Continuum robot

A robot and continuum technology, applied in the field of robotics, can solve the problems of heavy space utilization of drive system equipment, inability to accurately model and control, difficult to miniaturize and process, and achieve easy miniaturization, easy processing, and axial bearing capacity. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

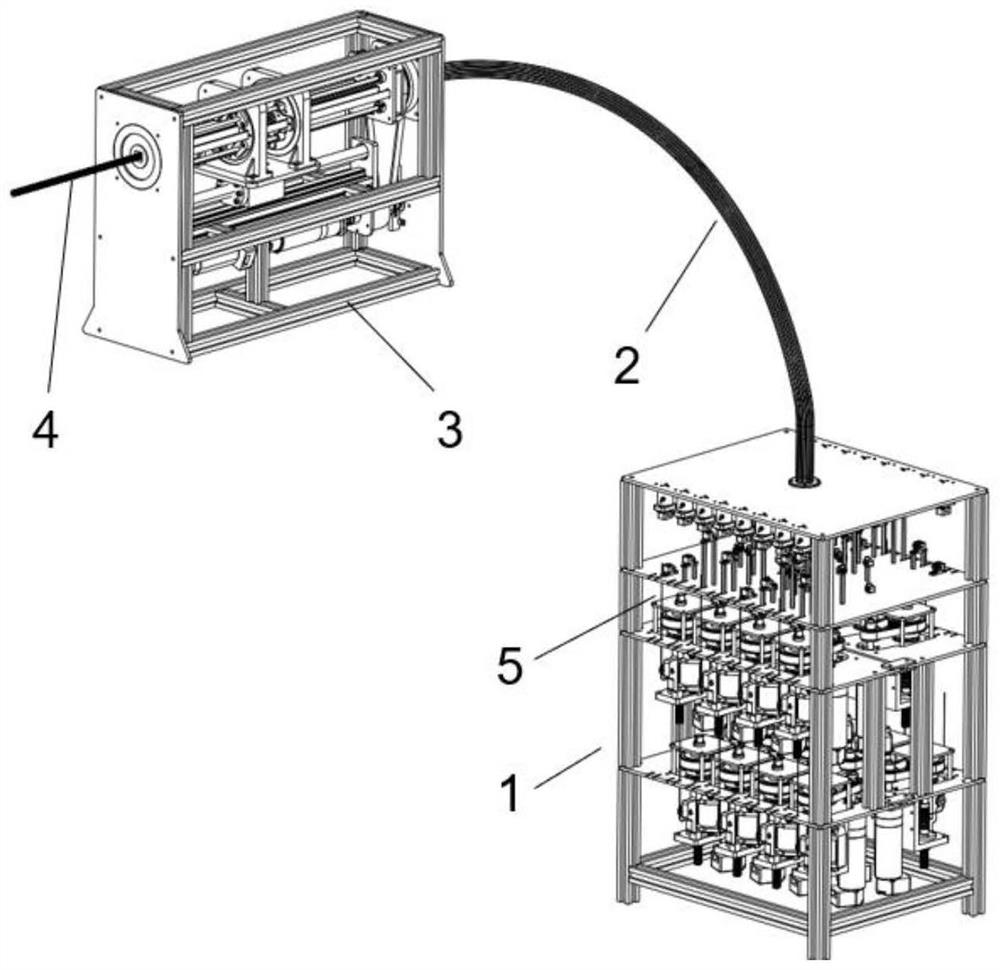

[0028] The overall structure of a continuum robot with a rollable execution arm according to an embodiment of the present invention can be found in figure 1 , is generally composed of a wire rope drive system 1, a wire tube 2, an actuator arm drive system 3, an actuator arm 4 and several drive wire ropes 5, wherein the drive wire rope 5, the wire pipe 2 and the actuator arm 4 are all flexible structures. Each component is described below.

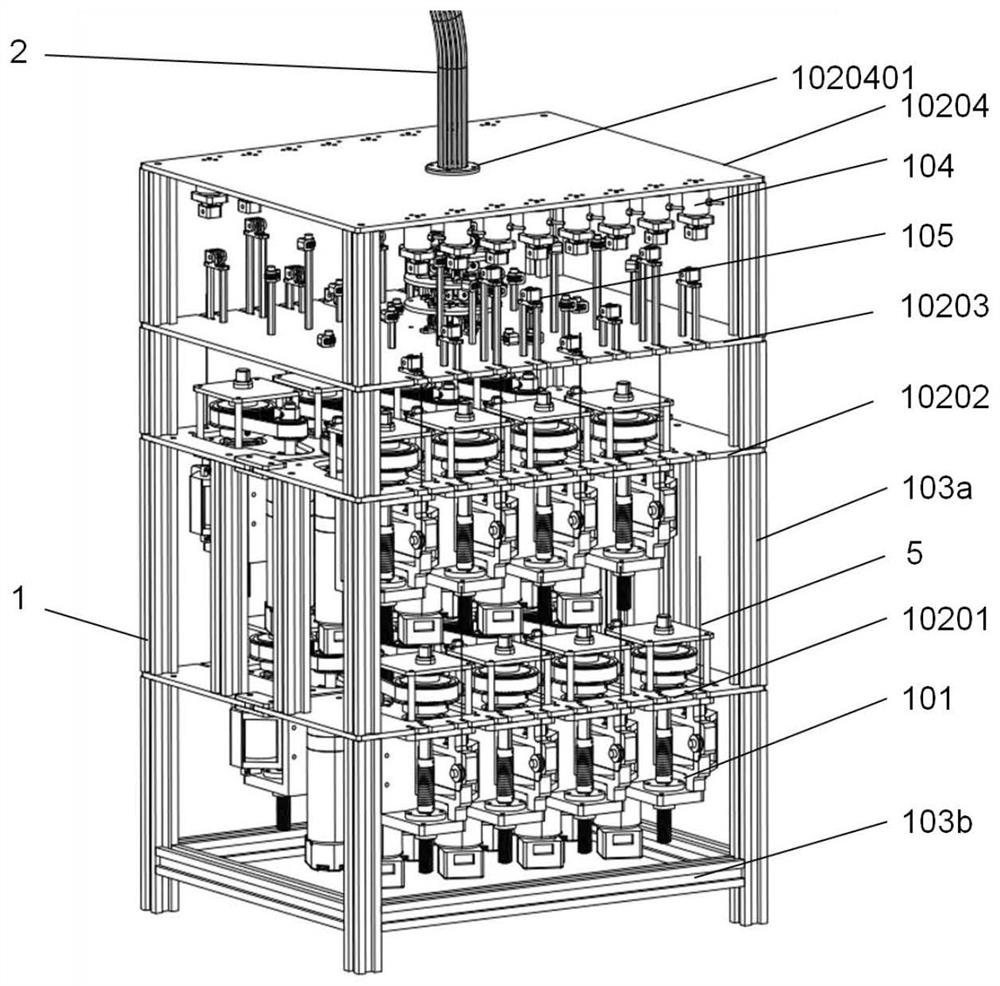

[0029] 1. Rope drive system

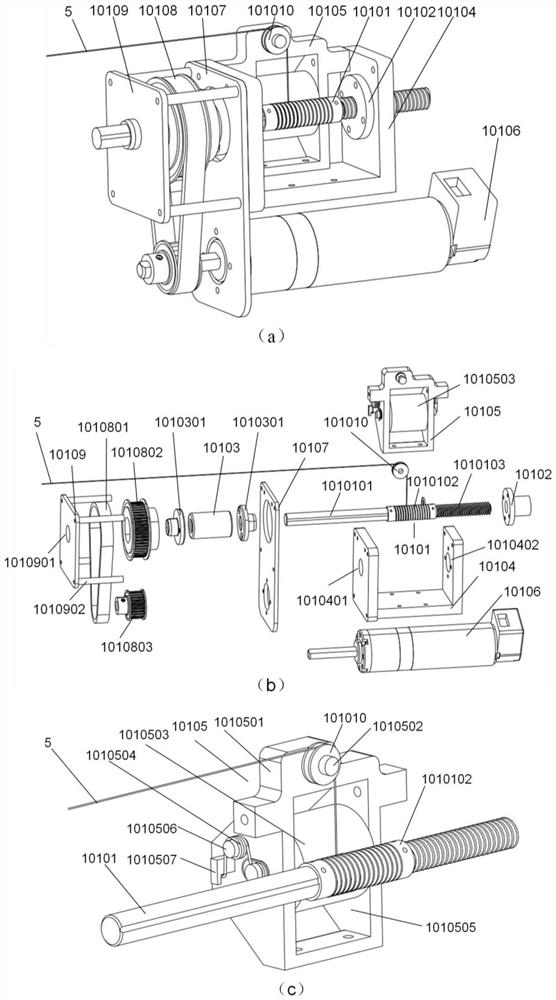

[0030] The overall structure of the wire rope drive system 1 participated in figure 2 , which can control 16 driving wires 5 . The wire rope driving system 1 includes a support composed of several pillars (aluminum square tubes are used in this embodiment) as the supporting skeleton and several fixed plates (10201, 10202, 10203, 10204) layered and fixed between the pillars. frame, 16 wire drive devices 101 evenly distributed in the lower area of the support frame, and 16 force sensors 104 and switching me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com