Rotary shuttle device for sewing machine

A sewing machine and bobbin technology, which is applied in the direction of sewing machine components, sewing machine ring mechanism, sewing equipment, etc., can solve the problem of sewing quality decline and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described by way of examples. Apparently, those skilled in the art can understand that these embodiments are only more specific descriptions and the scope of the present invention is defined by the appended claims rather than the embodiments.

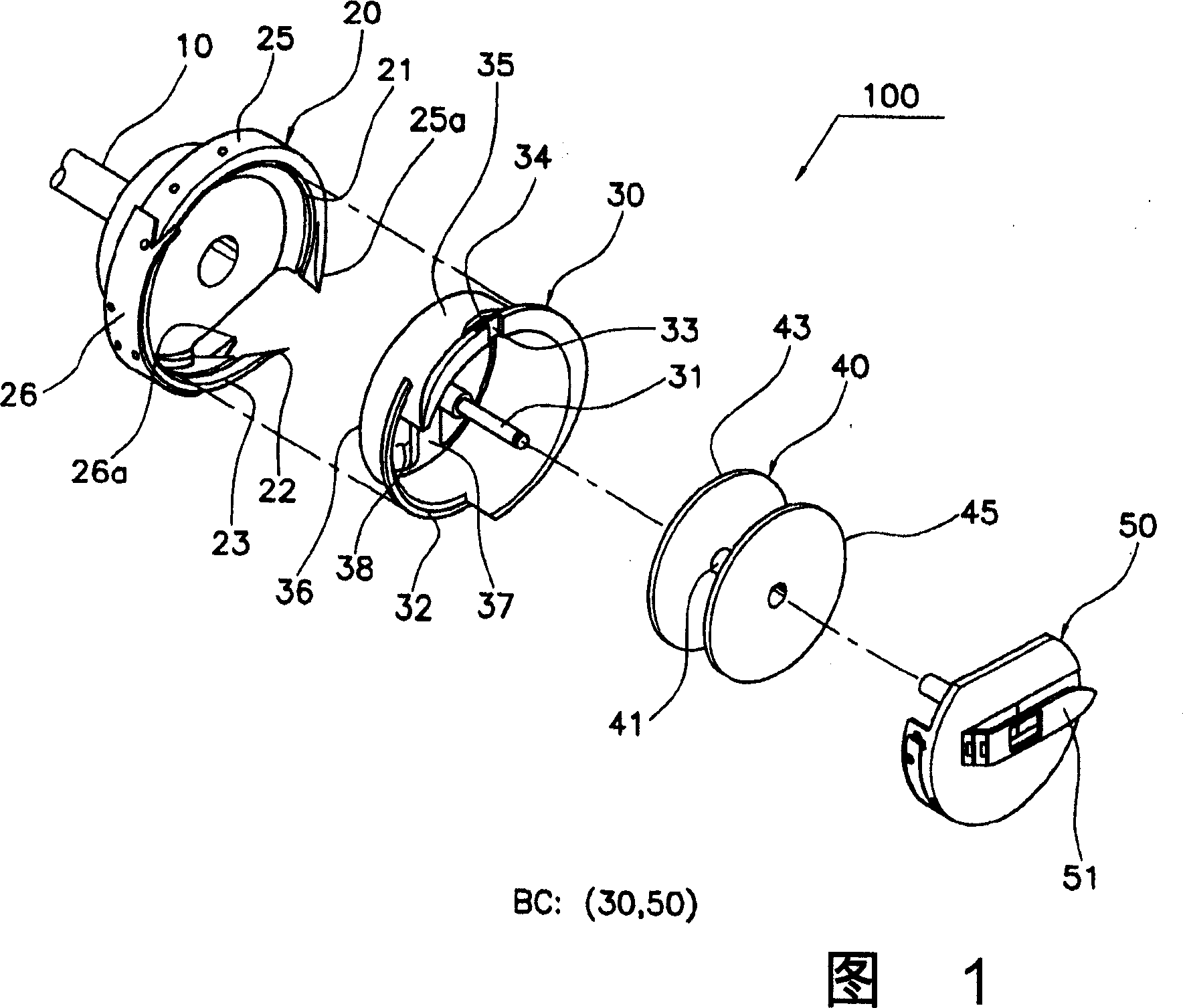

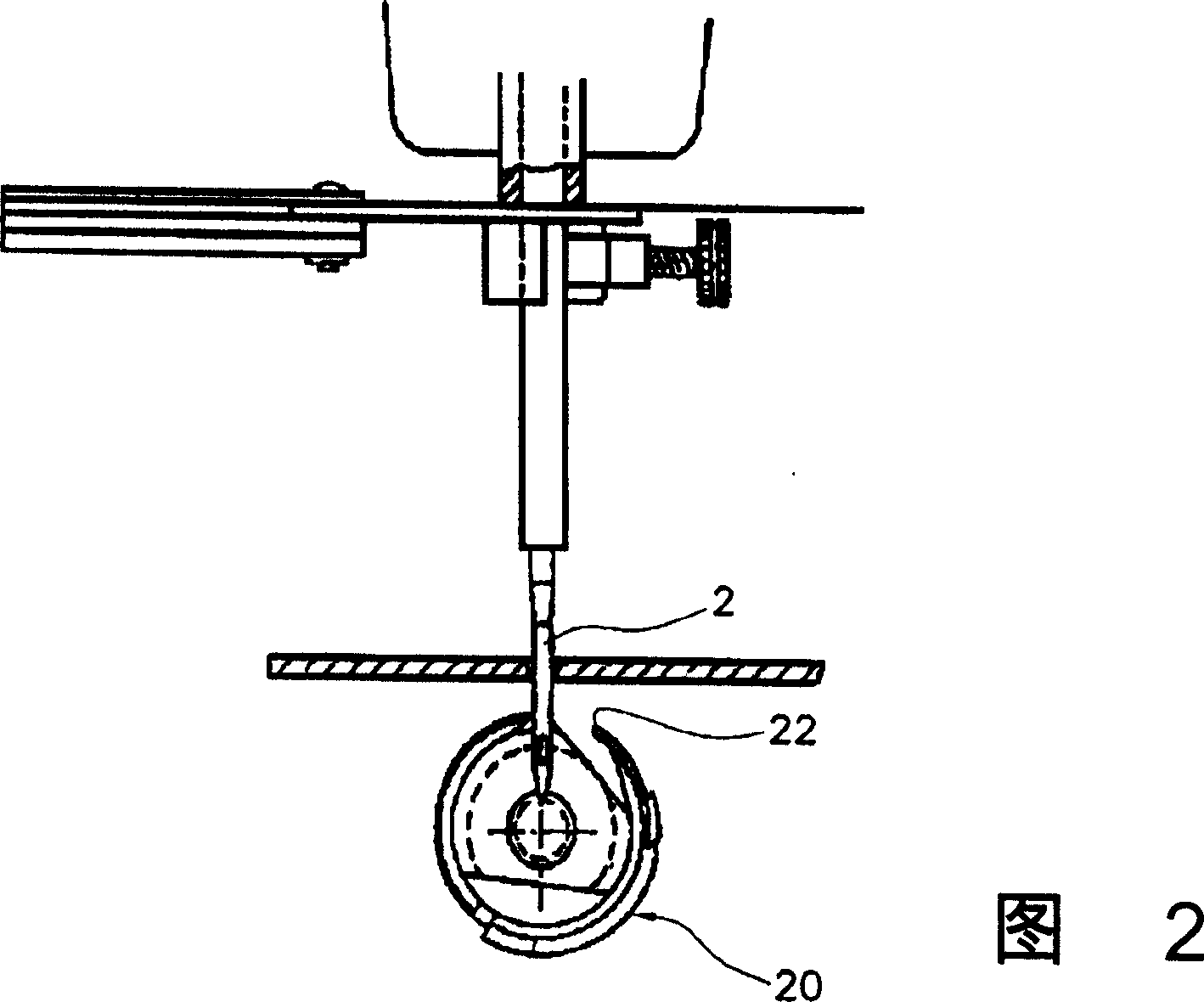

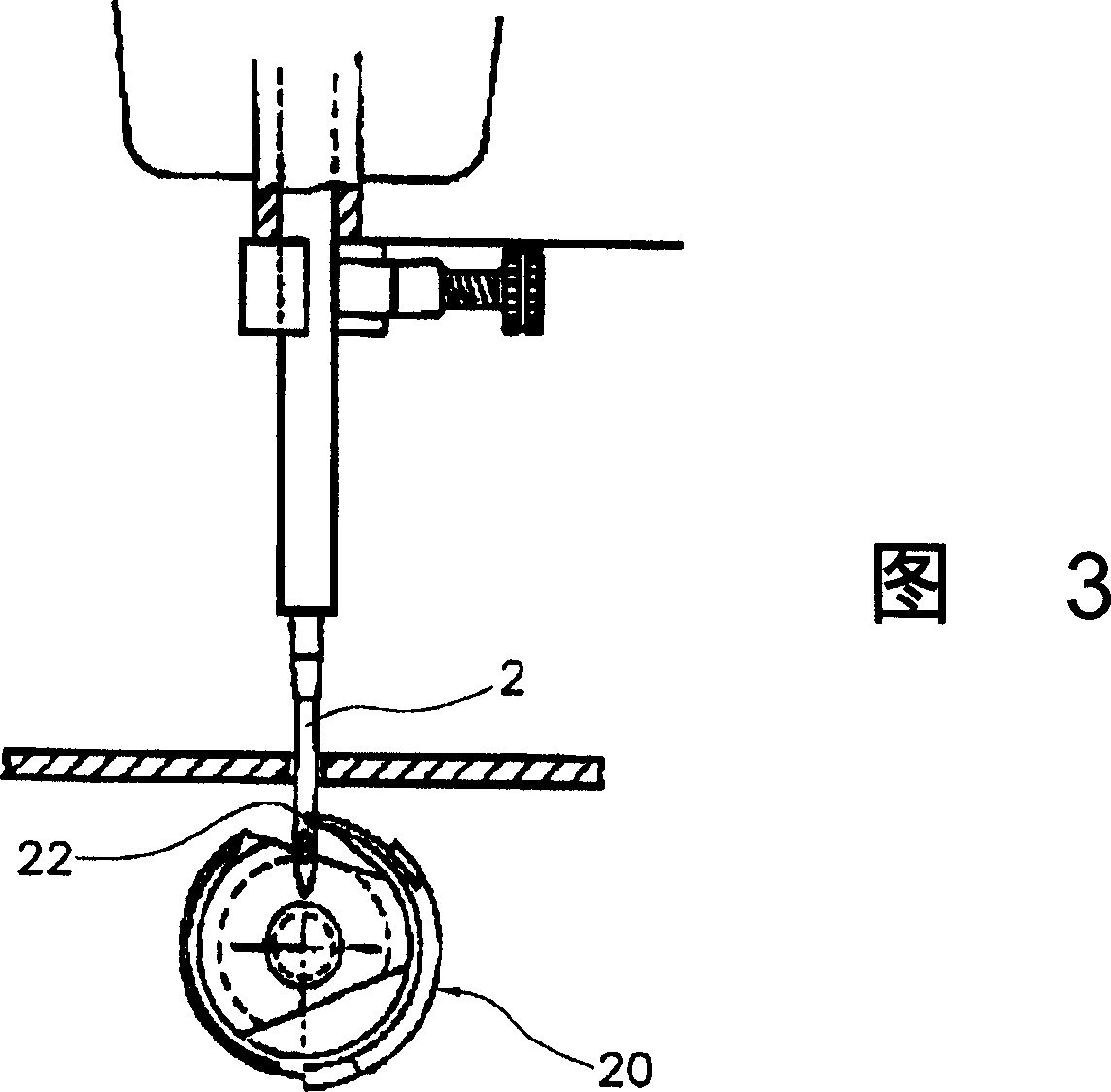

[0051] 18 is an exploded perspective view of a rotary hook device for a sewing machine according to an embodiment of the present invention, and FIG. 19 is a cross-sectional view of FIG. 18 . The rotary hook device 1 for a sewing machine according to an embodiment of the present invention includes a hook body 25 provided on a drive shaft 10; the bobbin case base 30 accommodated in the hook body 20 and a bobbin case main body 50 holding the bobbin outside; The winding shaft, a first flange formed at one end of the winding shaft to contact the bottom surface of the bobbin case base 30, and a second flange formed at the other end of the winding shaft. A portion of the first flange 430 is inclin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com