Process for producing rotationally symmetrical components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

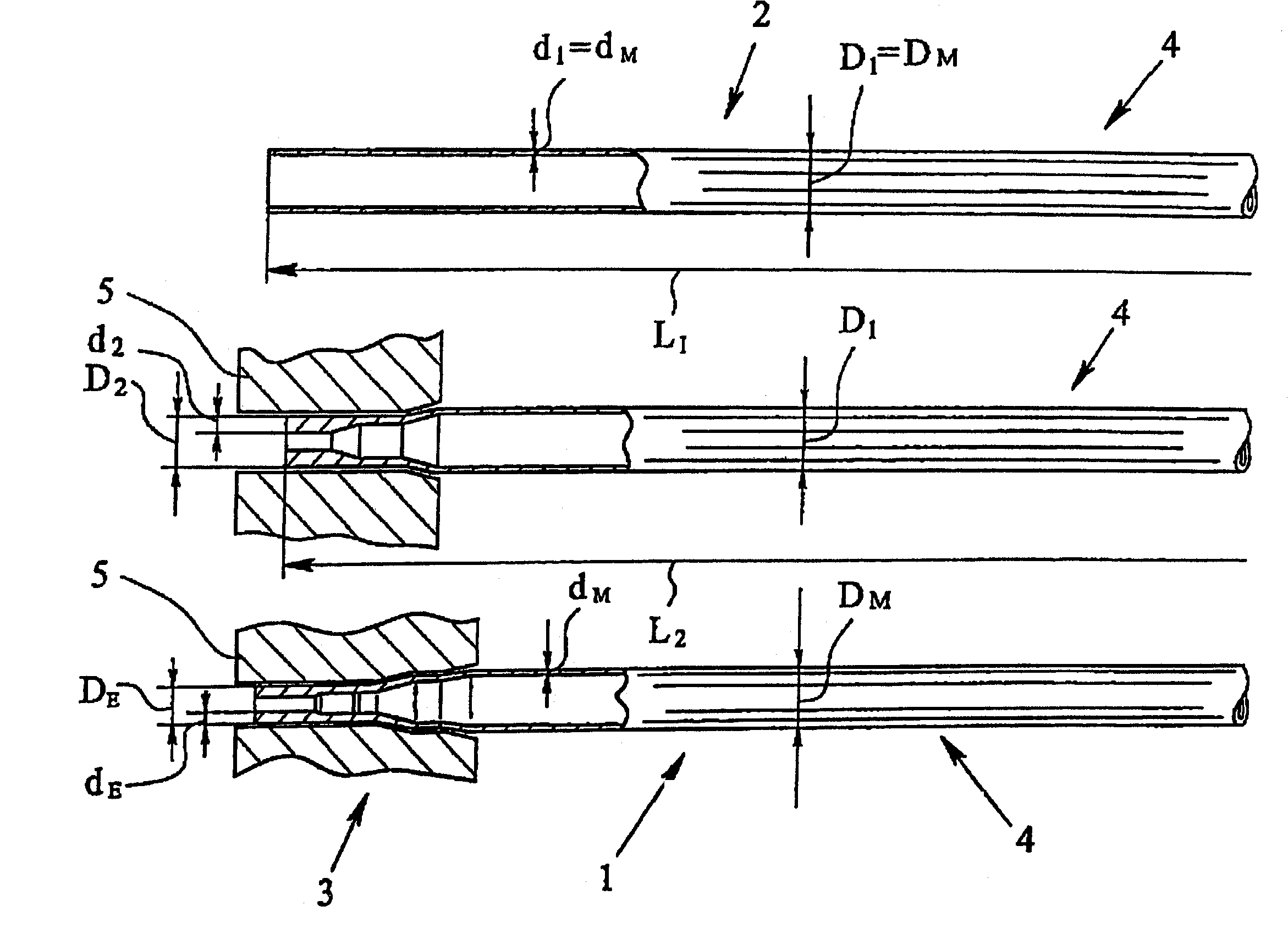

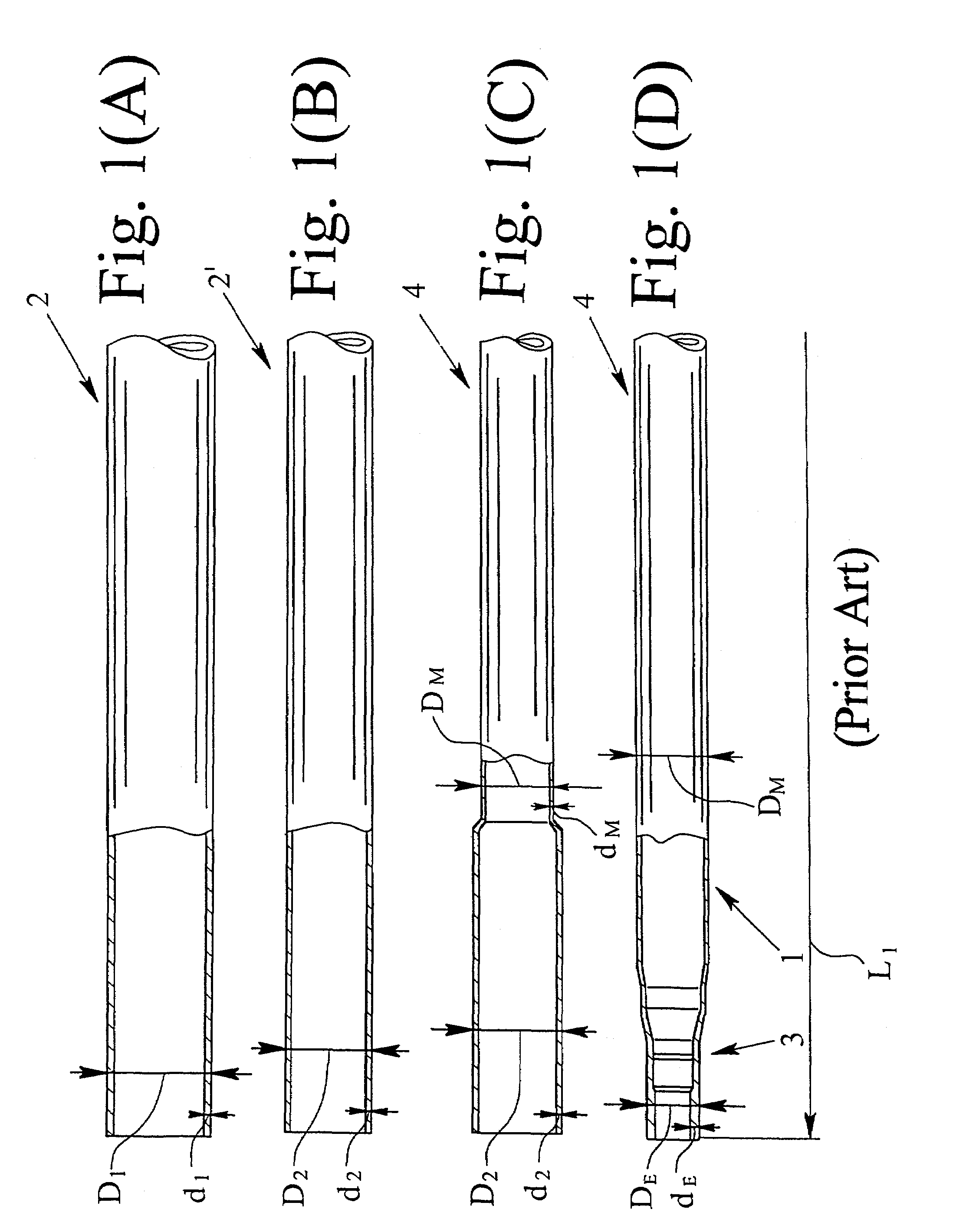

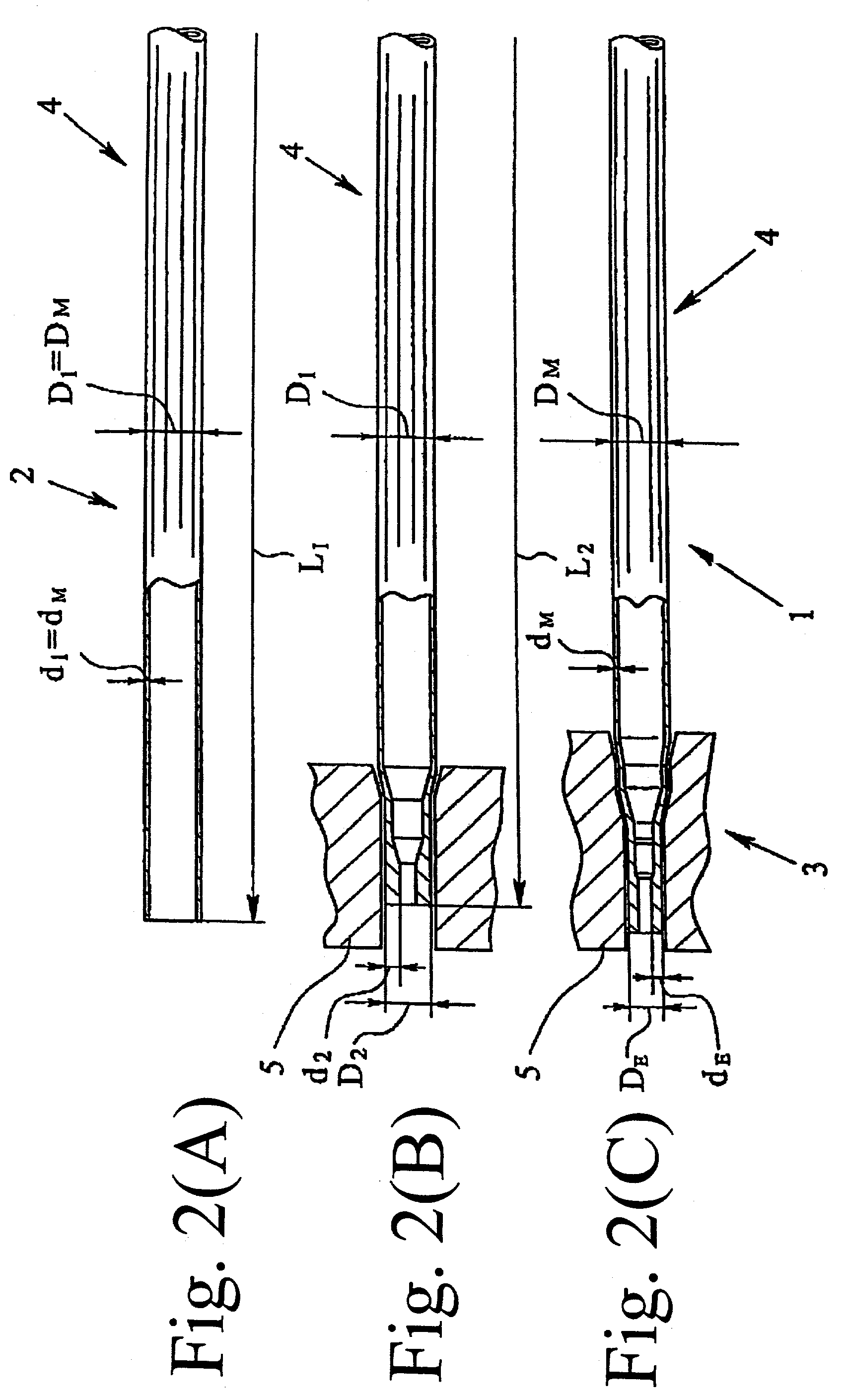

[0030]FIGS. 1A-1D schematically show the production sequence in the manufacture of a shaft 1 with an outside diameter D which varies over the entire length and a varying wall thickness d according to the process known from the prior art, proceeding from a pipe 2. Of the four production steps shown overall, the first two production steps (FIGS. 1A and 1B) relate to the production of the pipe 2, while the last two production steps (FIGS. 1C and 1D) relate to production of the shaft 1 from the pipe 2.

[0031]FIG. 1A shows a simply welded pipe 2 with an outside diameter D1 and a wall thickness d1. The wall thickness d1 corresponds to the thickness of the sheet metal or steel strip from which the pipe 2 has been bent. FIG. 1B shows the pipe 2′ after it has been drawn through a drawing die or drawing ring. By drawing the pipe 2, it has an outside diameter D21 and a wall thickness d21. This pipe 2′ is dimensioned such that from the pipe a shaft 1 with an end area 3 with the desired outside d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com