Textile winding roller

A technology for winding rollers and textile machines, which is used in the transportation of filamentous materials, thin material processing, transportation and packaging, etc., can solve the problem of insufficient uniformity and compactness of winding, reduced working efficiency of textile machines, and winding of winding rollers. The problem of small quantity, etc., achieves the effect of novel design, avoiding frequent replacement of winding rollers, and fast and uniform winding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

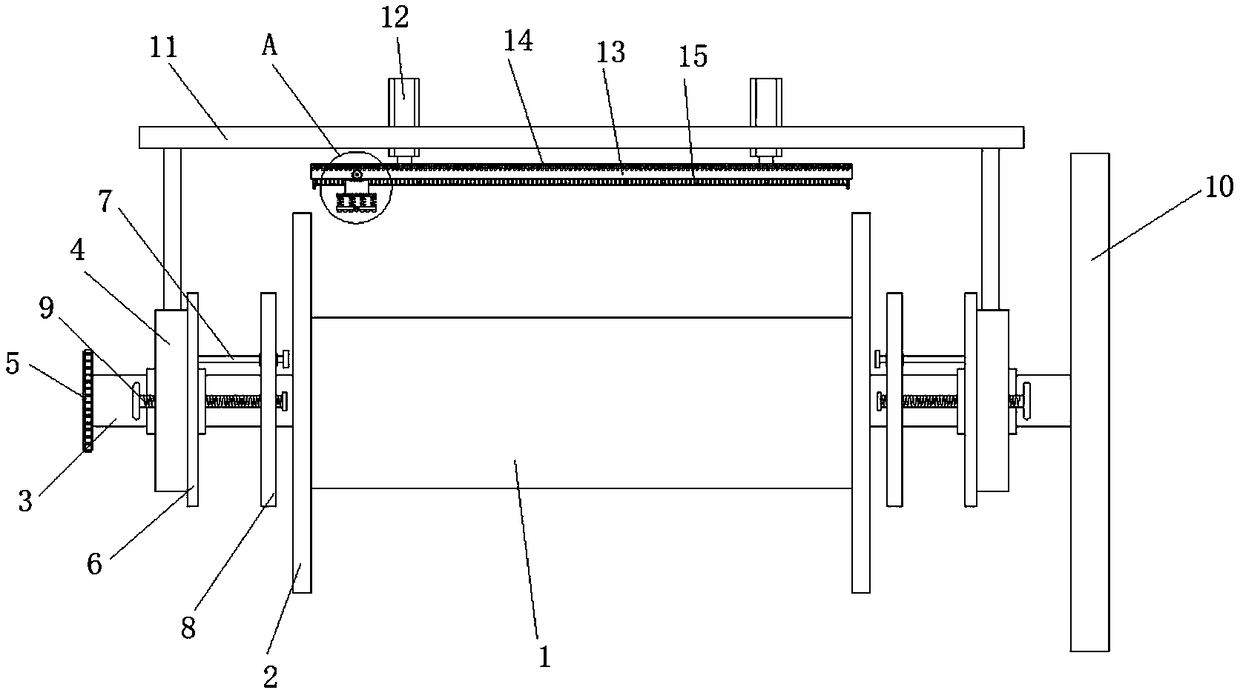

[0024] refer to figure 1 and 2 , a winding roller for textile use, comprising a winding roller main body 1, both ends of the winding roller main body 1 are provided with a limiting plate 2, and a supporting shaft is fixedly connected to the center of the circle on the side where the two limiting plates 2 are far away from each other 3, one end of a support shaft 3 away from the limit plate 2 is fixedly equipped with a transmission gear 5, and the transmission gear 5 meshes with the output shaft of the drive motor on the textile machine, and the other support shaft 3 is far away from the end of the limit plate 2. One end is fixedly connected with a support plate 10, the support plate 10 and the limit plate 2 are parallel to each other, the middle sections of the two support shafts 3 are equipped with a support block 4 through bearings, the support block 4 is a disc-shaped structure, and is provided with a connecting mechanism, The winding roller main body 1 is installed on the...

Embodiment 2

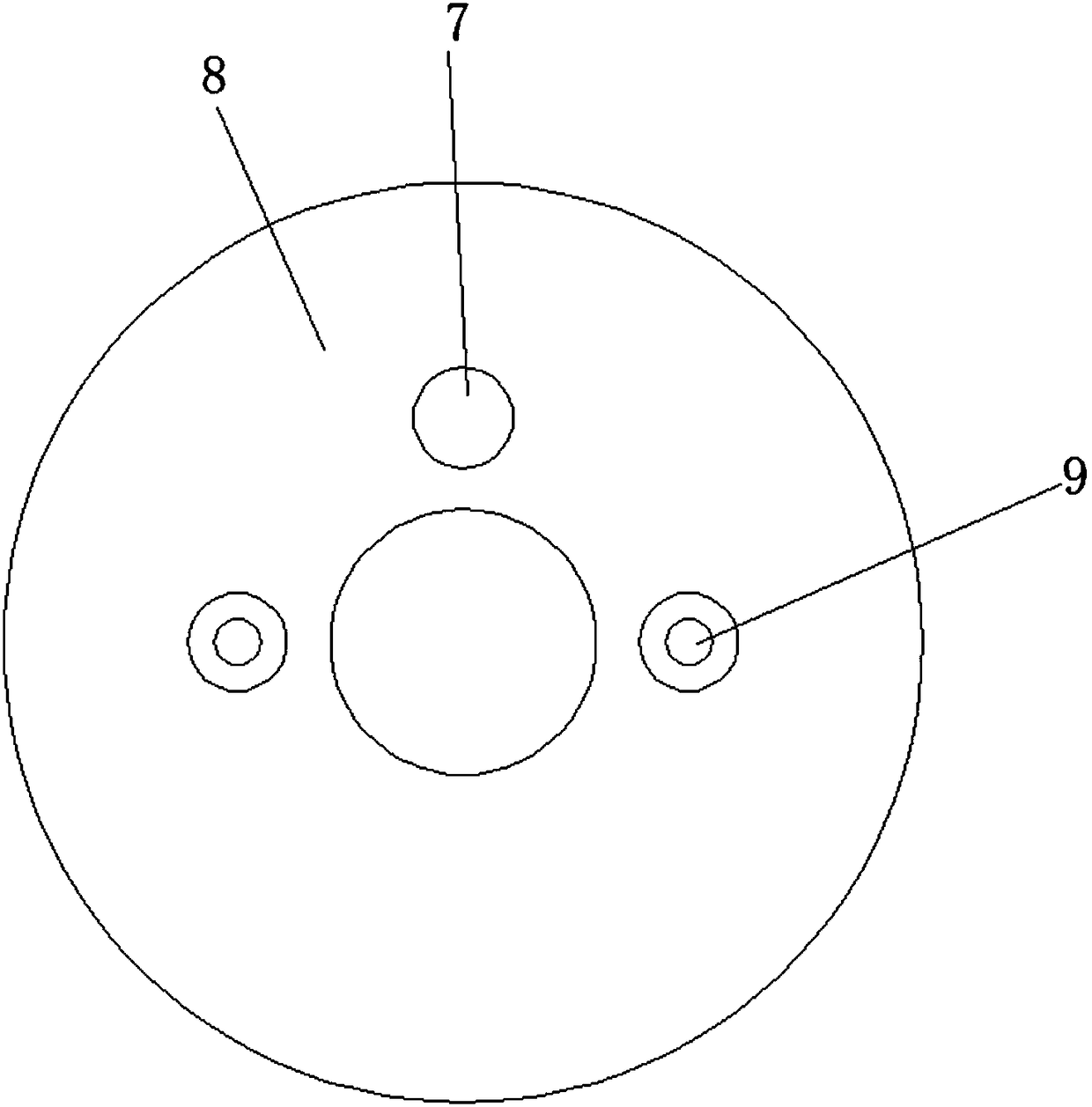

[0027] refer to figure 1 , 3 and 4, the connection mechanism includes a fixed ring plate 6, the fixed ring plate 6 is arranged on the side of the support block 4 close to the limit plate 2, and the side of the fixed ring plate 6 away from the support block 4 is provided with a guide near the support shaft 3 Slide bar 7, guide slide bar 7 and fixed annular plate 6 vertical settings, and one end away from fixed annular plate 6 is provided with circular spacer plate, movable annular plate 8 is installed on guide slide bar 7, fixed annular plate 6 and The sides of the movable annular plates 8 that are close to each other are all provided with anti-slip rubber pads, and the anti-slip rubber pads are provided with anti-slip protrusions, and the position of the support block 4 near the bearing is symmetrically provided with threaded holes that run through itself and the fixed annular plate 6 about the center of the circle, and Fastening bolts 9 are movably connected in the threaded ...

Embodiment 3

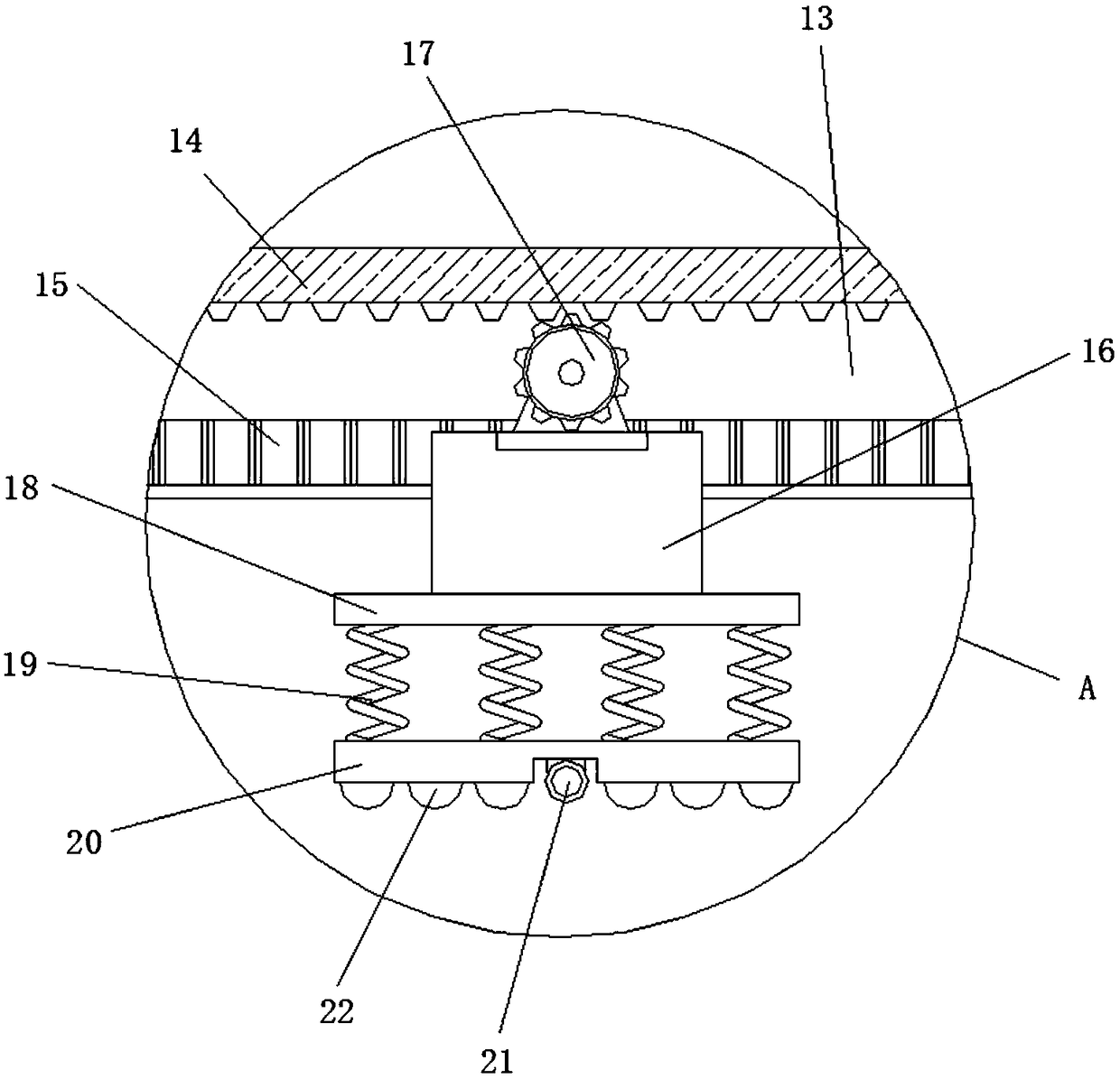

[0030] refer to figure 2, the wire management device includes a mobile base 16, and the mobile base 16 is movably installed on the moving track 15, and both ends of the moving track 15 are provided with limit blocks, and the driving motor 17 is installed on the moving base 16, and the output shaft of the driving motor 17 A drive gear is installed, the drive gear meshes with the transmission rack 14, the side of the mobile base 16 close to the winding roller main body 1 is provided with a mounting plate 18, and the side of the mounting plate 18 close to the winding roll main body 1 is equidistantly provided with compression springs 19. The end of the compression spring 19 away from the mounting plate 18 is fixedly connected to the leveling plate 20. A groove is provided in the middle of the side of the leveling plate 20 close to the winding roller body 1, and a wire management tube 21 is arranged in the groove. The wire management tube Rolling beads 22 are equidistantly arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com