Stator winding insulation structure

An insulation structure and stator winding technology, which is applied to the shape/style/structure of winding insulation, windings, electrical components, etc., can solve the problems of reducing the amount of winding and reducing power density, so as to increase the amount of winding and increase power effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In the manufacturing method of the rotor structure provided by the present invention, there are too many combination implementations, so it is not repeated here one by one, and only one preferred embodiment is listed for specific description.

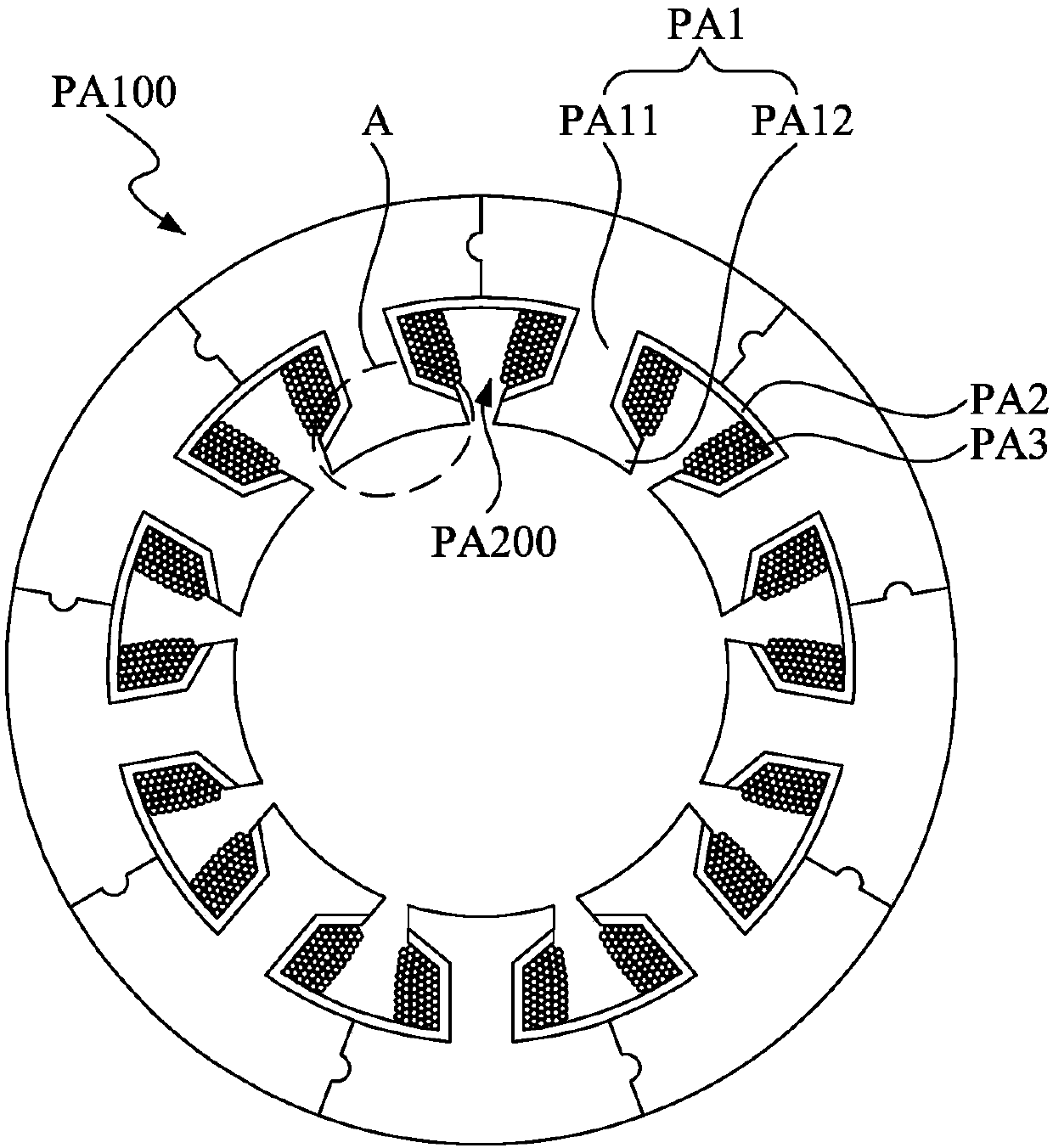

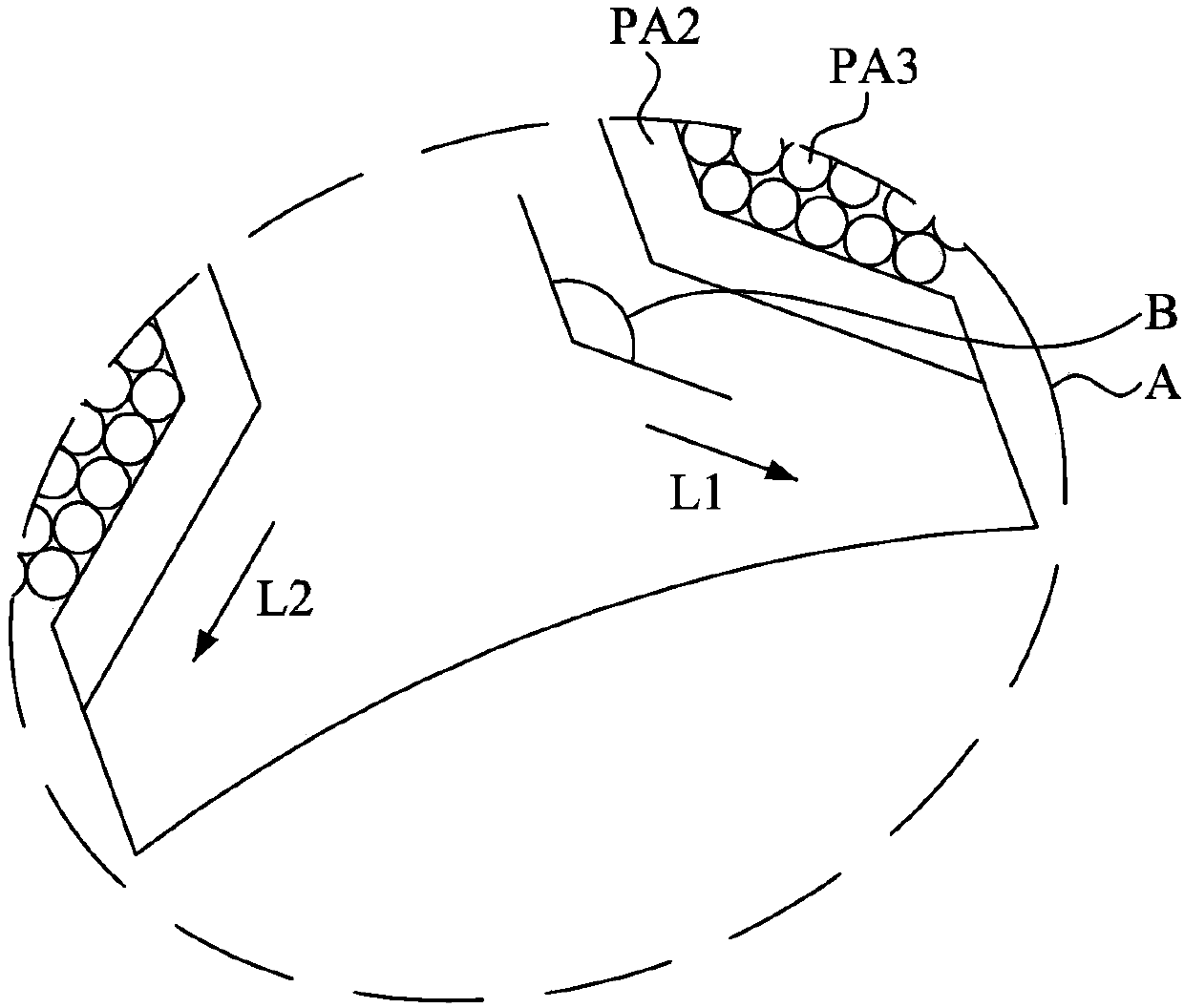

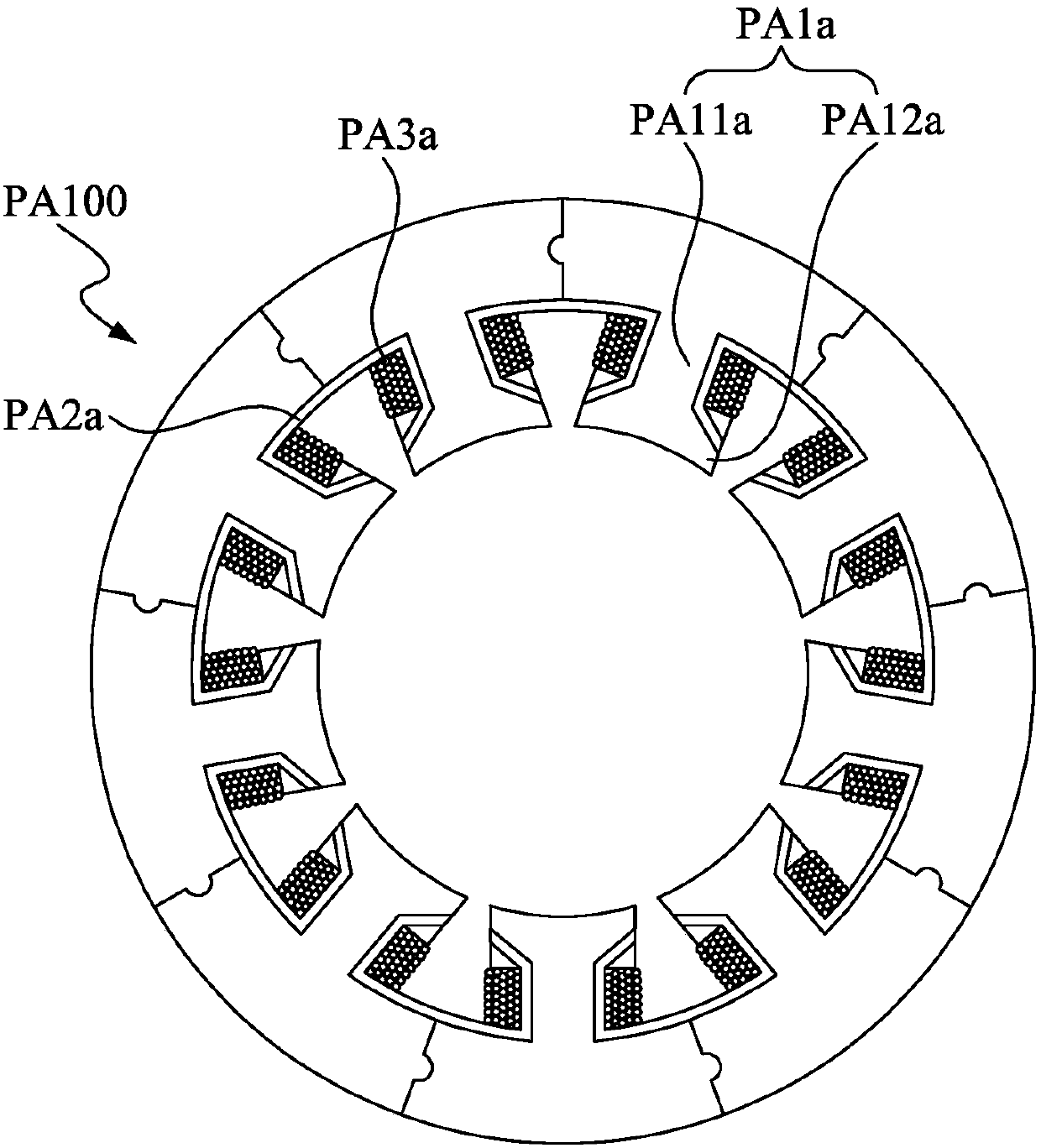

[0062] Please also refer to Figure 3 to Figure 7A , image 3 It is a top view showing that the stator winding insulation structure of the preferred embodiment of the present invention is arranged on the motor stator, Figure 4 It is a schematic cross-sectional view showing that the stator winding insulation structure of the preferred embodiment of the present invention is arranged on the motor stator, Figure 5 is a schematic diagram showing the structure of the tooth body, Figure 5A is displayed Figure 4 The partial enlarged view of the first ladder structure and the second ladder structure, Figure 6 It is a schematic cross-sectional view showing that the stator winding insulation structure of the preferred embodiment of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com