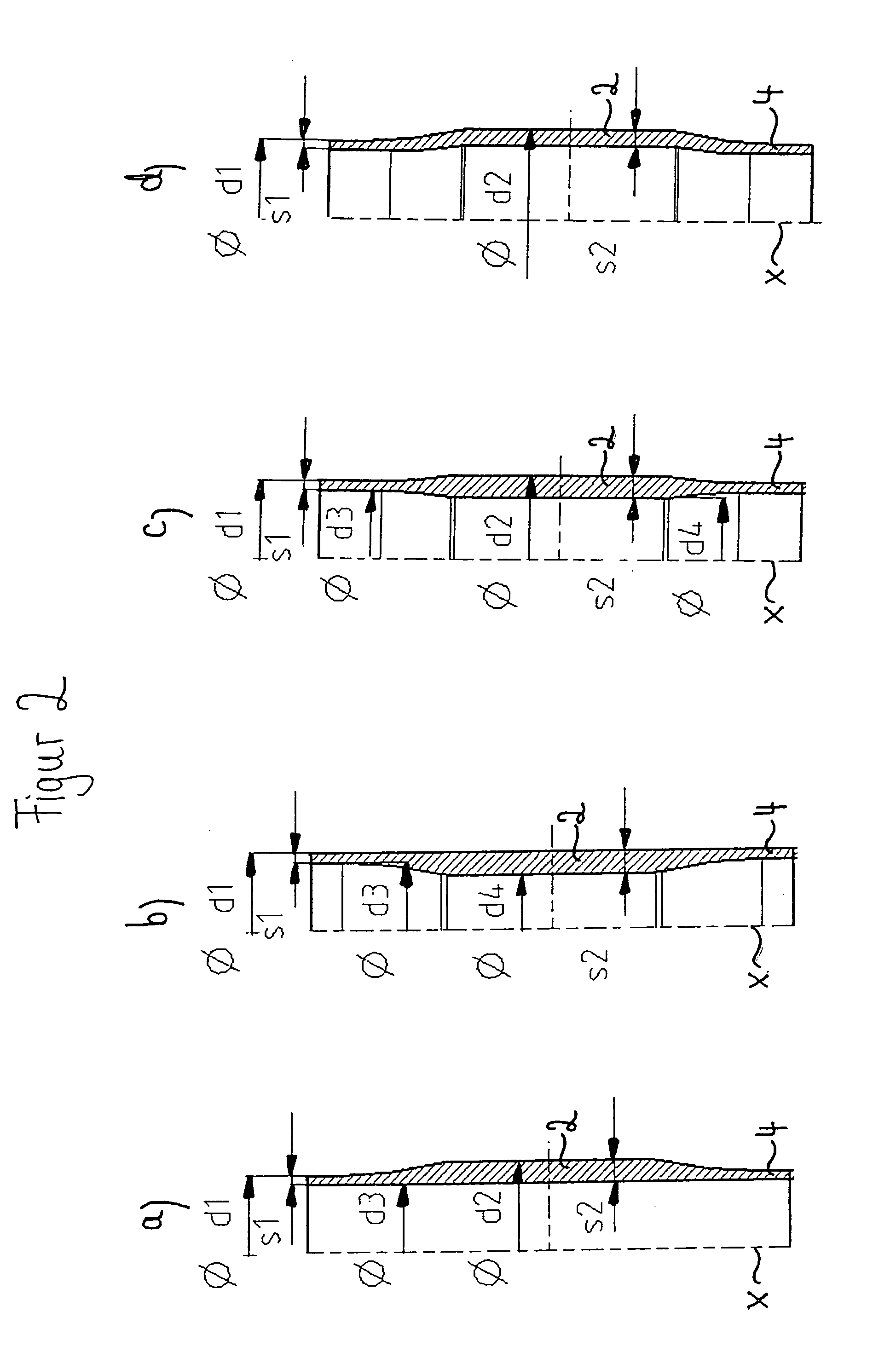

Process for producing rotationally symmetrical components

InactiveUS7275407B2More economicallyIncreasing the thicknessExtrusion diesForging hammersPartial heatingRadial forging

A process for producing a hollow monoblock shaft from a pipe, the pipe initially having a constant diameter and a constant wall thickness, and the monoblock component including at least one area of its length being of a smaller outside diameter and a greater wall thickness than the constant diameter and constant wall thickness of the pipe. The process can be carried out simply and economically by the following process steps:selecting a pipe with a wall thickness which corresponds to the smallest wall thickness of the finished component,partial heating of at least one area of the pipe,axial upsetting the heated area of the pipe andradial forging the heated area of the pipe.

Owner:MUHR UND BENNDER KG

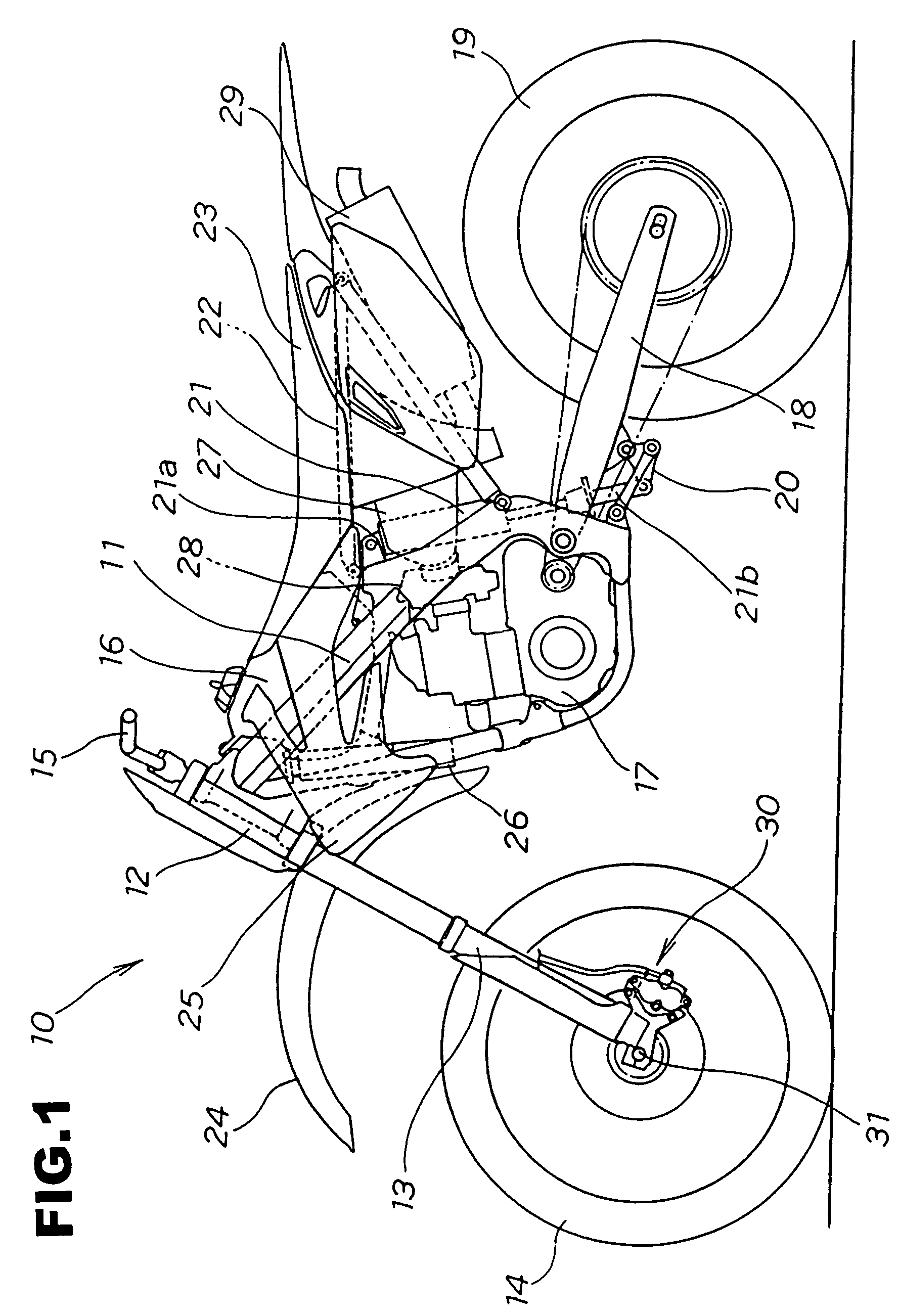

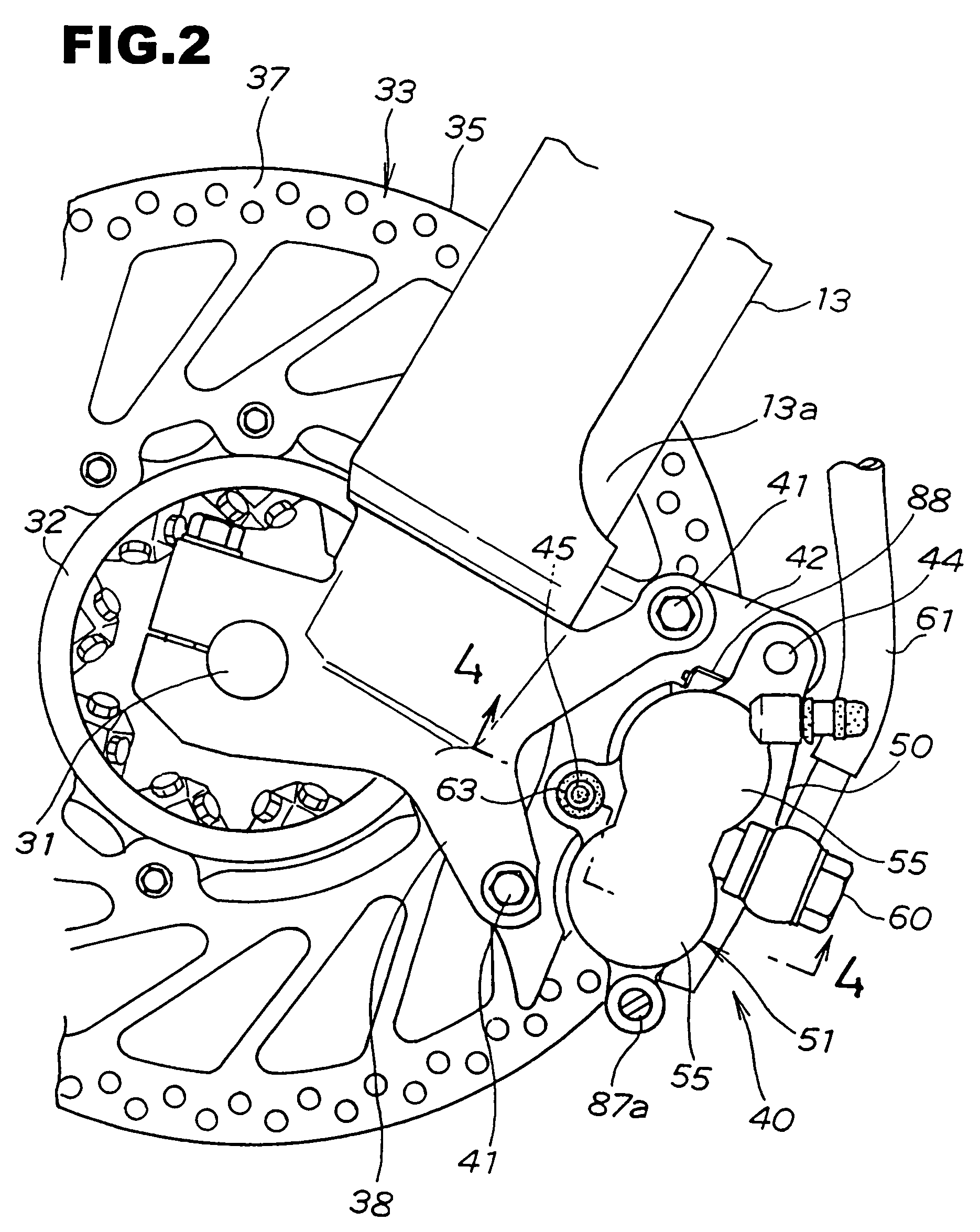

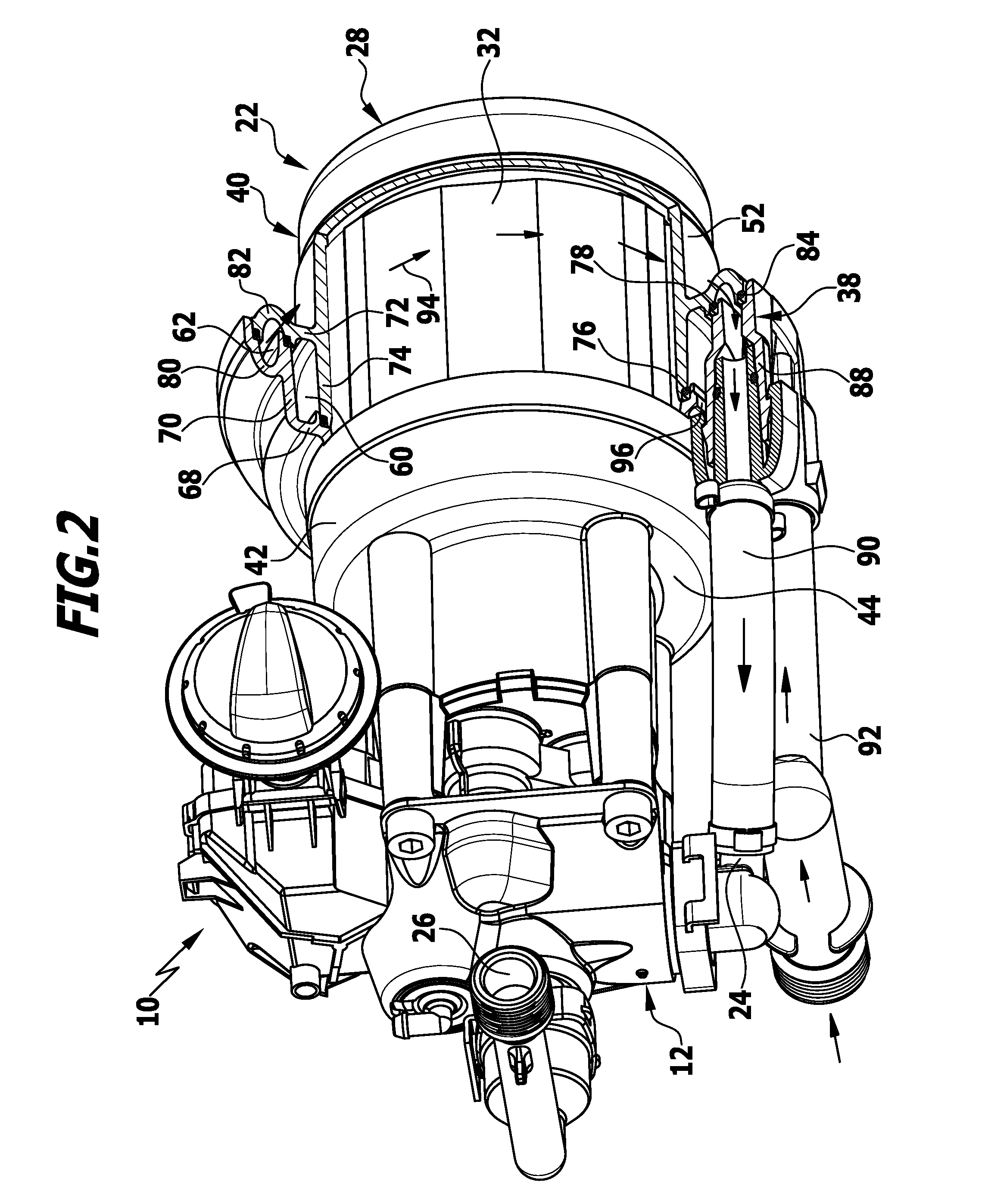

Disk brake unit for motorcycle

ActiveUS7275624B2Increase braking powerLarge wall thicknessFluid actuated brakesBraking element arrangementsEngineeringMechanical engineering

To provide a motorcycle disk brake that can ensure brake force and also enable miniaturization.A motorcycle disk brake unit (10) has a part (105) of a piston (56) which projects outwards from an outer edge (35) of a brake disk (33), and by forming parts (67), within an outer back plate (65) and an inner back plate (75), corresponding to the piston (56) following the piston (56) so that an outer pad (90) and an inner pad (95) do not project out further than the outer edge (35) of the brake disk (33), another part (68) following the outer edge (35) of the brake disk (33), and a bridge section (53) following respective back plates (65), (75), a part (54) of the bridge section (53) can project further inwards than the piston (56) resulting in miniaturization of disk brake unit (10).

Owner:HONDA MOTOR CO LTD

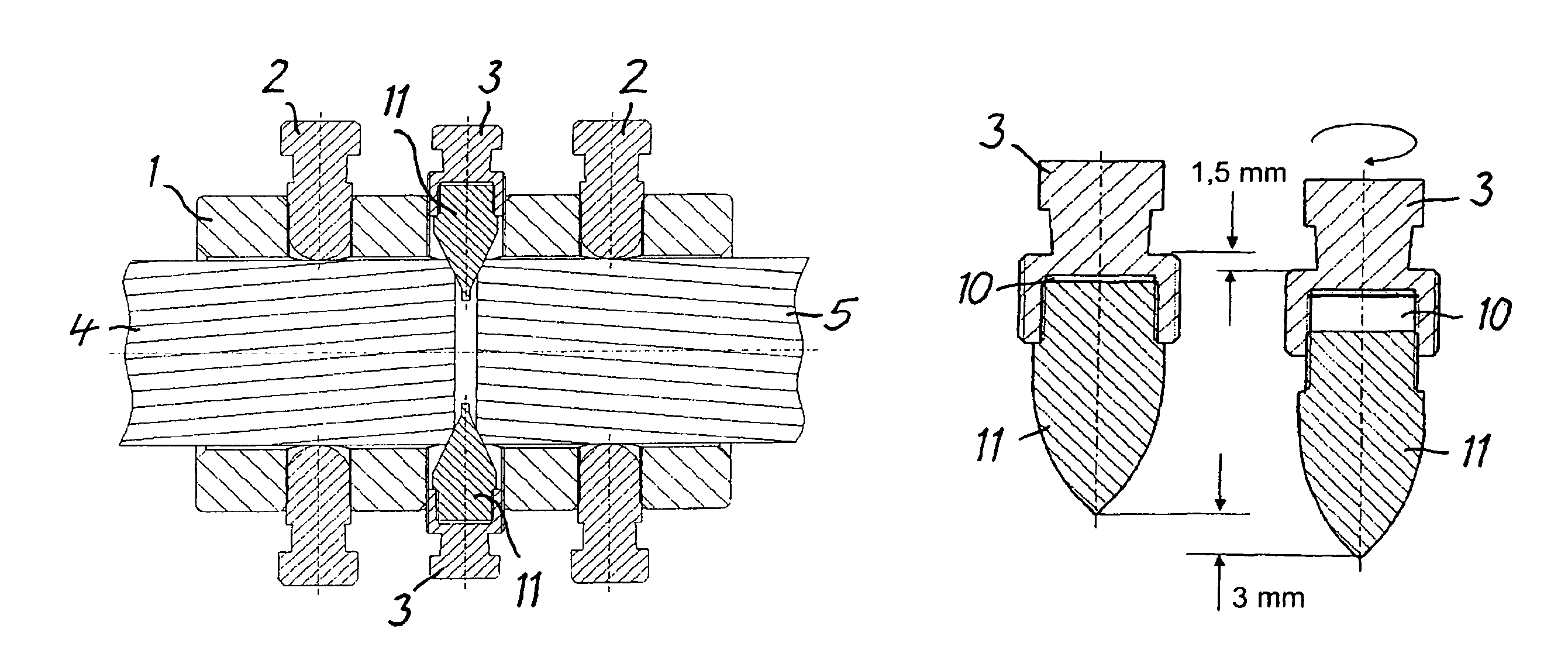

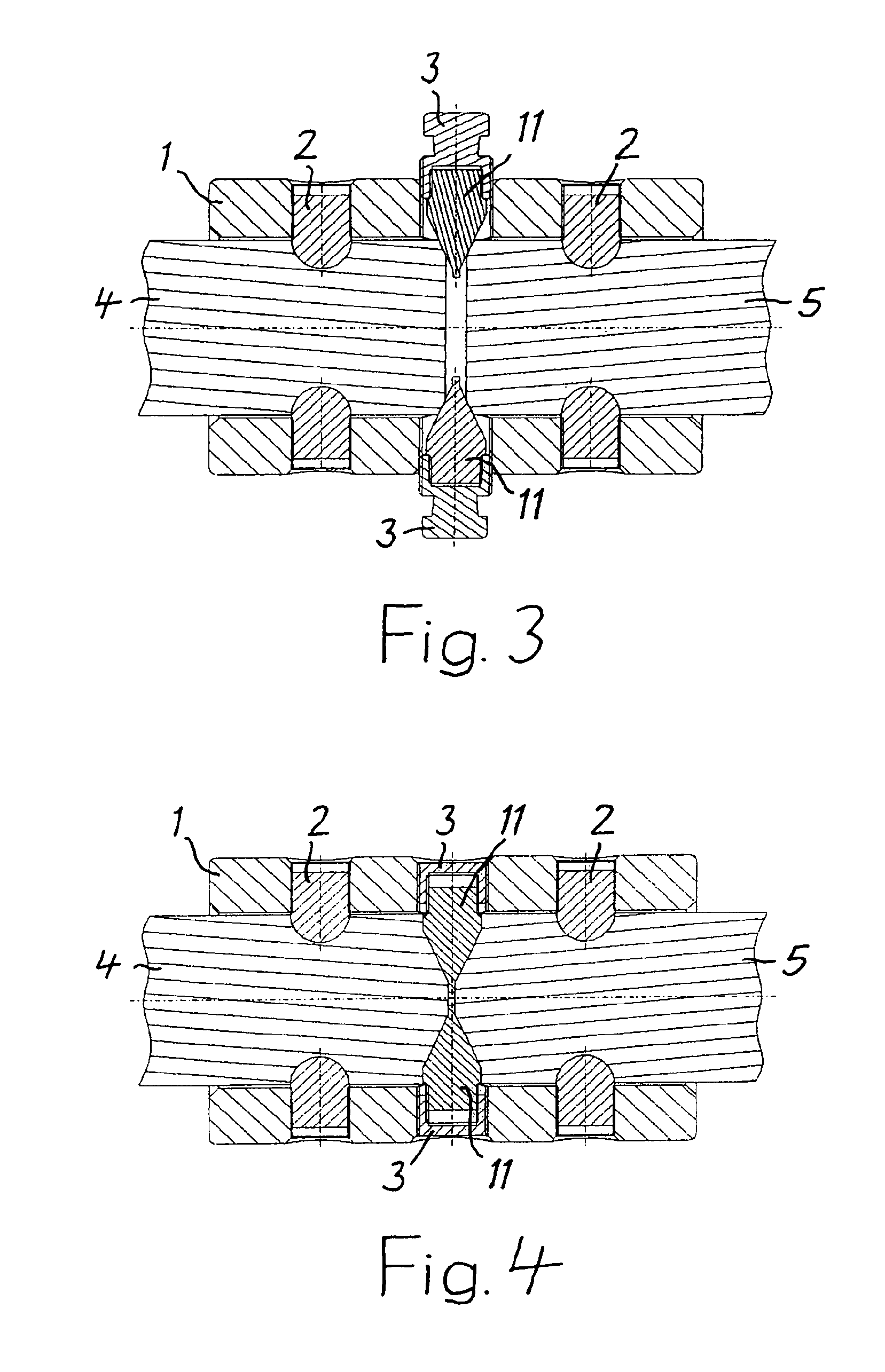

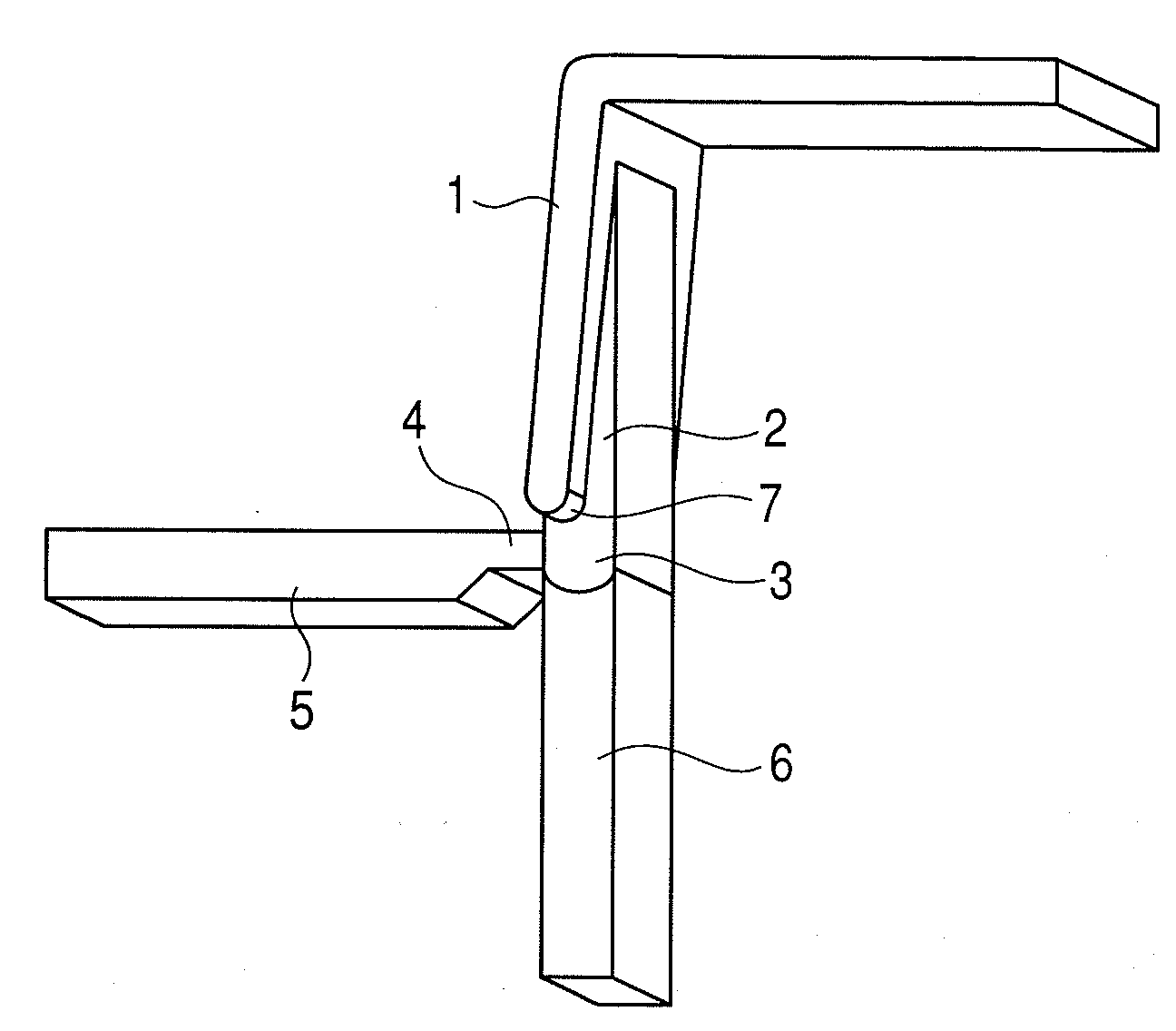

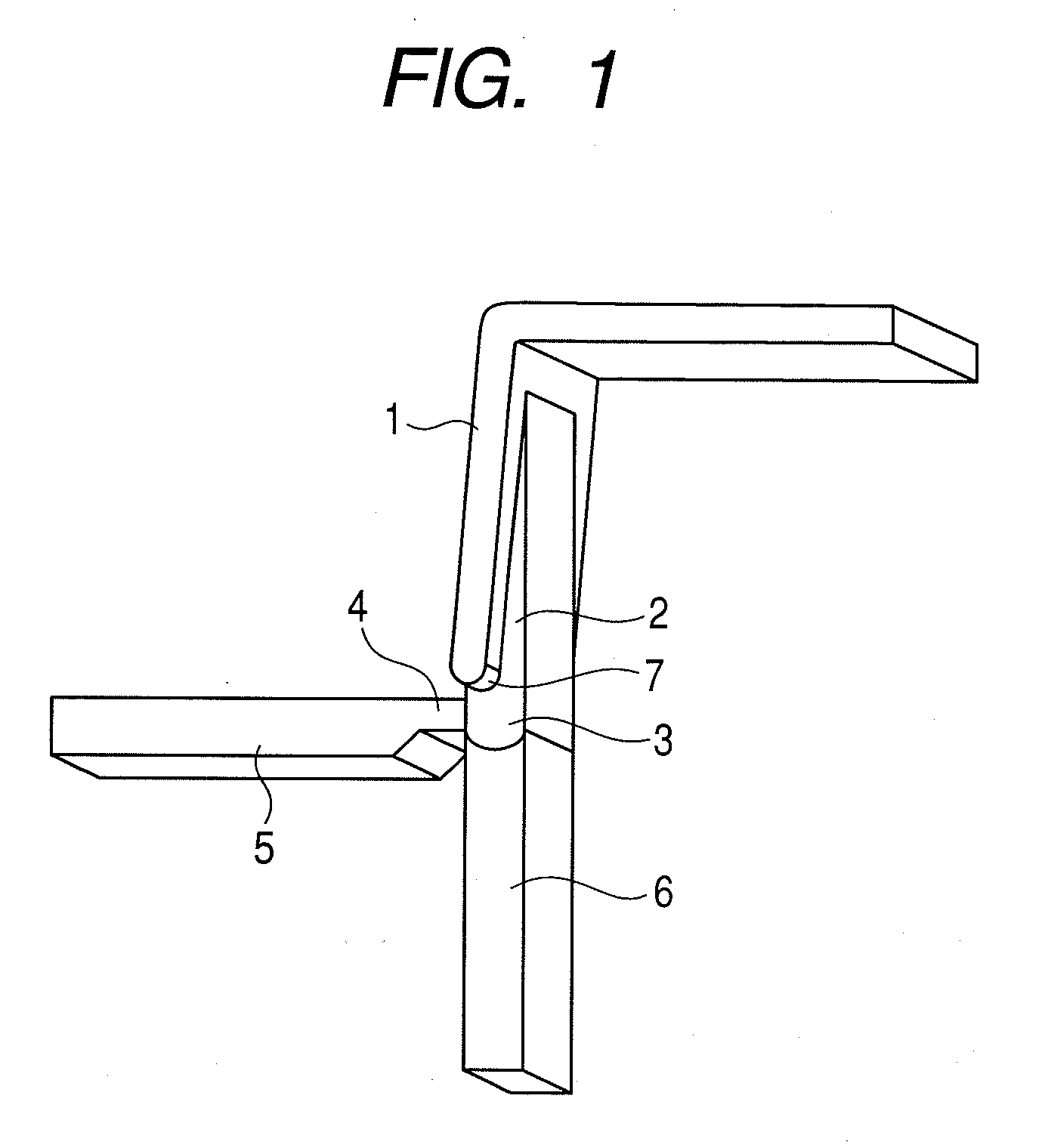

Injection molding process, resin molded product and mold

InactiveUS20100047500A1Improve productivityHigh appearance requirementsStampsFlexible coversInjection molding processComposite material

The invention provides an injection molding process, in which a gate is cut off within a mold in resin molding to obtain a good gate-cut surface, as well as a resin molded product and a resin molding mold. In the injection molding process, a cutting pin, which is connected to a cutting pin working plate provided in parallel with a driving device or an ejector plate provided in a mold, slides on a mold parting line between a fixed-side block, on which corner cutting or a R shape is provided at the approach port, and a movable-side block opposed to the fixed-side block. The wall thickness of a compression shape portion opposed to the cutting pin is larger than that of a gate and a product shape portion. The cutting pin compresses a resin in this portion toward the product shape portion at predetermined timing to cut off the gate portion and integrate the resin with the product shape.

Owner:CANON KK

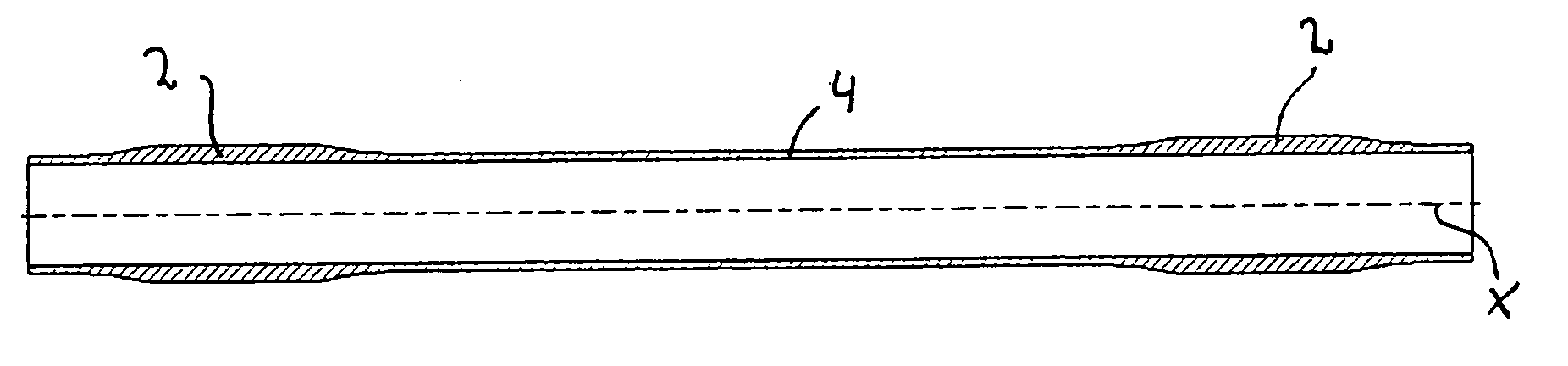

Axle body

ActiveUS20100013295A1Constant wall thicknessIncrease wall thicknessEngine componentsResilient suspensionsEngineeringCommercial vehicle

The invention relates to an axle body, particularly for a commercial vehicle, wherein the body is configured substantially as an axle pipe, which comprises a center section and at least one receiving section connected thereto for receiving an axle guide, wherein the axle body in the center section has a substantially constant wall thickness, and wherein the axle body in the receiving section, at least in some regions, has a wall thickness that is greater than the wall thickness of the center section.

Owner:SAF HOLLAND GMBH

Process for producing hollow metal articles

The invention concerns a process for producing a metallic hollow body (1), in which a hollow cast part (1′) is produced by metal casting, in which the cast part (1′) is deformed by means of internal high pressure deformation in the hollow body (1). In order to improve the quality of the hollow body (1), the cast part (1′) is so produced, that it has a wall thickness distribution supporting or simplifying the internal high pressure deformation.

Owner:DAIMLER AG

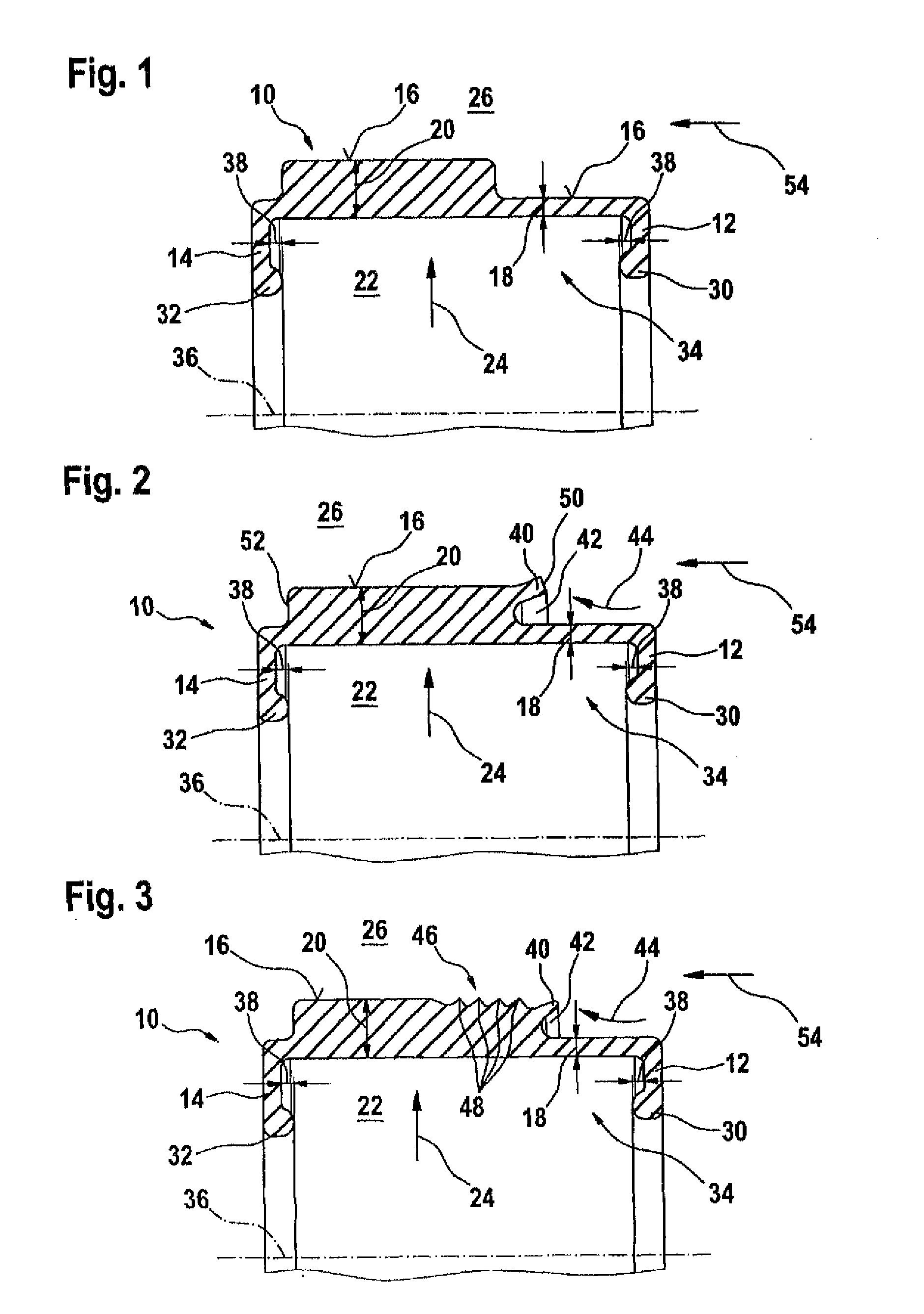

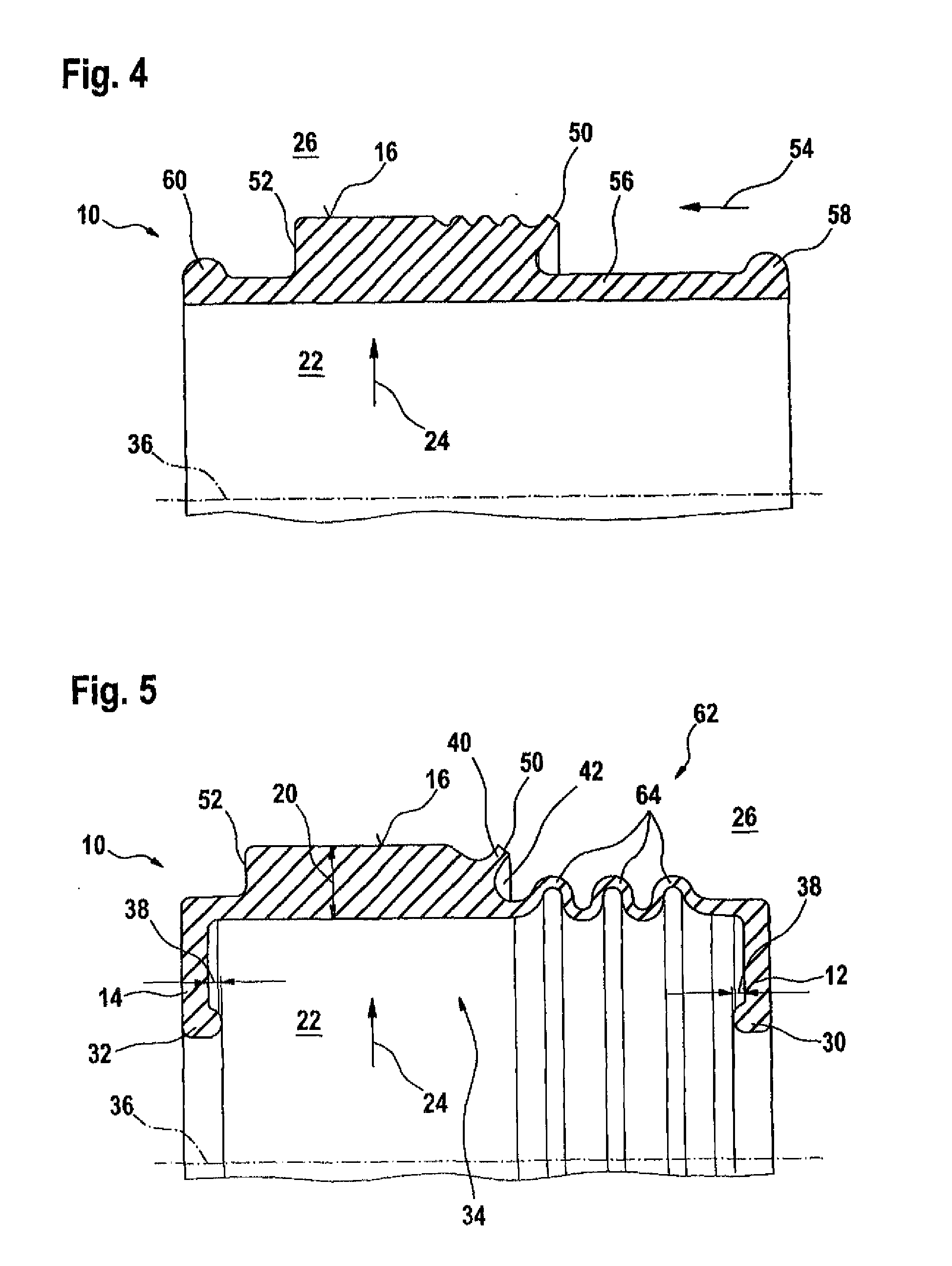

Pressurizable sealing element

ActiveUS20120112102A1Stable removalNotDiaphragm valvesOperating means/releasing devices for valvesEngineeringMechanical engineering

The invention relates to a sealing element (10) to be mounted on a plugging head (76). The plugging head (76) is introduced into an access opening in the pipeline (70) or pipe (70). The pressurizable sealing element (10) delimits at least one pressurizable cavity (22, 92) with an inner surface (78), and seals an inner wall (74) of the pipeline (70) or pipe (70) with a generated surface (16, 40, 46, 48) when a pressure pi is applied to the cavity (22, 92).

Owner:STADLER ACHIM

Plastic container

A plastic container for storing liquid under a low overpressure having a container body, to whose one longitudinal end a container neck is connected, which neck has a pour opening. A bottom section has a container bottom and an edge area pulled up on the sides and that turns into the container body, is connected to the other longitudinal end of the container body. The container bottom has a curved concave section, whose periphery is connected via an axially projecting, graduated transition area to a platform that runs into the edge area pulled up on the sides. The platform and at least one partial area of the graduated transition area are interrupted by a first number of grooves. In the concave section, a second number of panel-like projections are made, which essentially extend between the graduated transition area and the longitudinal axis and end before the graduated transition area.

Owner:ALPLA WERKE ALWIN LEHNER

Method of producing an optical member

InactiveUS7007510B2Improve thermal conductivityReduce areaGlass reforming apparatusGlass severing apparatusSpecial designEngineering

An object of the present invention is to provide an improved blank such that an optical member of a high homogeneity can be obtained therefrom, and to provide a vessel and a heat treatment method for heat-treating a highly uniform synthetic quartz blank. In a first aspect of the invention a special designed blank is provided showing a concave shaped outer surface. In a second aspect of the invention a special designed vessel for heat-treating blanks is provided, whereby the degree of heat emission at the center is set higher than that of the surroundings.

Owner:HERAEUS QUARZGLAS +1

Steering column comprising a steering bearing, and a steering bearing of a steering column

InactiveUS8997601B2Easy to manufactureReliable functionBall bearingsSteering columnsSteering columnEngineering

A steering column with a steering-column tube, a steering spindle and at least one steering bearing for the rotatable mounting of the steering spindle in the steering-column tube, the steering bearing having an outer ring sitting in the steering-column tube, an inner ring and rolling bodies arranged between the outer ring and a track section of the inner ring, wherein the inner ring bears against the steering spindle at only two points and, for this purpose, has a first section which axially adjoins the track section and bears under prestress against the steering spindle at the first point, and a second section which is axially spaced apart from the first section, which axially adjoins the track section, and which has a first end of the inner ring in interaction with the steering spindle at the second point.

Owner:SCHAEFFLER TECH AG & CO KG

Axle body

ActiveUS8353562B2Constant wall thicknessUniform toleranceEngine componentsResilient suspensionsEngineeringCommercial vehicle

Owner:SAF HOLLAND GMBH

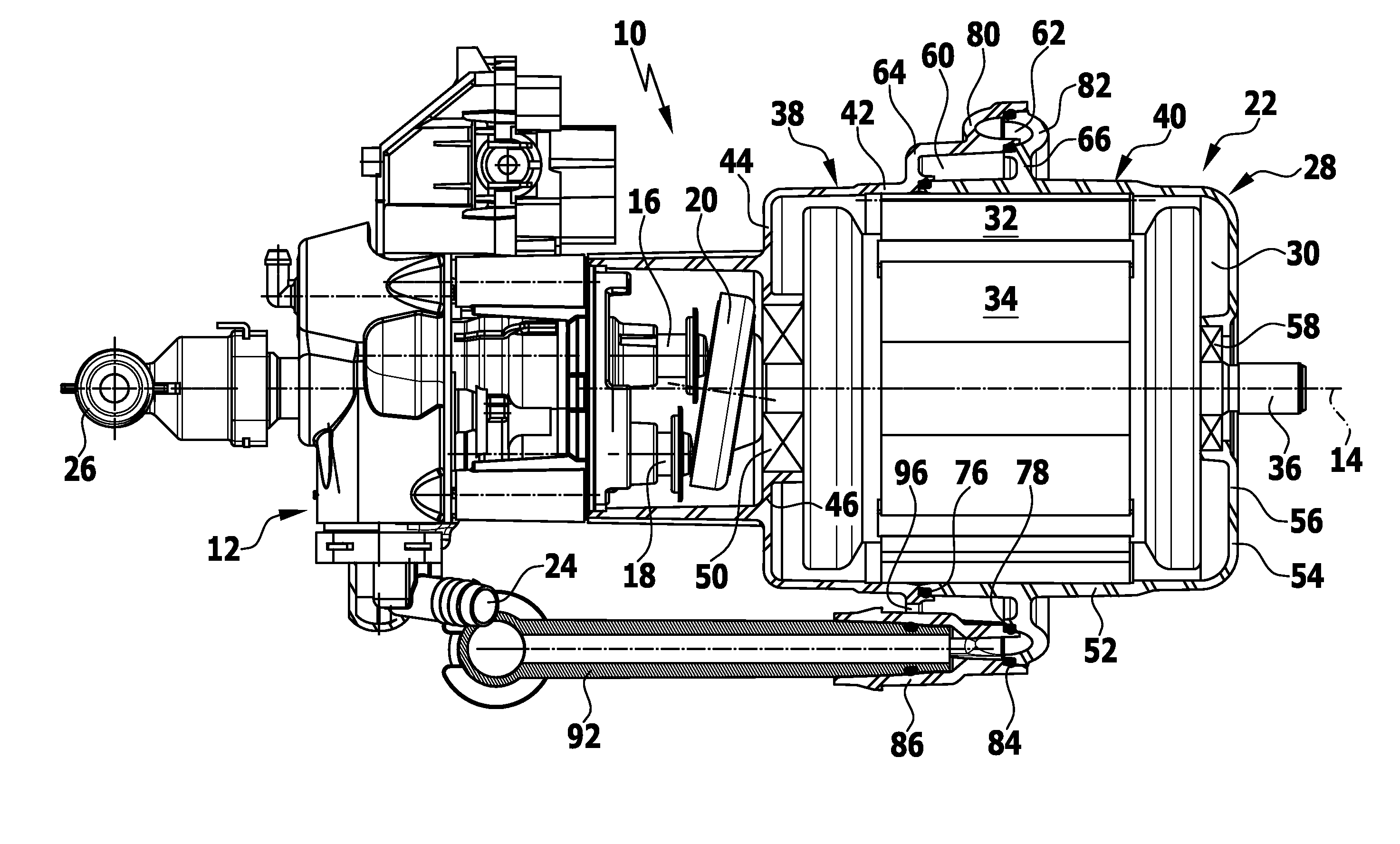

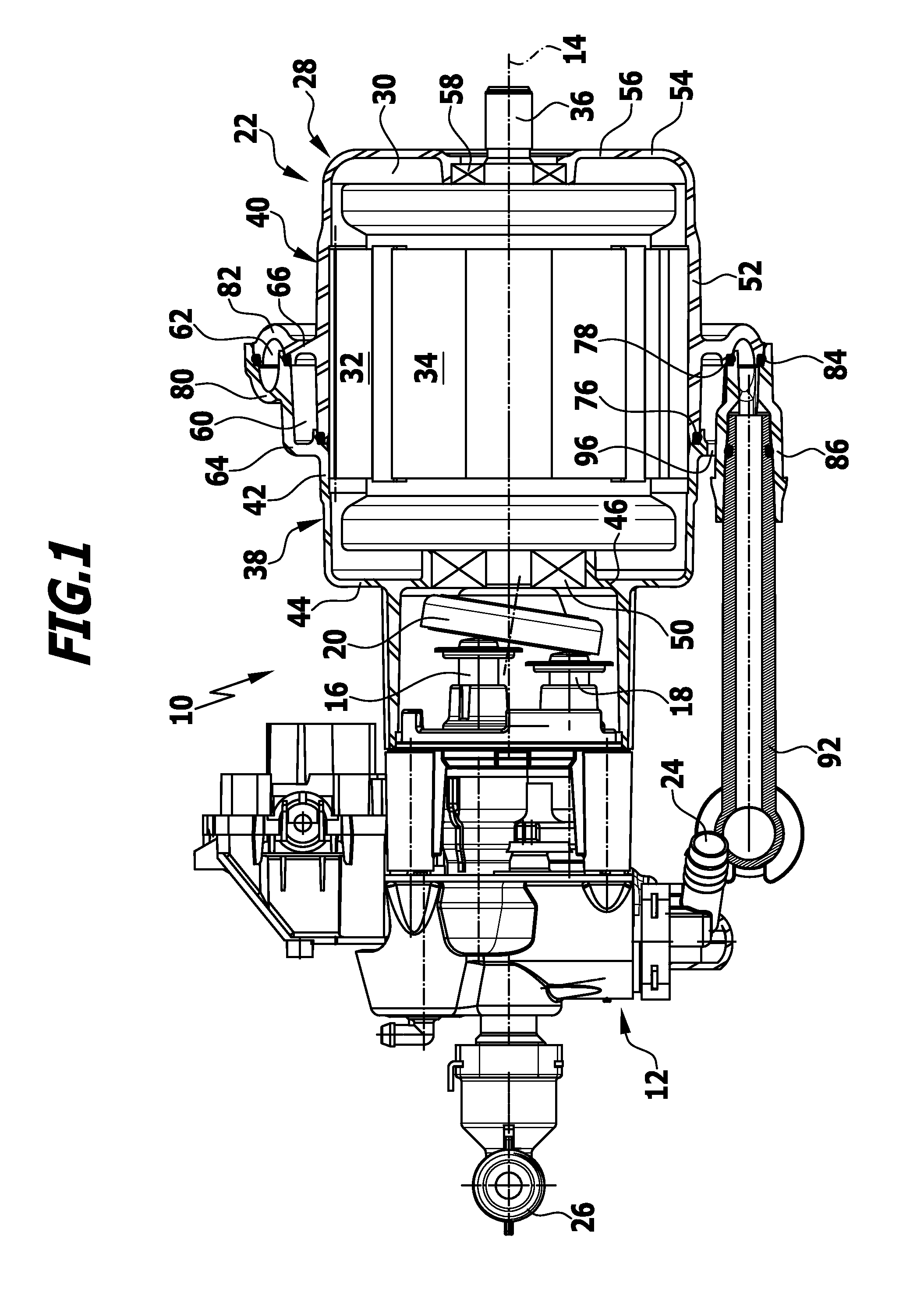

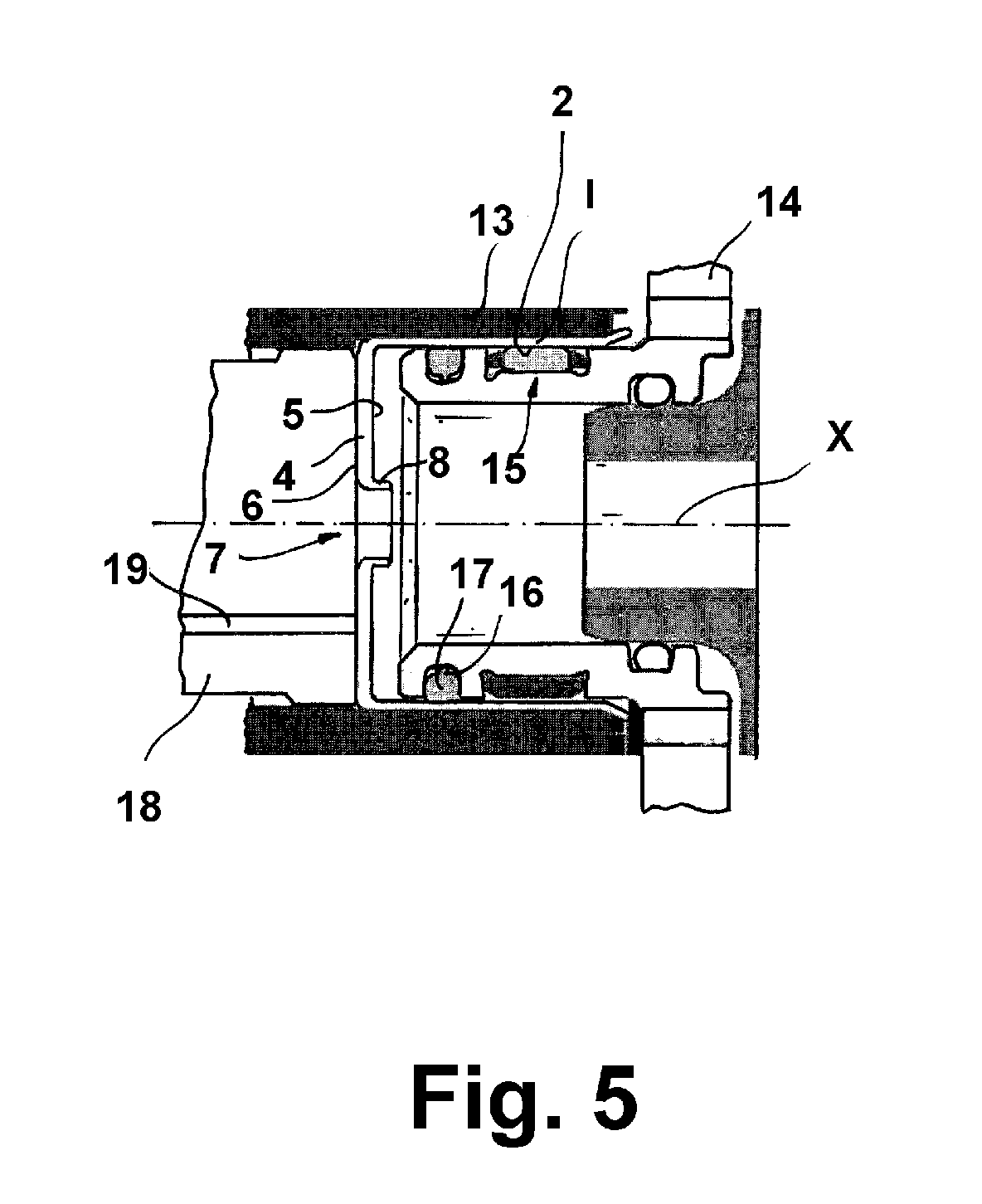

Motor-pump unit

ActiveUS20140154112A1Cost effective productionEasy to assemblePositive displacement pump componentsPiston pumpsEngineeringCooling channel

A motor-pump unit includes an electric motor and a pump. The electric motor has a motor housing, on the outside of which a cooling channel is arranged. The pump has a suction inlet and a pressure outlet. Liquid to be pressurized can be fed by way of the cooling channel to the suction inlet. In order that the motor-pump unit can be produced and assembled more cost-effectively, the motor housing includes a first housing part and a second housing part, which are connectable to each other in a liquid-tight manner and between them form the cooling channel.

Owner:ALFRED KARCHER GMBH & CO KG

Drawn bushing, particularly in form of a raceway bushing for an automatic transmission

ActiveUS20130067684A1Improve functional propertiesHigh shape accuracyBearing assemblyElectrical apparatusAutomatic transmissionMechanical engineering

A raceway bushing which has a substantially cylindrical peripheral wall that forms a bushing inner surface and a bushing outer surface, a bottom wall which extends from the peripheral wall and has an inner bottom surface and an outer bottom surface, and a bottom opening configured in the bottom wall. The bottom opening is bordered by an annular collar that rises axially beyond the inner bottom surface.

Owner:SCHAEFFLER TECH AG & CO KG

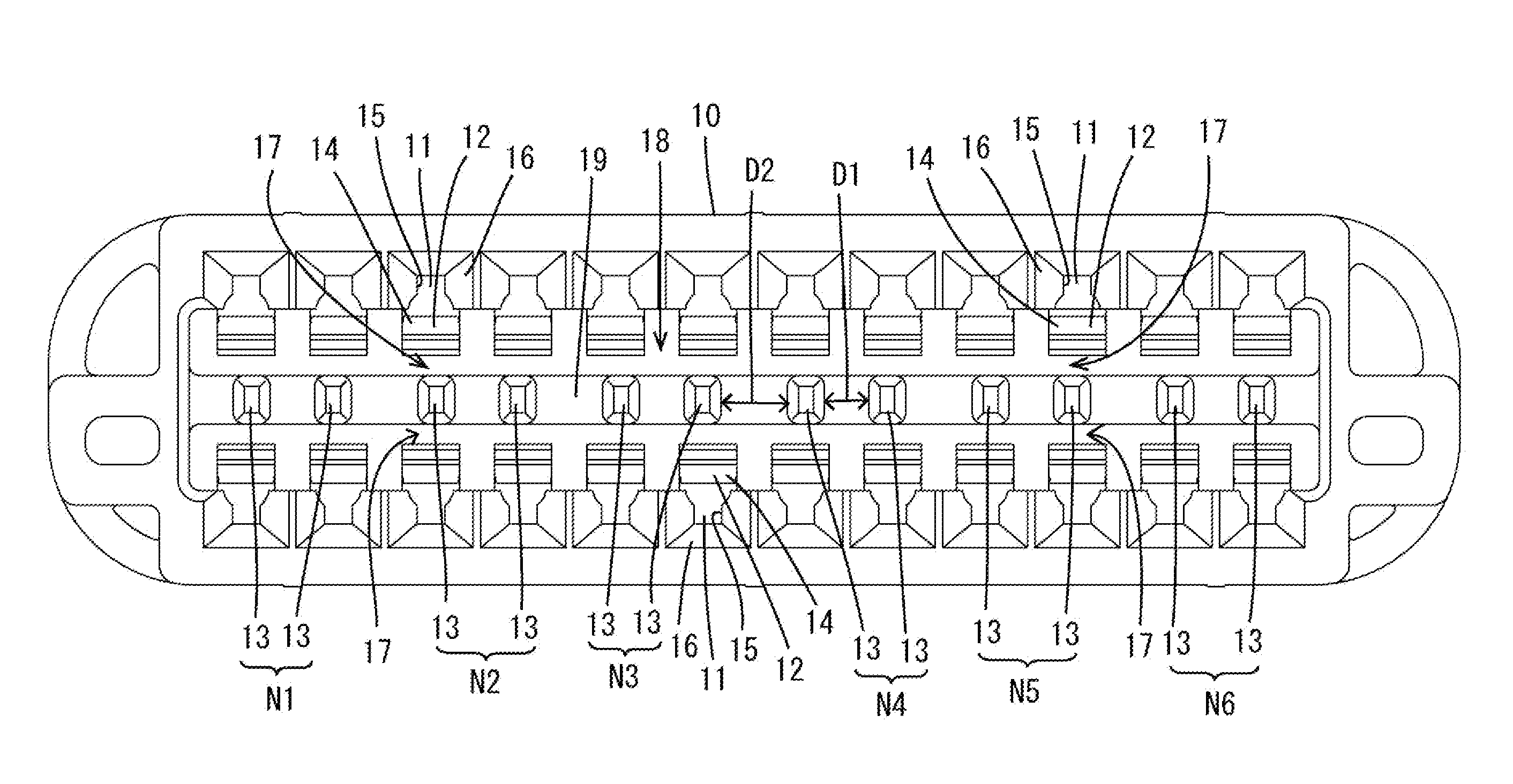

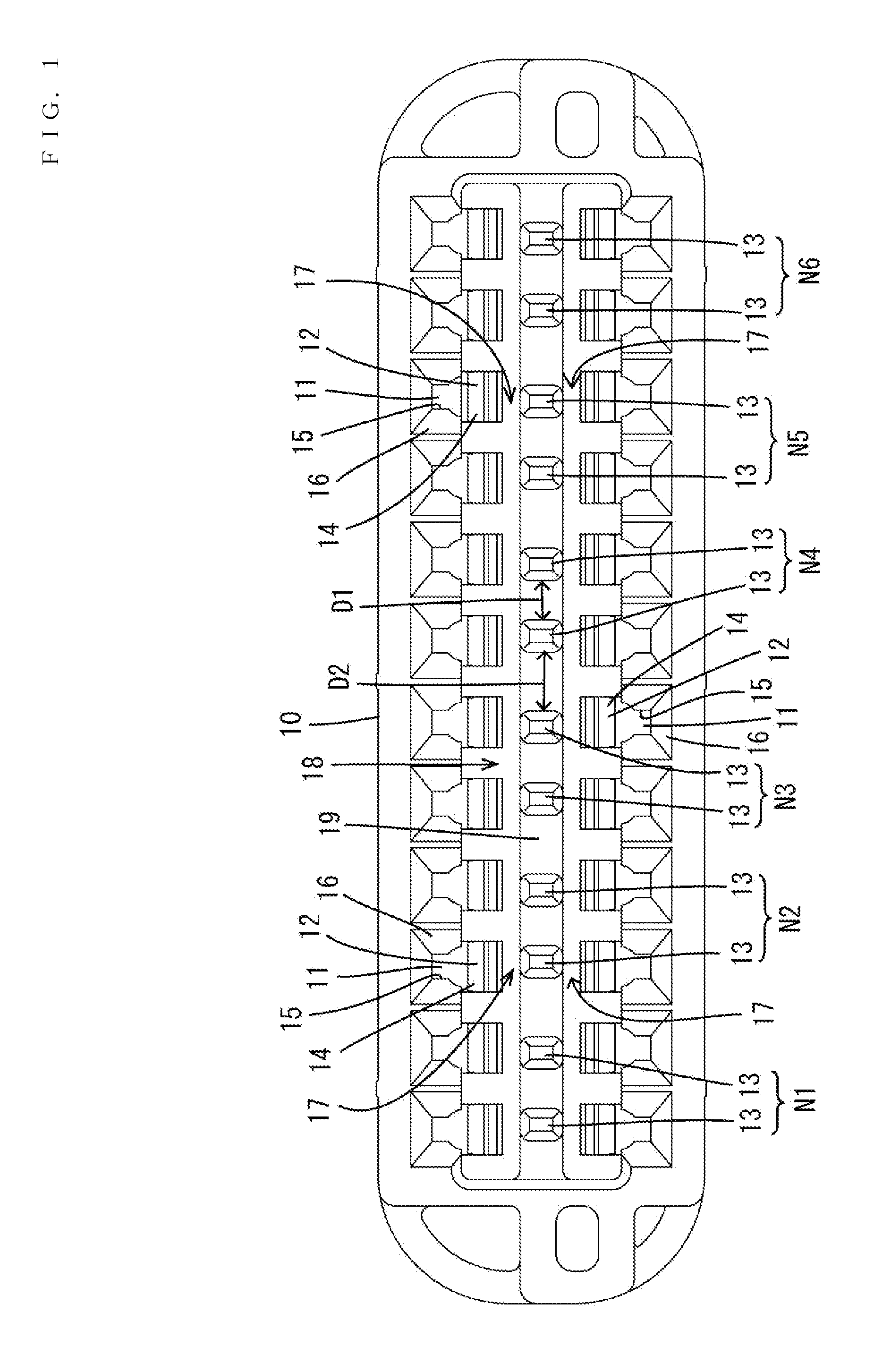

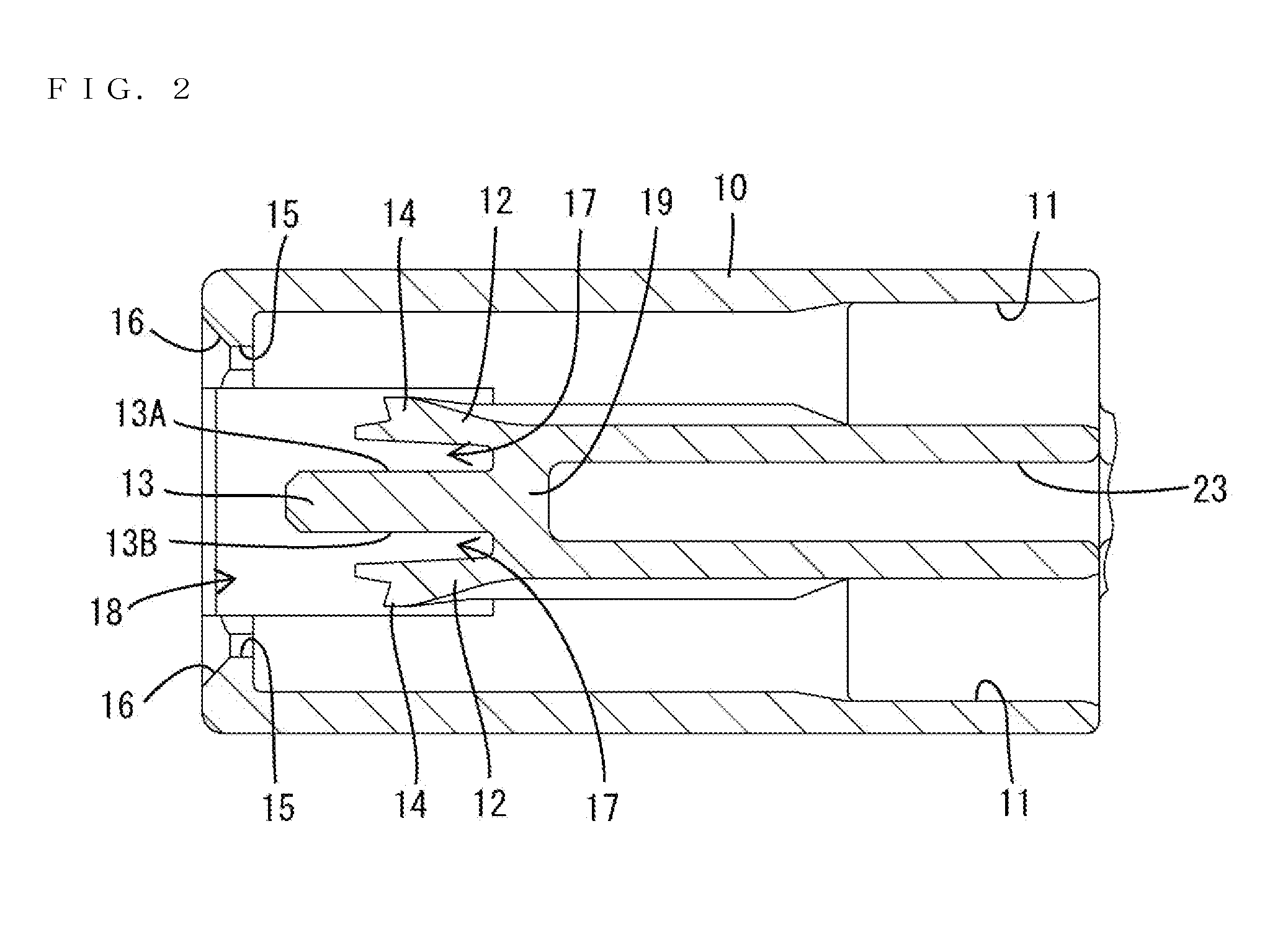

Connector and inspection tool

ActiveUS20150380853A1Structure of housing is not complicatedInspection reliability can be highContact member assembly/disassemblyCoupling device detailsEngineeringMechanical engineering

Owner:SUMITOMO WIRING SYST LTD

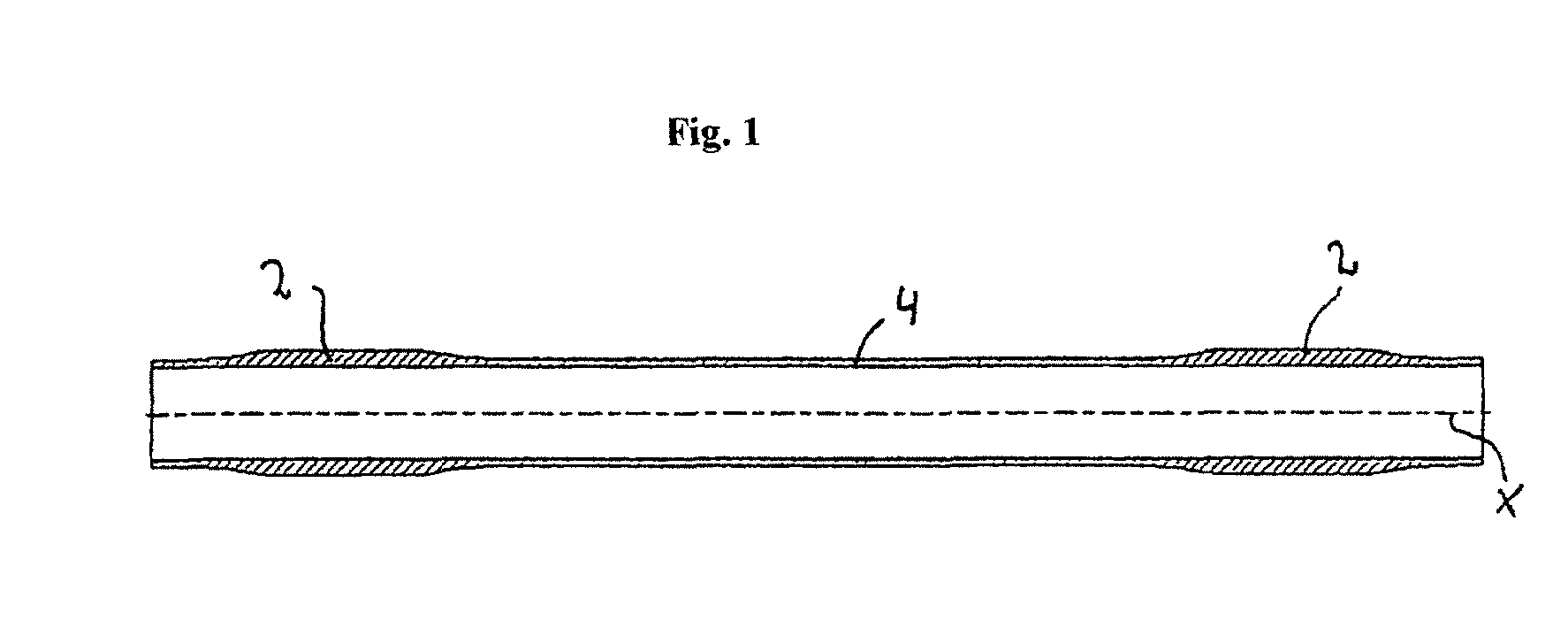

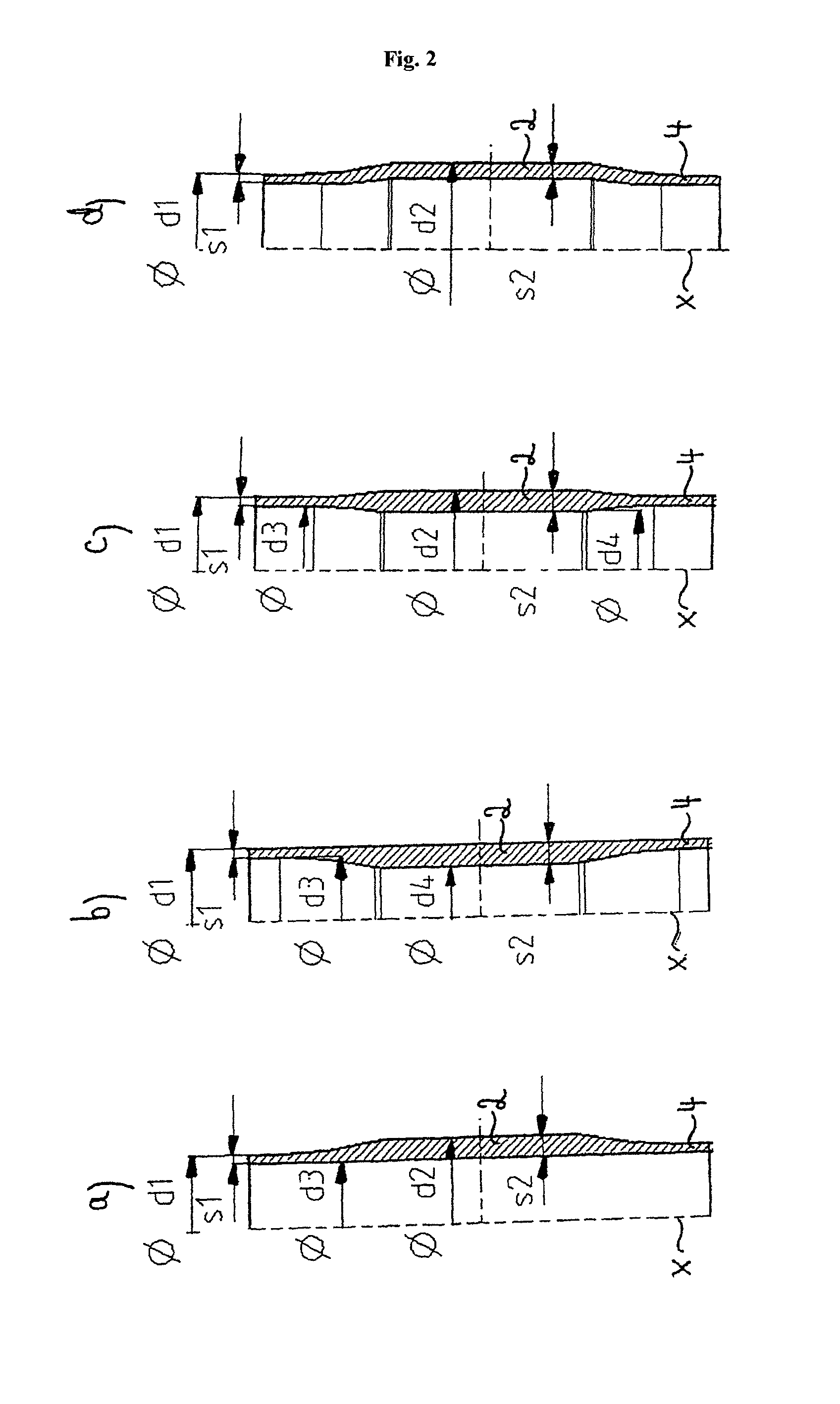

Membrane apparatus for receiving samples

InactiveUS7658982B2Improve sealingFixed uniformEnvelopes/bags making machineryUltrafiltrationBiomedical engineering

Owner:EPPENDORF AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com