Novel airproof oil pumping technology

A gas-proof and oil-pumping technology, which is applied to pumps with flexible working elements, liquid displacement machinery, machines/engines, etc., can solve the problems of reducing the fullness of the pump chamber, accelerating damage, shortening the pump inspection cycle, etc., to achieve The effect of reducing the influence of gas, increasing the service life, and reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

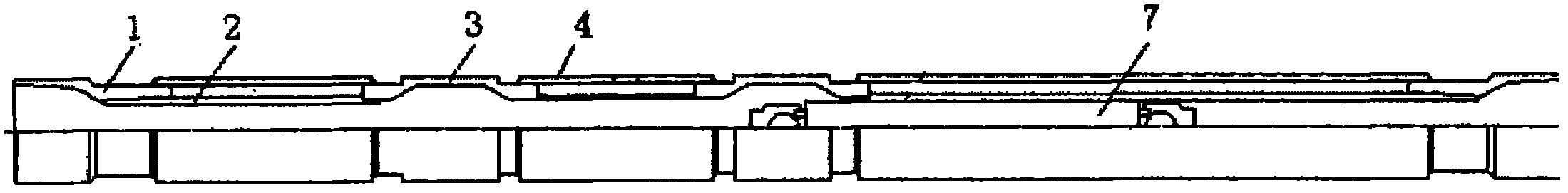

[0029] The novel air-proof oil pumping technique that the present invention relates to comprises the following steps:

[0030] (a) The plunger is at the bottom dead center, and both the fixed ball valve and the floating ball valve are closed;

[0031] (b) The plunger continues to move upward, the lower part of the plunger leaves the ventilation chamber, and the upper part of the plunger has entered the sealing chamber;

[0032] (c) The plunger reaches the top dead center of the pump;

[0033] (d) The plunger starts to stroke downwards, at this time the plunger swimming valve is closed, and when the plunger passes through the ventilation chamber, the gas in the ventilation chamber enters the oil pipe;

[0034] (e) The plunger continues to descend, the swimming valve is opened, and when the plunger passes through the ventilation chamber, the gas accumulated in the ventilation chamber enters the oil pipe.

[0035] The plunger goes back and forth once to realize an oil pumping c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com