Patents

Literature

56results about How to "Increase the amount of winding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

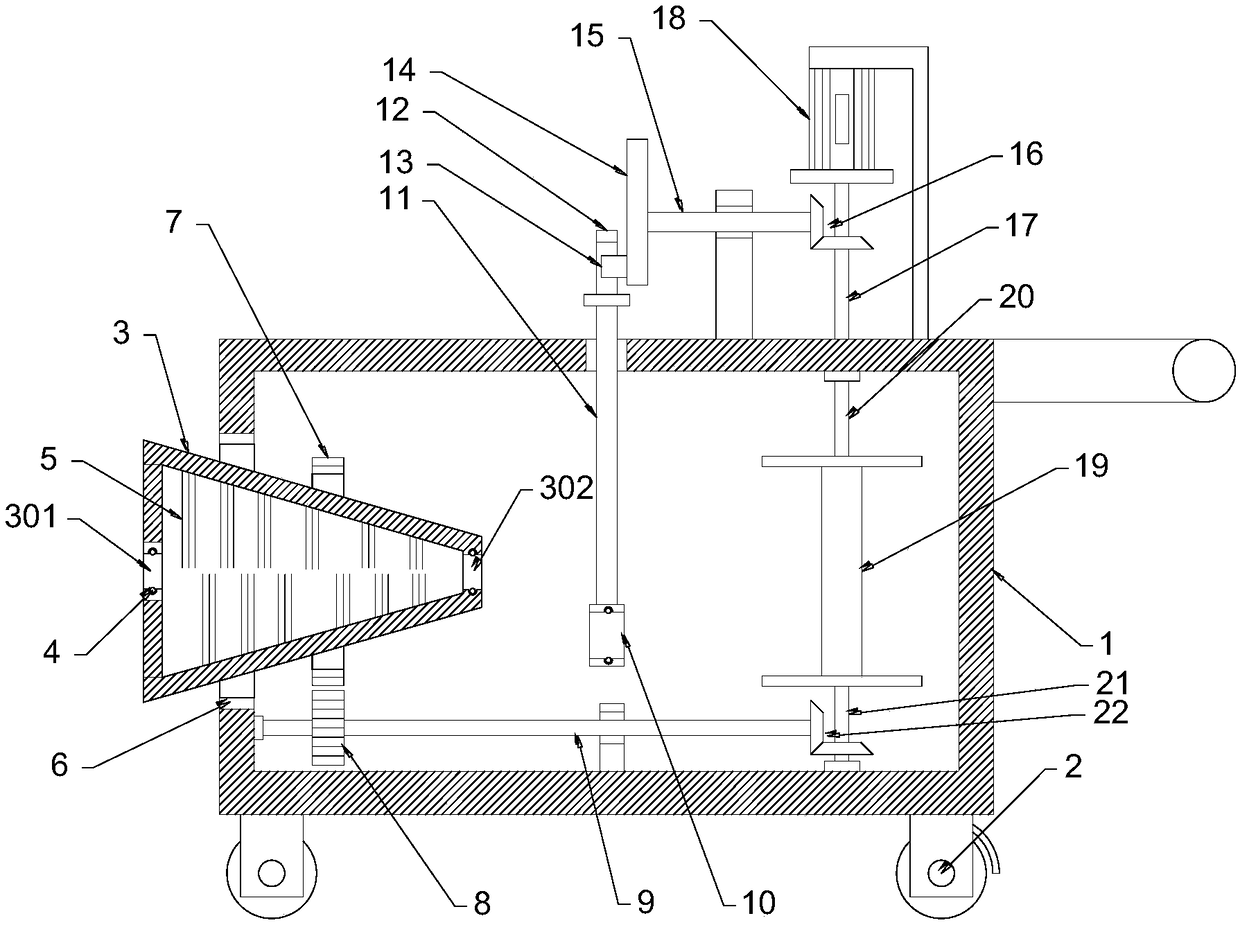

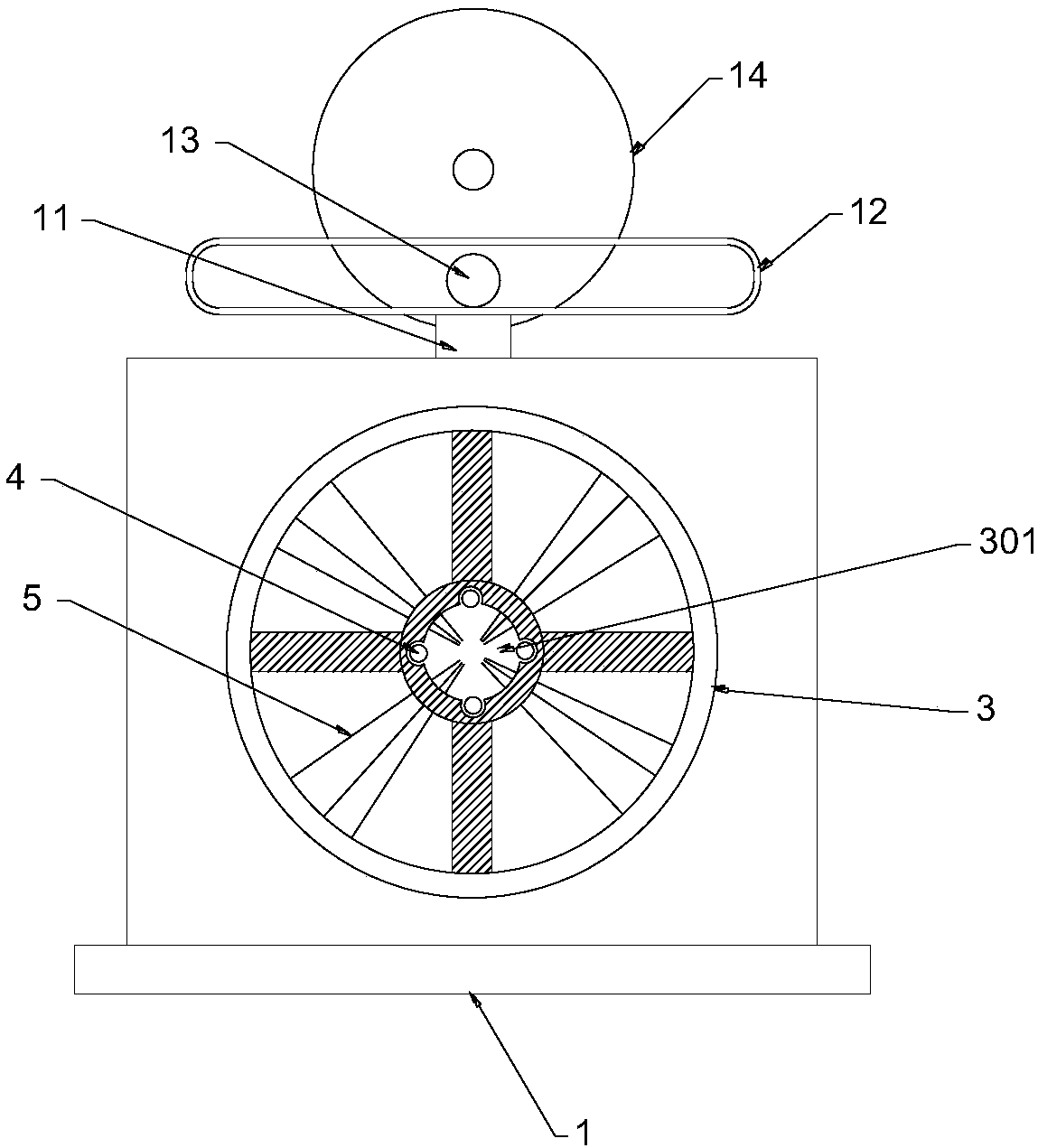

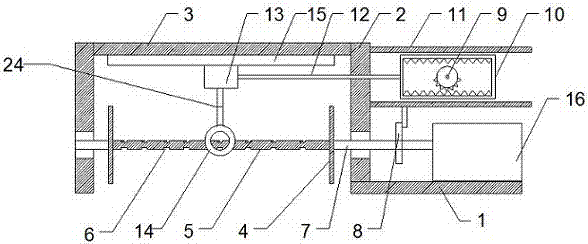

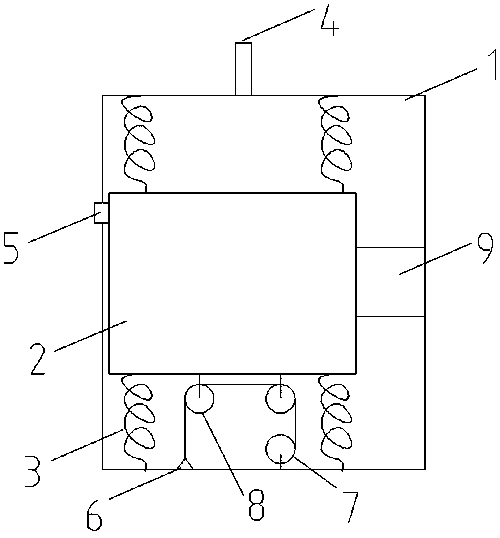

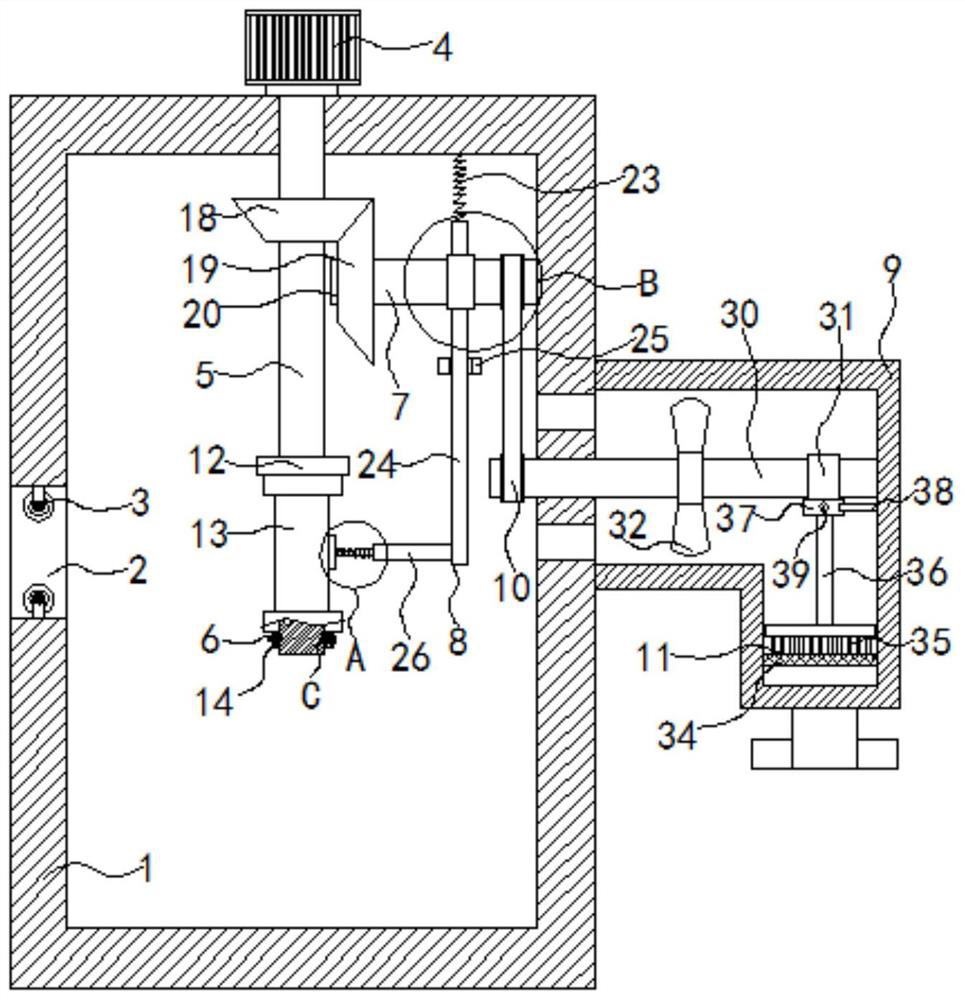

High-efficiency cable winding device for power cable

The invention discloses a high-efficiency cable winding device for a power cable. The high-efficiency cable winding device comprises a trolley body, a cleaning mechanism and a winding mechanism; a cleaning device is arranged at the left side of the trolley body; the cleaning device comprises a cleaning cone; brush bristles are uniformly distributed at the inner surface of the cleaning cone; the winding mechanism is arranged at the right side of the cleaning cone; and the winding mechanism comprises a limiting ring and a winding roller. According to the high-efficiency cable winding device disclosed by the invention, the rotating cleaning cone is arranged for brushing the surface of the cable so as to remove dust and other particles on the surface of the cable, thus convenience is providedfor subsequent winding of the cable; the cable is kept clean; the service life of the cable is prolonged; by arranging the limiting ring, the cable can be wound on the winding roller according to a certain sequence in a winding process of the cable, thus the cable is wound on the winding roller more uniformly and more compactly, the winding quantity is increased and the winding effect is improved.

Owner:安徽盛琛电力工程有限公司

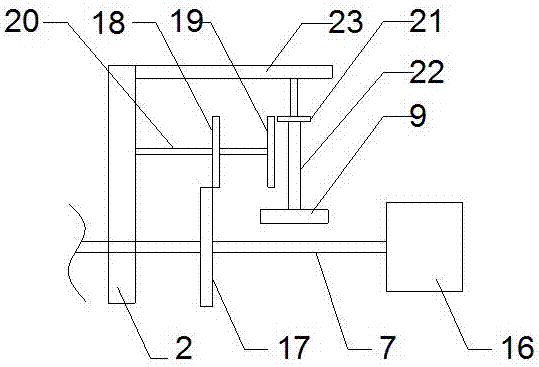

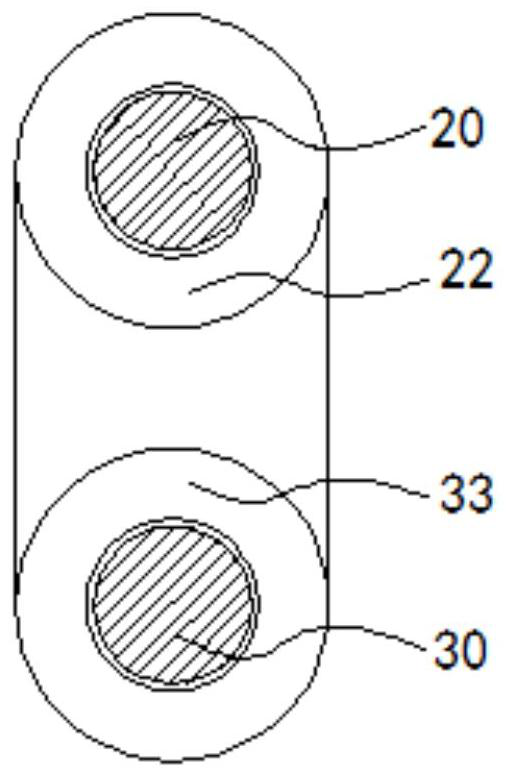

Electric wire and cable winding and unwinding device

ActiveCN105883484AEasy to wrapImprove winding efficiencyFilament handlingElectric machineryConductor Coil

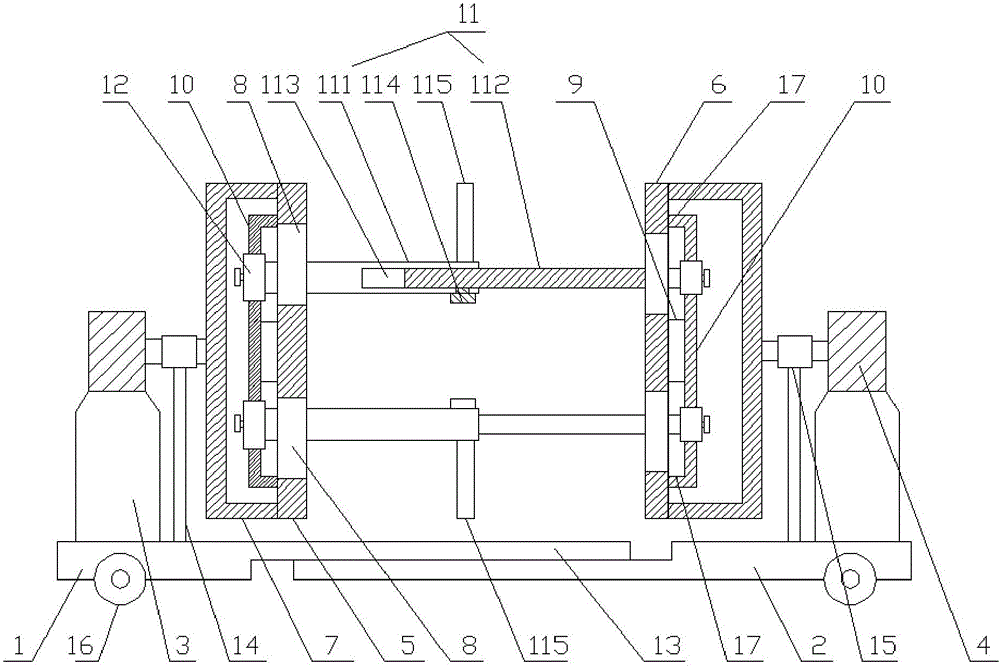

The invention discloses an electric wire and cable winding and unwinding device which comprises a left bottom plate and a right bottom plate, wherein mounting bases are arranged on both of the left bottom plate and the right bottom plate; servo motors are mounted on both of the mounting bases; further, two servo motors are the same in heights but opposite in directions; screw rods are transversely arranged; the electric wire and cable winding and unwinding device also comprises a cable winding and unwinding rack used and matched with side servo motors on a left and a right; the cable winding and unwinding rack comprises a left side plate, a right side plate, and frames which are mounted on an outer side of the left side plate and an outer side of the right side plate. In the electric wire and cable winding and unwinding device, two spools are adopted to hold and wind an electric wire and a cable; the cable is wound on the spools, so that the cable can be held and wound; a certain space exists between the two spools; moreover, two ends of each of the two spools are mounted on loop bars through sleeves; the space between the two spools can be regulated through regulating the positions of the sleeves; after the space is increased, the length of the cable wound on the spools can be increased after the spools are rotated for one revolution each time; the winding efficiency of the cable is improved.

Owner:JURONG FUDA ELECTRIC TECH

Textile winding roller

ActiveCN108178025AInstalled and disassembledImprove replacement efficiencyFilament handlingYarnGear wheel

The invention discloses a textile winding roller comprising a winding roller body. The two ends of the winding roller body are both provided with limiting plates. The circle centers of the sides, faraway from each other, of the two limiting plates are each fixedly connected with one end of a supporting shaft. The end, far away from the corresponding limiting plate, of one supporting shaft is fixedly provided with a transmission gear. The transmission gear is meshed with an output shaft of a drive motor on a spinning machine. The end, far away from the limiting plate, of the other supporting shaft is fixedly connected with a supporting disk. The supporting disk is parallel to the corresponding limiting plate. The middle sections of the two supporting shafts are provided with supporting blocks through bearings. The textile winding roller is novel in design and convenient and rapid to use, the winding roller body is fixedly installed on a machine frame of the spinning machine through a connection mechanism, installation is firm, and disassembly is convenient and rapid; and a yarn carding device can tightly press the yarn during carding, so that the winding amount of a single windingroller body is improved, frequent replacement of the winding roller is avoided, and the work efficiency of the spinning machine is improved.

Owner:安徽海洋网业有限公司

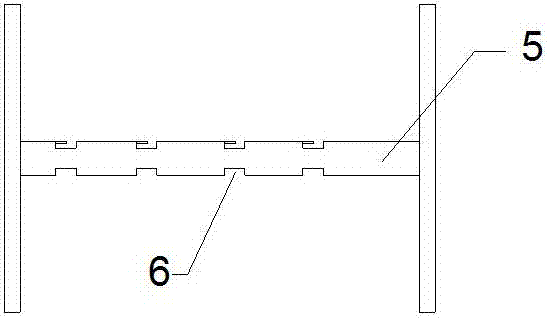

Uniform winding device for chemical fiber filament

InactiveCN107500027AWrap tightly and evenlyPrevent slidingFilament handlingFiberReciprocating motion

The invention discloses a uniform winding device for chemical fiber filaments, which comprises a bottom plate, a vertical plate and a horizontal plate; a bobbin is arranged under the horizontal plate, and a wire clamping groove is arranged in the center of the bobbin around the shaft; the bobbin is fixed A drive shaft is connected, and the drive shaft extends to the right side of the vertical plate and is connected with a winding motor; a guide ring is provided on the outside of the winding drum, and the guide ring is connected to a slider through a connecting rod, and the slider is slidably connected to a slide rail, and the slide rail It is fixedly connected with the horizontal plate; the slider is fixedly connected with the rack frame through the cross bar, and the rack frame is slidably connected with a sliding groove; the rack of the rack frame is engaged with a semi-circular gear, and the semi-circular gear is connected with the drive shaft through the linkage mechanism connect. The present invention is equipped with a reciprocating guide ring, so that the filaments are tightly and evenly wound on the rabbet, which improves the winding efficiency and winding volume; the present invention is provided with an intermediate winding shaft with a wire holding groove to avoid long The yarn slips and falls off, improving the efficiency of winding.

Owner:盐城千之诺机械有限公司

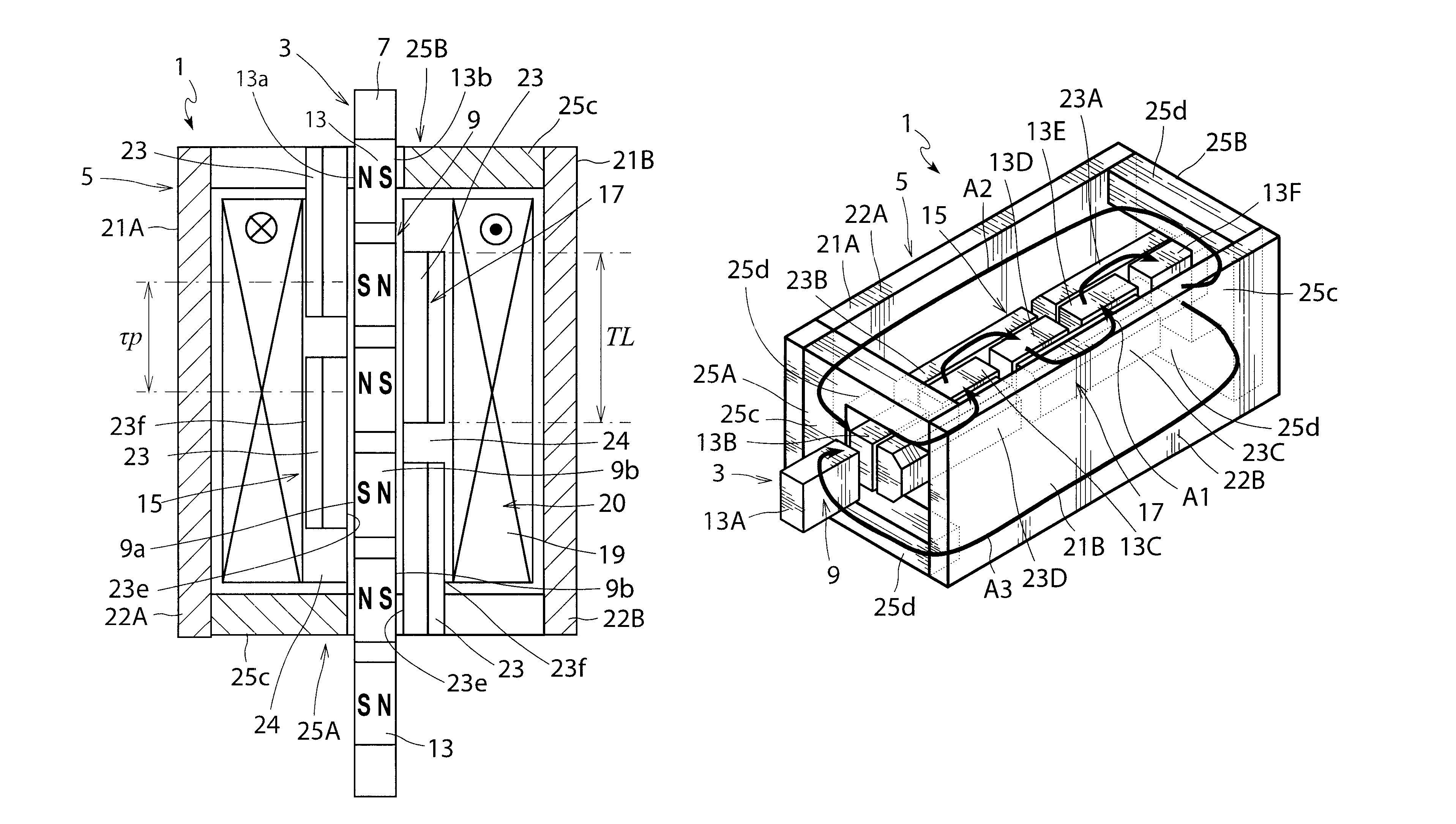

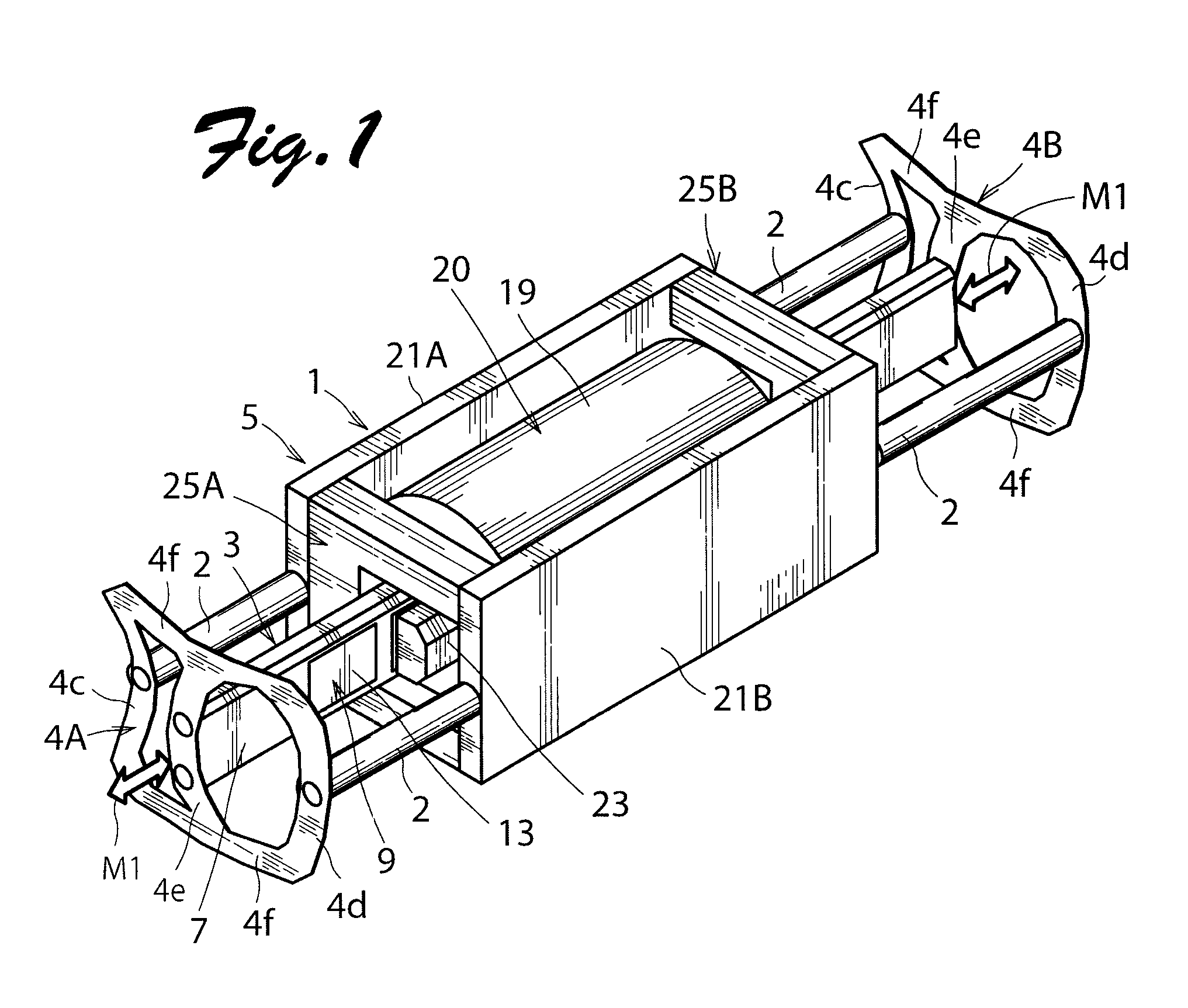

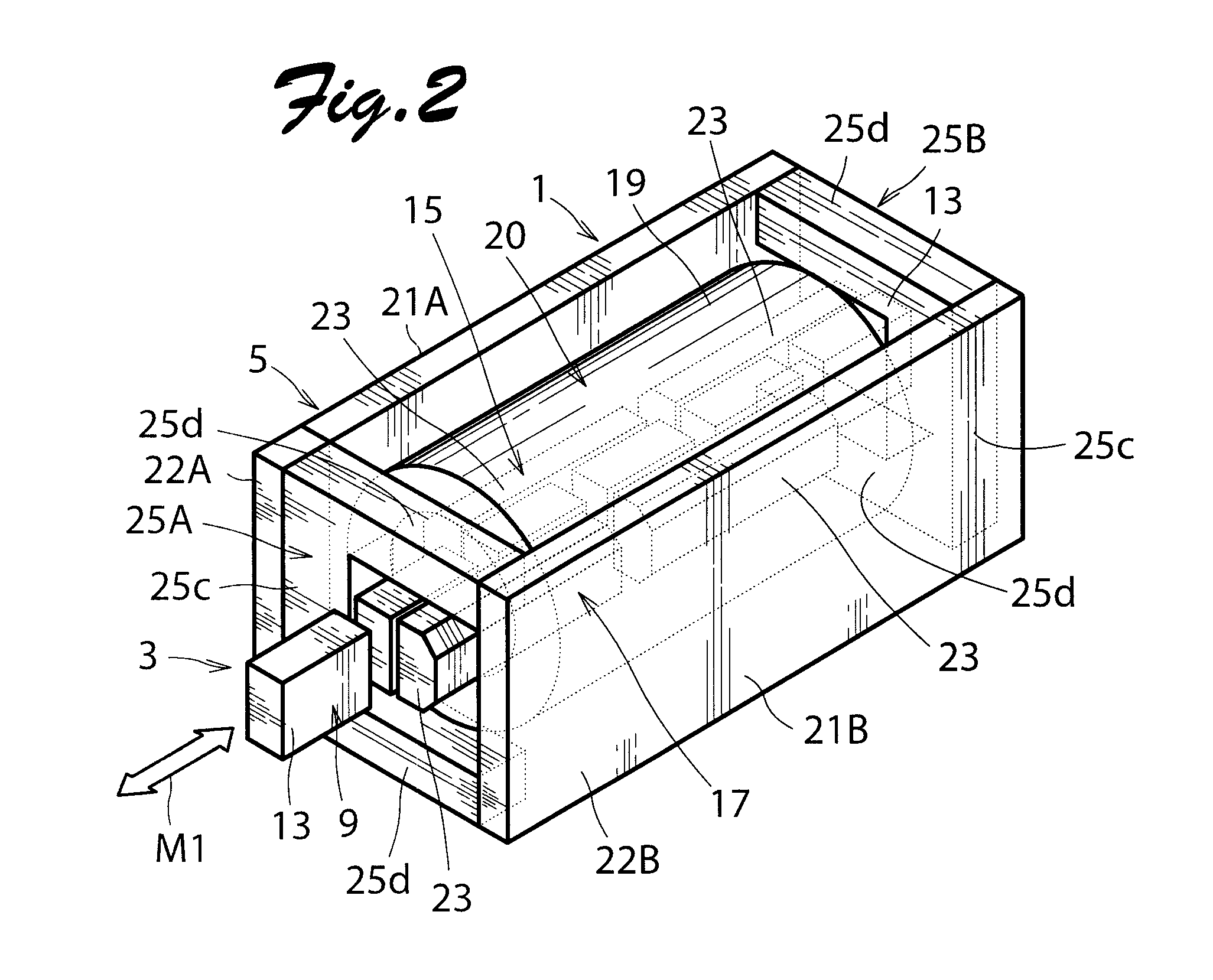

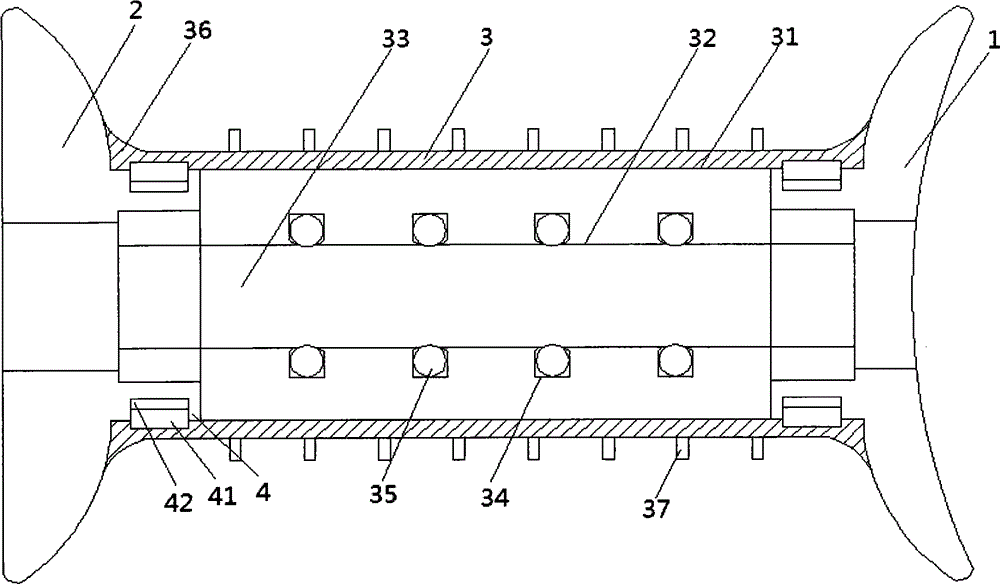

Electrical machine apparatus

ActiveUS8569916B2Enhanced maximum thrust and maximum outputIncrease the amount of windingMagnetic circuitMechanical energy handlingElectrical conductorElectrical polarity

A mover includes a permanent magnet array including permanent magnets magnetized in a perpendicular direction perpendicular to a motion direction of the mover such that magnetic poles having different polarities alternately appear on magnetic pole surfaces of the permanent magnets along the motion direction. A stator includes first and second magnetic pole portion assemblies disposed on both sides of the permanent magnet array in the perpendicular direction and each including magnetic pole portions facing the magnetic pole surfaces, and a single phase winding that excites the magnetic pole portions forming the first and second magnetic pole portion assemblies. The winding has a hollow structure formed by winding a winding conductor into a coil such that the magnetic pole portions included in the first magnetic pole portion assembly and the magnetic pole portions included in the second magnetic pole portion assembly are located in an internal space of the winding.

Owner:SANYO DENKI CO LTD

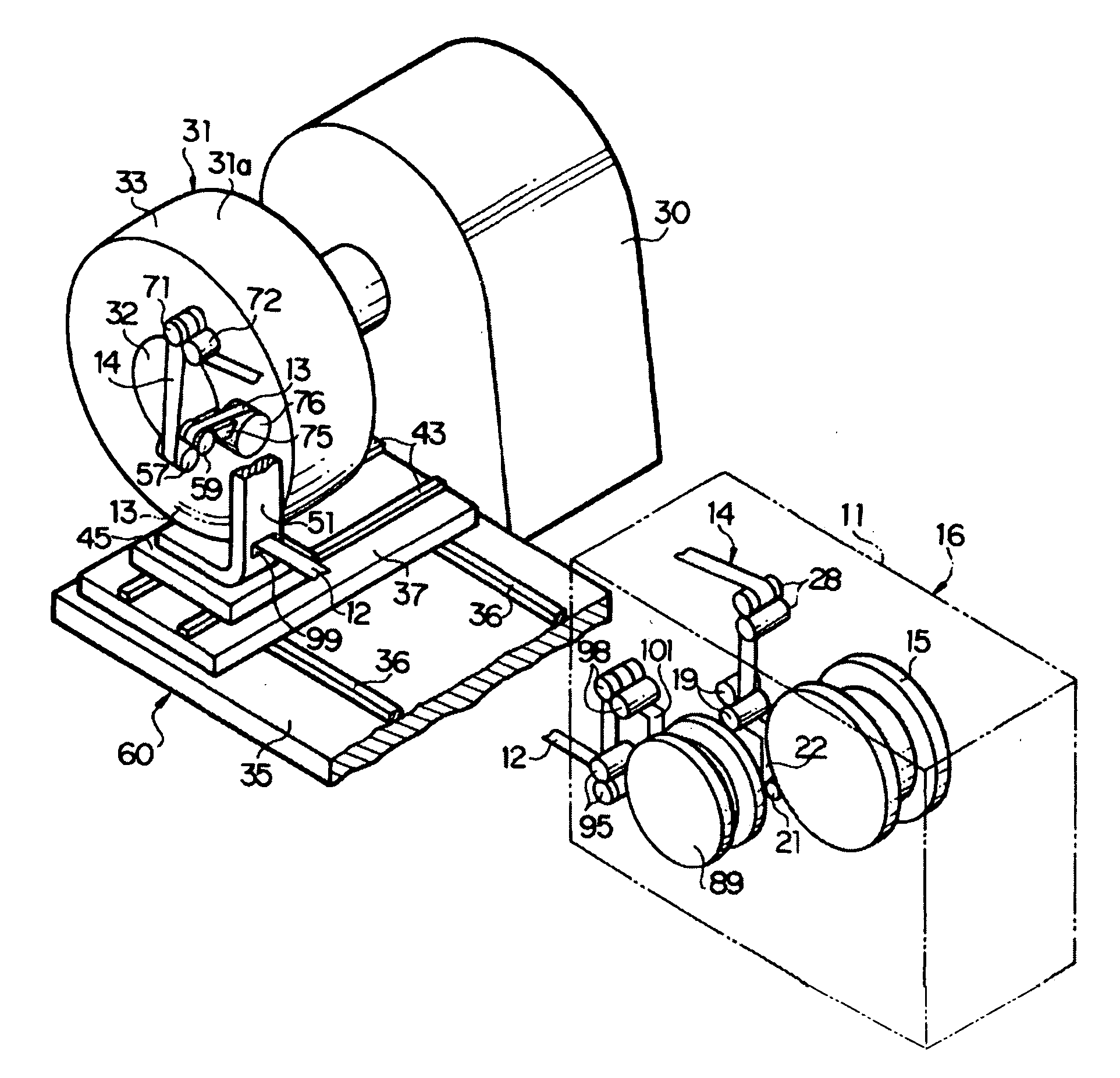

Method and apparatus for manufacturing unvulcanized tires

A ribbon-like element supplied from a supply source is wound on the rotating toroidal support member, when a first rotatable guide roller arranged spaced from the outer surface of the support member is moved in parallel with the meridian direction along the outer surface of the support member, and turned so that the direction of its rotational axis approaches a tangent relative to the outer surface of the winding member. A second guide roller is arranged on a straight line perpendicular to a plane containing the moving trajectory of the first guide roller and passing through the first guide roller, and has a rotational axis that extends in the widthwise direction of the ribbon-like body extending from the supply source toward the winding member. When the second guide roller is driven to achieve a parallel movement integrally with the first guide roller, the ribbon-like element contacts successively with the second and first guide rollers in this sequence, before it is supplied to the outer surface of the support member.

Owner:BRIDGESTONE CORP

Winding device for textile fabric processing

PendingCN109399289AIncrease the amount of windingMeet the needs of useWebs handlingEngineeringMechanical engineering

The invention discloses a winding device for textile fabric processing. The winding device comprises a supporting bottom plate. The two ends of the supporting bottom plate are symmetrically provided with supporting rods perpendicular to the supporting bottom plate. Connecting shafts are rotatably mounted in the middle portions of the two supporting rods through bearings. Each connecting shaft is provided with an abutting notch. A winding shaft is fixedly mounted between the two connecting shafts through the abutting notches. The two ends of the winding shaft are both provided with abutting blocks. The abutting blocks are mounted in the corresponding abutting notches in an abutting mode. Sliding grooves are formed in the positions, located above the connecting shafts, of the adjacent sidesof the two supporting rods in the length direction of the supporting rods. Sliding blocks are movably mounted in the sliding grooves. According to the winding device, the winding shaft is fast and convenient to dismantle and replace; a fabric wound around the winding shaft is compressed and flattened simultaneously through a compressing roll under the action of expansion springs, the fabric winding capacity of the winding shaft is improved, the fabric is flattened, and the use requirements of a user are met. Thus, the winding device is suitable for application and popularization.

Owner:阜宁县荣泰纺织品有限公司

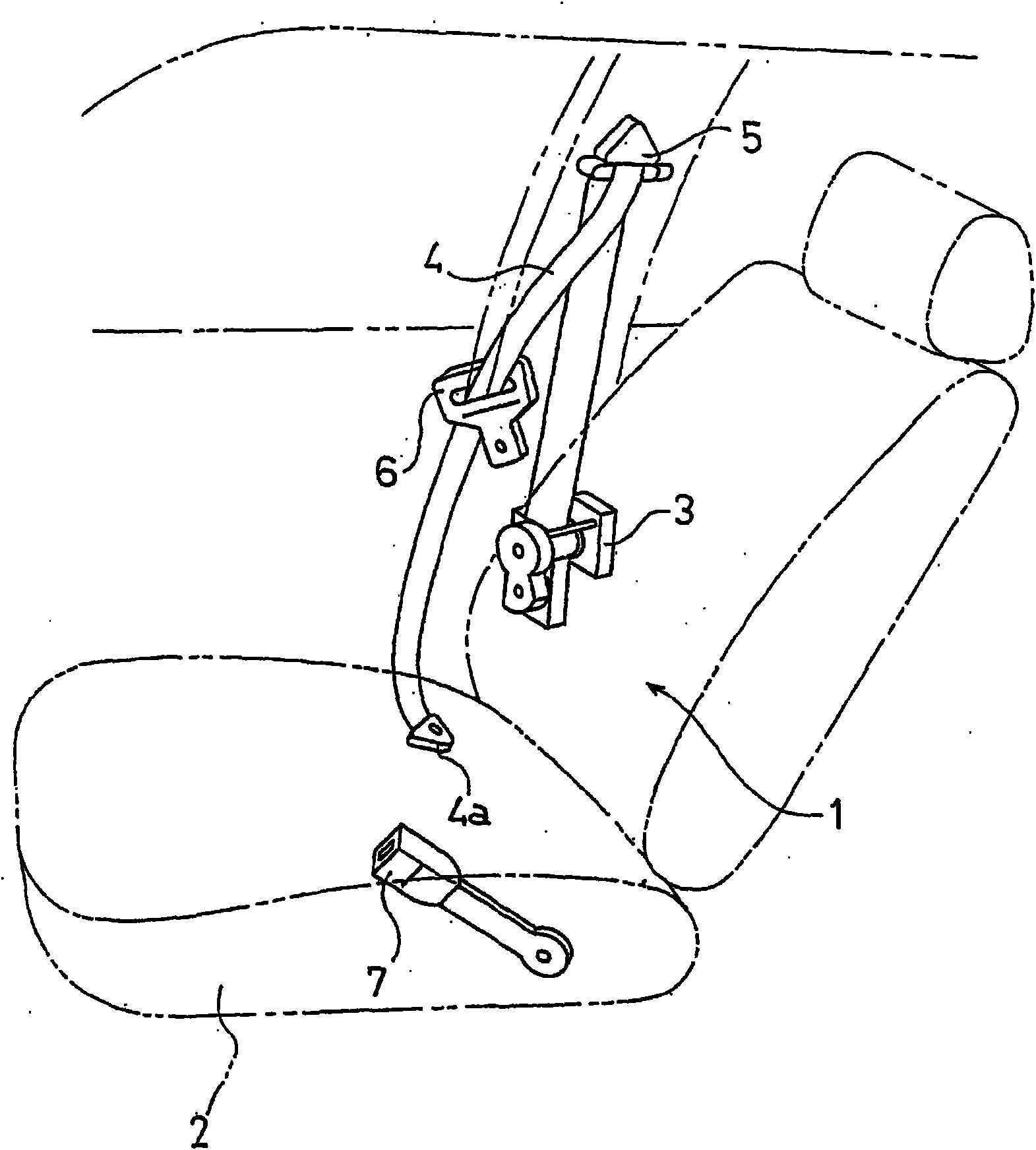

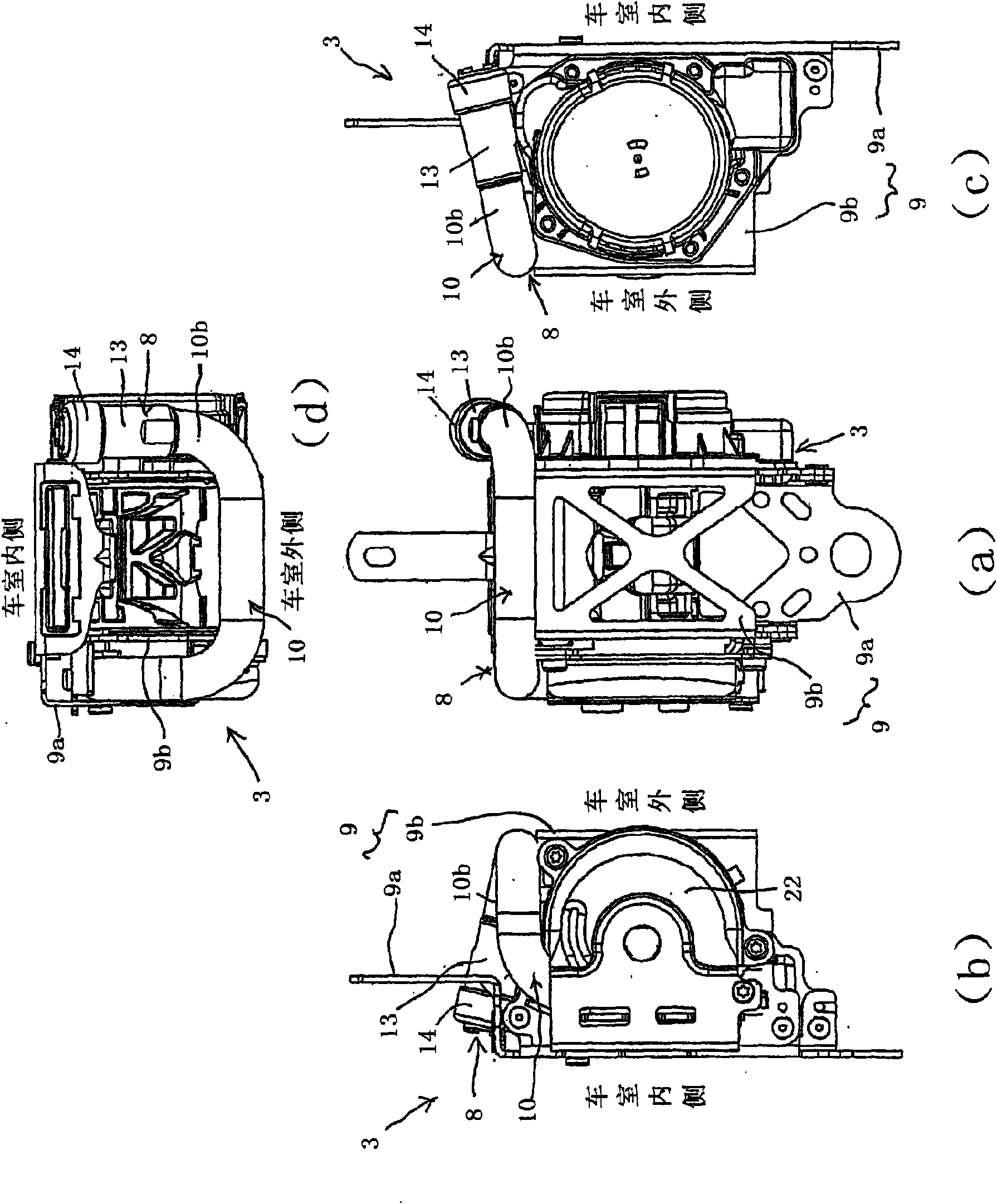

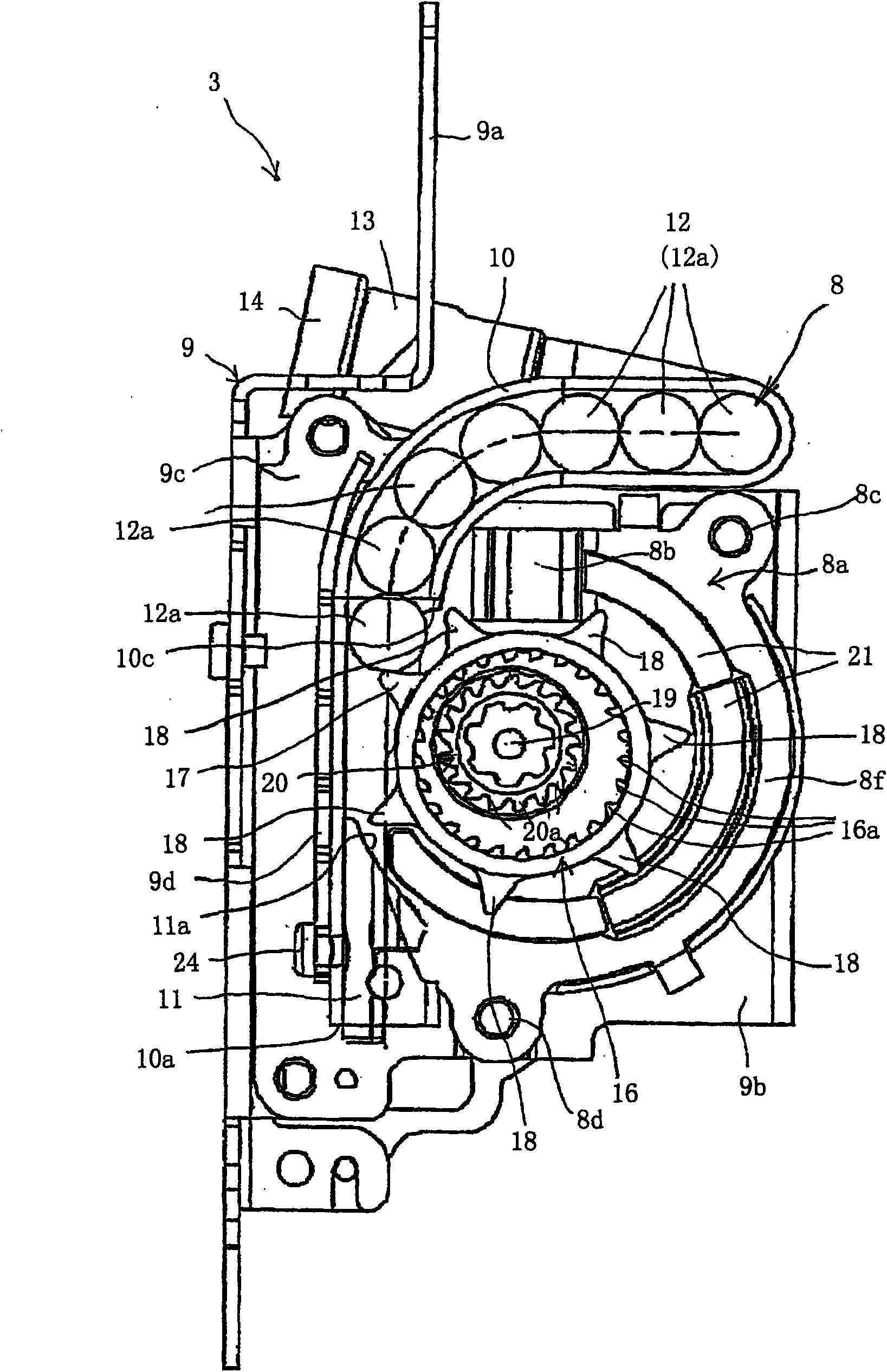

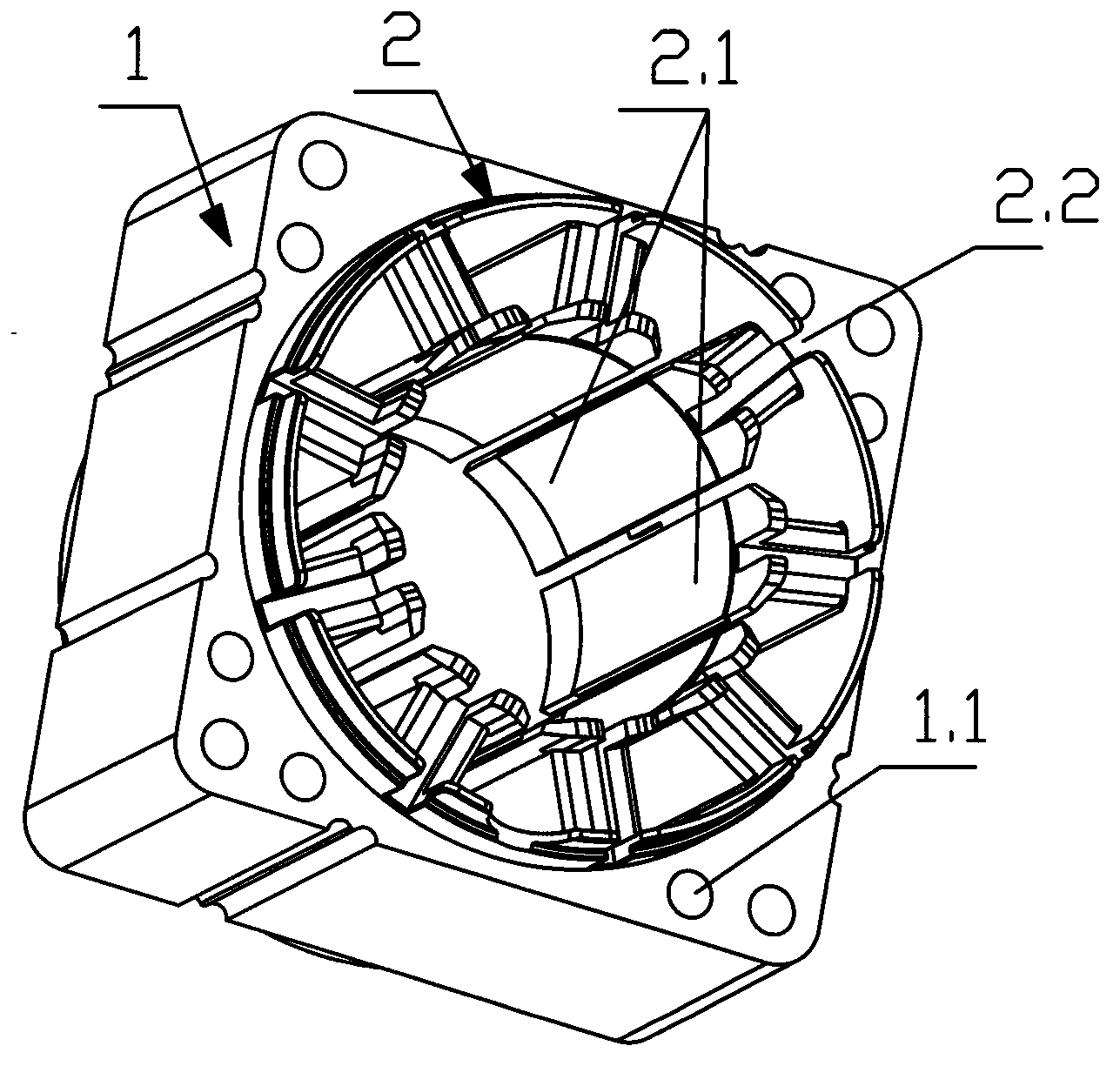

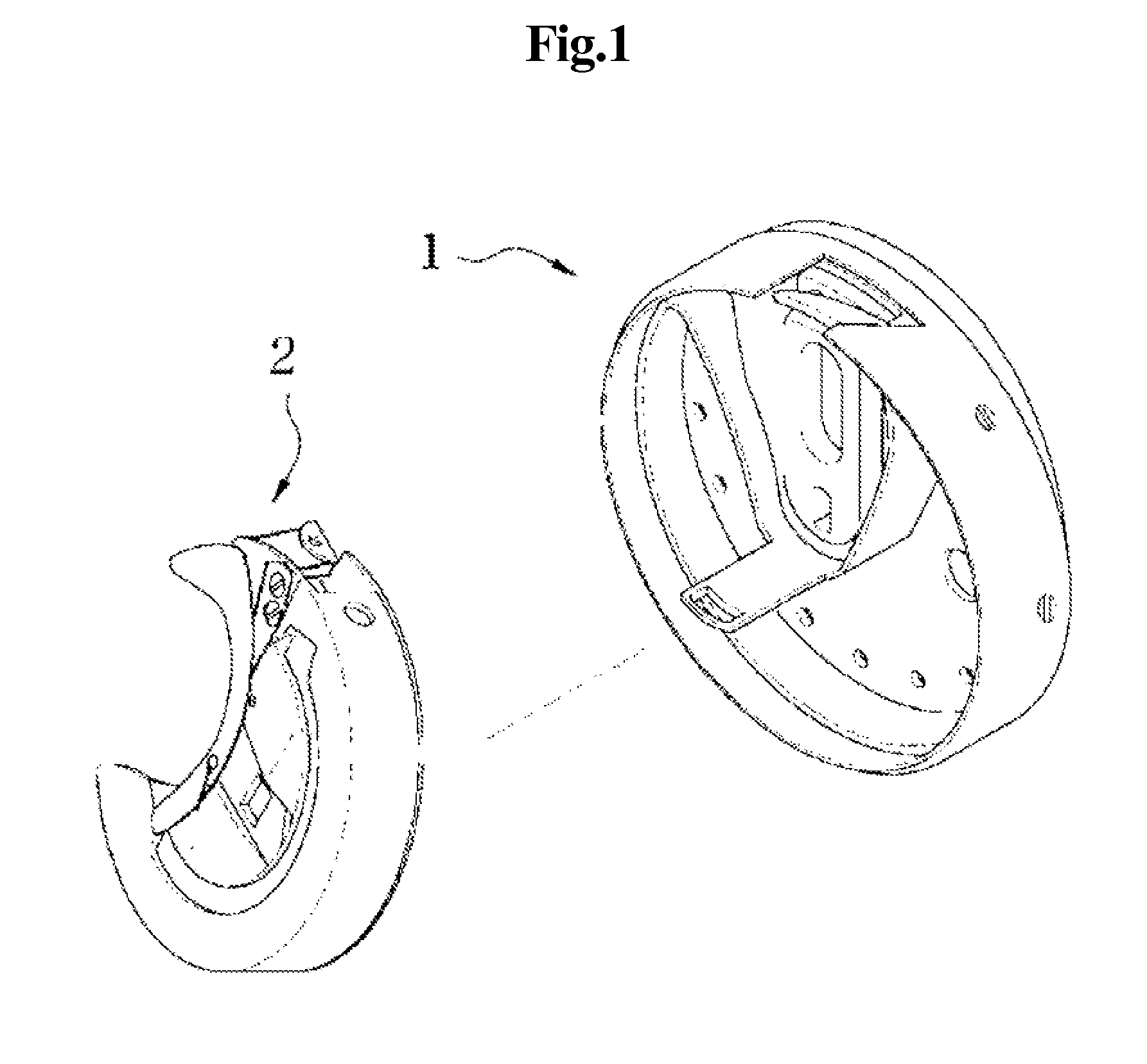

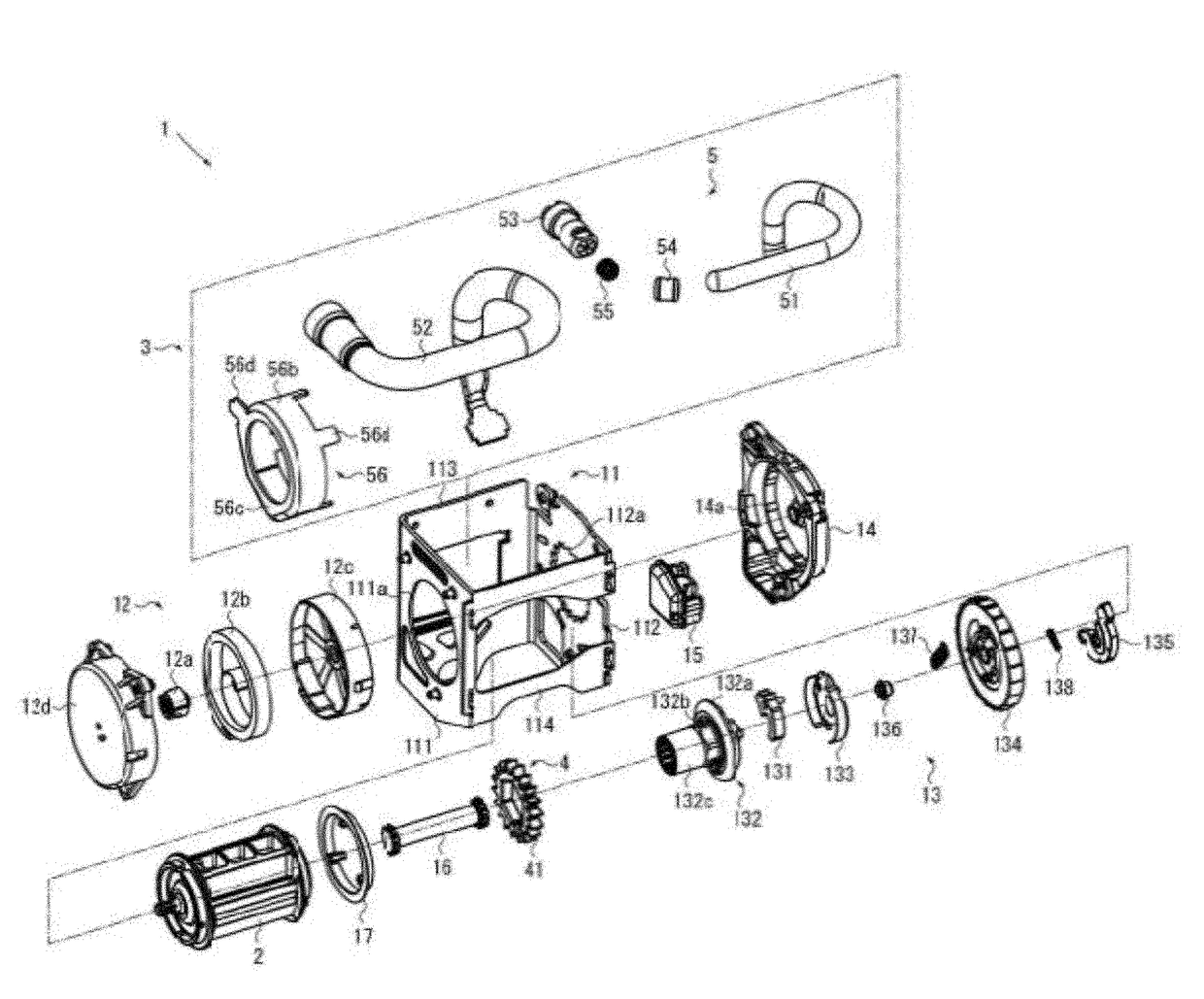

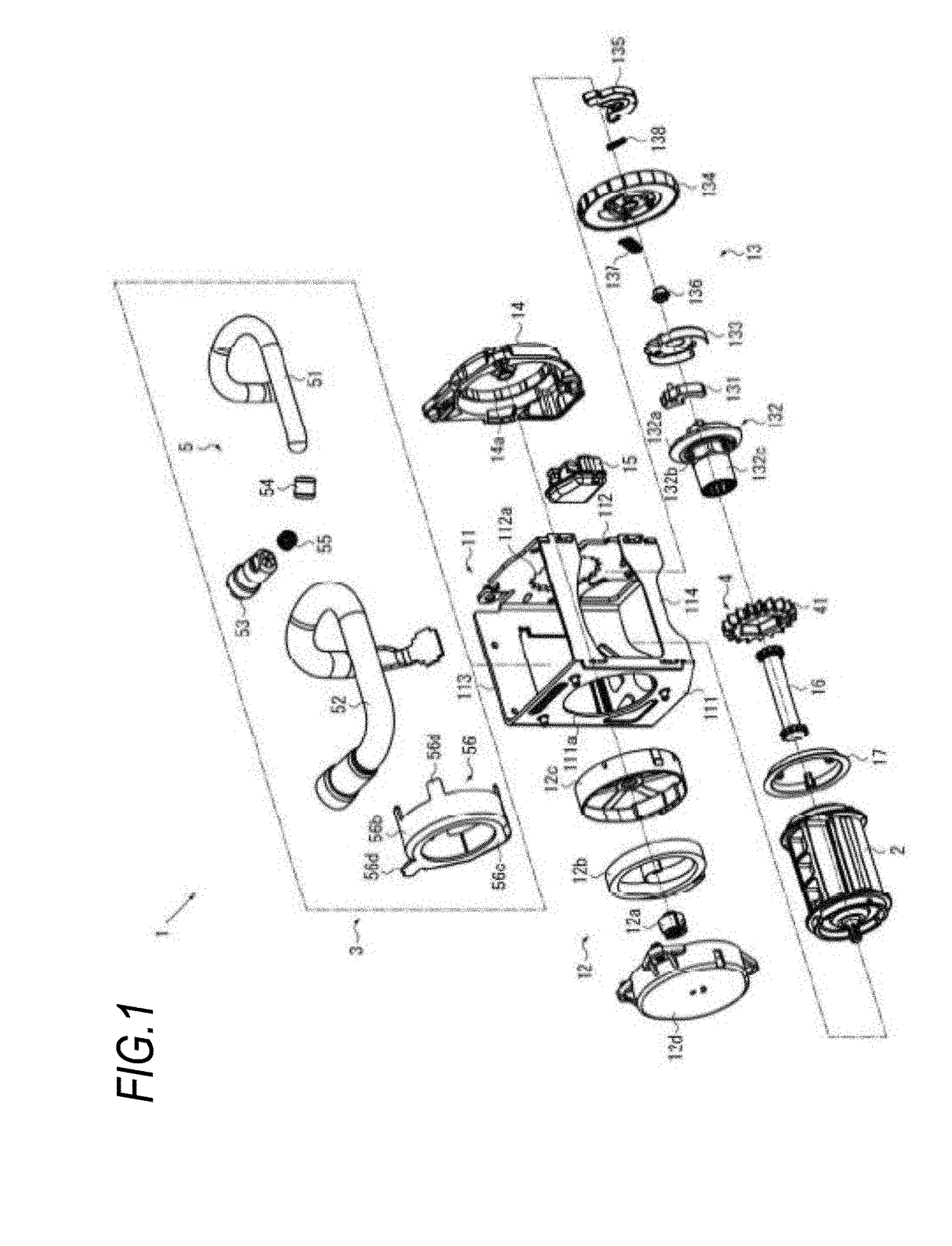

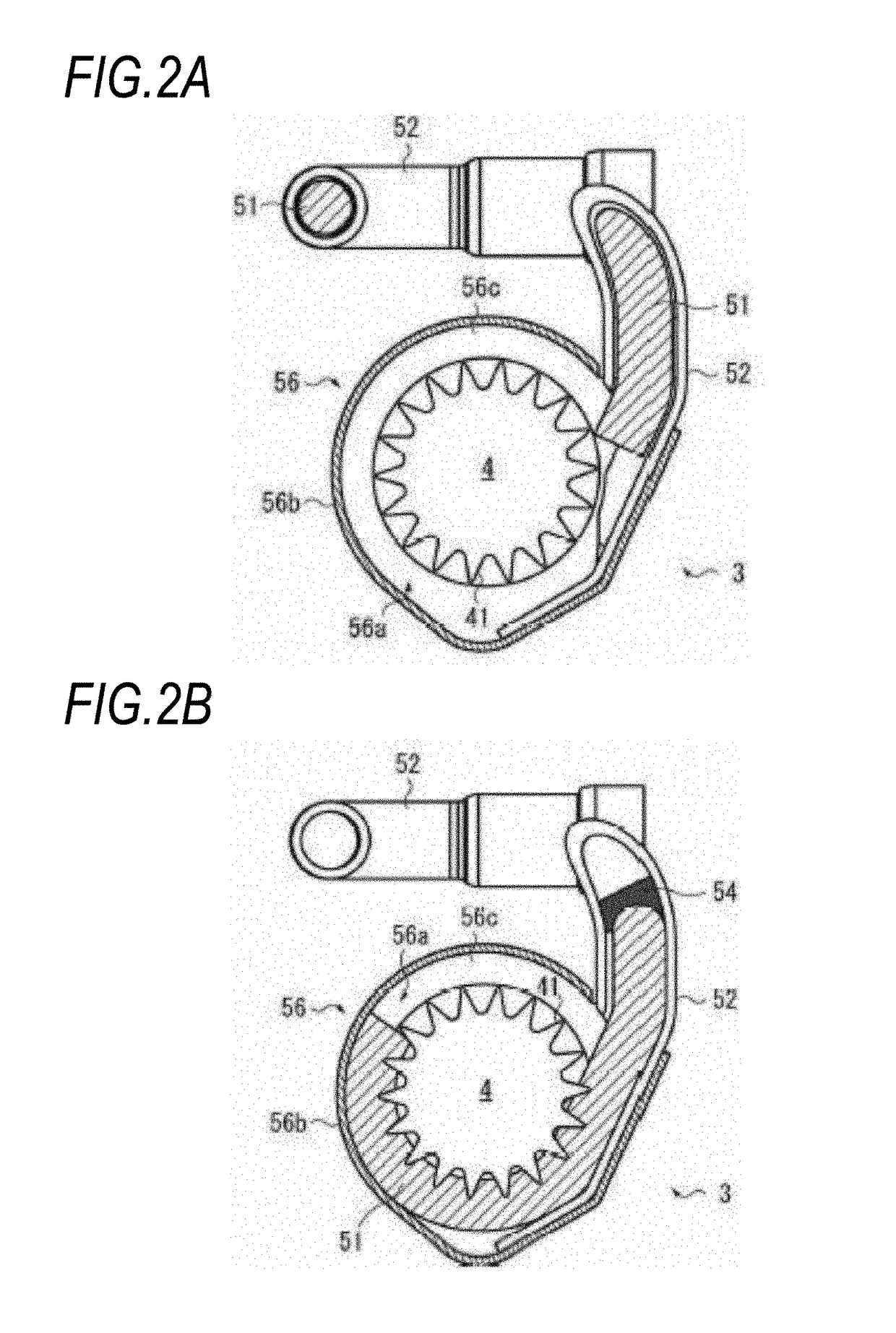

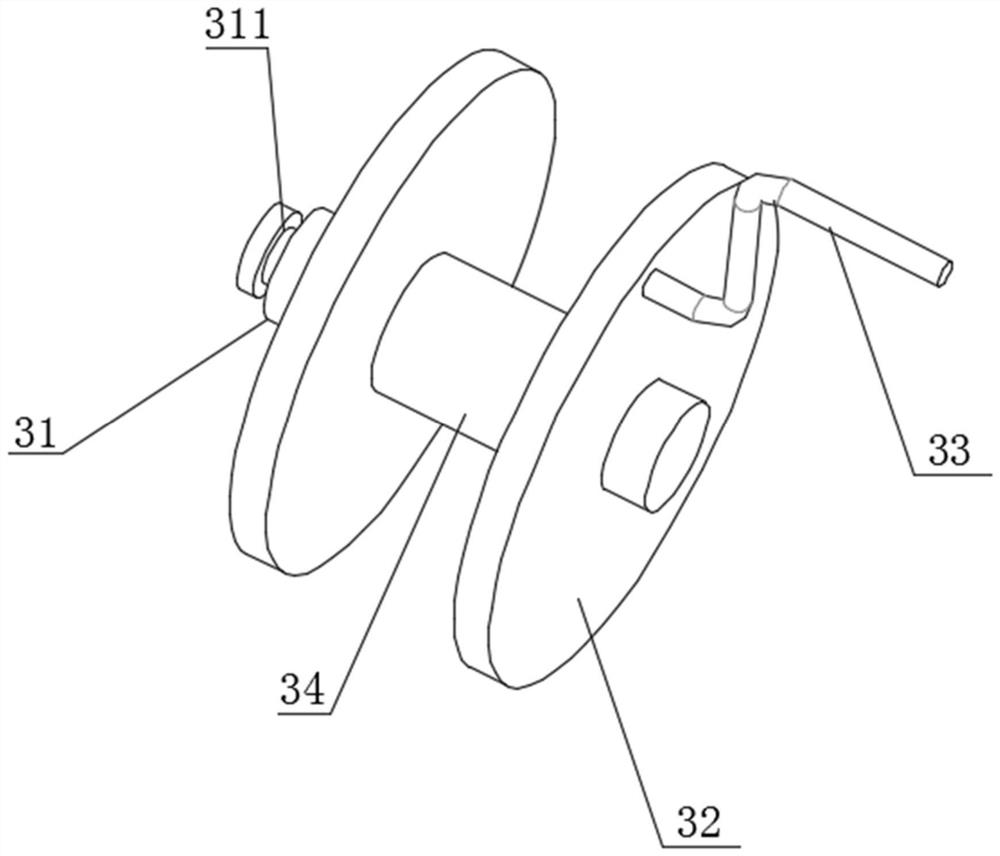

Pretensioner, seatbelt retractor and seatbelt device

The present invention relates to a pretensioner, a seatbelt retractor and a seatbelt device. In order to provide a compact and less expensive pretensioner (8) for improving the work assembly efficiency while effectively transmitting the pressing force of plural force transmission members (12) to a ring gear (16), plural balls (12a) inside a pipe (10) are pressed under the pressure of gas from a gas generator (14) in an emergency. The first ball (12a) presses a lever (17), and the balls (12a) other than the first ball (12a) sequentially press subsequent levers (18) such that the ring gear (16)rotates to move rightward. Internal teeth (16a) of the ring gear (16) are meshed with external teeth (20a) of a pinion (20) attached to a rotary shaft (19) at a side of a spool. The pinion (20) then rotates to allow the spool to retract a seatbelt. The first ball (12a) abuts on a ball stopper portion (10d) of the pipe (10) to stop the rest of the balls (12a) such that most of the balls (12a) are located in a circular movement path.

Owner:JOYSON SAFETY SYST JAPAN GK

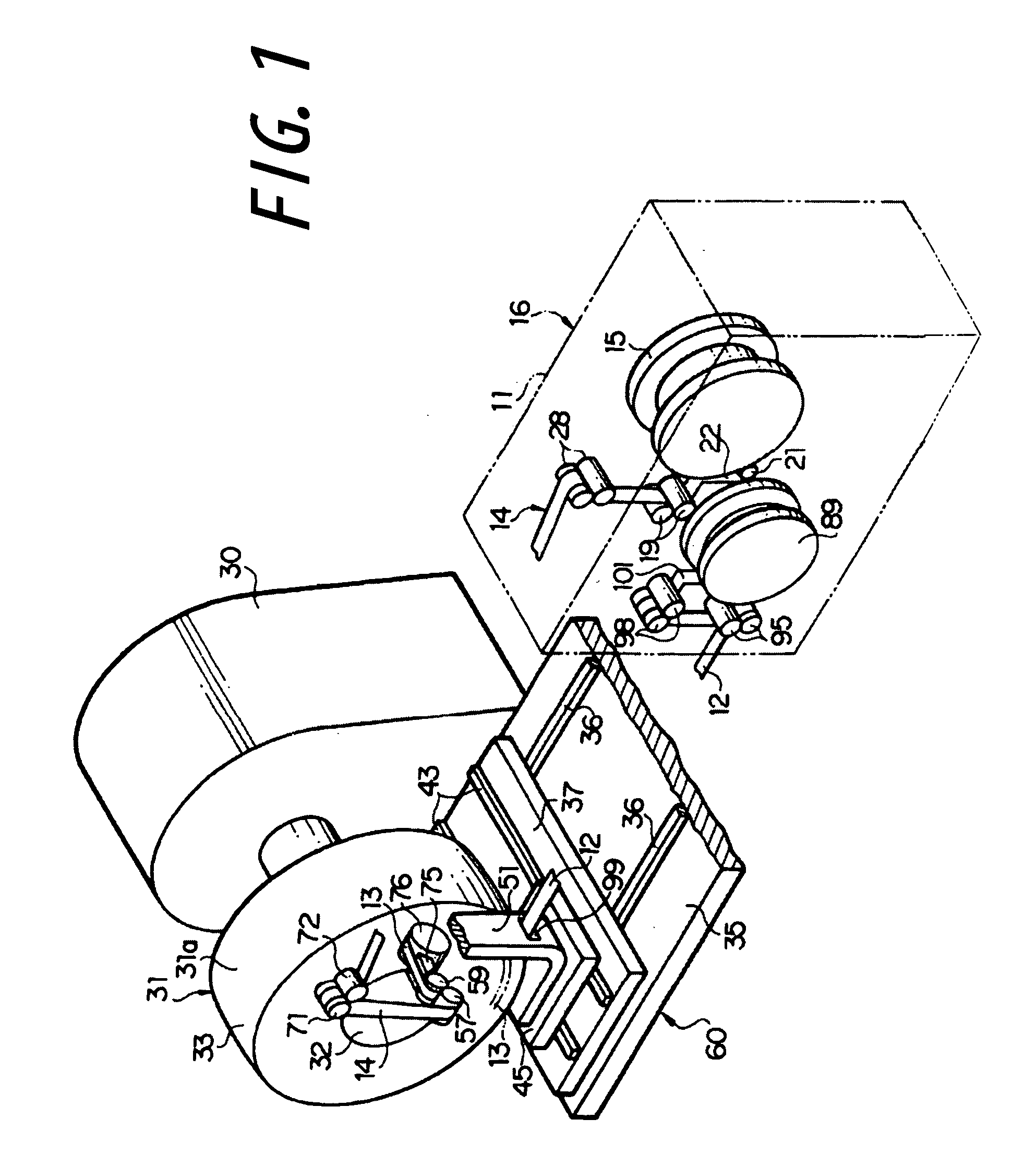

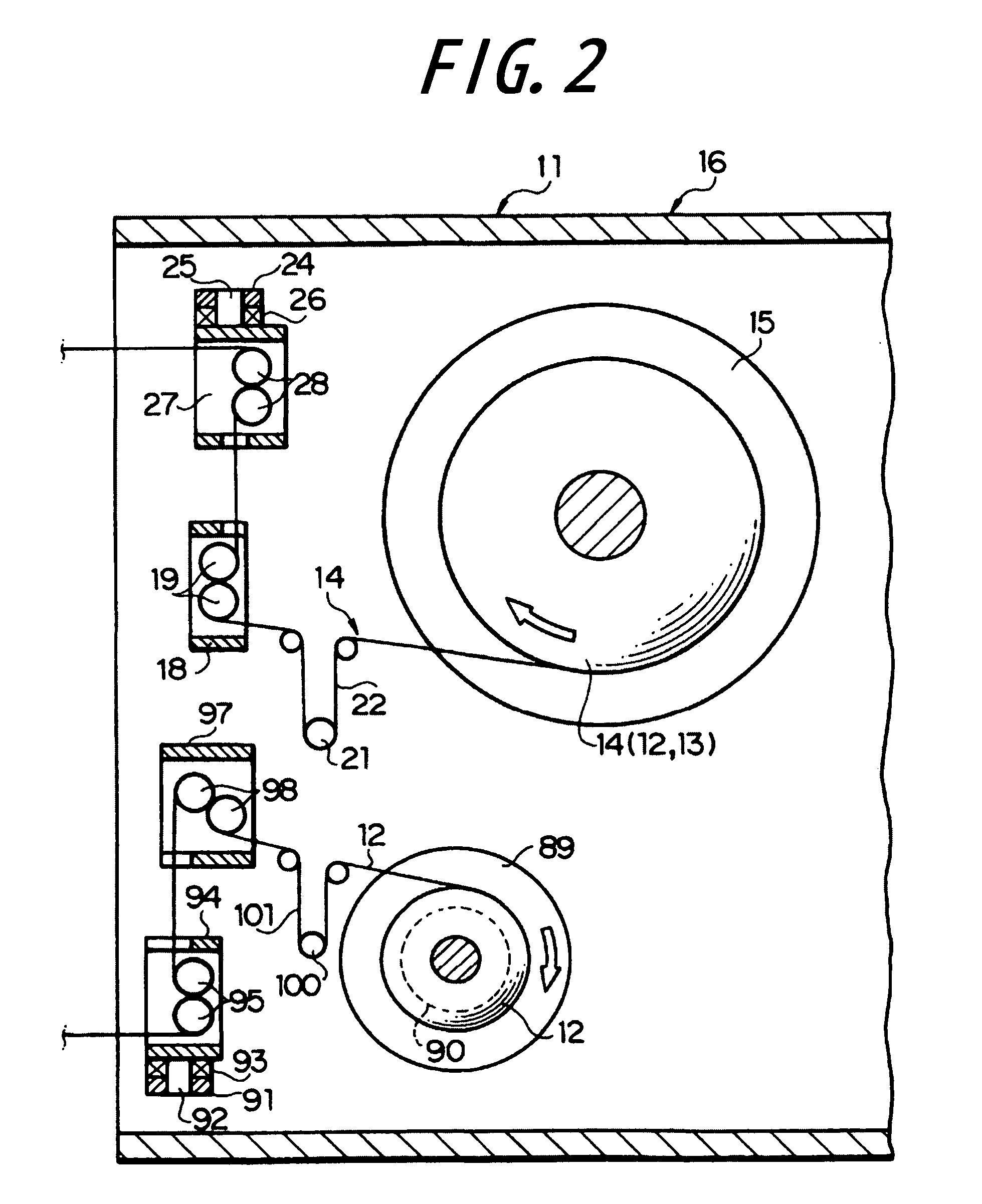

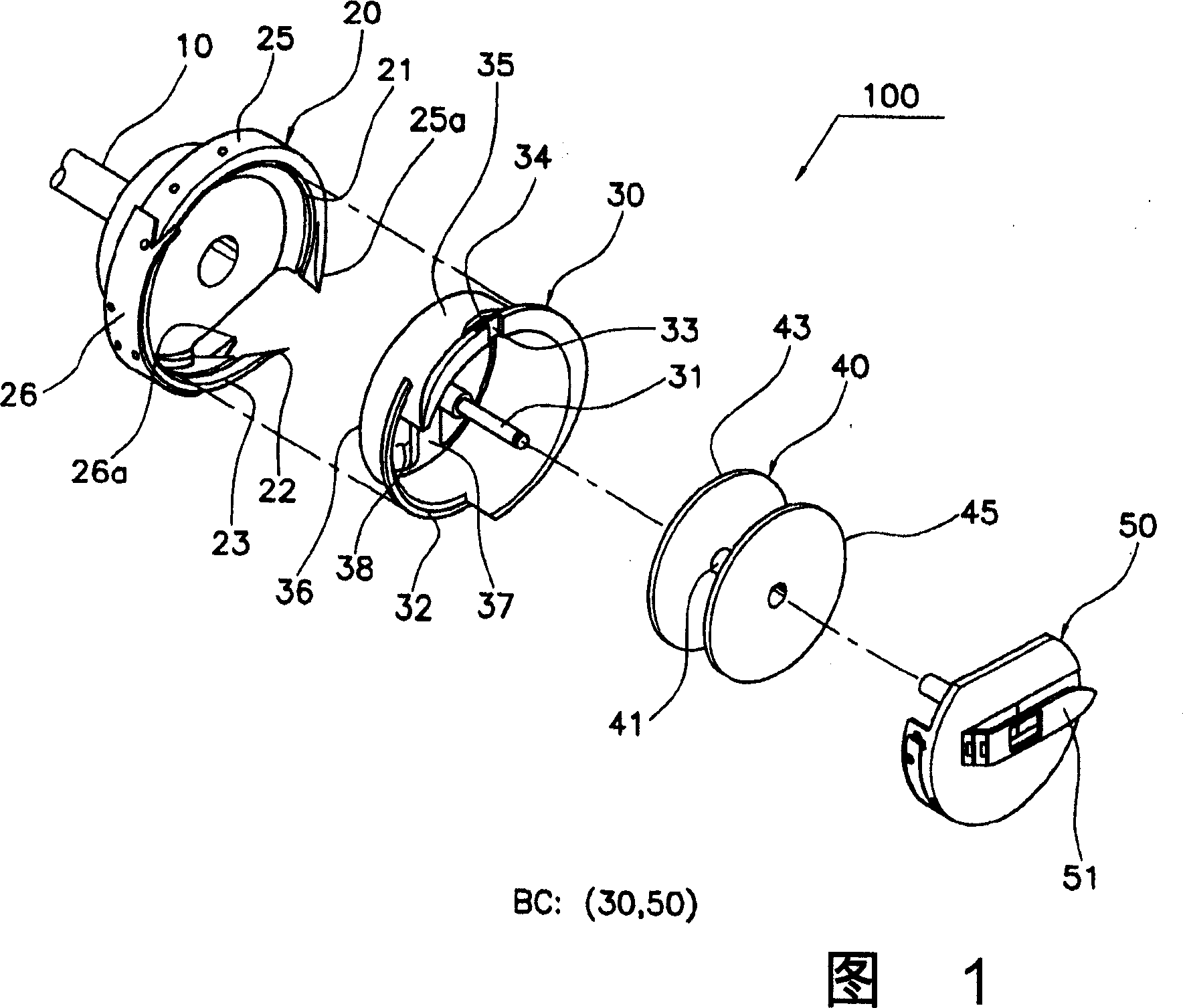

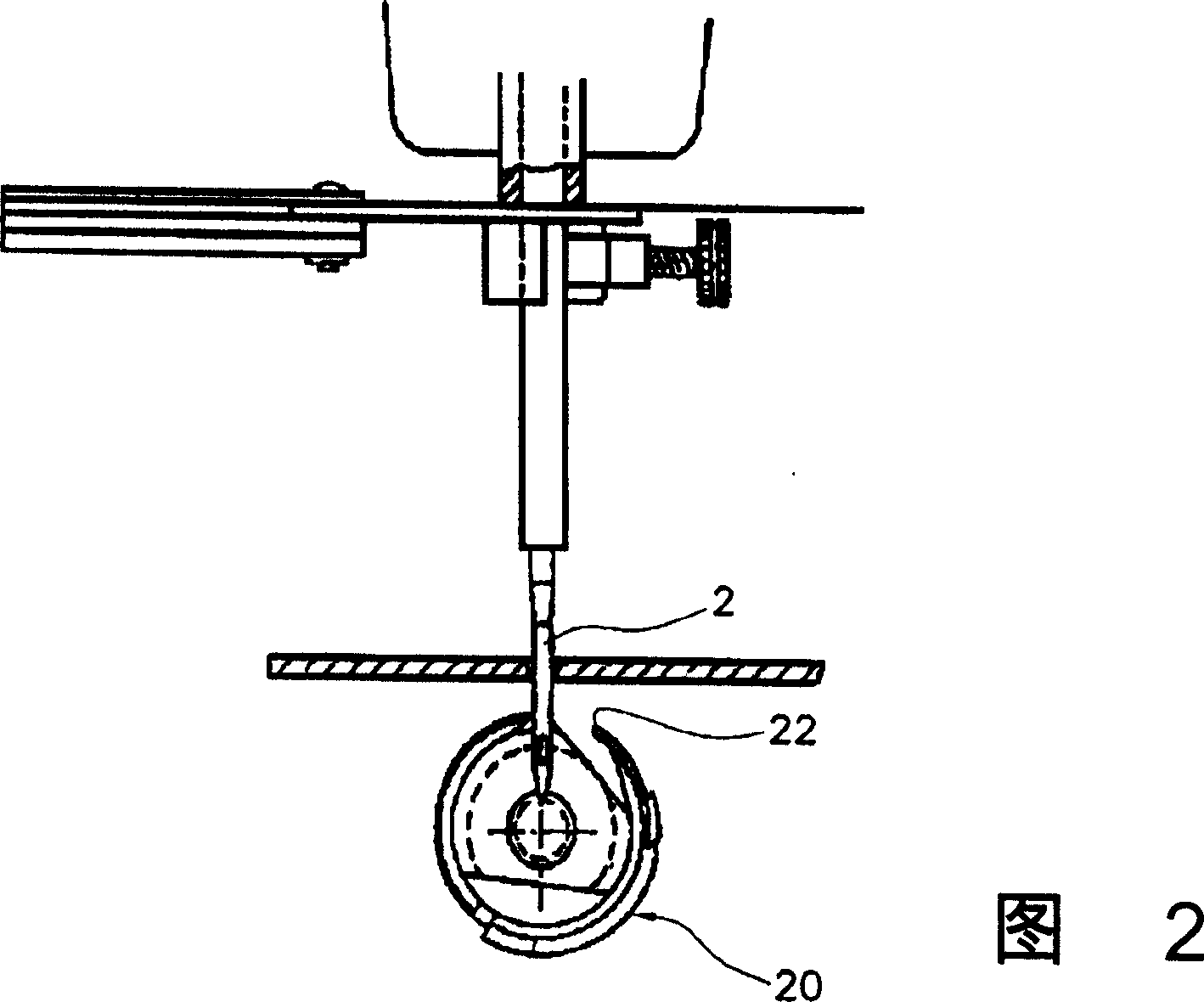

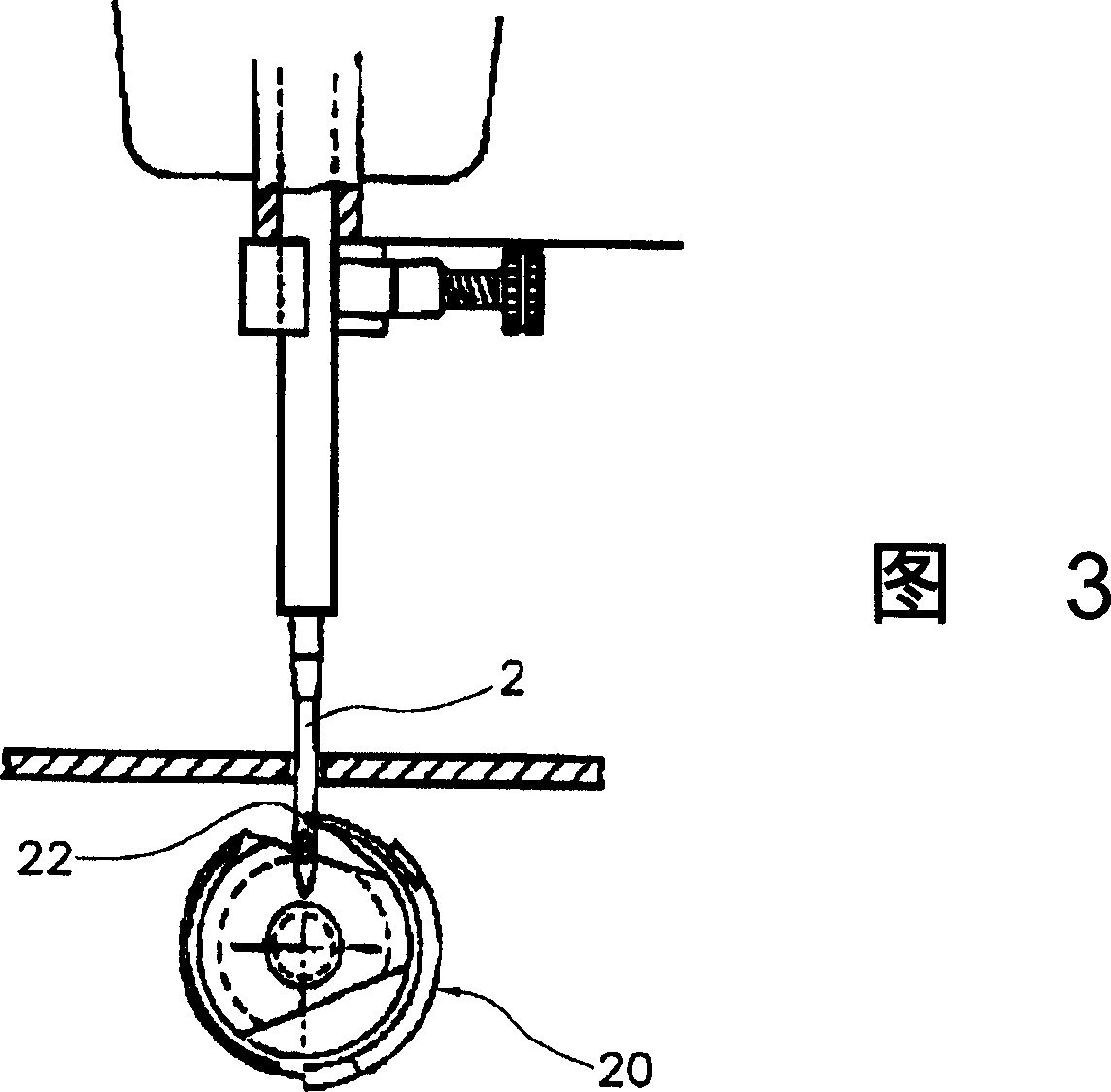

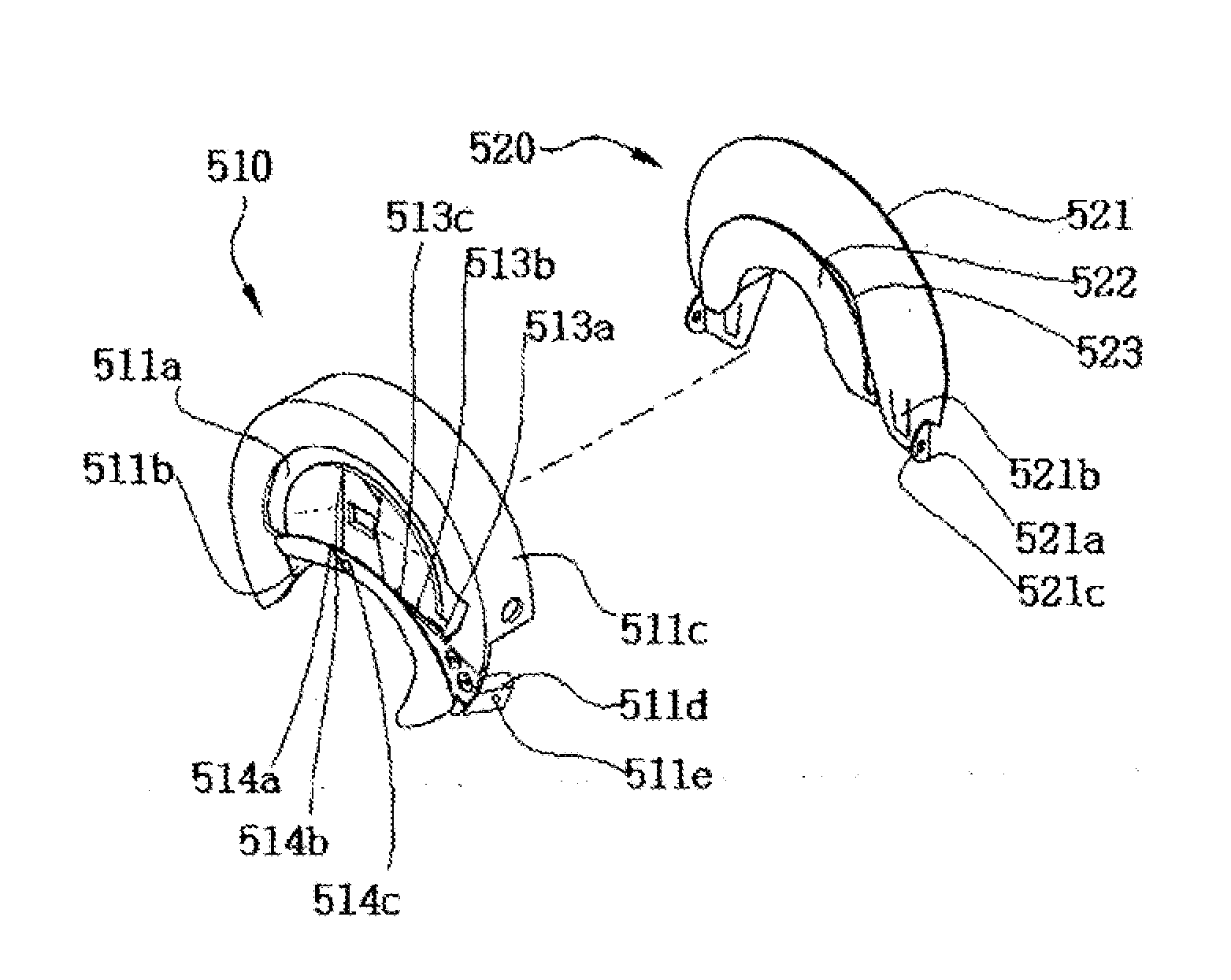

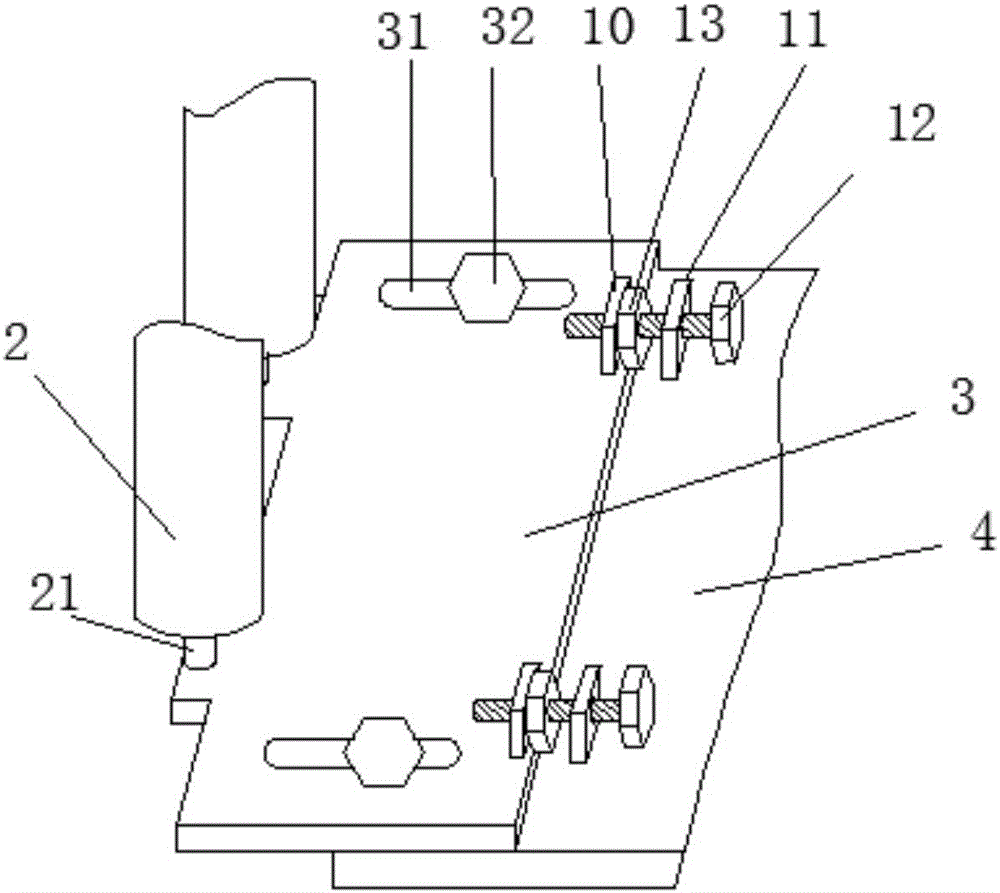

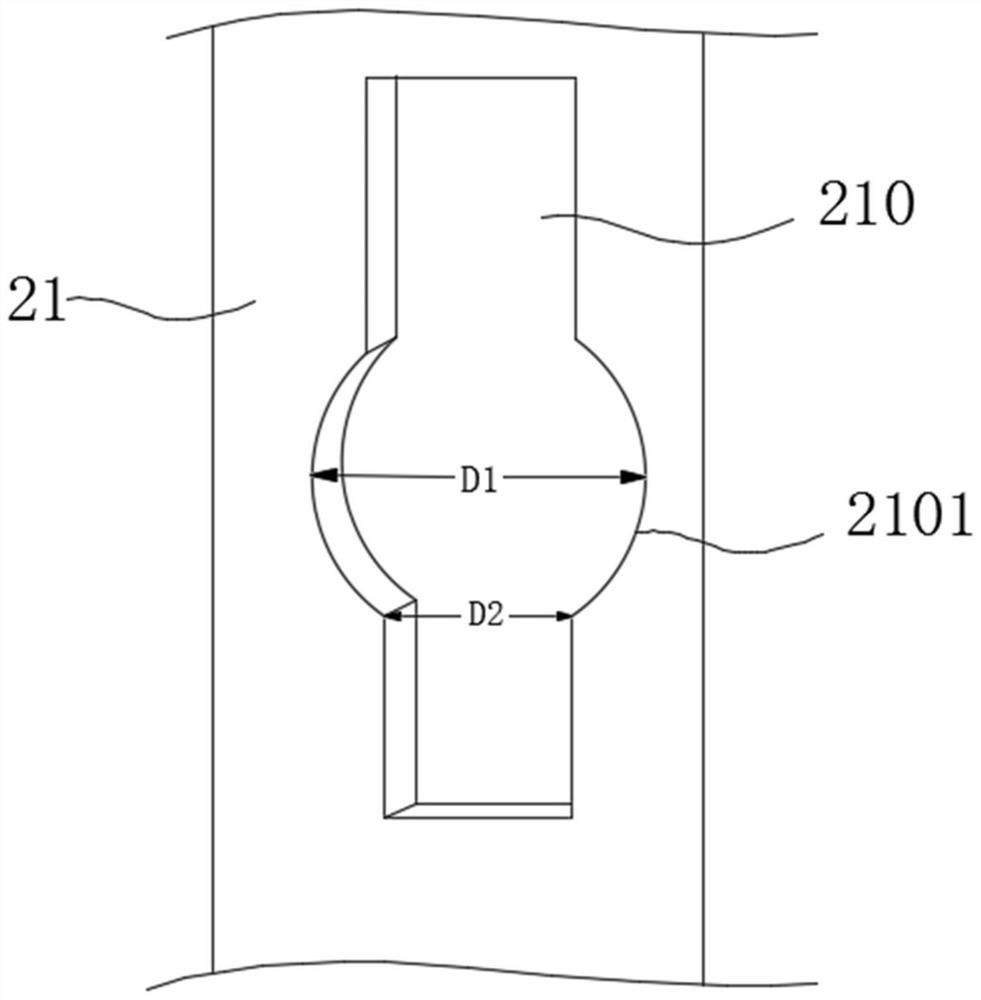

Rotary shuttle device for sewing machine

The present invention relates to a rotary shuttle device for a sewing machine, in which an inclined portion is formed at a first flange of a bobbin so as to allow a significant increase in a winding amount of lower thread and prevent a thread breakage and a thread tangle, and also in which a hook body is adapted to have a single model of gib and a replacement of the hook body is not needed regardless of a sewing speed and a thickness of a sewing material so as to obtain a good sewing quality, thereby remarkably reducing a cost of a component and workforce and labor for replacing the component. The rotary shuttle device for a sewing machine, comprising a hook body disposed at a driving shaft; a bobbin case provided with a bobbin case base having a stud rod and accommodated in the hook body and a bobbin case body for holding a bobbin at an outside; and a bobbin formed with a winding shaft which is disposed in the bobbin case and on which lower thread is wound, a first flange formed at one of the winding shaft so as to be contacted with a bottom surface of the bobbin case base and a second flange formed at the other end of the winding shaft, is characterized in that the bobbin has an inclined portion in which a part of the first flange is inclined toward a winding portion.

Owner:KOBEST

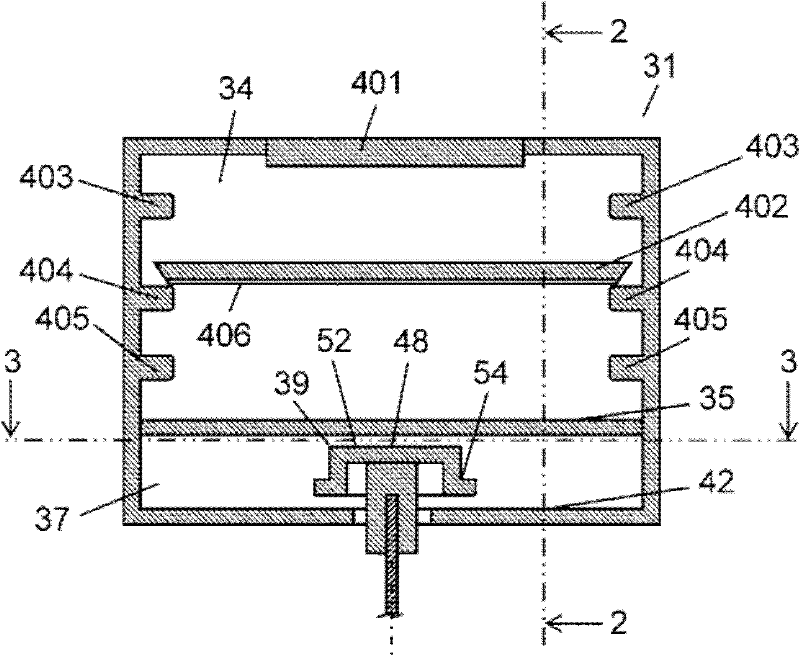

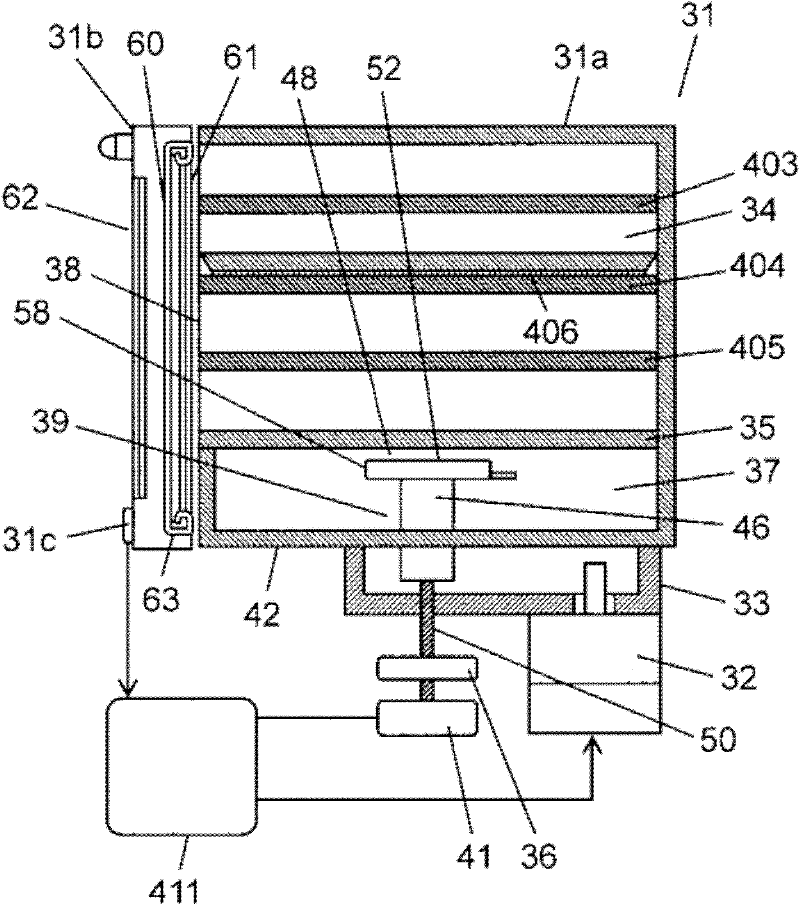

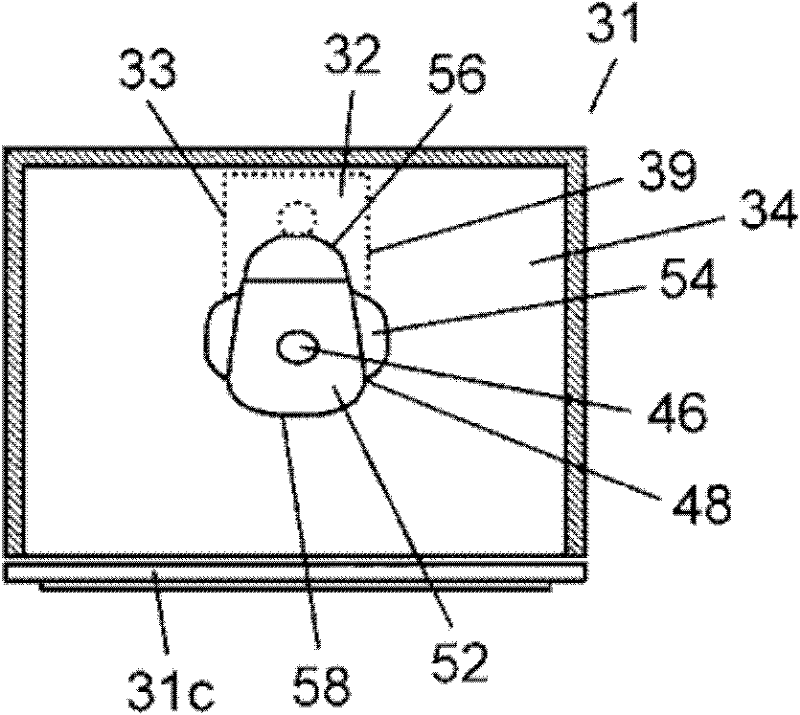

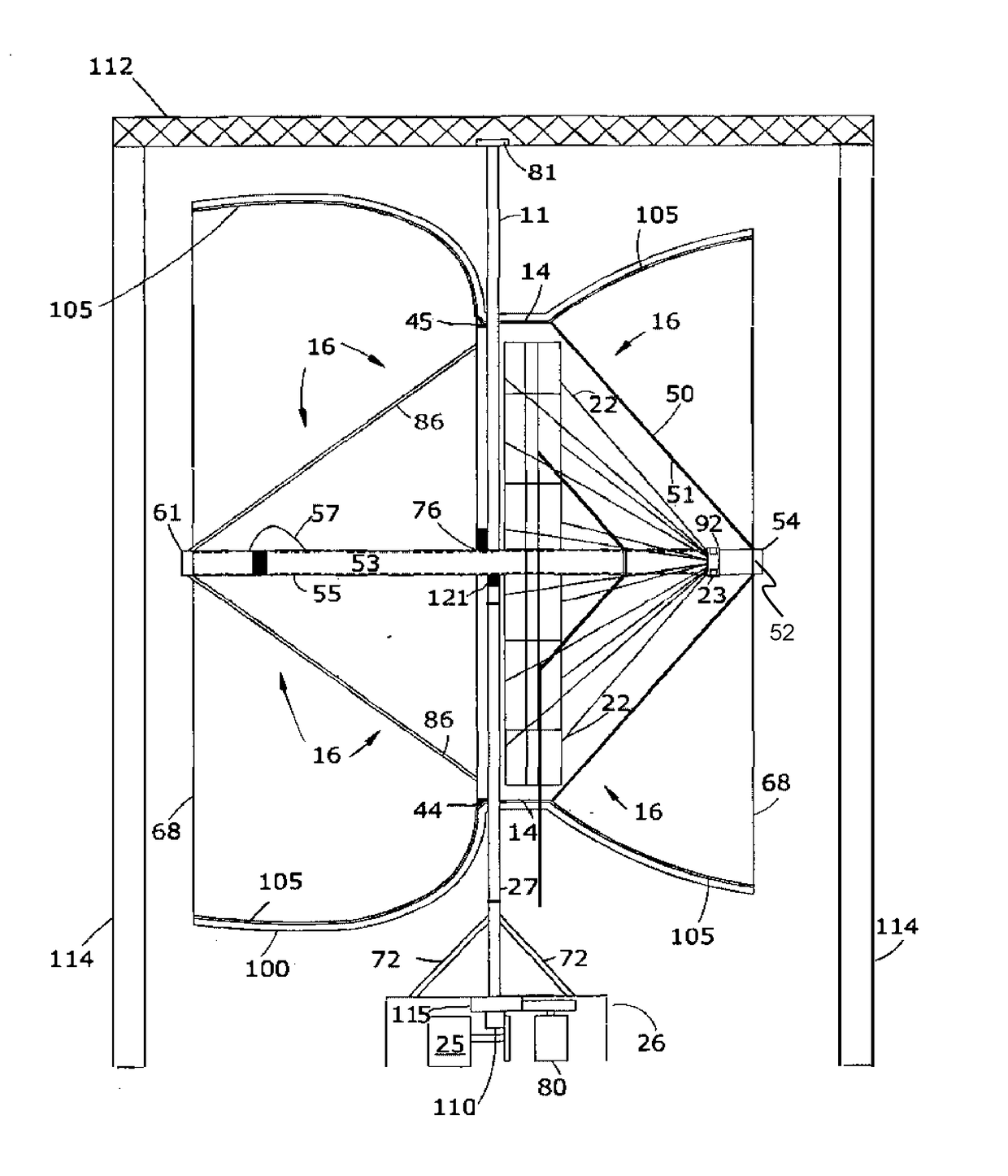

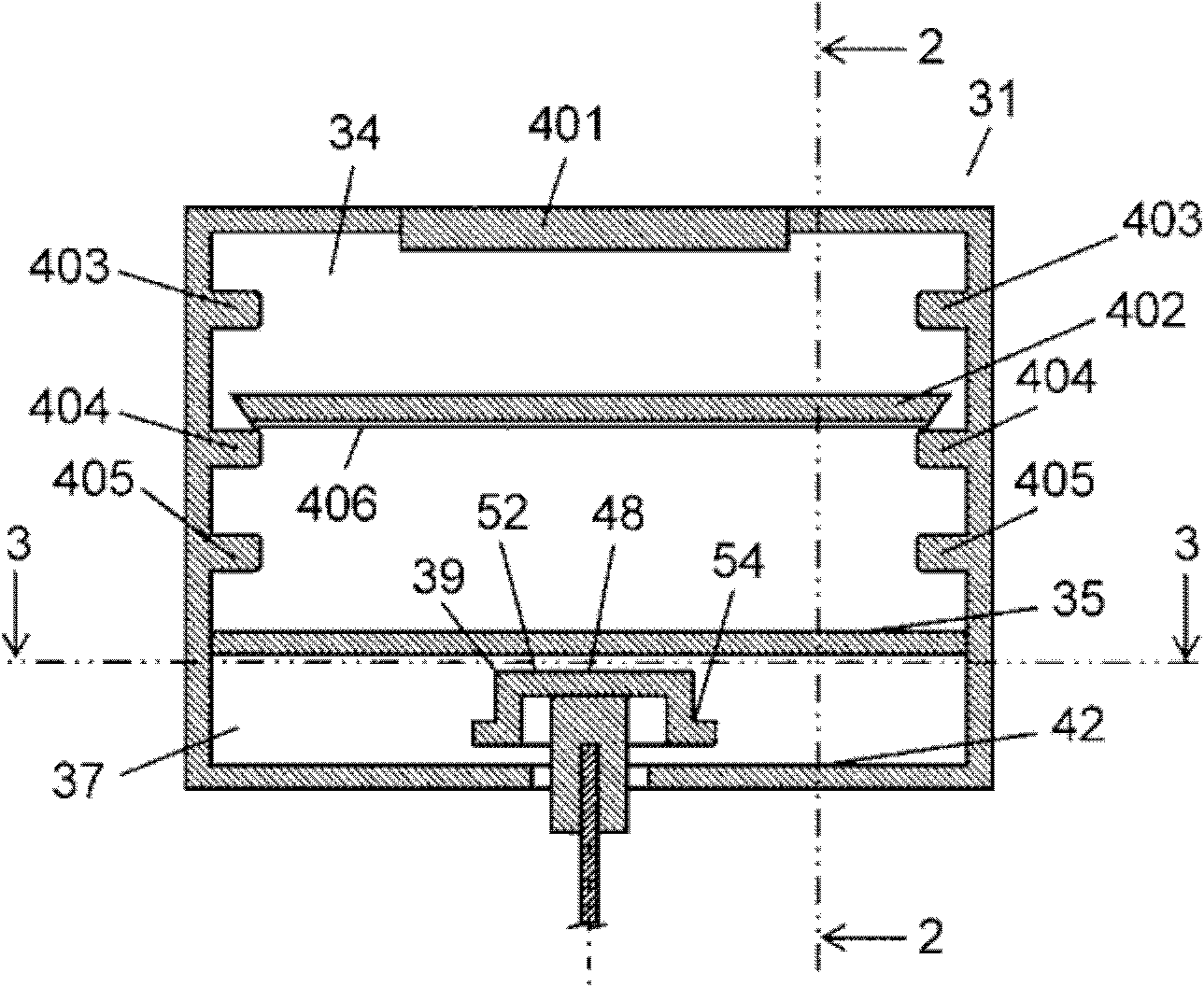

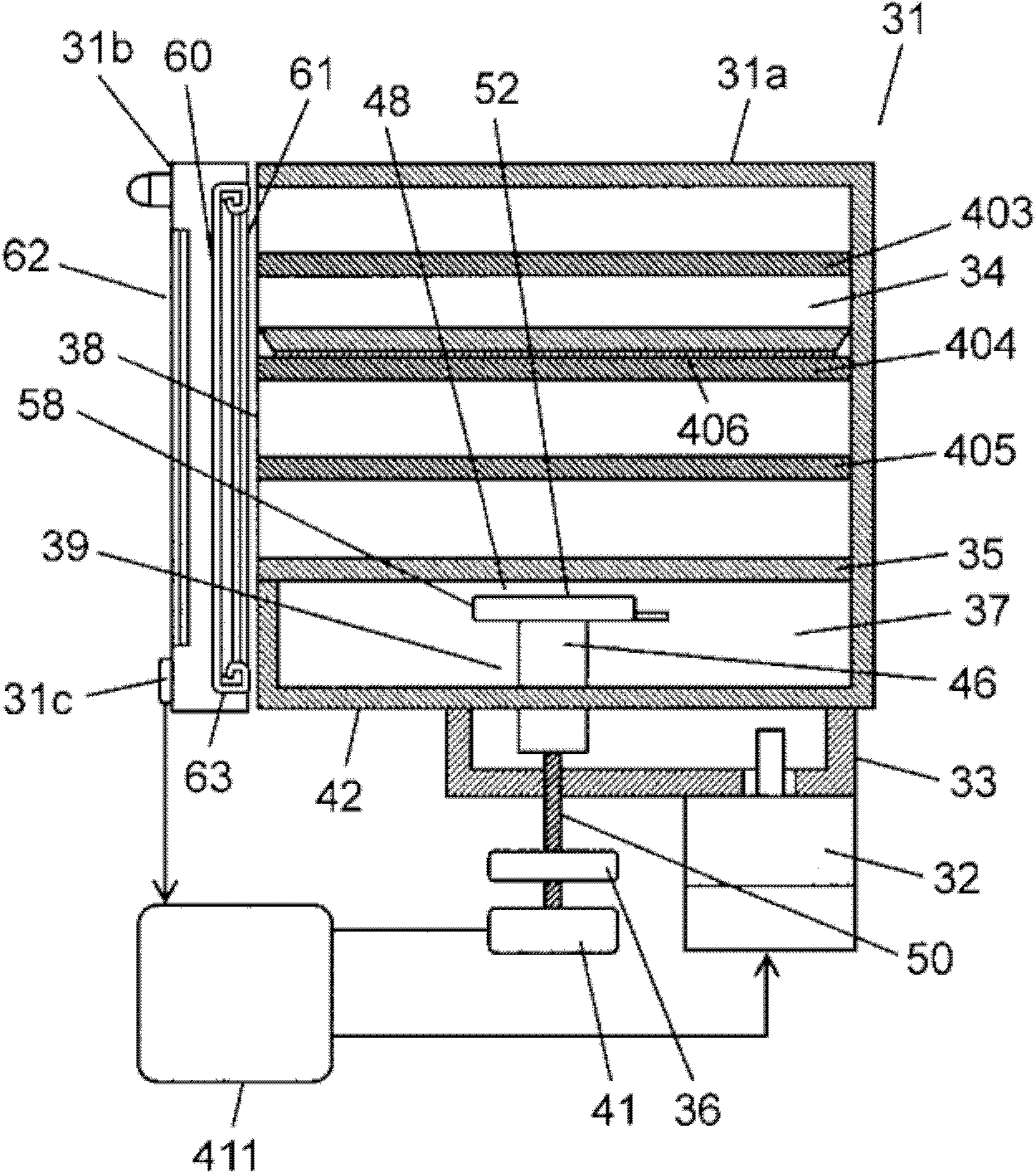

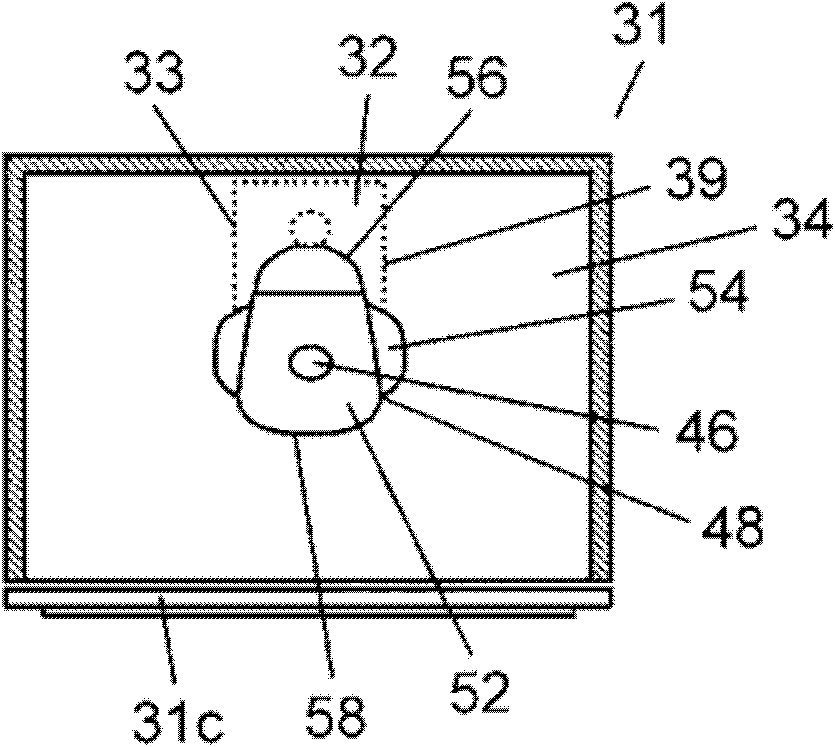

Microwave heating cooker

ActiveCN102265092AIncrease the amount of windingWill not complicate the structureDomestic stoves or rangesLighting and heating apparatusDirectivityCooker

The present invention relates to a microwave cooking device comprising: a heating chamber (34) which is provided with a glass-equipped door (31b) located at the front face opening and is adapted to contain an object to be heated; a waveguide tube (33) for transmitting to the heating chamber (34) a microwave emitted from a microwave generating section (32); an electricity supply section (39) having directivity and supplying the microwave from the waveguide tube (33) to the heating chamber (34); a drive section (41) for rotationally driving the electricity supply section (39); and a control section (411) for controlling the drive section (41) such that the microwave is supplied to a space above a tray, with the electricity supply section (39) directed to the door, using the inside of the glass as the main transmission path for the microwave. A thaw function and a grill function can be automatically and continuously performed without operation by the user.

Owner:PANASONIC CORP

Spinning yarn bobbin with long service life

The invention discloses a spinning yarn bobbin with the long service life. The spinning yarn bobbin comprises a top disc, a bottom disc and a bobbin body. The bobbin body is cylindrical and comprises a bobbin outer wall and a bobbin inner wall. Transition faces are arranged at the two ends of the bobbin outer wall, and the surfaces of the transition faces are of an arc downward-concave structure. A cylindrical hollow cavity is formed in the bobbin inner wall, and a plurality of protruding rings are linearly arranged on the surface of the bobbin outer wall in the horizontal direction. Ball grooves are symmetrically formed in the inner side of the bobbin inner wall, and balls are arranged in the ball grooves and clamped in the ball grooves. Holes with the diameters being smaller than those of the ball grooves are formed in the positions, corresponding to the ball grooves, of the bobbin inner wall.According to the spinning yarn bobbin, the ball grooves with the balls are formed in the bobbin inner wall, so that the yarn bobbin is more balanced in rotation, direction friction of the bobbin inner wall and a rotating shaft is avoided, friction damage of the yarn bobbin is avoided, and the service life of the yarn bobbin is prolonged; the bobbin body is connected with the top disc and the bottom disc through pipe fittings, and the yarn bobbin can be conveniently dismounted and replaced.

Owner:何小平

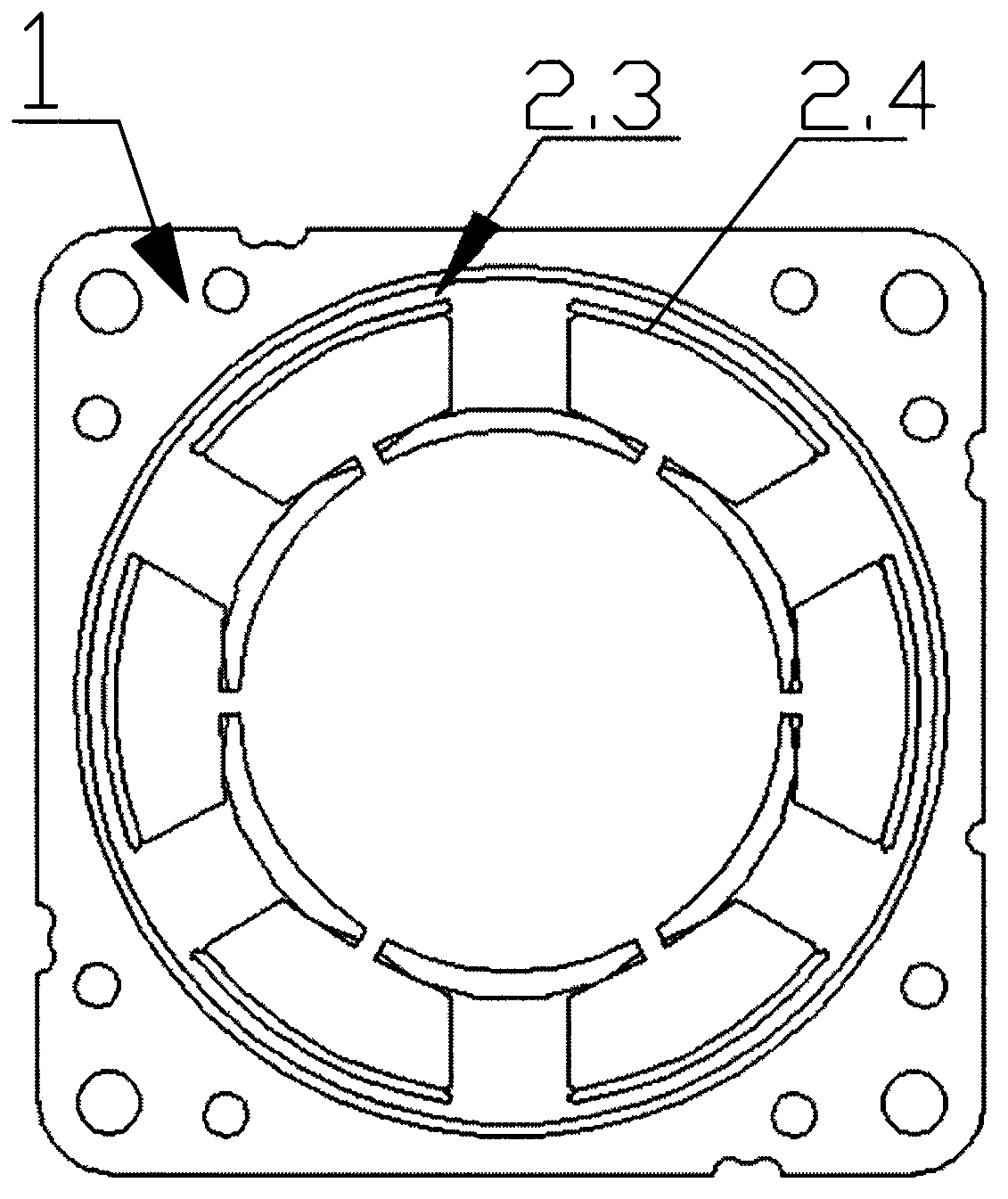

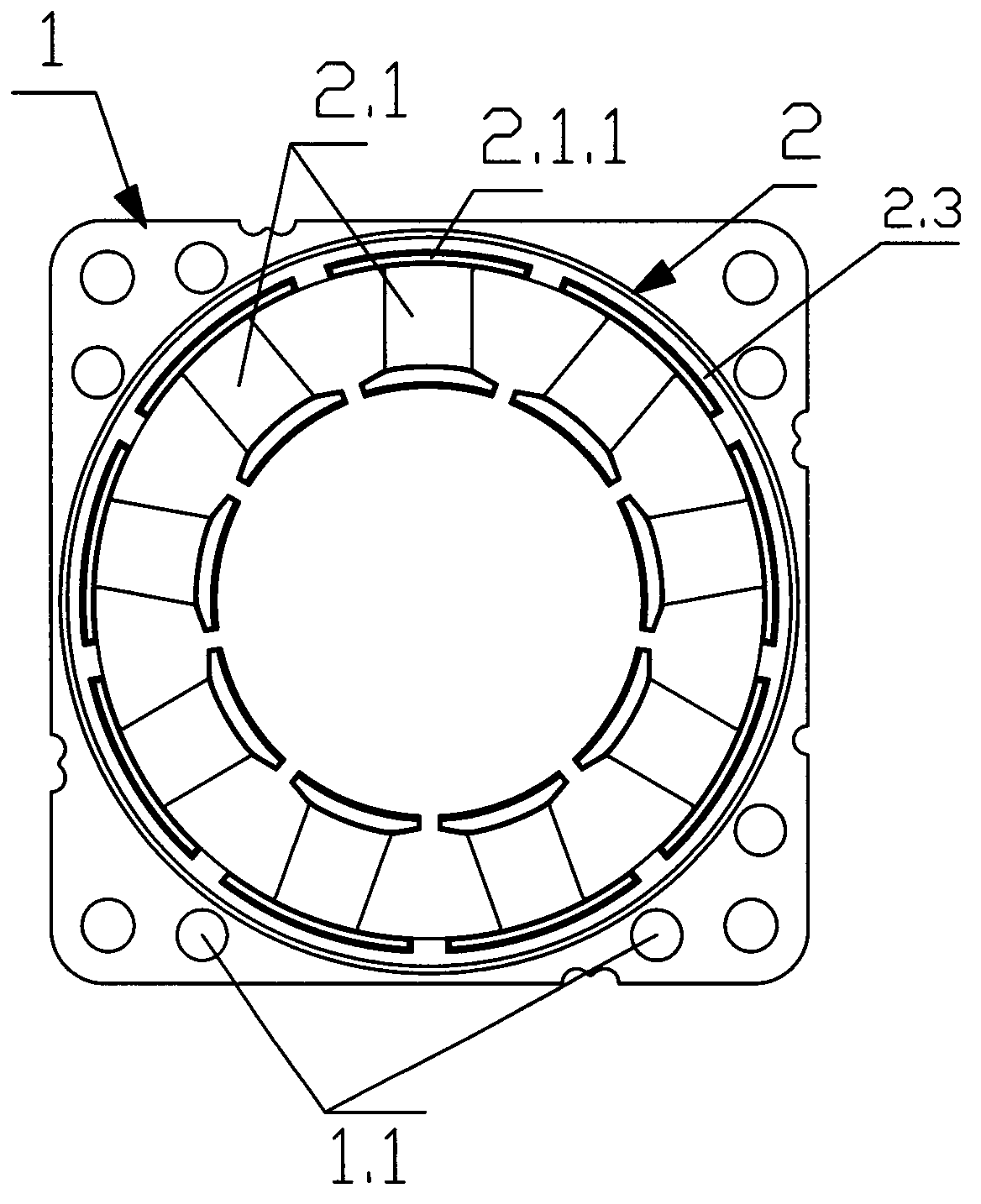

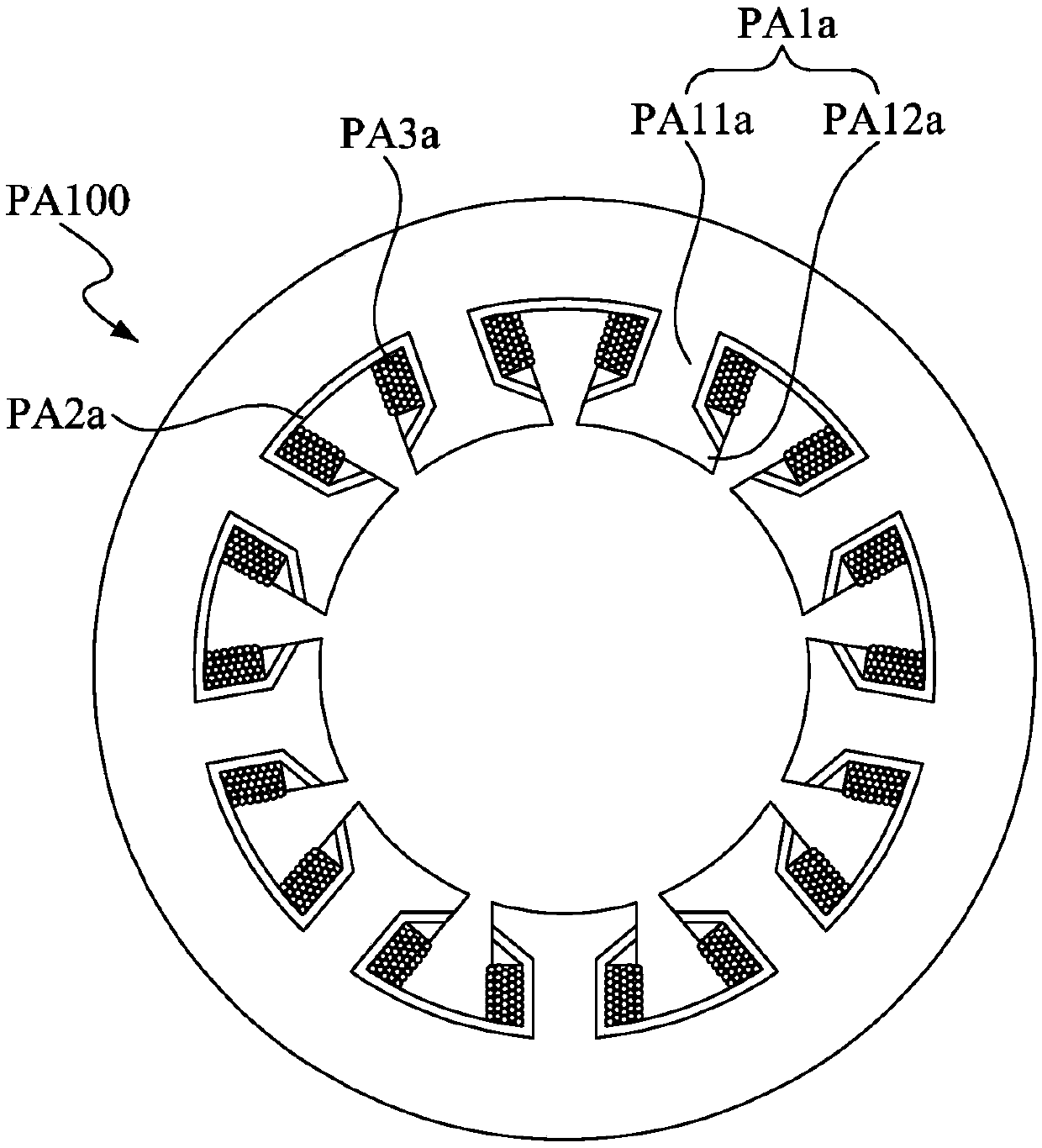

Motor stator

InactiveCN104300705AEasy to ensure accurate positionAccurate locationWindingsMagnetic circuit stationary partsEngineeringInjection moulding

The invention discloses a motor stator which comprises an iron core, a coil and a framework, wherein a through hole is formed in the center of the iron core, and a plurality of wire slot bodies convenient to wind the coil are formed in the inner wall of the framework. The motor stator is characterized in that the framework is subjected to integral injection molding and is molded in the through hole of the iron core. A plurality of threading grooves convenient for threading are formed in the edge of the obverse side of the framework, and a wiring slot used for containing a coil leading-out wire is formed in the reverse side of the framework. The framework of the stator is integrally molded, so that the motor stator is simple in structure and saves mounting process. The motor stator has the advantages of improving the motor performance and reducing damage of enameled wires during operation. The motor stator belongs to the technical field of motors.

Owner:ZHEJIANG ZOBOW MECHANICAL & ELECTRICAL TECH

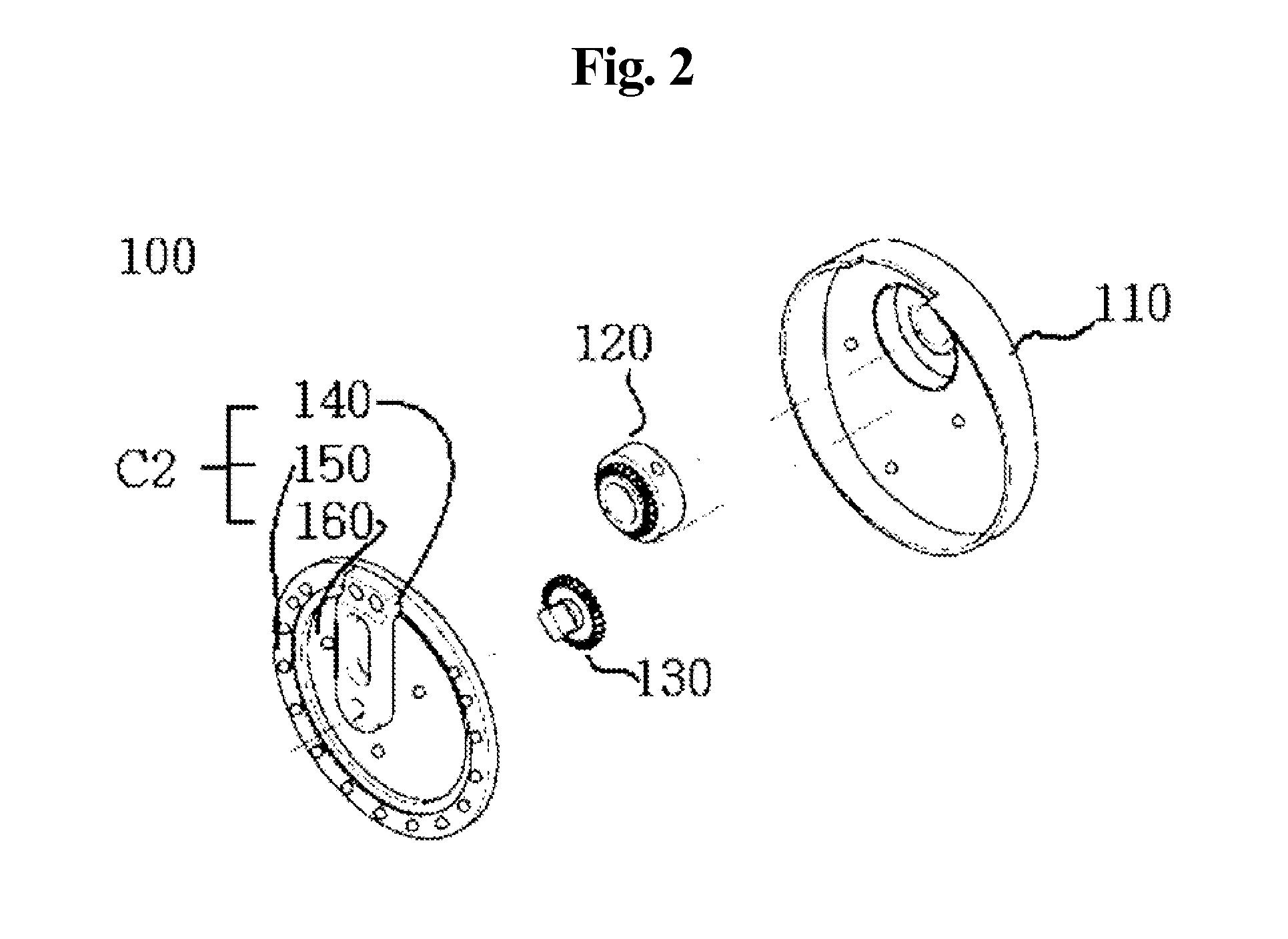

Under-thread supply device for sewing machine

ActiveUS20150292130A1Enhanced efficiencyAmount of wind be increaseSewing-machine control devicesThread-break detectorsEngineeringSewing machine

Owner:SINJIN STEEL

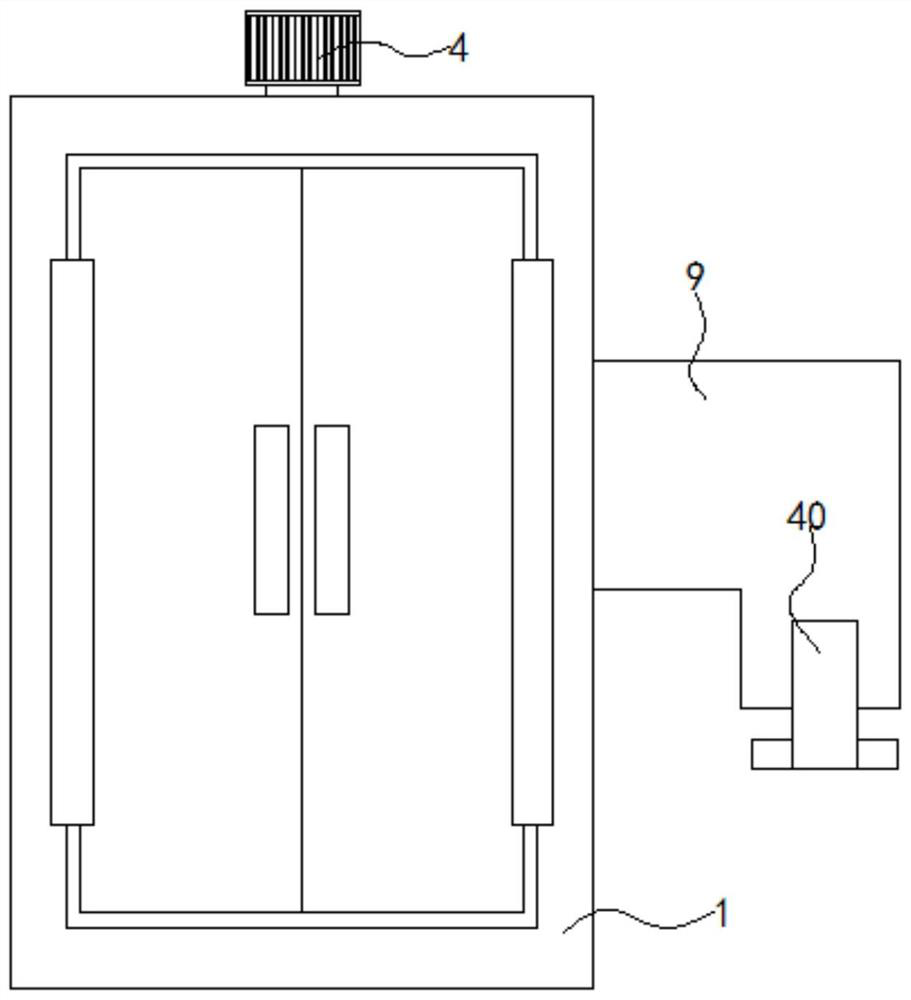

Novel elevator releveling device

The invention discloses a novel elevator releveling device, and relates to the field of elevator releveling. The novel elevator releveling device comprises a car frame and a car arranged in the car frame; the upper end and the lower end of the car frame are connected with the upper end and the lower end of the car through an elastic structure correspondingly; and a traction connection piece is arranged at the upper end of the car frame, and a leveling sensor is arranged on the car. The novel elevator releveling device is characterized in that the upper end of the car frame is provided with a winding strip fixing piece and a winding wheel; and the lower end of the car is provided with a fixed pulley, one end of a winding strip is fixed to the winding strip fixing piece, the other end of thewinding strip bypasses the fixed pulley to be connected to the winding wheel, and the winding strip has the certain winding amount on the winding wheel, so that certain tensioning force of the winding strip exists between the car frame and the car, and the winding wheel rotates to change the winding amount of the winding strip, so that releveling of the car is conducted. The novel elevator releveling device has the advantages that the structure is simple, and accurate and safe releveling can be achieved.

Owner:AOTE RAMBO ELEVATOR CO LTD

Pretensioner, retractor and seat belt device

InactiveUS20180043859A1Suppress enlargementIncrease the amount of windingBelt retractorsDrive wheelSeat belt

A pretensioner includes a driving wheel and a power transmission unit. A spool is disposed to be rotatable in the driving wheel. The spool winds a webbing which restrains an occupant. The power transmission unit transmits power to the driving wheel during an emergency. The power transmission unit includes a resin-made long body, a pipe and a gas generator. The resin-made long body rotates the driving wheel. The pipe contains the resin-made long body. The gas generator supplies an operation gas into the pipe. The resin-made long body discharged from the pipe is configured to rotate the driving wheel while the resin-made long body is wound around the driving wheel.

Owner:JOYSON SAFETY SYST JAPAN KK

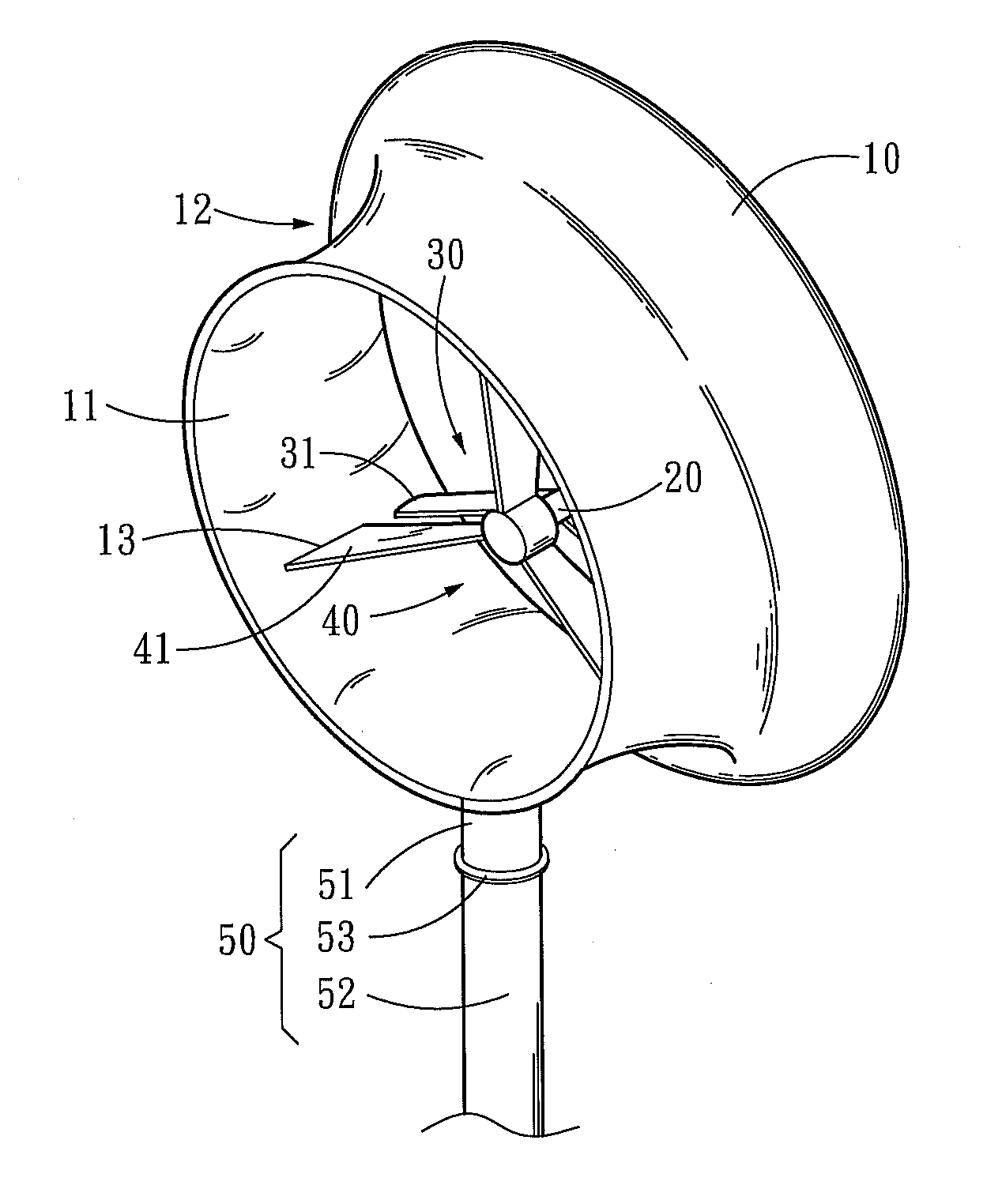

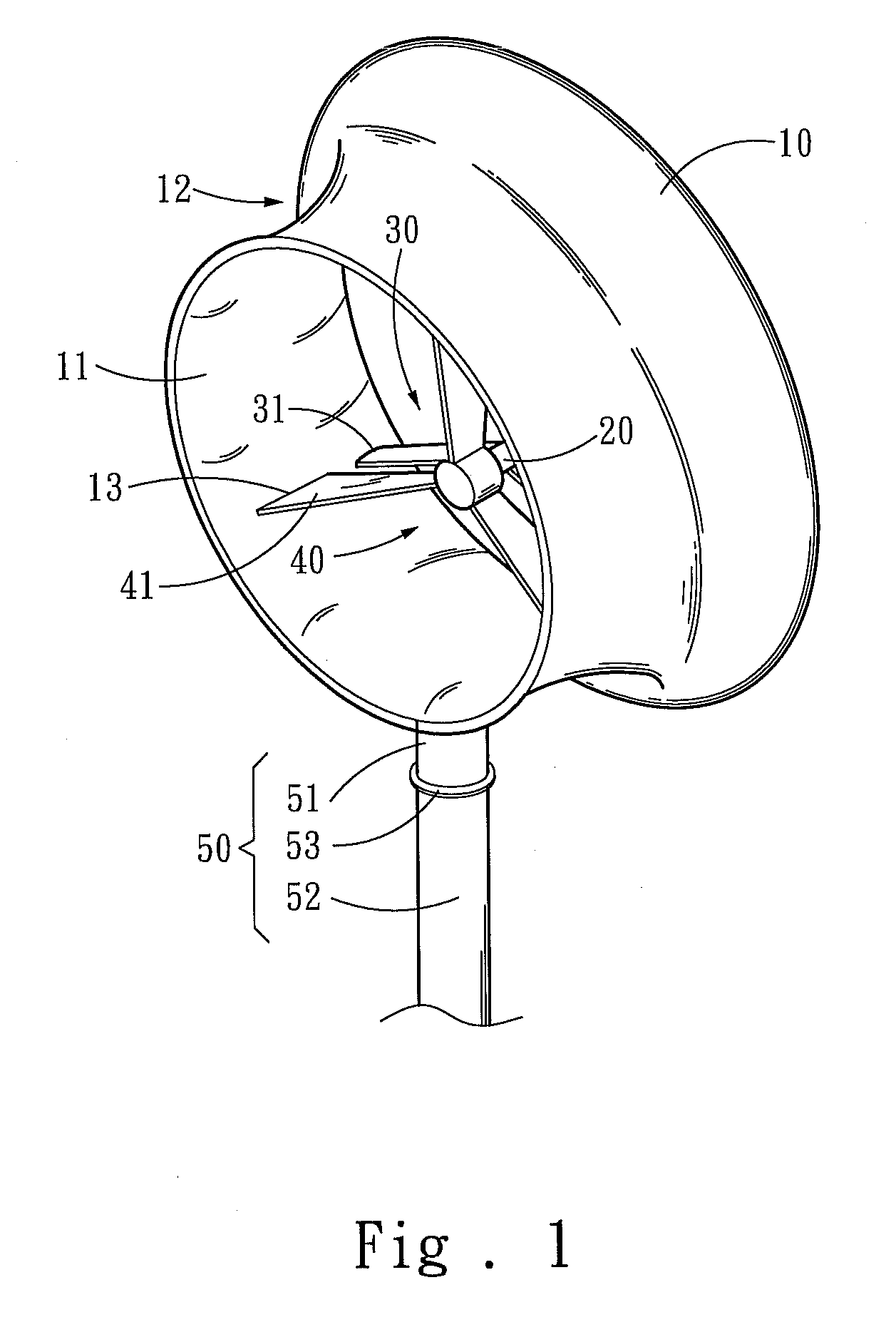

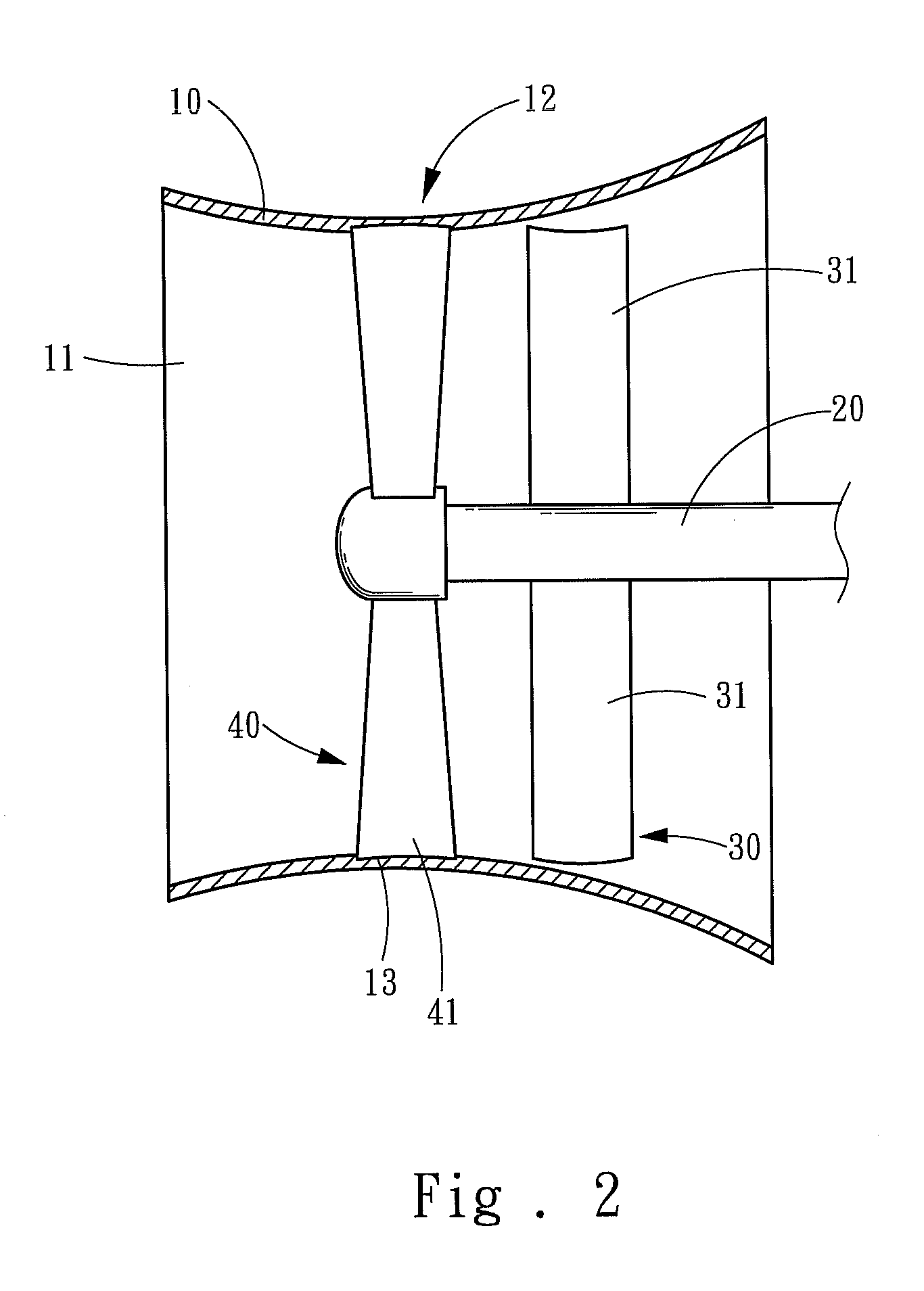

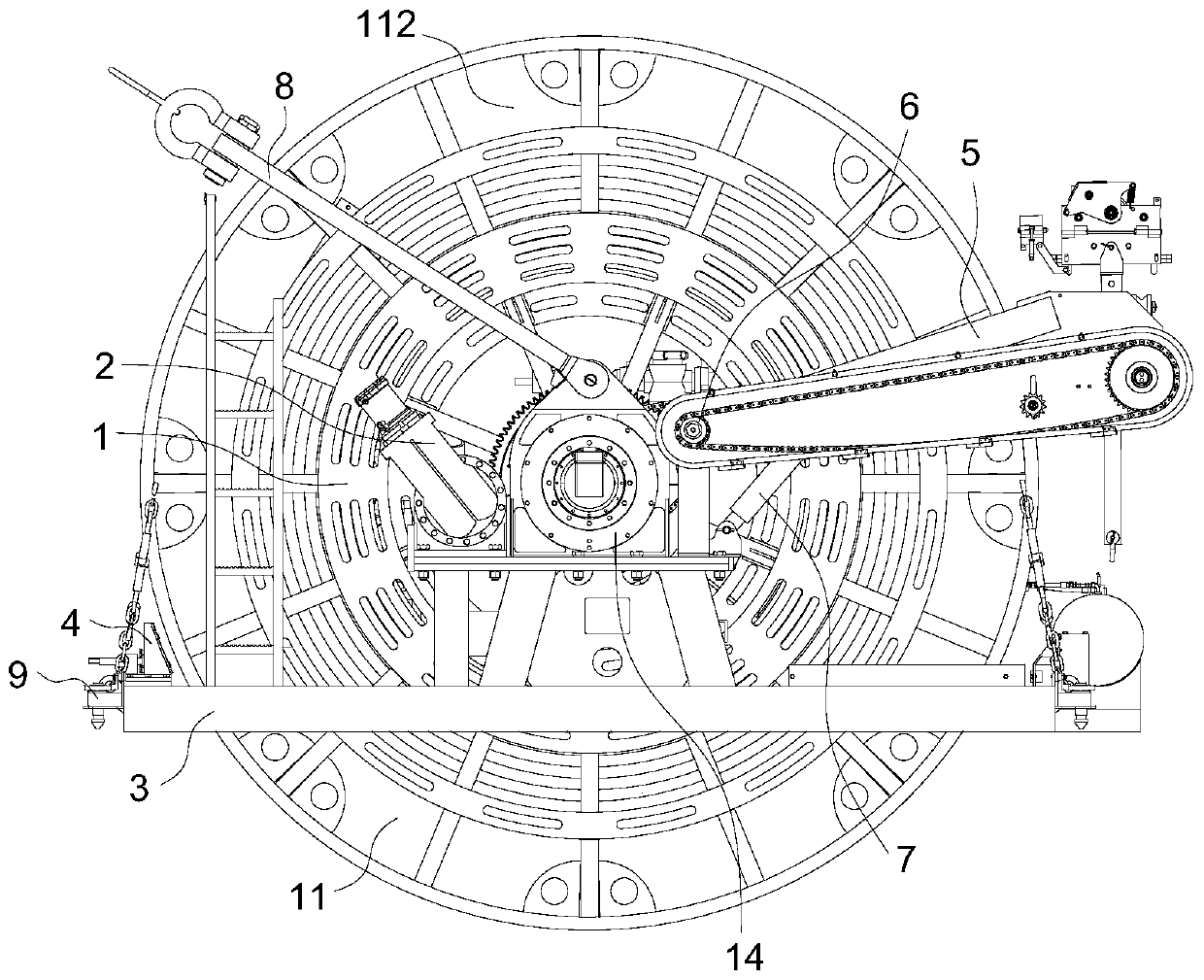

Wind power generation apparatus

InactiveUS20120321454A1Increase installation possibilityImprove comprehensive applicabilityPump componentsWind motor supports/mountsEngineeringWind force

A wind power generation apparatus includes a wind collecting hood, a rotary shaft, a rotary structure and a wind guiding structure. The wind collecting hood is a hollow circular barrel to form an airflow passage. The rotary shaft is located in the airflow passage of the wind collecting hood. The rotary structure is mounted onto the rotary shaft. The wind guiding structure is fastened to the wind collecting hood and located at the front end of the rotary structure. The wind guiding structure directs direction of airflow and accelerates the airflow to become swirling airflow to directly blow the rotary structure at optimal angles, thus capability of driving the rotary structure to rotate by wind is increased and starting wind power of the rotary structure is reduced. The rotary structure is still rotated at where the wind is smaller to provide electric power.

Owner:YU ZHI XUAN +1

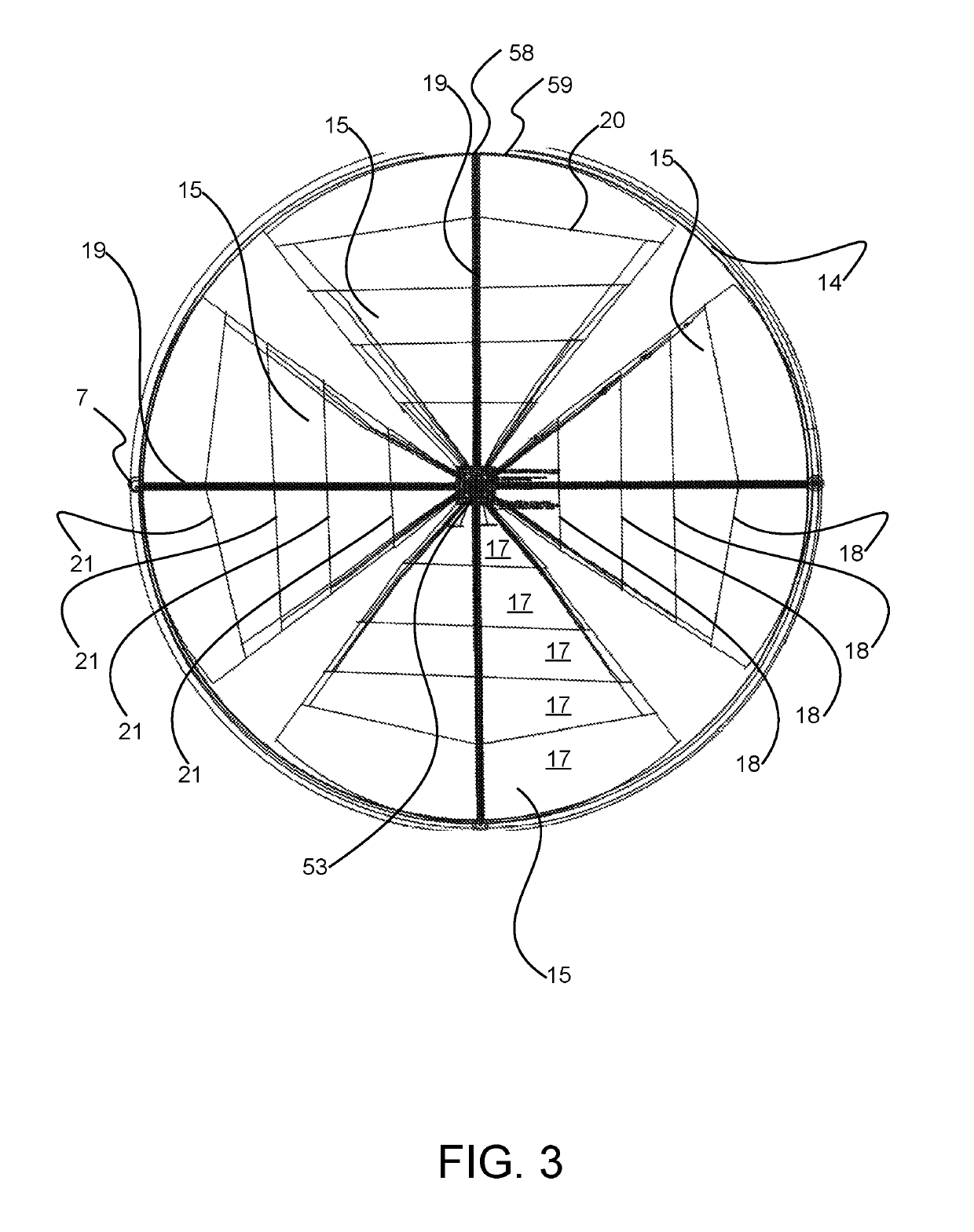

Wind turbine for use in high winds

ActiveUS20170248122A1Increase the amount of windingAccelerated trainingWind motor controlWind energy with water energyElectricityMountain pass

A wind energy generation turbine is built to take advantage of high winds in mountain passes and other areas of extreme wind velocity. A windmill section is raised high by support structures. Electricity generators are kept in the base of the windmill to reduce elevated weight. A nozzle or shroud channels wind into a narrow raceway to take advantage of the Venturi effect. Windmill blade tips housed within a circular raceway are strengthened by blade tip connectors and blade spar struts against high wind forces. Windmill blade angle and windmill wind facing are dynamically altered by computerized motors for maximum efficiency. Windmill blade angle and / or generator load maintain ratio of windmill blade tip speed to wind speed for efficiency. Turbine speed translation gears are able to decouple windmill from 60 Hz cycle or use water pumps and gravity to store energy at peak generation times.

Owner:WILLIAMS DARELL ALLEN

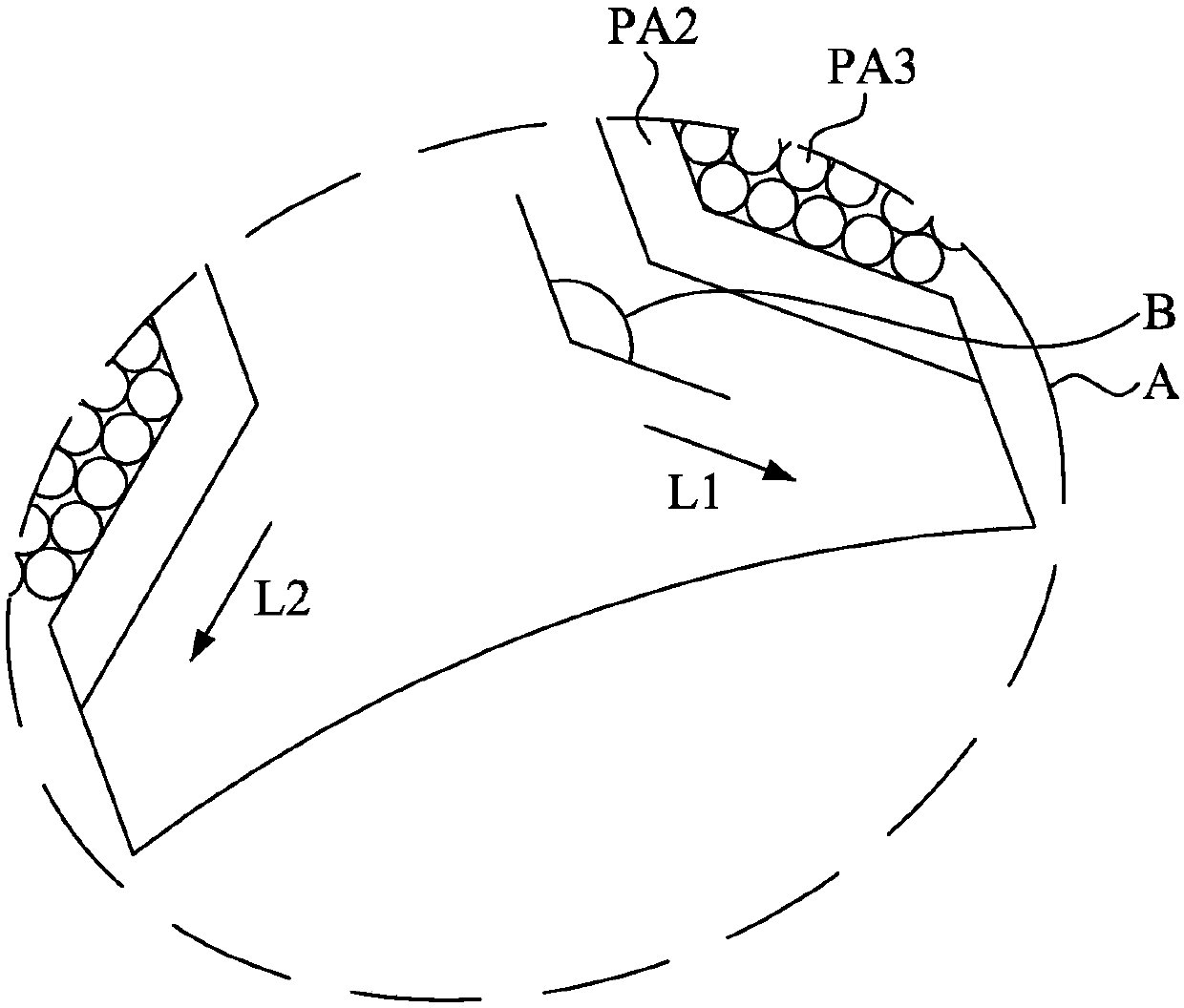

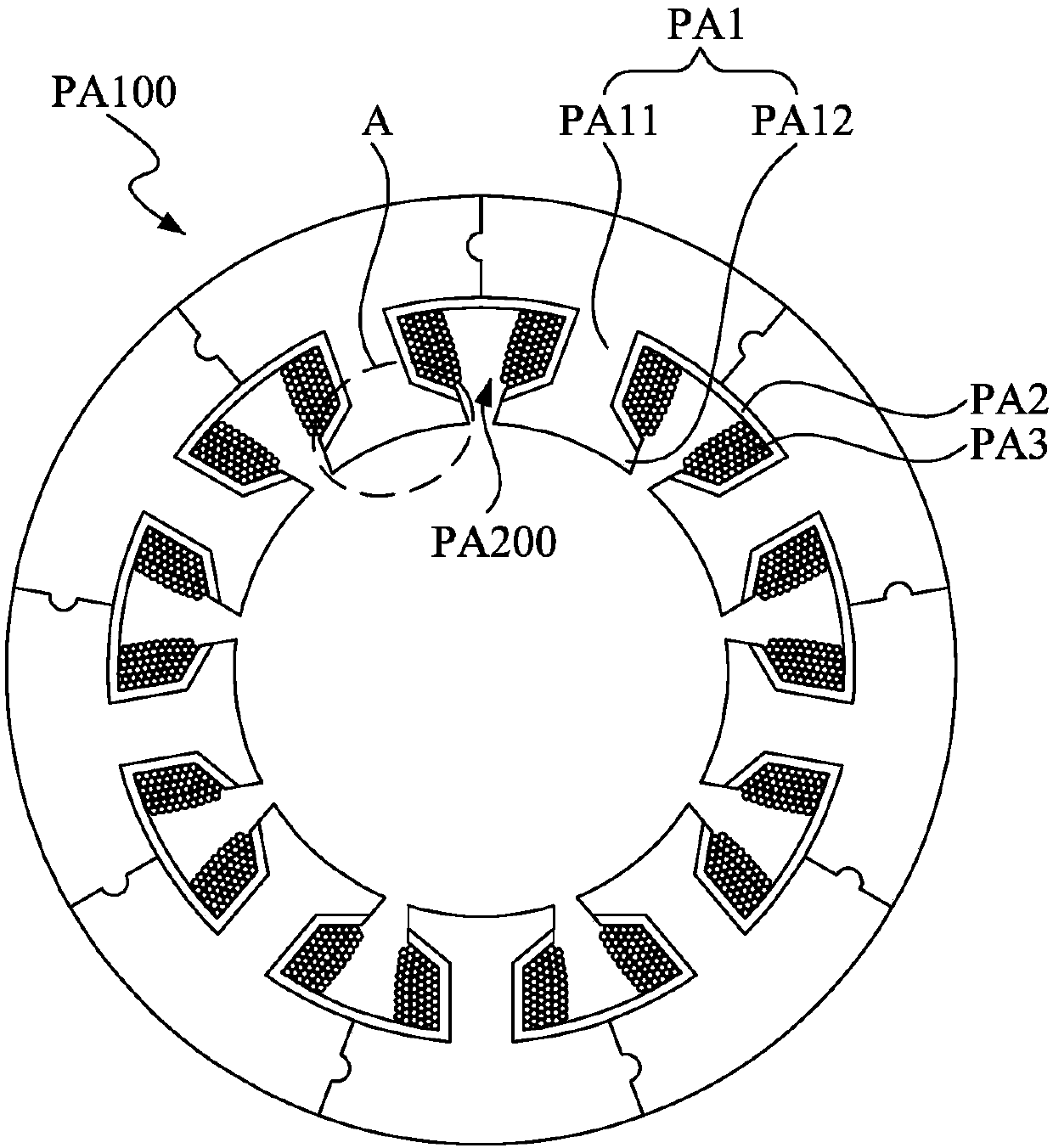

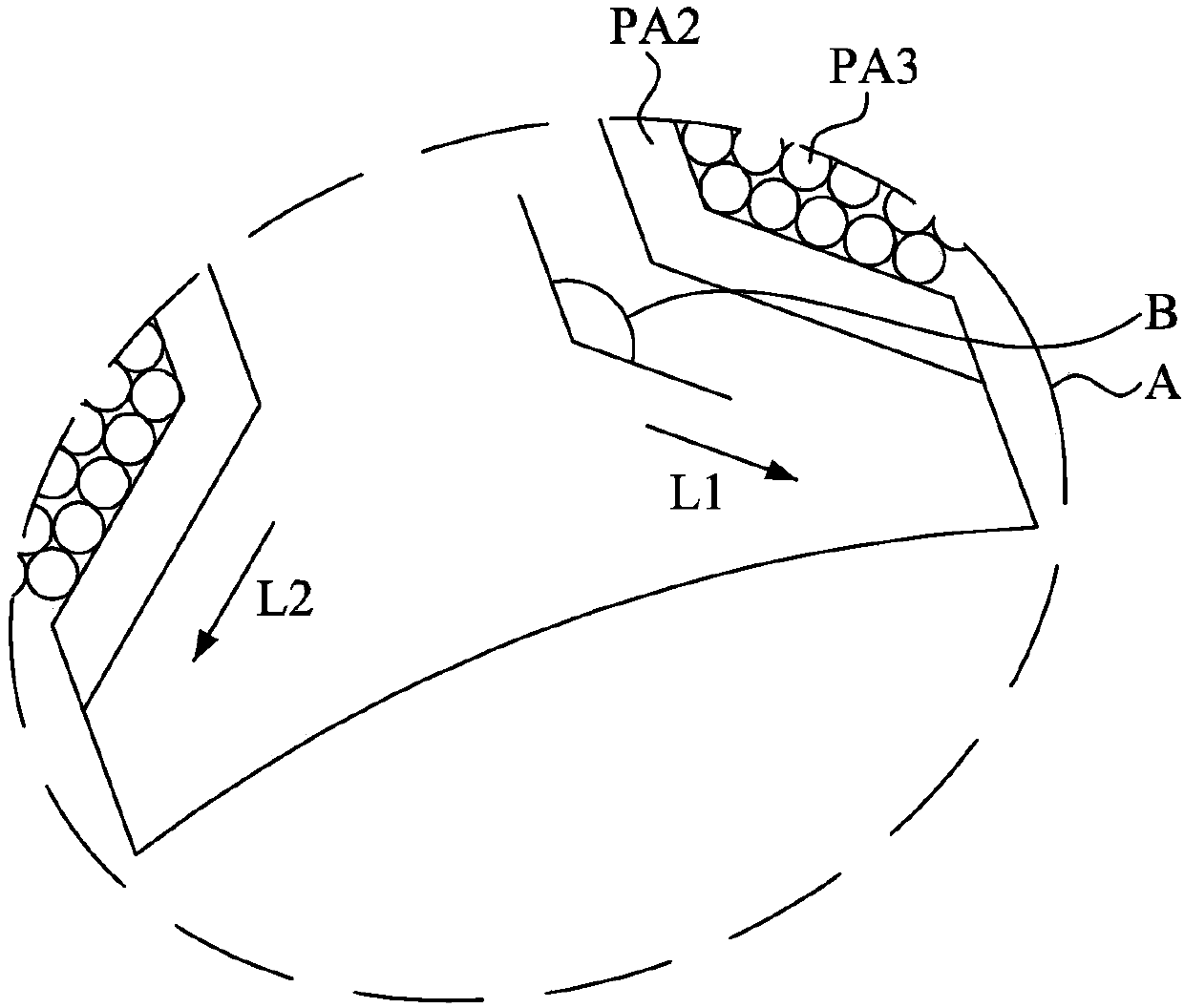

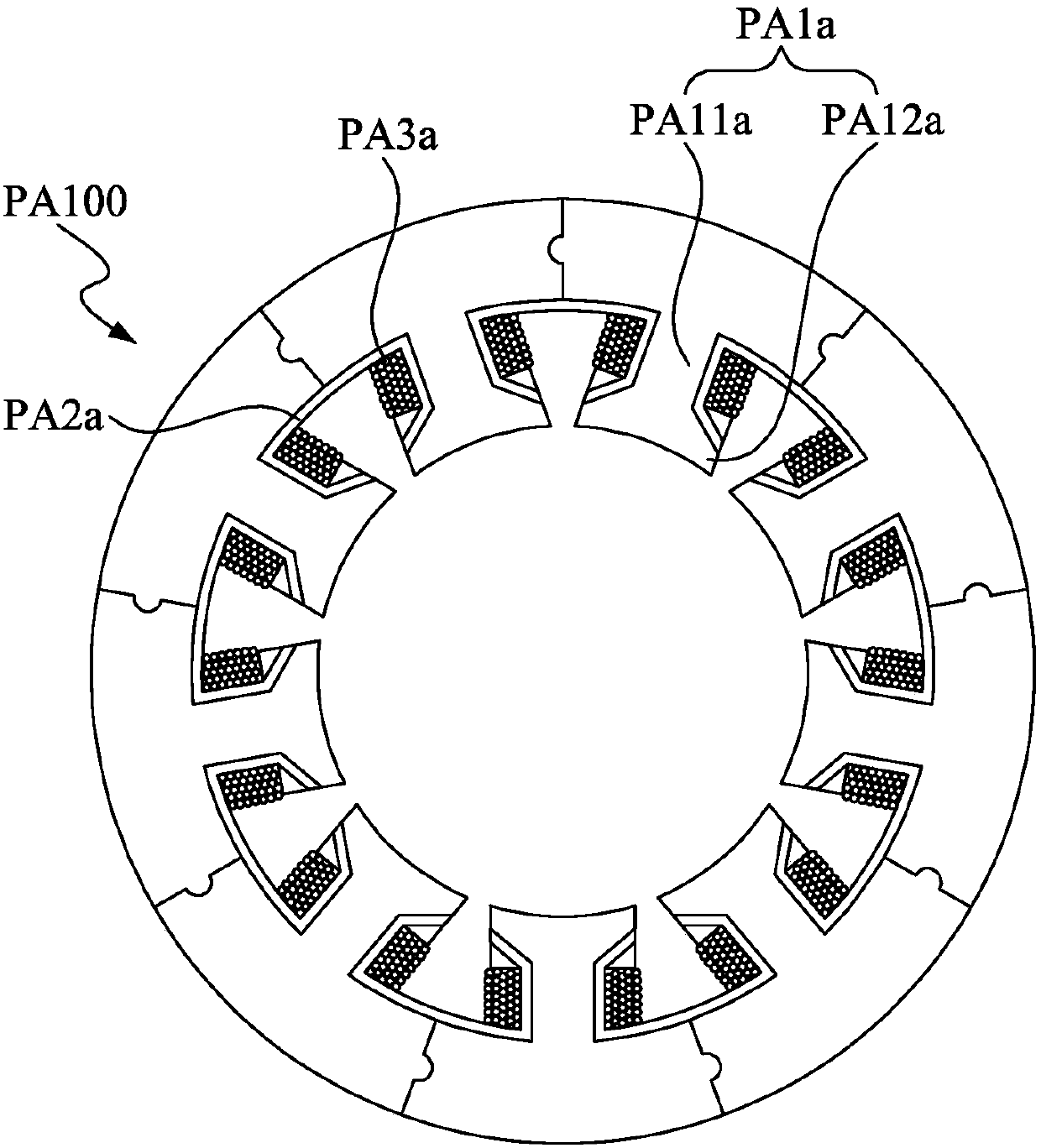

Stator winding insulation structure adhered to two stator teeth

The invention relates to a stator winding insulation structure adhered to two stator teeth. The stator winding insulation structure is arranged on a motor stator which comprises a plurality of statorteeth. A winding space is formed between the stator teeth which are adjacent with each other. The stator winding insulation structure which adheres to the two stator teeth is arranged in the winding space. A first frame and a second frame extend from an insulation frame. At least one in a plurality of step structures of the frame extends from a first folding edge which is adjacent with the tooth body to a second folding edge that is far from the tooth body. The distance between the first folding edge and an axis is smaller than that between the second folding edge and the axis. At least one inthe plurality of step structures of the second frame extends from a third folding edge which is adjacent to the other stator tooth to a fourth folding edge that is far from the other stator tooth. The distance between the third folding edge and the axis is smaller than that between the fourth folding edge and the axis.

Owner:TECO ELECTRIC AND MACHINERY

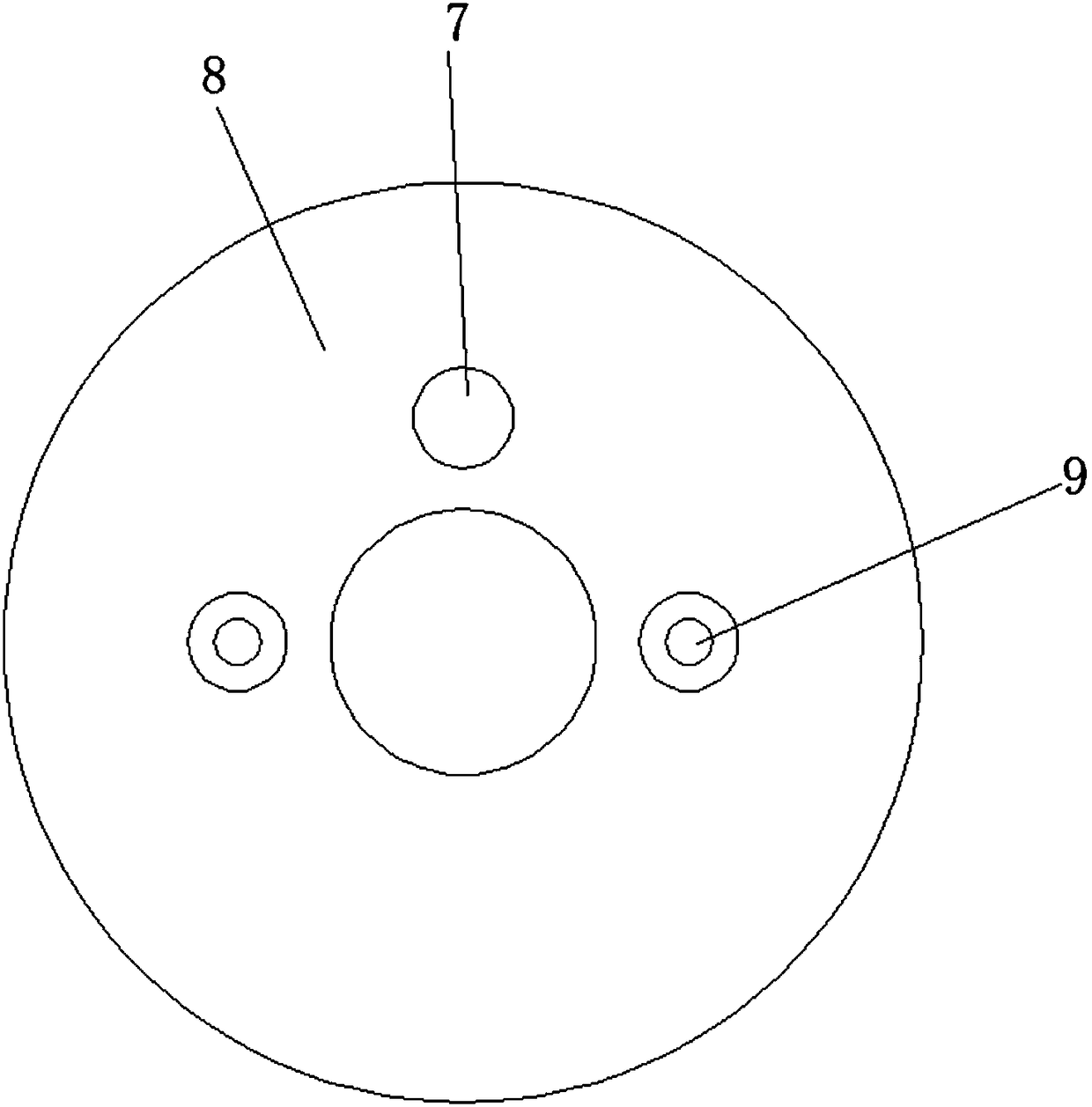

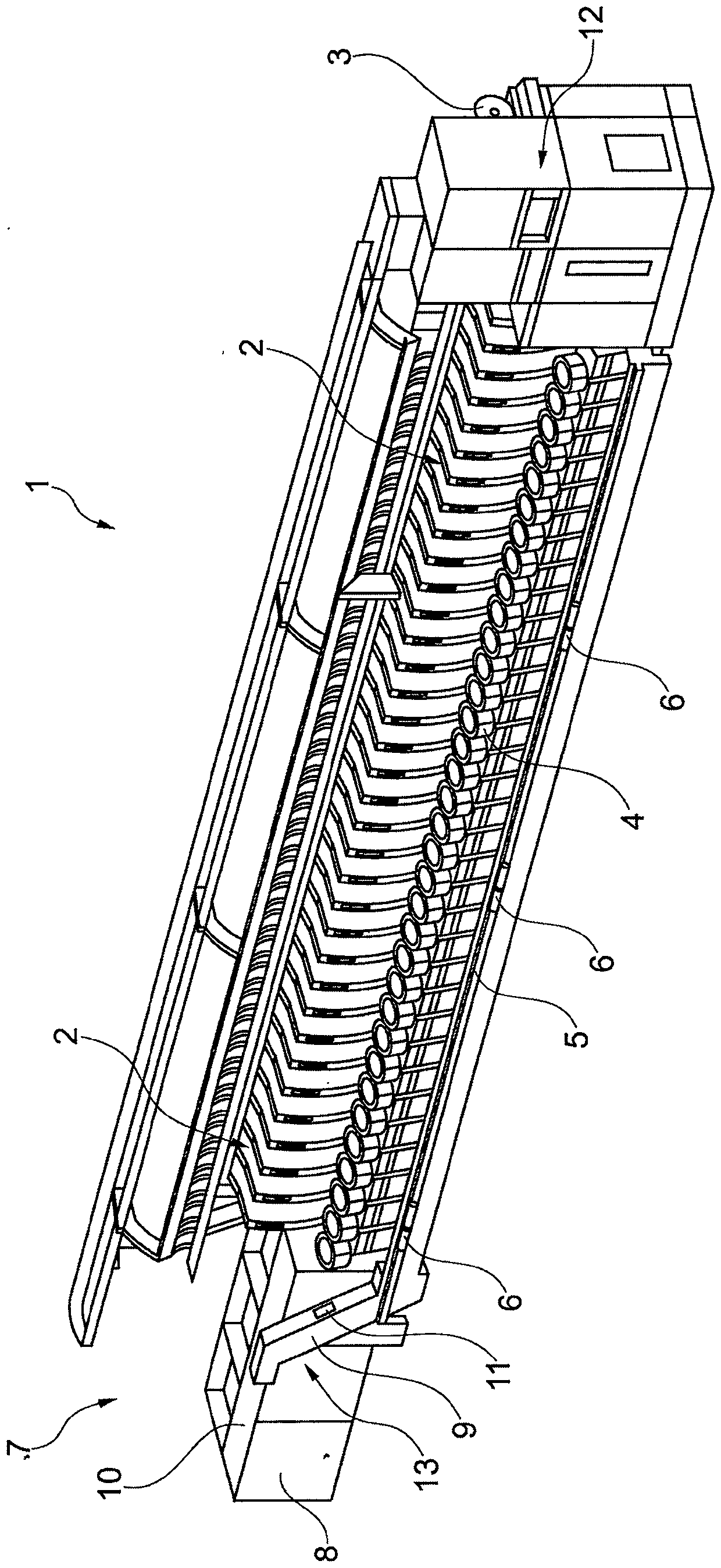

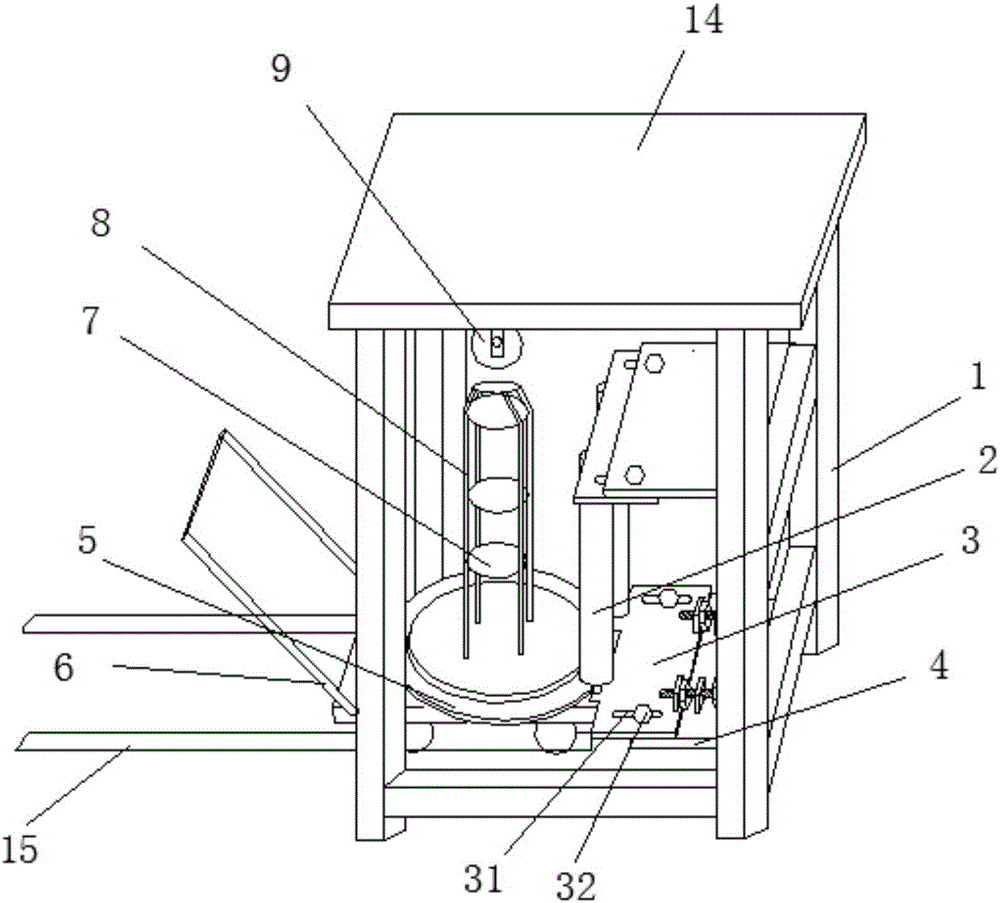

Detection device for recognizing yarn residue on spinning tube

InactiveCN107651504APrecise positioningIncrease the amount of windingFilament handlingOptically investigating flaws/contaminationYarnBobbin

The invention relates to a detection device (13) for recognizing yarn residue on a spinning tube (6). It also relates to a winder (1) having a circular magazine (4) and including such a detection device and a method of recognizing yarn residue on a spinning package tube (6). According to the invention, the detection device has a mechanism for horizontally laying a spinning package tube (6) and a sensor (11), the sensor (11) being constructed and arranged so that it detects the tube of the spinning package when it passes flatly. The sensor (11) is connected to the control device (12) for transferring data, and the control device (12) is set up to compare the detected data with a predetermined reference value and complete the spinning bobbin tube (6) There is a yarn residue, an estimate of which area of the yarn remains on the spinner tube (6) and how much yarn quantity the yarn residue has, and the control device (12) is designed to start spinning according to the evaluation of different selections of yarn tube (6).

Owner:SAURER GERMANY GMBH & CO KG

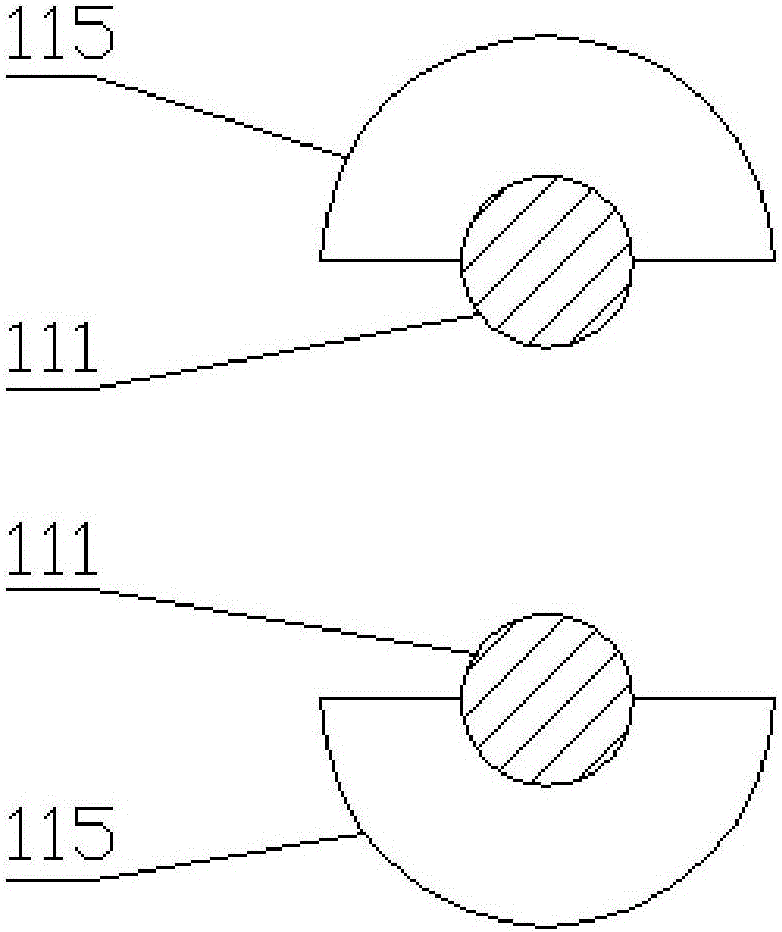

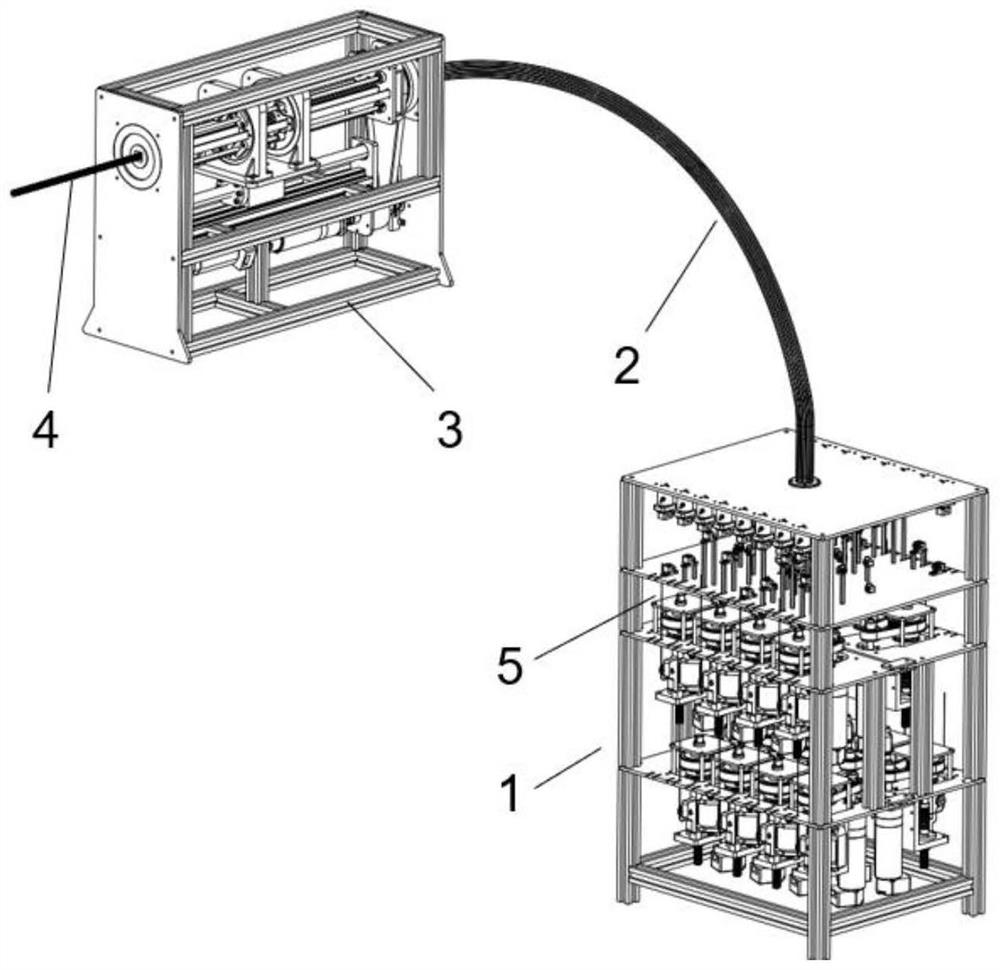

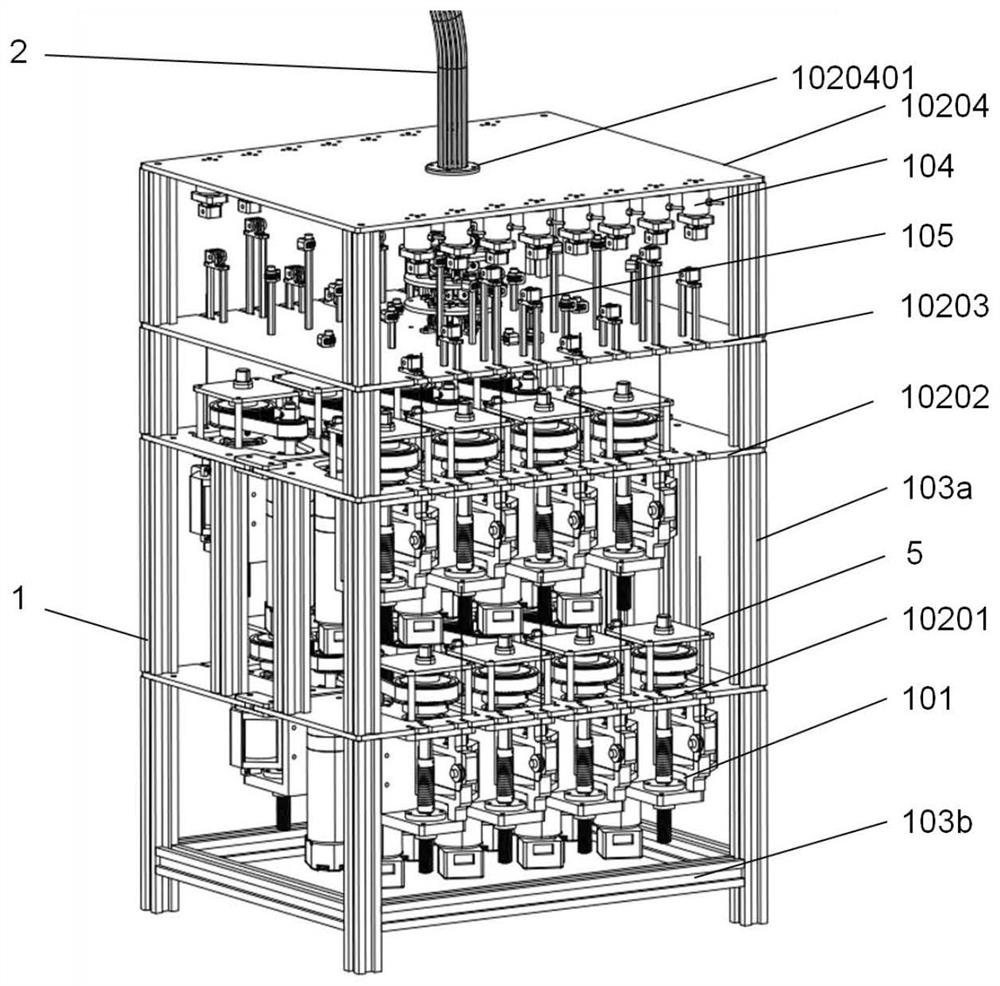

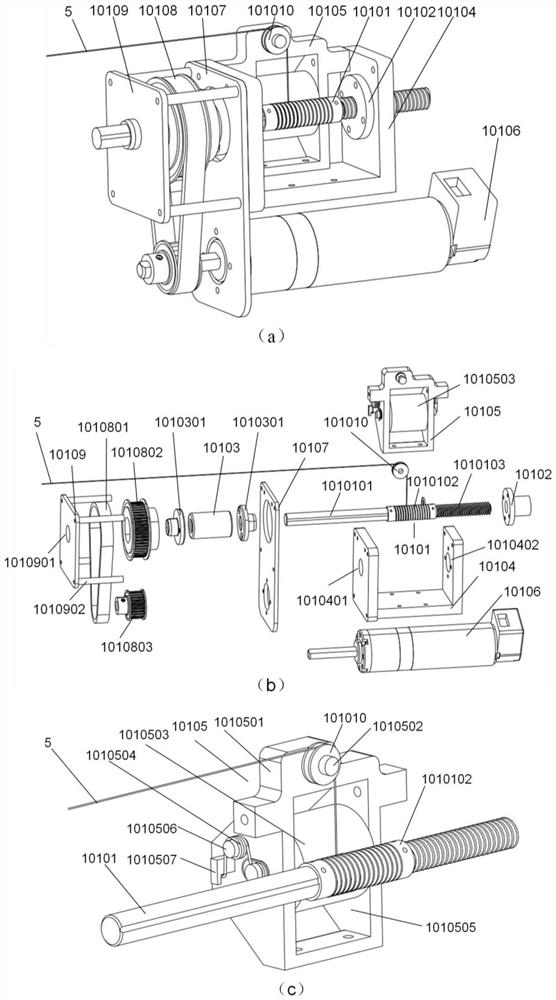

Continuum robot

PendingCN113172645AAvoid lostSolve the coupling problemProgramme-controlled manipulatorJointsSimulationSupport plane

The invention provides a continuum robot which comprises driving ropes, a driving system of the driving ropes, a rope pipe, an execution arm and a driving system of the execution arm. The rope driving system is used for controlling all the driving ropes and comprises a support frame, a plurality of rope driving devices which are uniformly fixed to the support frame and correspond to the driving ropes in number, and a way switching mechanism. The execution arm driving system is used for introducing the driving ropes in the rope pipe into the execution arm and providing driving force for the execution arm through the driving ropes. The execution arm comprises a plurality of joint sections which are connected in sequence, and each joint section is controlled by the corresponding driving rope to move. Each joint section is formed by sequentially connecting a plurality of identical joints in series. Each joint comprises two rolling contact joint bodies of the same structure, connecting bodies fixed to the outer sides of the rolling contact joint bodies correspondingly and two flexible rods fixed to the outer sides of the rolling contact joint bodies through the connecting bodies. The continuum robot has the advantages that a joint model is accurate, miniaturized processing is easy, and a driving structure is simple.

Owner:TSINGHUA UNIV

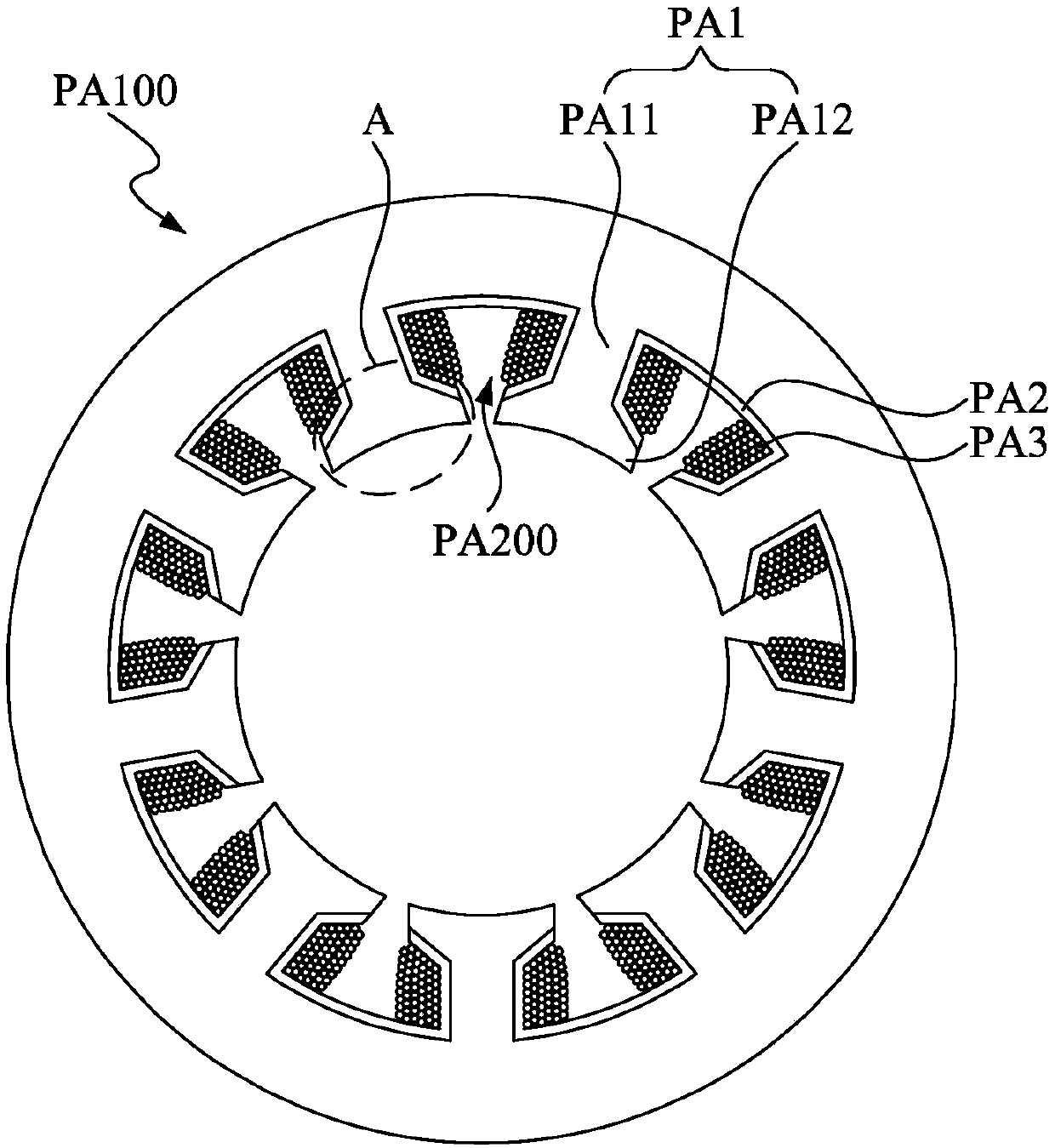

Stator winding insulation structure

InactiveCN107800218AIncrease the amount of windingImprove power densityWindings insulation shape/form/constructionMechanical engineeringStator

The invention relates to a stator winding insulation structure which is arranged on a motor state that is composed of a plurality of stator teeth. A first frame body and a second frame body of the stator winding insulation structure respectively extend from a first insulating frame body and a second insulating frame body. At least one in a plurality of step structures of the first frame extends from a first folding side which is adjacent to the tooth body to a second folding side that is far from the tooth body. The distance between the first folding side and a central axis is smaller than thedistance between the second folding side and the central axis. At least one in the plurality of step structures of the second frame extends from a third folding side which is adjacent with the statortooth to a fourth folding side that is far from the stator tooth. The distance between the third folding side and the central axis is smaller than the distance between the fourth folding side and thecentral axis. A connecting frame is connected with the first insulating frame body, the second insulating frame body, the first frame and the second frame.

Owner:TECO ELECTRIC AND MACHINERY

Wind turbine for use in high winds

ActiveUS10364795B2Increase the amount of windingAccelerated trainingWind motor controlWind energy with water energyElectricityMountain pass

A wind energy generation turbine is built to take advantage of high winds in mountain passes and other areas of extreme wind velocity. A windmill section is raised high by support structures. Electricity generators are kept in the base of the windmill to reduce elevated weight. A nozzle or shroud channels wind into a narrow raceway to take advantage of the Venturi effect. Windmill blade tips housed within a circular raceway are strengthened by blade tip connectors and blade spar struts against high wind forces. Windmill blade angle and windmill wind facing are dynamically altered by computerized motors for maximum efficiency. Windmill blade angle and / or generator load maintain ratio of windmill blade tip speed to wind speed for efficiency. Turbine speed translation gears are able to decouple windmill from 60 Hz cycle or use water pumps and gravity to store energy at peak generation times.

Owner:WILLIAMS DARELL ALLEN

Taking-up equipment for wiredrawing production

The invention provides taking-up equipment for wiredrawing production. The taking-up equipment comprises a support provided with a wire passing wheel. A trolley is arranged below the wire passing wheel and provided with a taking-up device. The support is provided with a wire blocking device. The taking-up device comprises a horizontally-arranged rotary table driven by a motor. The wire blocking device comprises a vertically-arranged wire blocking column. The upper end and the lower end of the wire blocking column are connected with the support through connecting mechanisms. The bottom face of the wire blocking column makes contact with the upper surface of the rotary table. According to the taking-up equipment for wiredrawing production, the wire passing wheel is arranged on the support, and a taking-up mechanism is arranged under the wire passing wheel and arranged on the trolley and can rotate; and the support is provided with the wire blocking device, when a coil is wound, the wound coil is limited through the wire blocking device, and tidiness of the wound coil with the same diameter is guaranteed.

Owner:TIANJIN HUAYUAN WIRE PROD

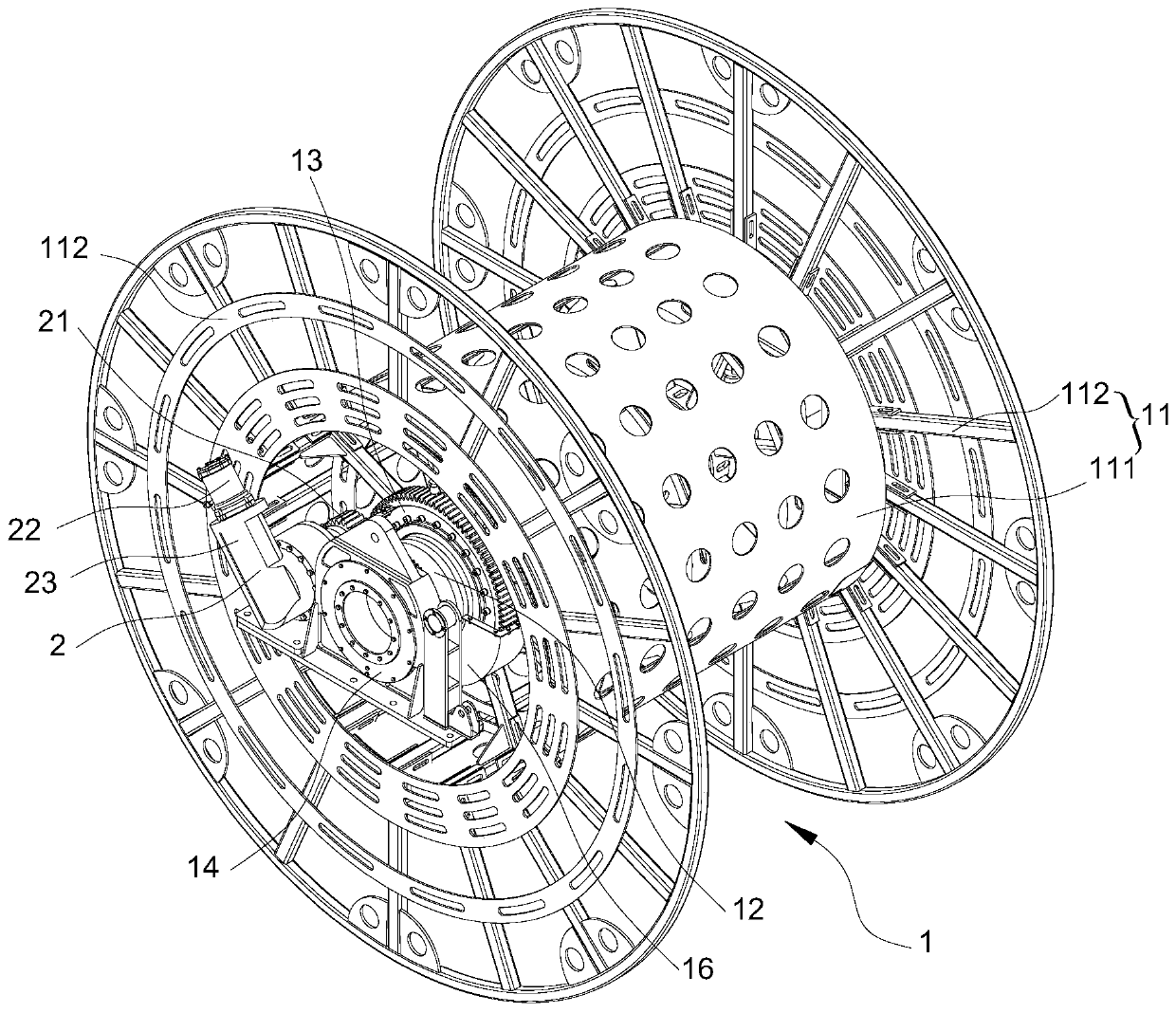

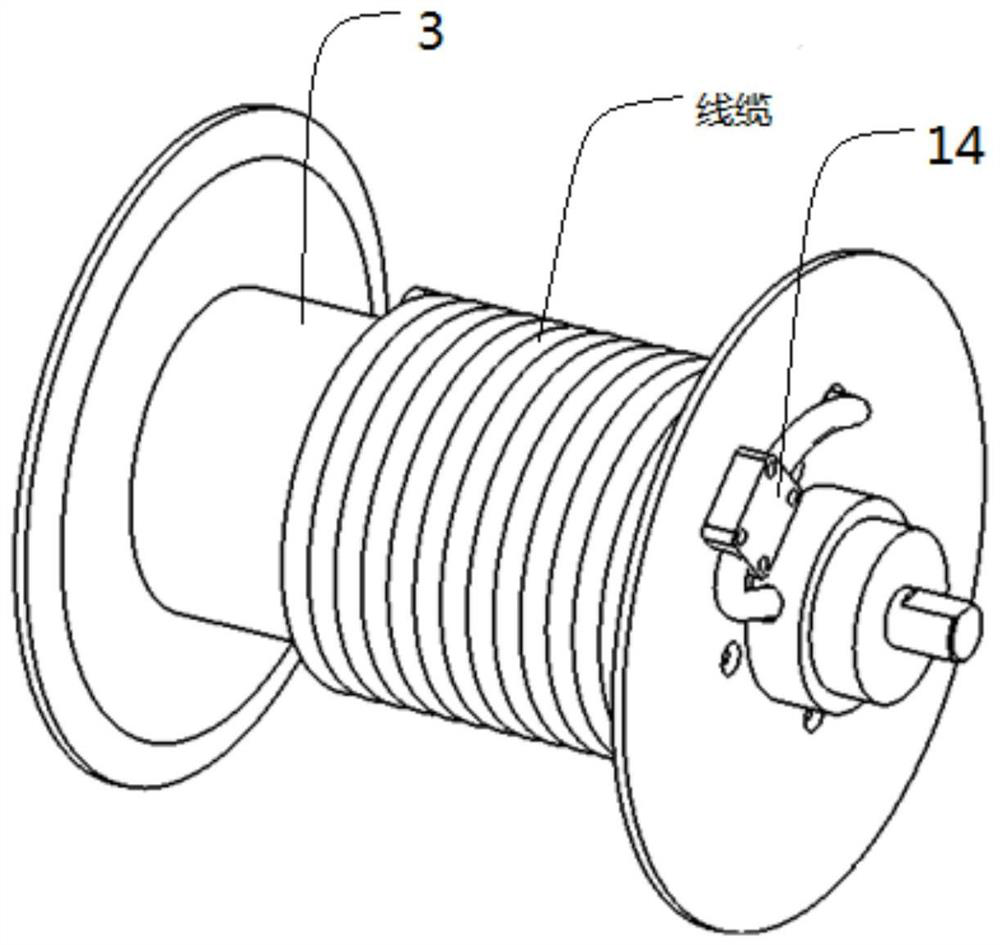

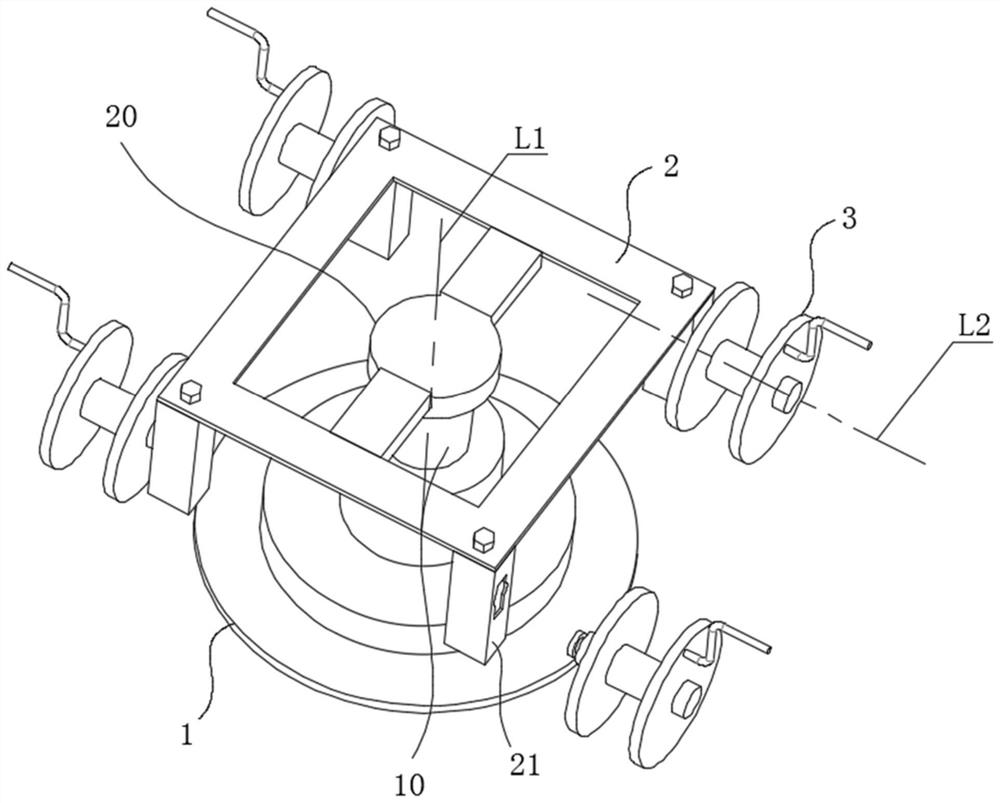

Coiled tubing reel device and coiled tubing vehicle

InactiveCN110939397AIncrease widthIncrease the amount of windingDrilling rodsDrilling casingsLow speedGear wheel

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

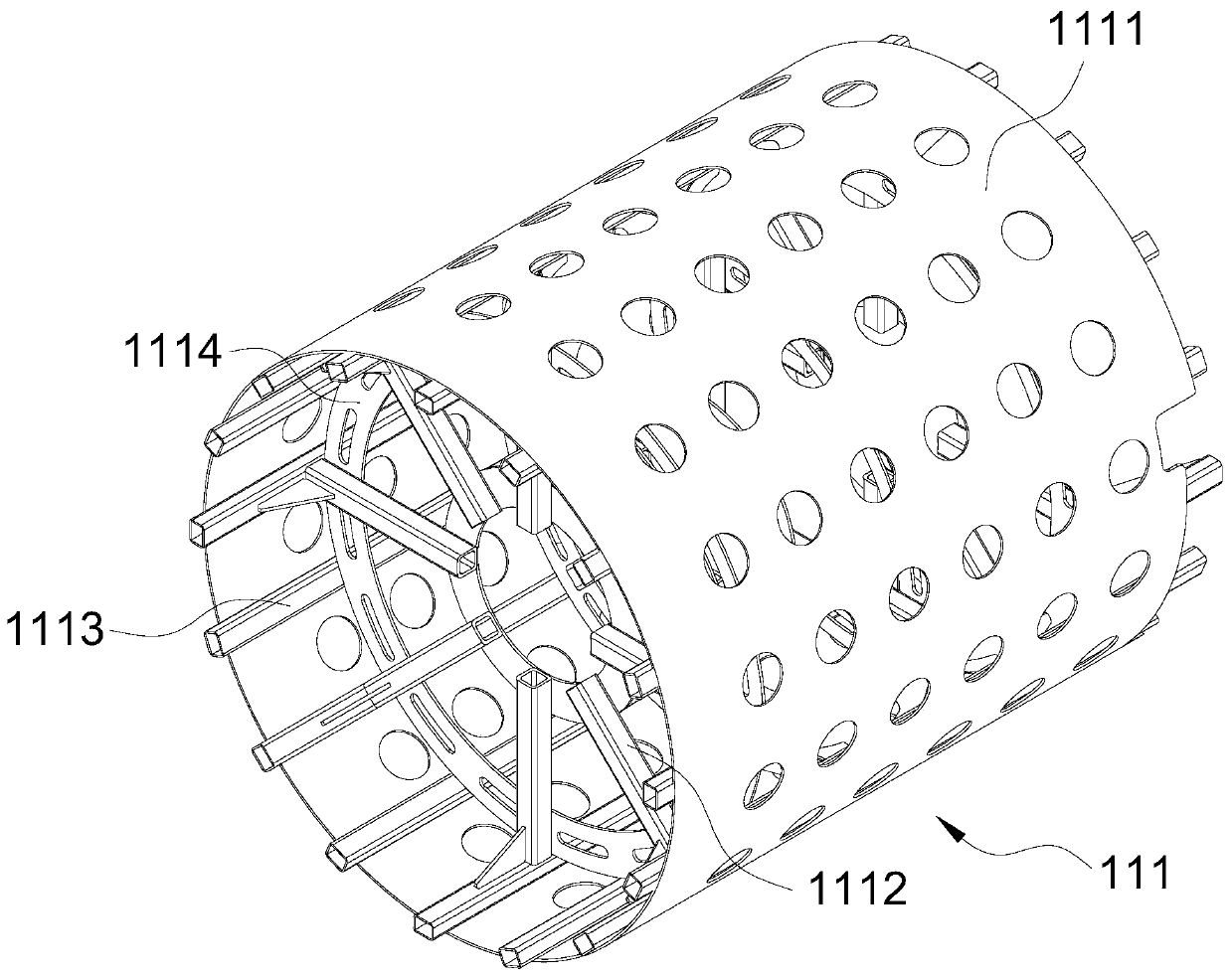

Bobbin-free large-winding-amount winding device

The invention provides a bobbin-free large-winding-amount winding device. The winding device comprises a frame assembly and further comprises a first iron ring and a second iron ring. The frame assembly comprises a first rod, a second rod and a third rod. The second rod and the third rod are fixedly connected with the two ends of the first rod correspondingly. The first rod, the second rod and the third rod are connected to form a U-shaped mechanism. The first iron ring is movably connected with the second rod through a first iron pin. The second iron ring is movably connected with the third rod through a second iron pin. The bobbin-free large-winding-amount winding device has the following beneficial effects that due to the fact that no bobbin is arranged, a whole yarn reel is completely solid, and the winding amount of yarn is increased; and due to the fact that no bobbin is applied, resources are saved, and a large amount of cost is reduced for enterprises.

Owner:NANTONG JINSHAN TEXTILE

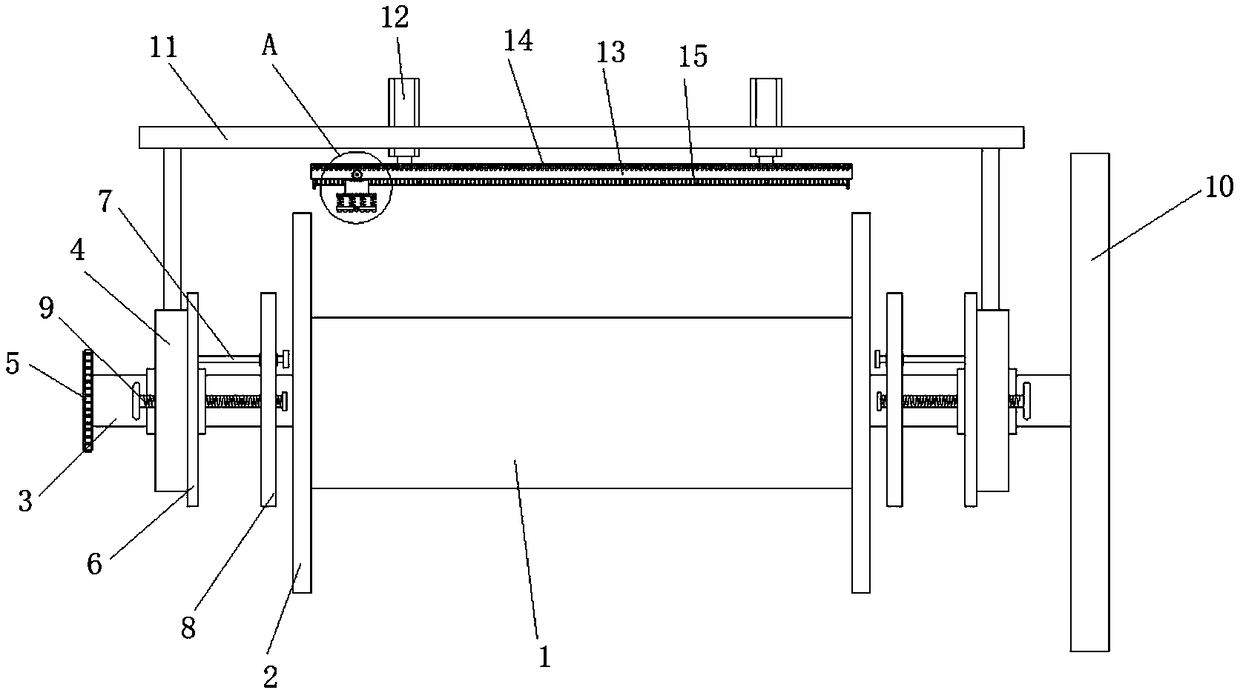

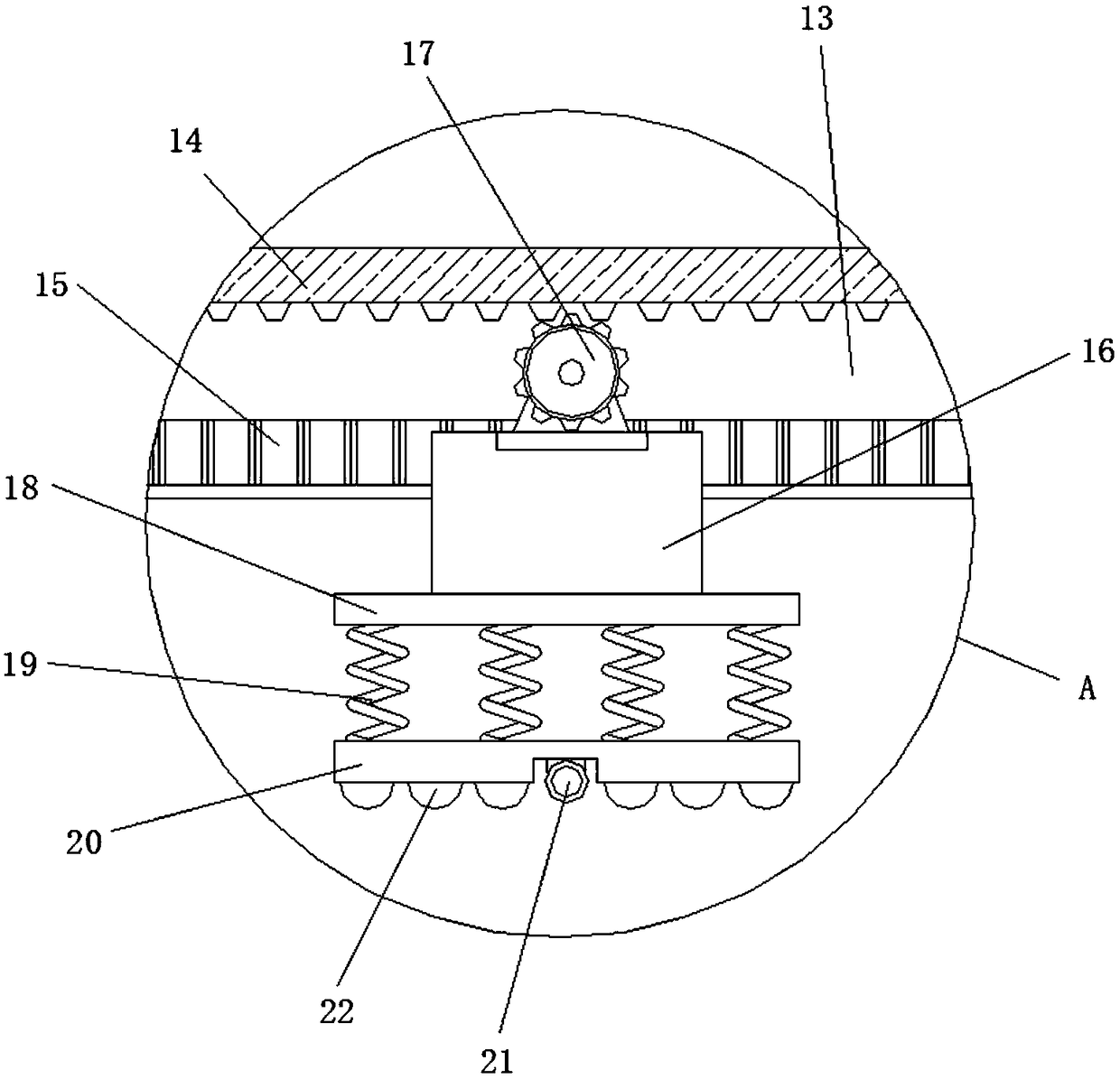

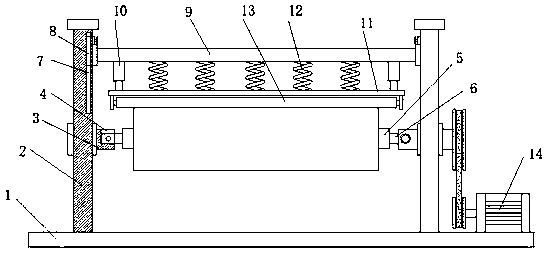

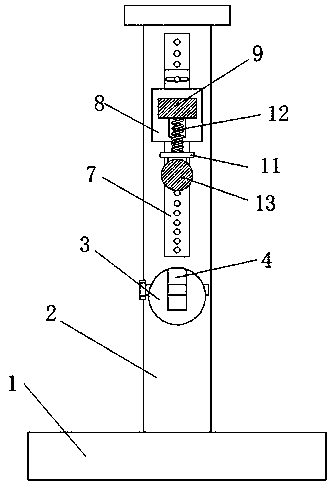

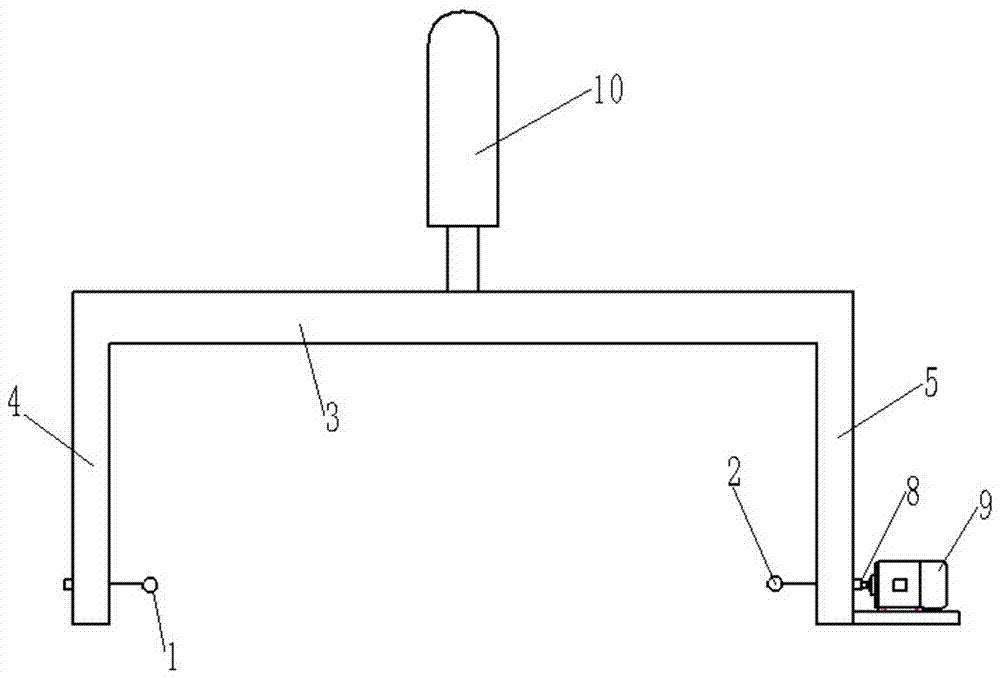

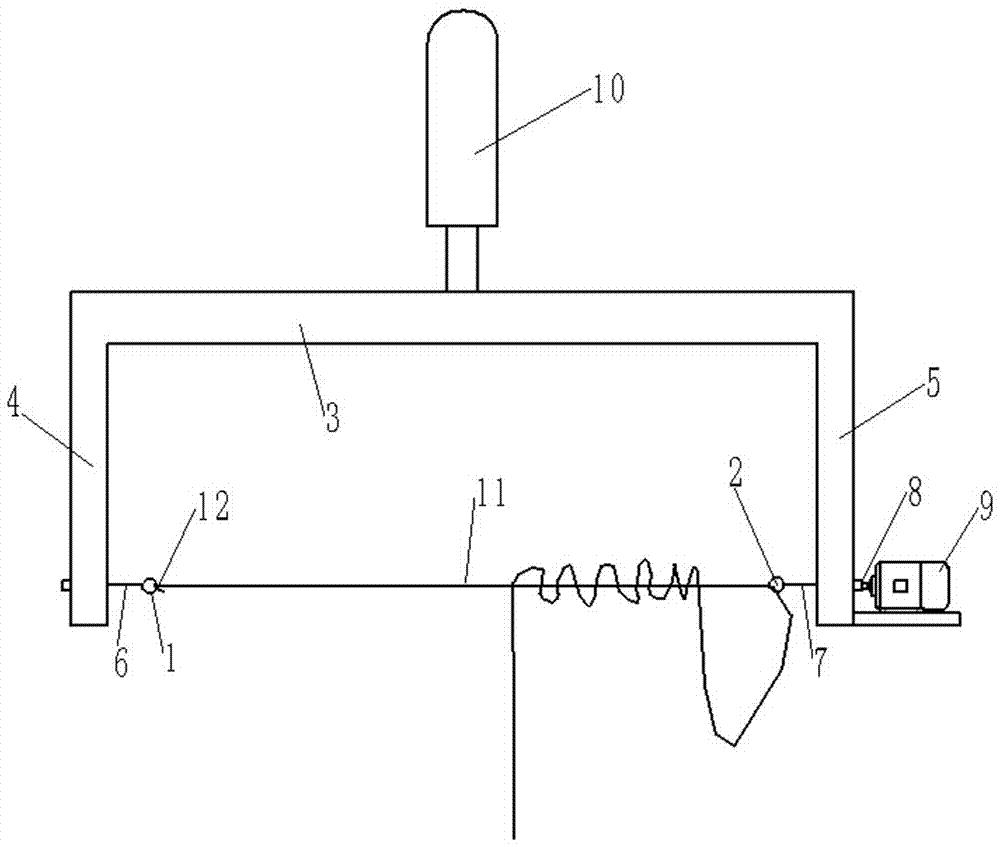

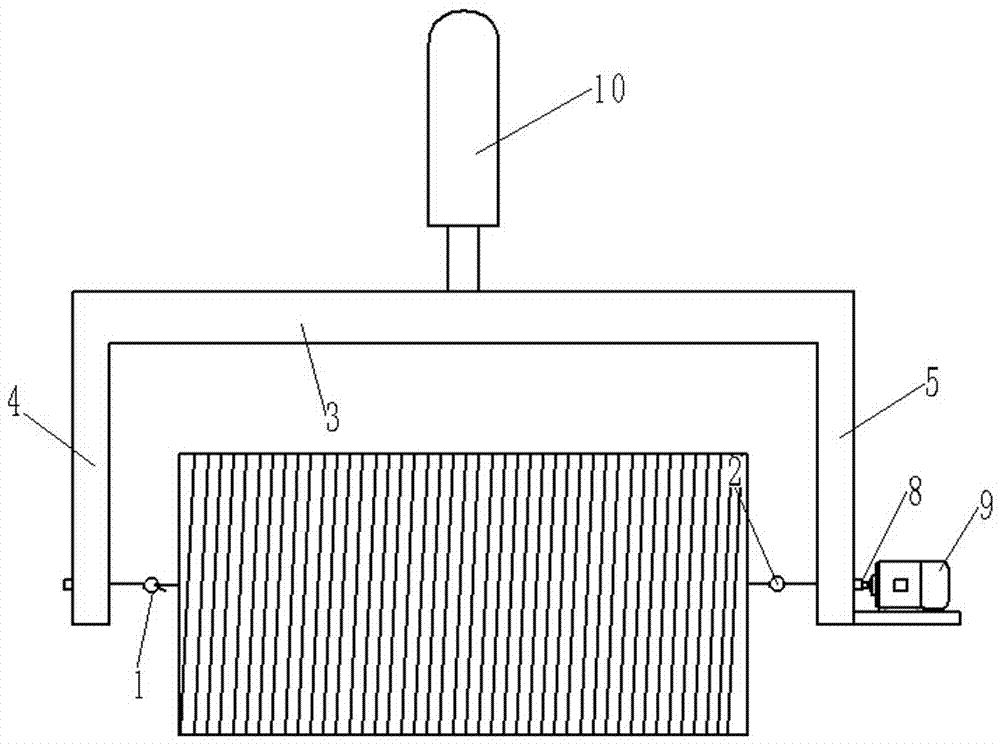

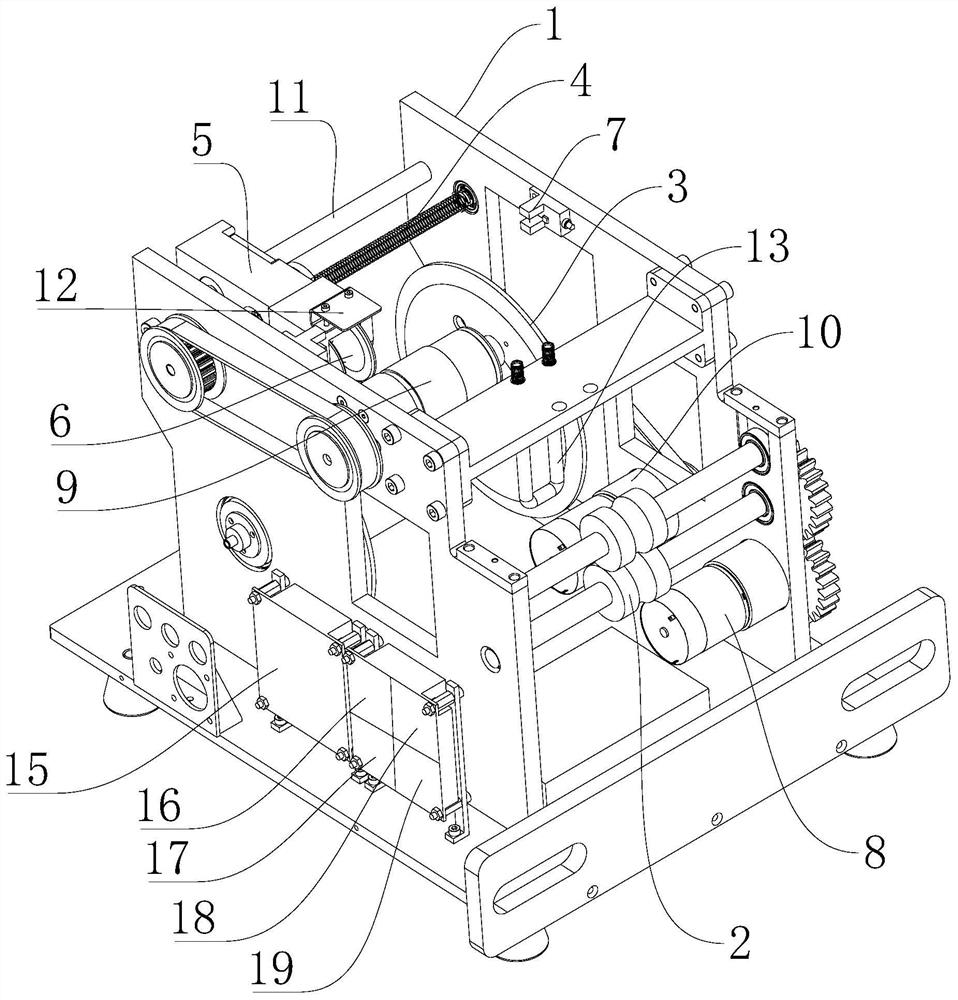

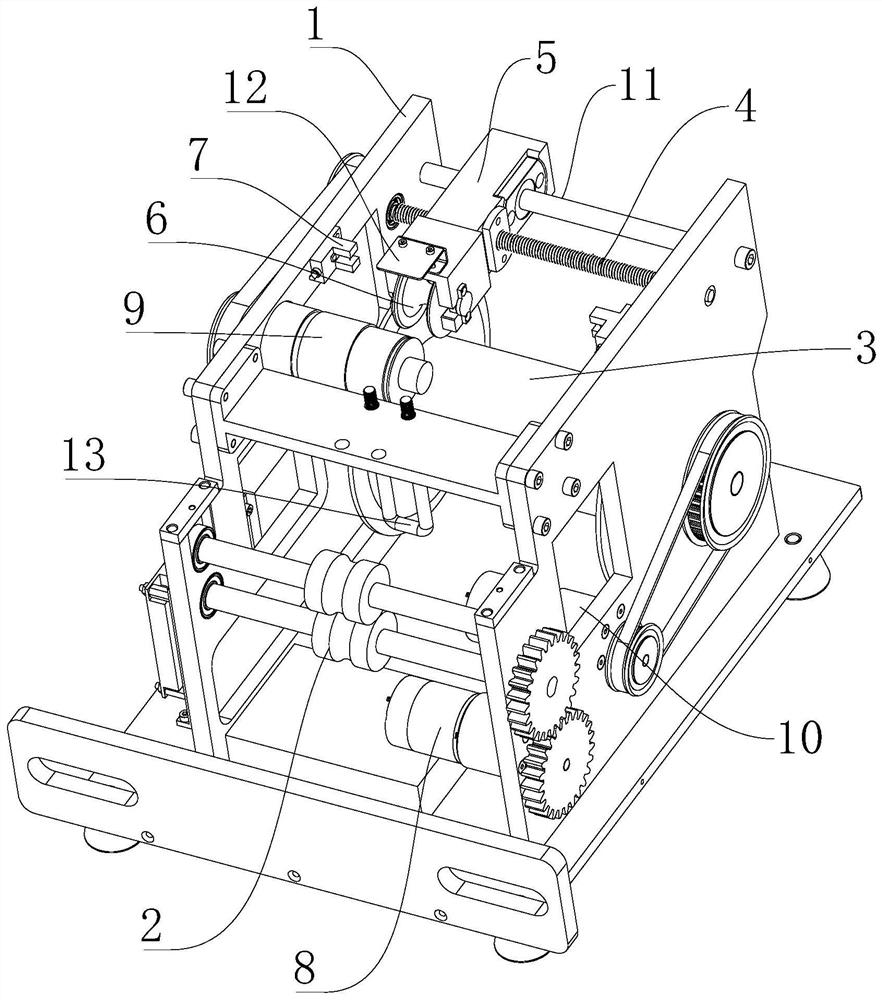

Winding device for multi-layer uniform winding, control system and control method thereof

ActiveCN111675024BSimple structureStable and efficient line effectFilament handlingMotor speedControl system

The invention discloses a winding device for multi-layer uniform winding and its control system and control method, including a frame, a wire feeding wheel, a router, a cable drum, and a wire feeding wheel respectively driven on the frame. , wire feeding wheel motors for screw rods and cable drums, screw motors and cable drum motors. The invention starts the motor according to the set timing, and develops a multi-motor speed matching method suitable for the winding device, which can make the cable arrangement more regular, reliable and adjustable, and has higher control precision, and The invention enables the cables to be evenly arranged in multiple layers, and the arrangement is neat and orderly, the volume of winding and unwinding is increased, and the winding effect is stable and efficient.

Owner:SICHUAN UNIV +1

Microwave cooking device

ActiveCN102265092BIncrease the amount of windingWill not complicate the structureDomestic stoves or rangesLighting and heating apparatusMicrowaveTransmission channel

Owner:PANASONIC CORP

A distribution wire take-up device

The invention belongs to the technical field of electric power auxiliary tools, and discloses a power distribution wire take-up device, comprising: a base; a frame body, the frame body is arranged above the base, and the frame body can rotate around its own central axis , the frame body is provided with a plurality of vertices along the circumference; wire wheels, the wire wheels are arranged on each of the vertices in a one-to-one correspondence, and the wire wheels can rotate around their own wire take-up axes. The frame can rotate around the base, so that the wire wheel at each vertex position rotates. Multiple vertexes form multiple wire take-up stations. The wire wheel at the position is transferred and continues to wind the cable. This multi-station winding mechanism cooperates with the rotary station alternate operation method to increase the winding amount.

Owner:GUANGDONG POWER GRID CO LTD +1

A convenient detachable winding device for cotton sewing thread production

Owner:徐州顺泰纺织科技股份有限公司

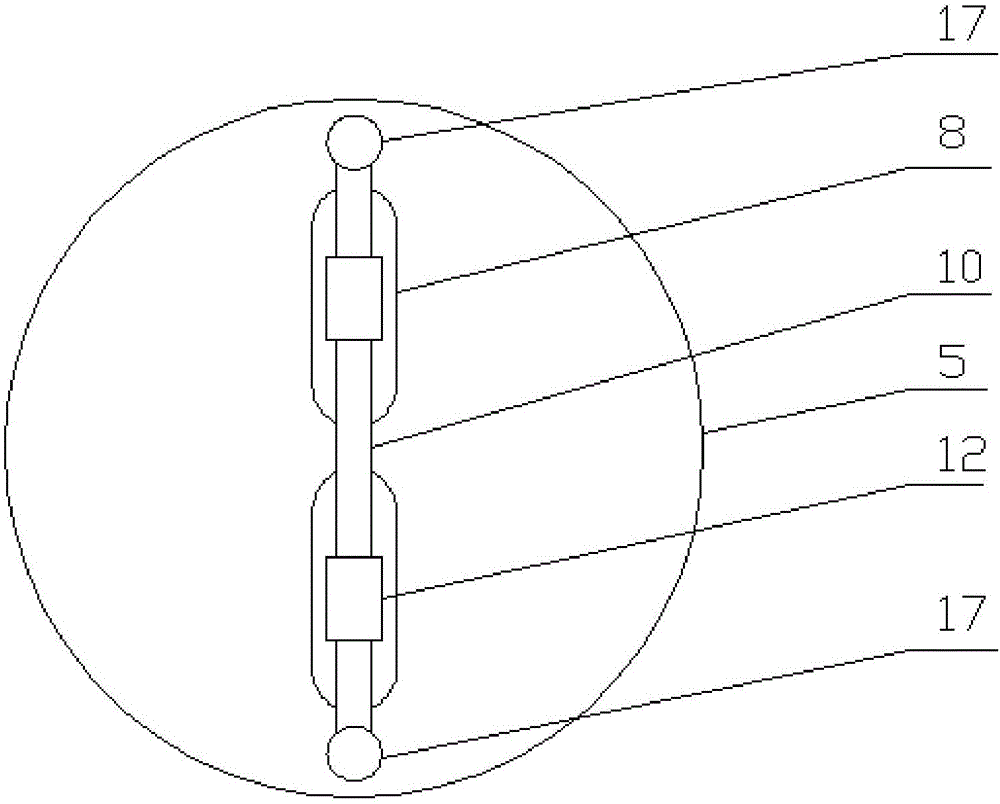

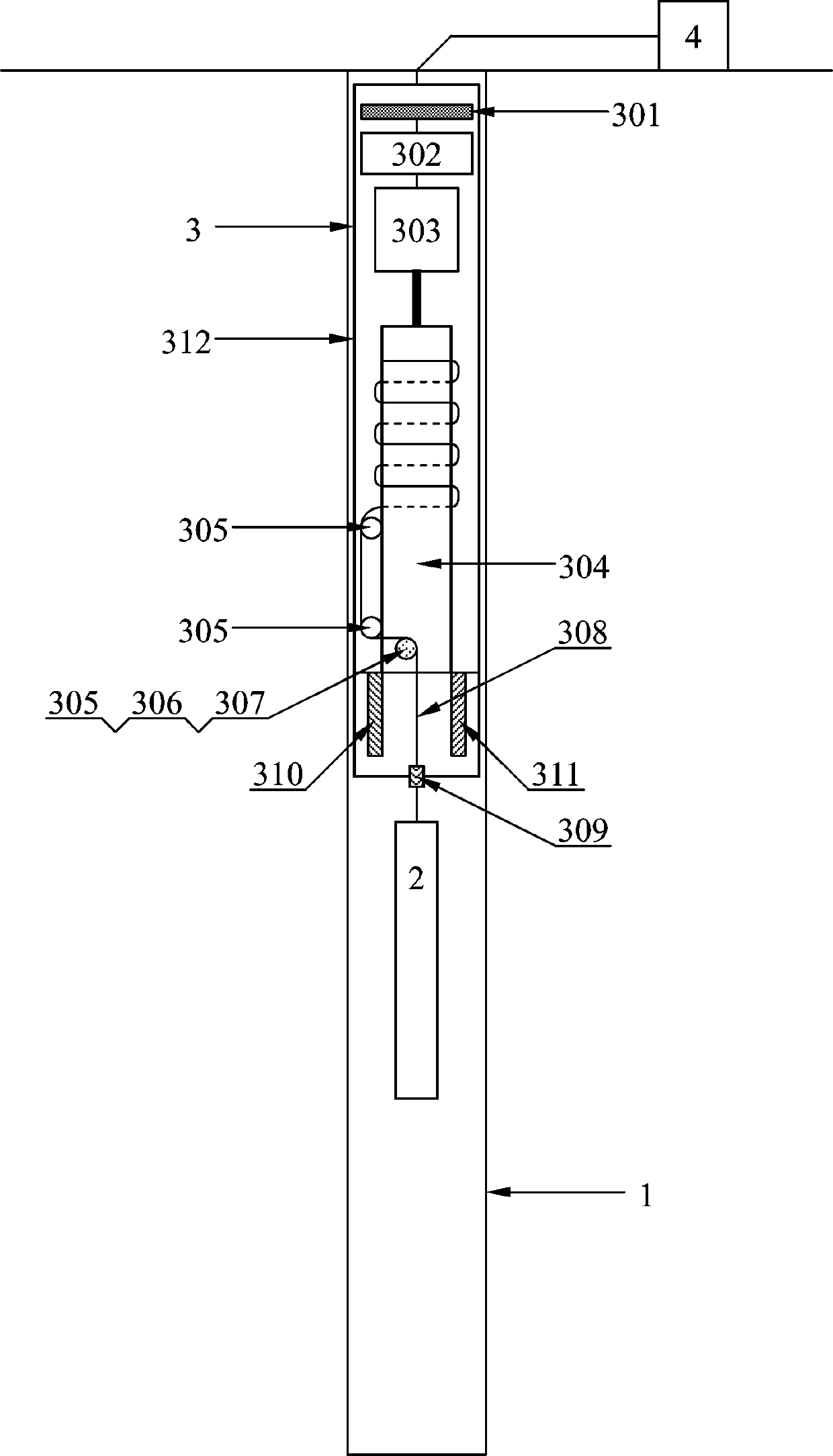

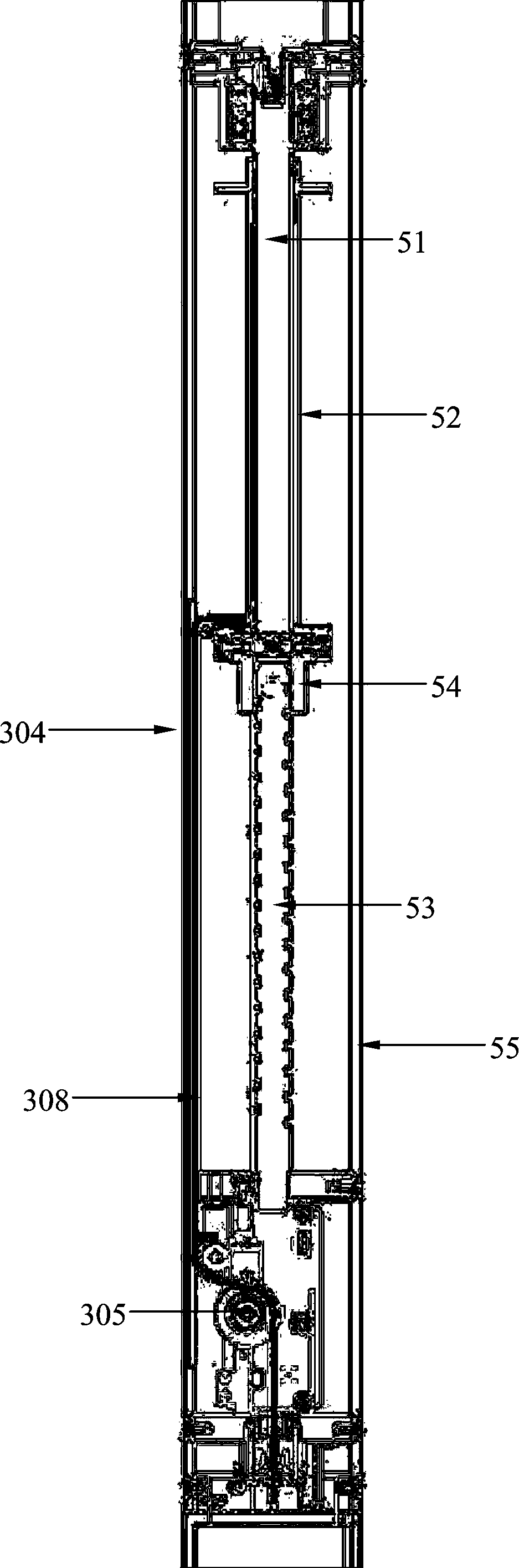

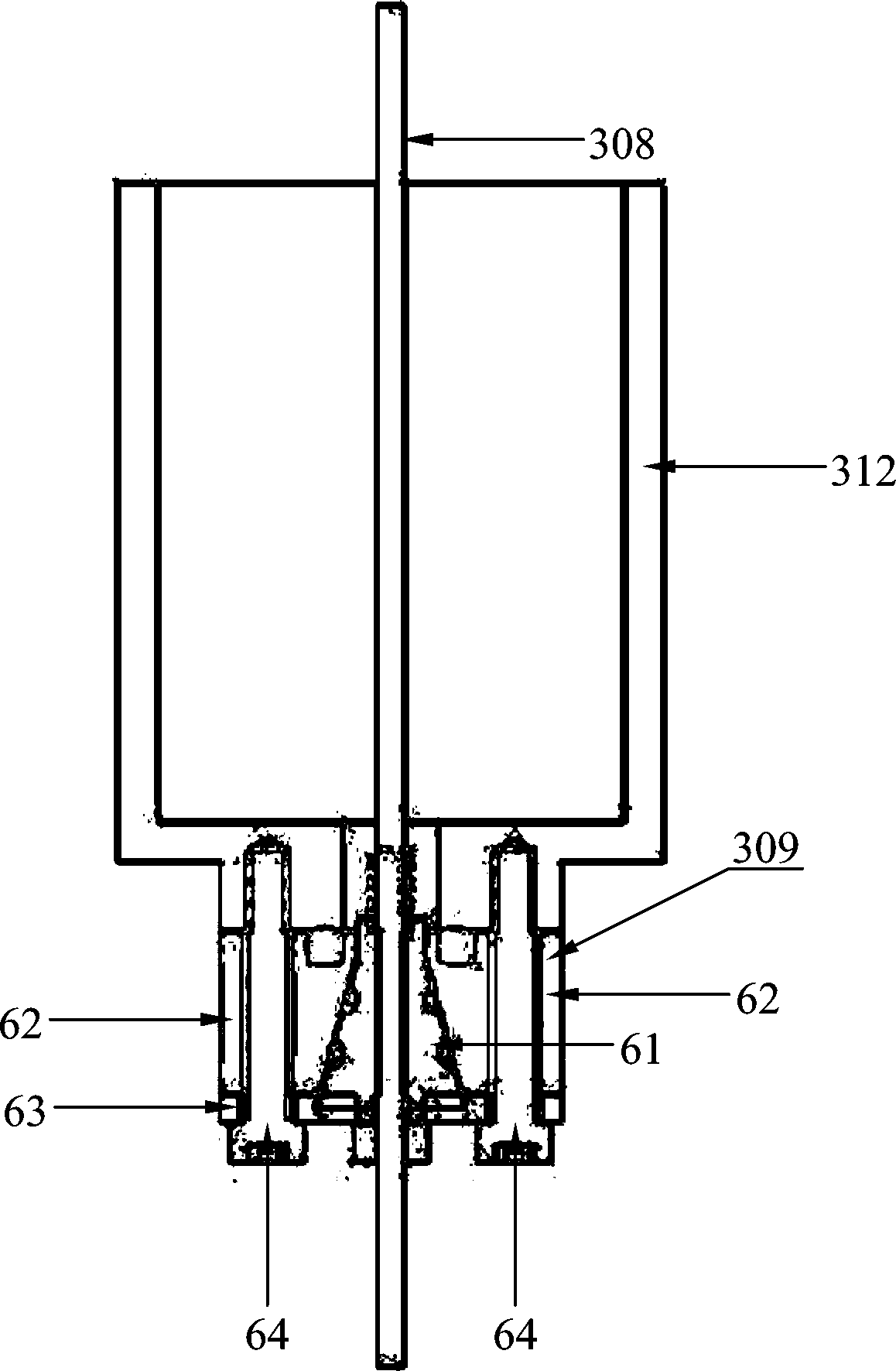

Embedded automatic inclinometry robot and using method thereof

PendingCN111024039AWith waterproof functionImprove waterproof performanceIncline measurementSimulationElectric machinery

The invention relates to the field of inclination measurement, in particular to an embedded automatic inclinometry robot and a using method thereof. The embedded automatic inclinometry robot comprisesa wireless probe (2), and is characterized in that the robot further comprises a lifting device (3) and a power supply box (4), the lifting device (3) is fixed to the top of an inclinometer pipe (1),the lifting device (3) comprises a remote communication antenna (301), a main control circuit (302), a stepping motor (303), a lifting module (304), a Bluetooth communication module (310), a wirelesscharging module (311) and a sealed shell (312), and the power supply box (4) is connected with the lifting device (3) through a cable. The using method of the embedded automatic inclinometry robot ischaracterized by being implemented according to the following steps in sequence: (1) mounting; (2) supplying power; (3) setting; (4) communication; (5) measuring; and (6) sending. The robot is compact in structure and high in environmental adaptability.

Owner:浙江同禾传感技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com