Traction drive of a rail vehicle for driving and generative braking

A traction drive and generator braking technology, applied in electric braking systems, control systems, motor vehicles, etc., can solve the problems of braking performance, inherent braking characteristic curve without constant braking torque curve of rotational speed, etc. problem, to achieve the effect of simple structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

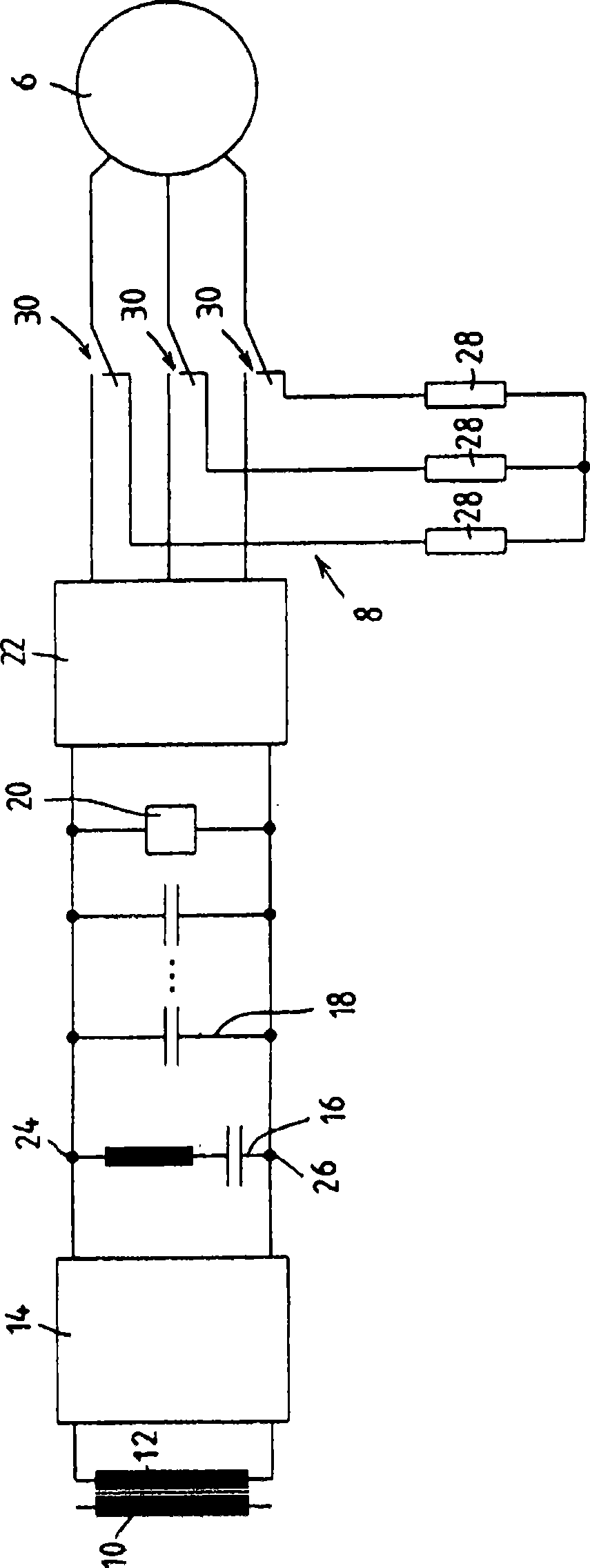

[0020] figure 1 The traction drive system 1 for AC trams (also known as AC rail vehicles) is shown in detail in , where 2 represents a traction transformer, 4 represents a traction converter, and 6 represents a permanent magnet excitation synchronous motor , with 8 representing a braking device. The traction transformer 2 has a primary winding 10 and a plurality of secondary windings 12, only two of which are shown here. The traction converter 4 has two four-quadrant regulators 14 , a snubber circuit 16 , a capacitor battery 18 , an overvoltage protection device 20 and a pulse converter 22 on the machine side. Two four-quadrant regulators 14 are connected in each case to a secondary winding 12 of the traction transformer 2 on the AC voltage side and connected in parallel on the DC voltage side. The absorber circuit 16 , the capacitor battery 18 , the overvoltage protection device 20 and the DC voltage-side input connection of the motor-side pulse converter 22 are connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com