Cycloidal pin gear hydraulic pump

A cycloidal gear and hydraulic pump technology, which is applied in the field of hydraulic pumps, can solve problems such as high rotor precision requirements, large working pressure fluctuations, and difficulties in processing and manufacturing, so as to eliminate the influence of oil pressure stability and increase the discharge volume , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

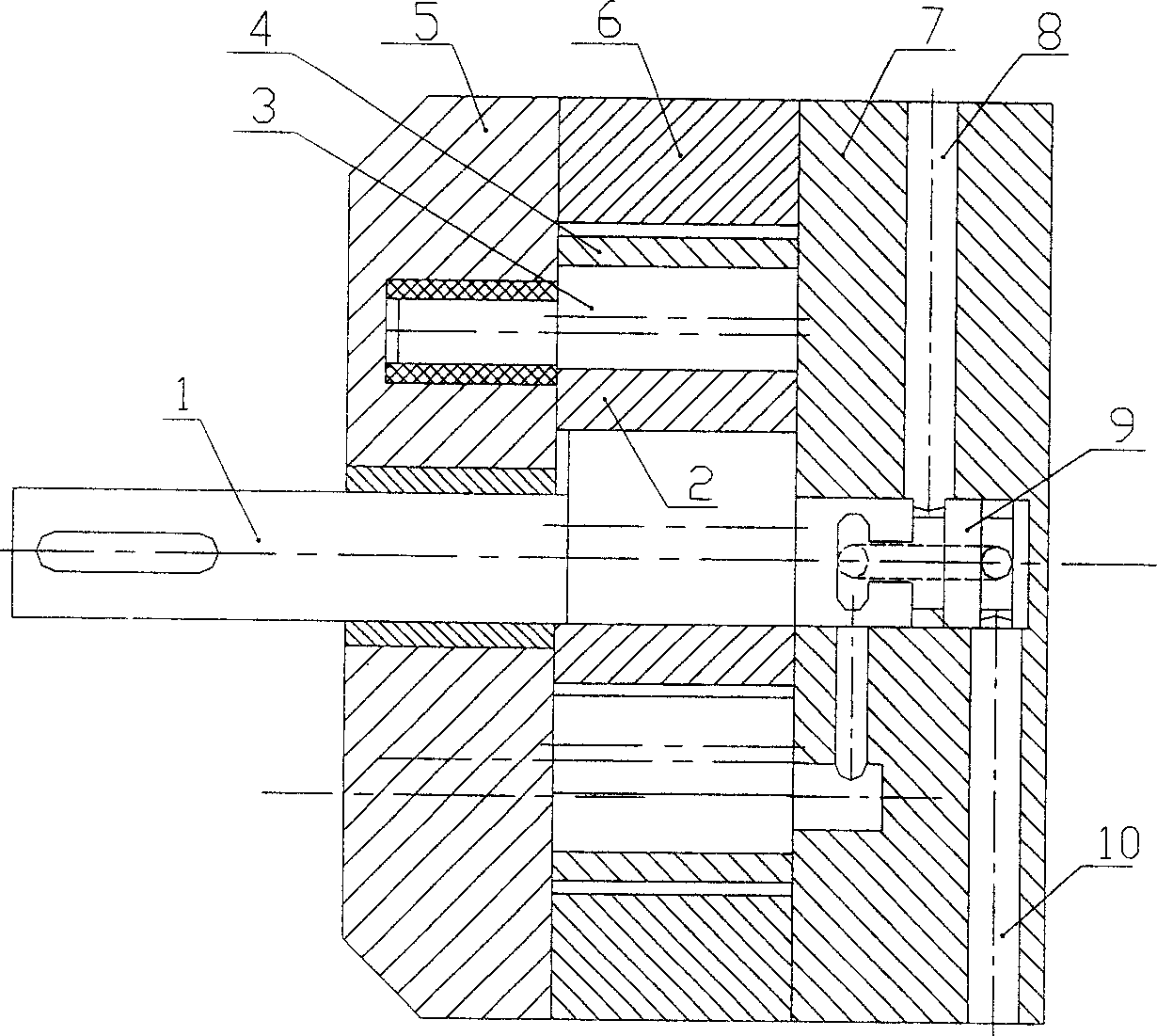

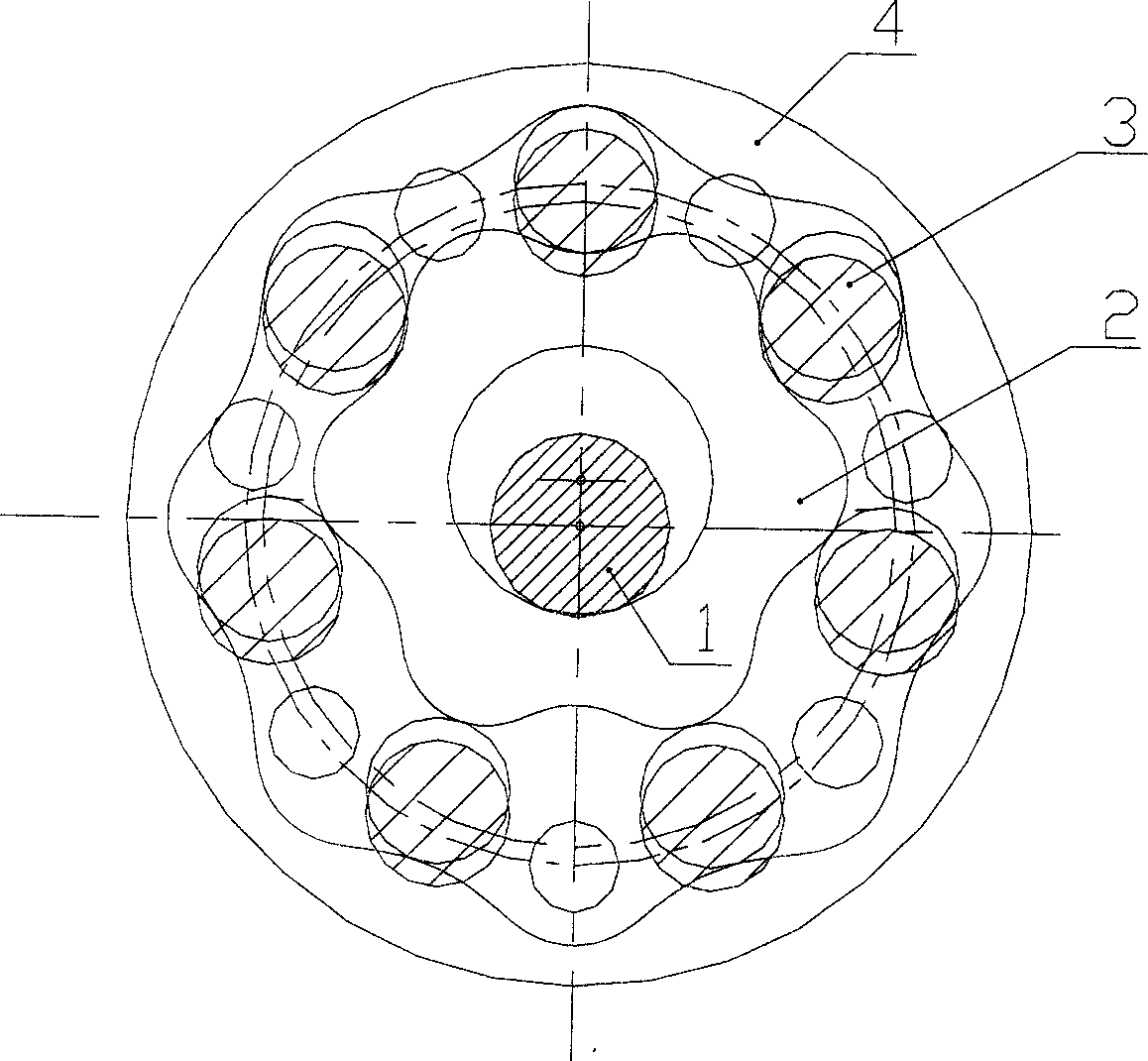

[0035] A needle-tooth cycloidal gear hydraulic pump, its structure is as follows figure 1 shown. The hydraulic pump is mainly composed of a transmission shaft (1), an inner rotor (2), a needle tooth (3), a hypocycloid wheel (4), a front end cover (5), a pump body (6), a rear end cover (7), Liquid inlet (8), liquid outlet (10), flow distribution shaft (9) and other components. The transmission shaft (1) is an eccentric shaft, which drives the inner rotor (2) to rotate; the inner rotor (2) is a short epicycloid wheel or a circular wheel; the pin teeth (3) are eccentric pin teeth (3), and rotate eccentrically, The position of the rotation axis is fixed, and the rotation axis of the needle teeth (3) is distributed on a cylindrical surface with the rotation axis of the hypocycloid wheel (4) as the axis; the hypocycloid wheel (4) is a short hypocycloid ring gear, and the inner rotor (2) set eccentrically with respect to the hypocycloid wheel (4); the inner rotor (2), the needle t...

Embodiment 2

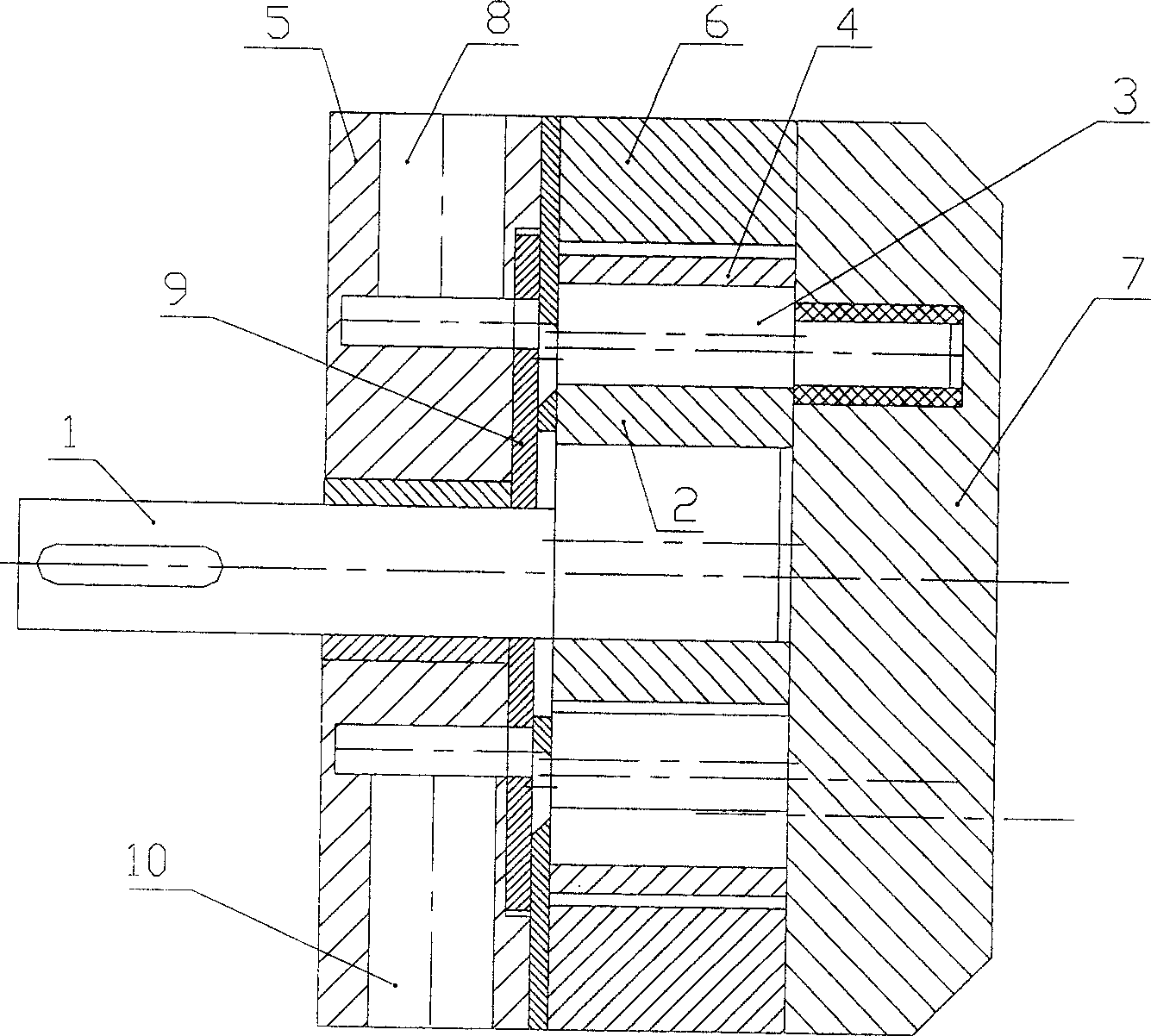

[0037] A needle-tooth cycloidal gear hydraulic pump, its structure is as follows image 3shown. The hydraulic pump is mainly composed of transmission shaft (1), inner rotor (2), needle teeth (3), hypocycloid wheel (4), front end cover, pump body (6), rear end cover (7), liquid inlet (8), liquid outlet (10), distribution plate (9) and other components. The transmission shaft (1) is an eccentric shaft, which drives the inner rotor (2) to rotate; the inner rotor (2) is a circular wheel or a short epicycloidal wheel; the pin teeth (3) are eccentric pin teeth (3), and rotate eccentrically, The position of the rotation axis is fixed, and the rotation axis of the needle teeth (3) is distributed on a cylindrical surface with the rotation axis of the hypocycloid wheel (4) as the axis; the hypocycloid wheel (4) is a short hypocycloid ring gear, and the inner rotor (2) set eccentrically with respect to the hypocycloid wheel (4); the inner rotor (2), the needle teeth (3), and the hypocy...

Embodiment 3

[0039] A needle-tooth cycloidal gear hydraulic pump, its structure is as follows Figure 4 shown. The hydraulic pump is mainly composed of transmission shaft (1), inner rotor (2), needle teeth (3), hypocycloid wheel (4), front end cover, pump body (6), rear end cover (7), liquid inlet (8), liquid outlet (10), flow distribution shaft (9) and other components. The transmission shaft (1) is fixedly connected with the hypocycloid wheel (4); the inner rotor (2) is a short epicycloid wheel or a disc; the pin teeth (3) are eccentric pin teeth (3), and rotate eccentrically, The axial position is fixed, and the rotation axis of the needle teeth (3) is distributed on the cylindrical surface with the rotation axis of the hypocycloid wheel (4) as the axis; the hypocycloid wheel (4) is a short hypocycloid ring gear, and the inner rotor ( 2) It is arranged eccentrically with respect to the hypocycloid wheel (4); the inner rotor (2), the needle teeth (3), and the hypocycloid wheel (4) form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com