Spinning yarn bobbin with long service life

A long-life bobbin technology, applied in the field of textile yarn bobbins, can solve the problems of shortened bobbin life, reduced yarn volume in bobbins, interlaced yarn winding, etc., to increase winding volume, avoid direct friction, and rotate smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

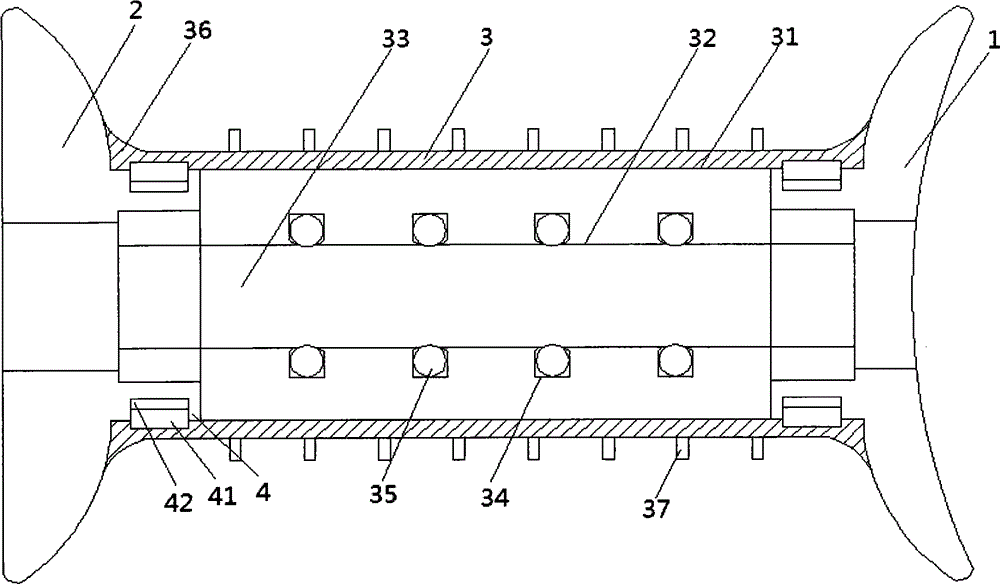

[0011] see figure 1 , in an embodiment of the present invention, a textile yarn bobbin with a long service life includes a top plate 1, a top plate 2, and a bobbin 3, the bobbin 3 is cylindrical, and includes a tube outer wall 31 and a tube inner wall 32. The two ends of the outer wall 31 of the cylinder are provided with a transition surface 36, the surface of the transition surface 36 is an arc-shaped concave structure, the thickness of the outer wall 31 of the cylinder is 8 mm, the thickness of the inner wall 32 of the cylinder is 22 mm, and the inner wall of the cylinder 32 is cylindrical The hollow cavity 33 of the tube outer wall 31 is linearly provided with several protruding rings 37 along the horizontal direction, so the protruding rings 37 and the tube outer wall 31 are integrally formed, and the number of protruding rings 37 is at least five. When making yarn, the yarn can be wound in sequence without interlaced winding, which provides convenience for subsequent pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com