Single-tube jet pump liquor drainage technology method for normal-pressure shale gas well

A technology of shale gas wells and process methods, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., and can solve the problems of easy erosion damage of hydraulic jet pumps, low drainage efficiency of electric submersible pumps, power fluid Problems such as high injection pressure, to achieve the effect of improving the efficiency of liquid drainage and gas production, reducing the problem of liquid level commissioning, and large liquid drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following non-limiting examples are used to further illustrate the present invention and understand the present invention.

[0021] The present invention is an atmospheric shale gas well single-tube jet pump drainage process method, which includes the following steps:

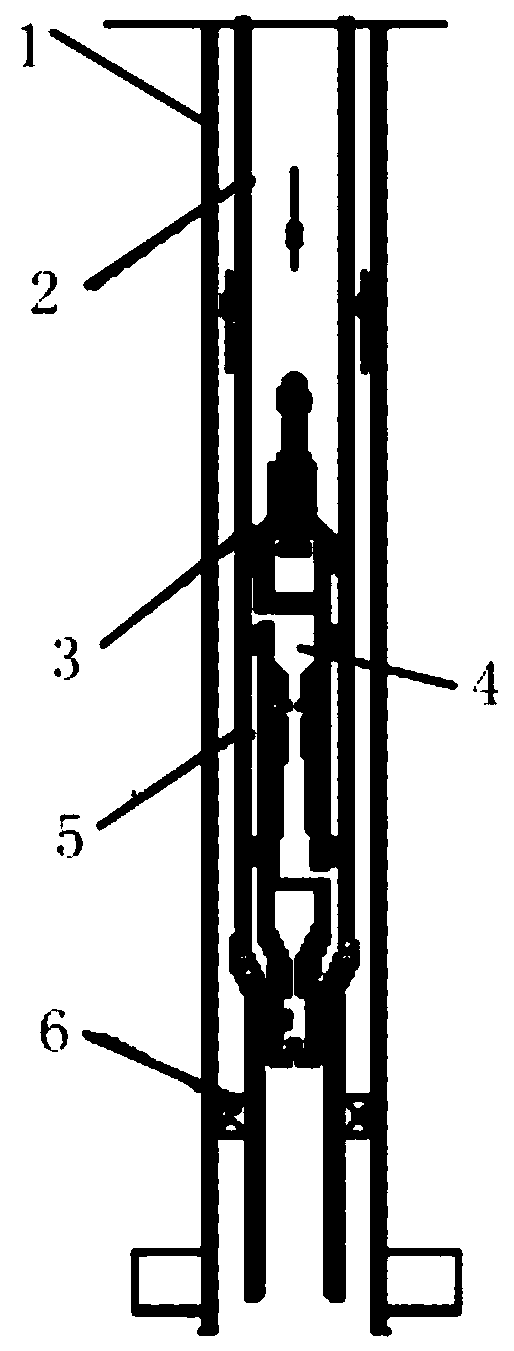

[0022] 1) Determine the working parameters, running depth, nozzle size, string components, etc. of the jet pump according to the well condition, preliminary operation and discharge conditions, and production requirements; figure 1 As shown, the pipe string assembly includes a packer assembly 6, a jet pump working barrel 3, and an oil pipe 2;

[0023] 2) Connect the ground assembly tools, run in the casing 1, the packer assembly 6, the jet pump barrel 5, and the tubing 2 in sequence; the packer assembly 6 is located below the jet pump barrel 5;

[0024] Among them, the jet pump barrel 5 includes a lifting system, a jet pump barrel sealing joint, a jet pump barrel tailstock, and a check valve assembly that are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com