Connector and inspection tool

a technology of inspection tool and connector, which is applied in the direction of connection, electrical apparatus, coupling device connection, etc., can solve the problems of affecting inspection reliability, affecting inspection reliability, and easy displacement of relative positions of inspection tool and inspection tool from a proper position, so as to enhance positioning reliability, avoid complicated housing structure, and maintain high inspection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

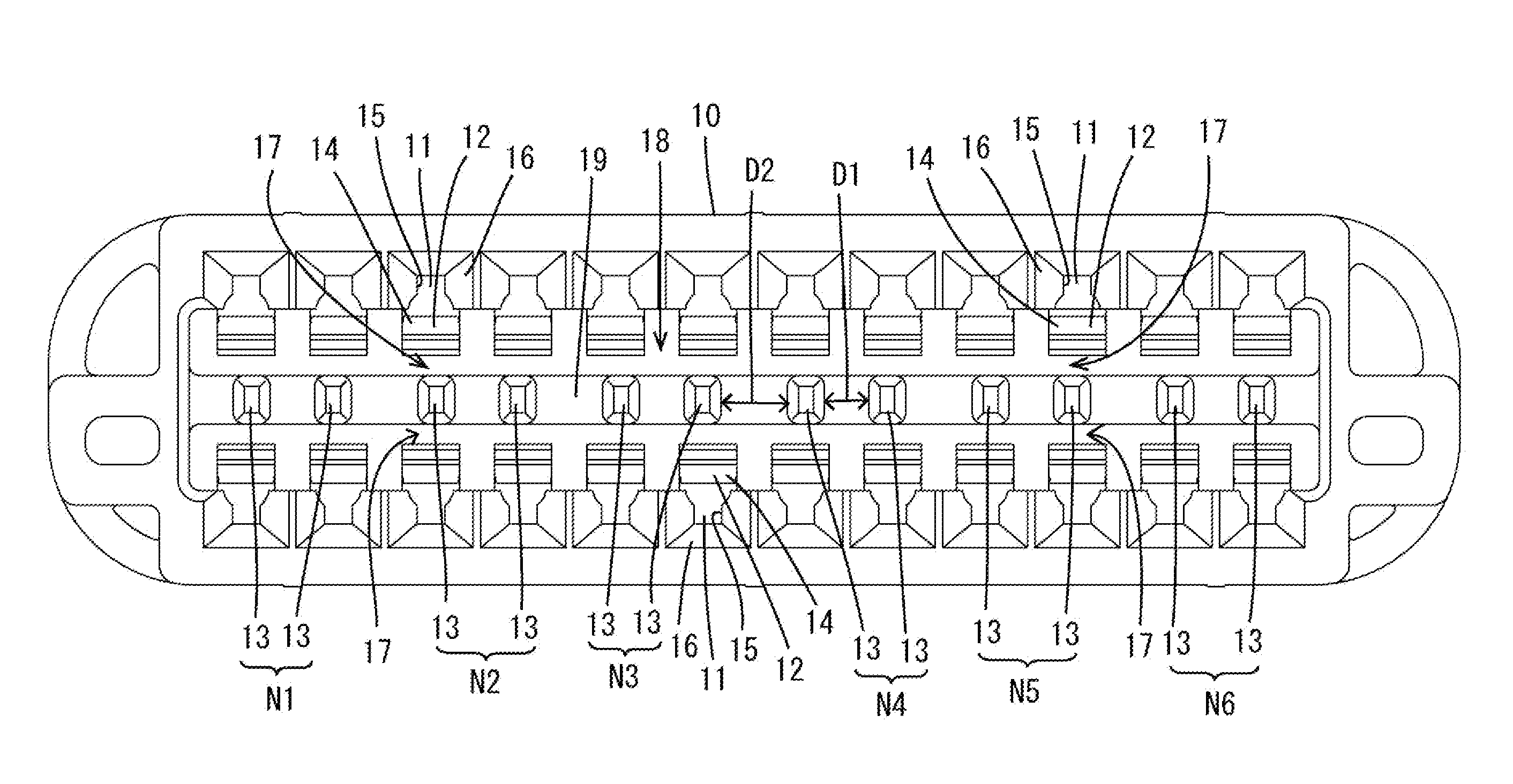

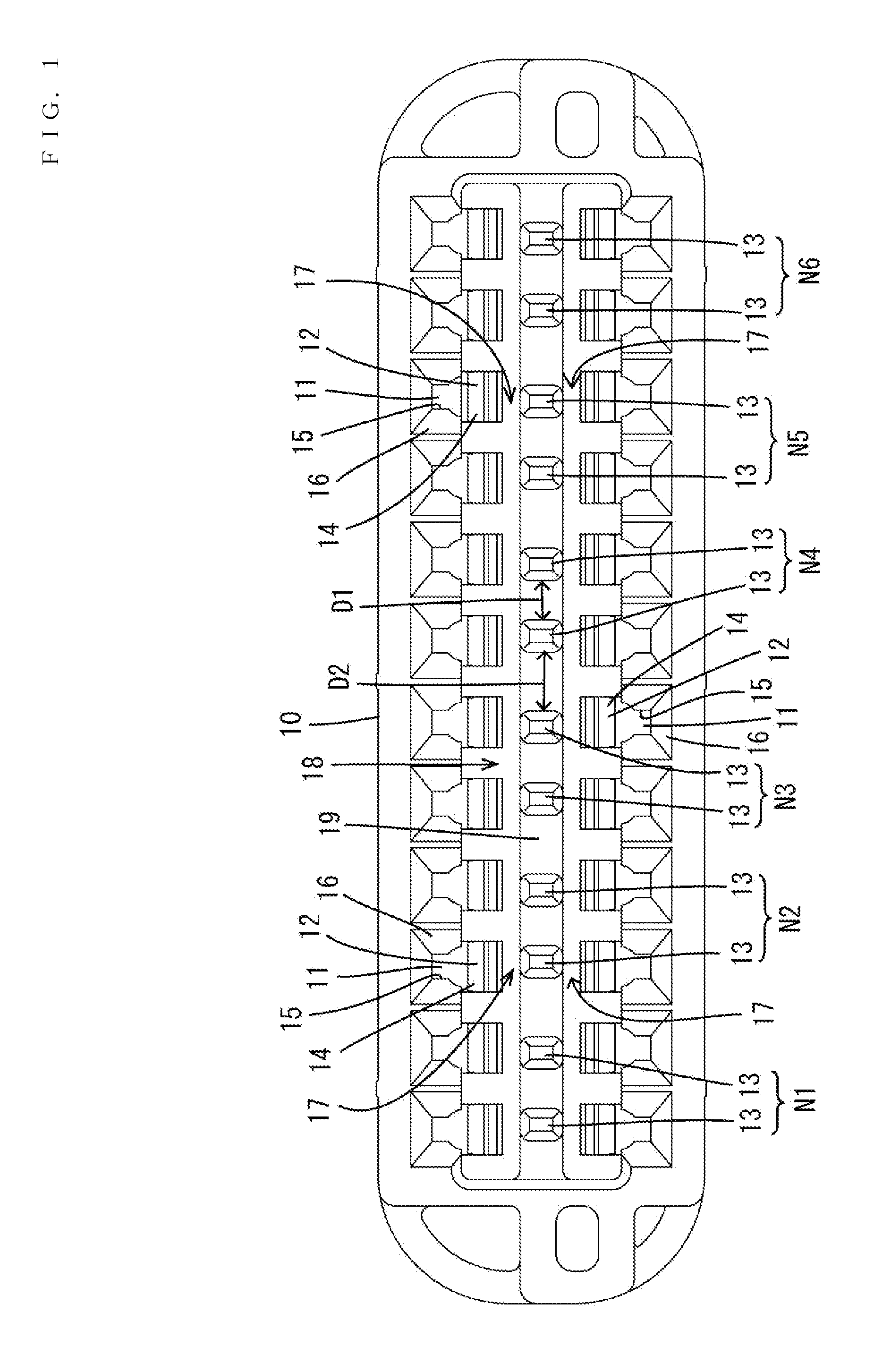

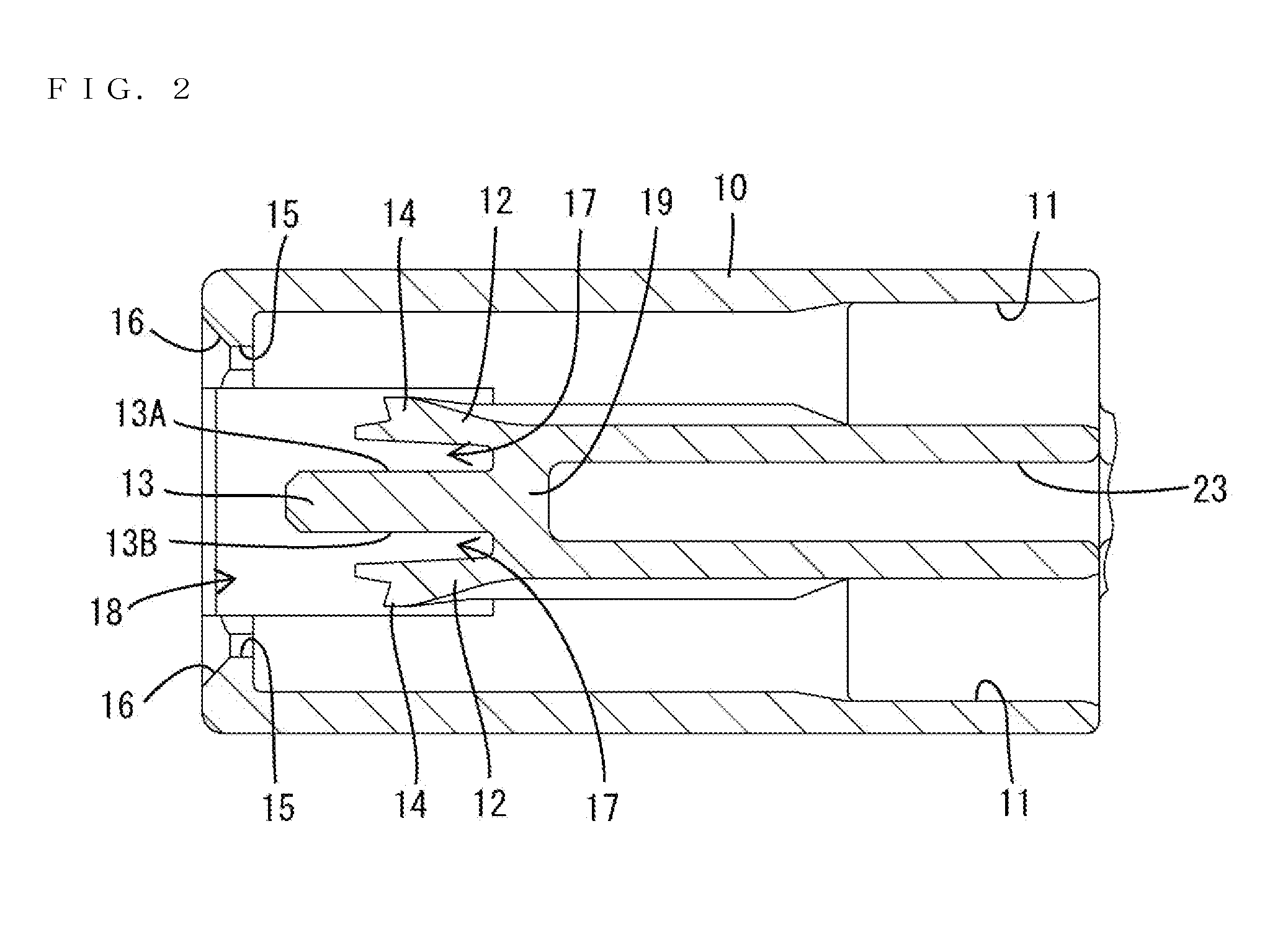

[0019]A connector according to an embodiment of the invention is illustrated in FIGS. 1-6 and includes a housing 10 that is made of synthetic resin and is connectable to an unillustrated mating housing. Terminal fittings 60 made of electrically conductive metal are to be mounted into the housing 10. An inspection tool 70 is mounted into the housing 10, as shown in FIG. 4, to determine whether or not an inserted state of the terminal fittings 60 is proper. In the following description, a front-back direction of the connector is defined so that a front of the terminal fittings 60 in an inserting direction into the housing 10 is a front end and a front-back direction of the inspection tool 70 is defined so that an end facing the front of the housing 10 at an initial position is a front end. Further, a vertical direction is based on each figure except FIG. 3. Furthermore, a width direction is a direction perpendicular to the front-back direction and the vertical direction and synonymous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com