Elevator tractor

A technology of elevator traction machine and traction wheel, which is applied to elevators, electrical components, electromechanical devices, etc. in buildings, and can solve the problems of high brake performance requirements, small braking torque, lifting, etc., and improve the overall transmission efficiency , reduce performance requirements, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

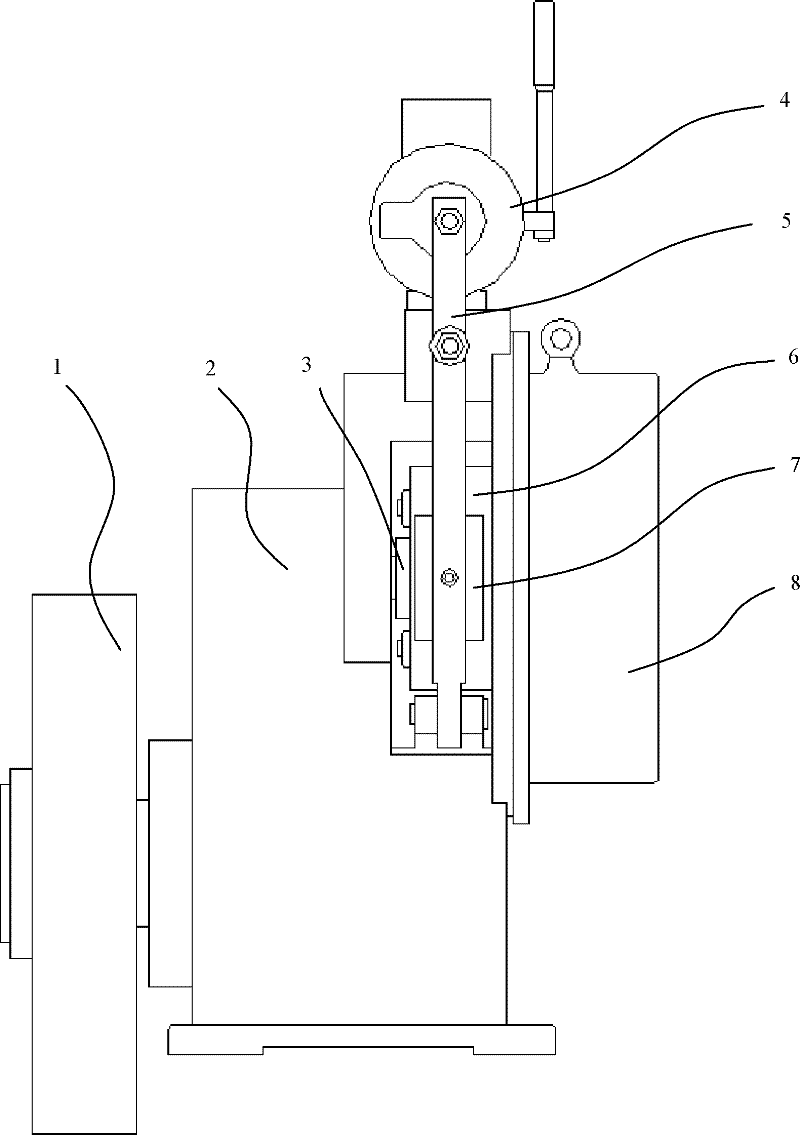

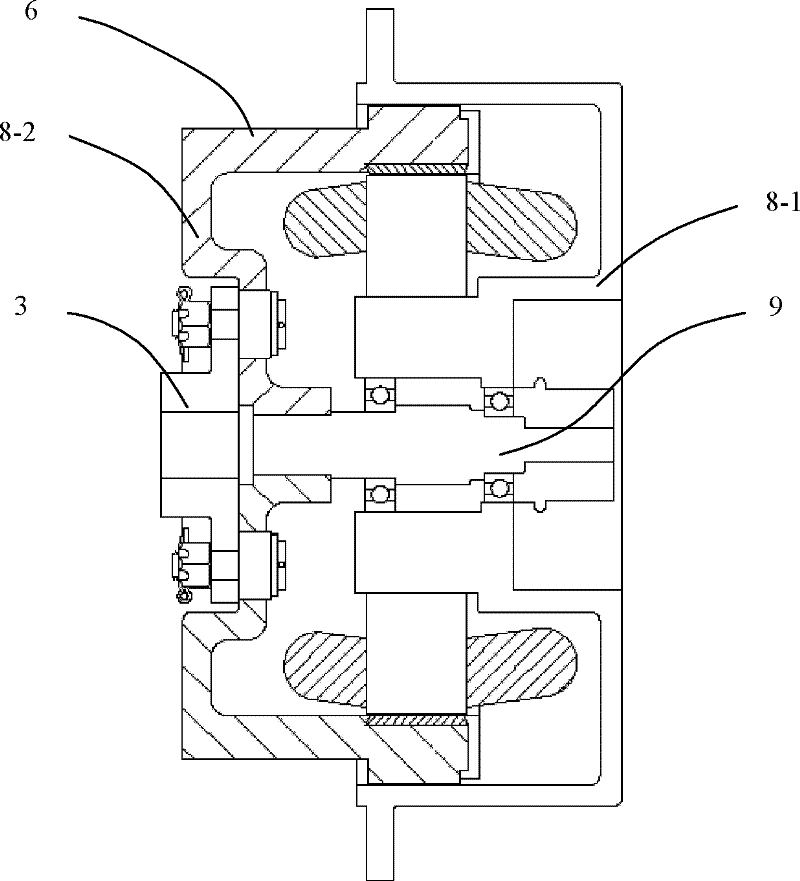

[0025] see Figure 1 to Figure 4 , the elevator traction machine described in the present invention includes a synchronous motor 8, a reduction box 2, a traction wheel and an electromagnetic brake 4, wherein the electromagnetic brake 4 includes a brake wheel 6 and a brake shoe 7 that cooperate with each other for braking, so The synchronous motor 8 includes a motor body 8-1 and an outer rotor 8-2, the brake wheel 6 is integrated on the outer rotor 8-2, the outer rotor 8-2 and the brake wheel 6 are located between the motor body 8-1 and the deceleration Between the boxes 2, the outer rotor 8-2 of the synchronous motor 8 is a part of the coupling 3, the input shaft 10 of the reduction box 2 is connected with the main shaft 9 of the synchronous motor through the coupling 3, and the output shaft 10 of the reduction box 2 It is concentrically connected with the main shaft of the traction wheel 1. In this embodiment, the reduction box 2 is a two-stage reduction structure, including ...

Embodiment 2

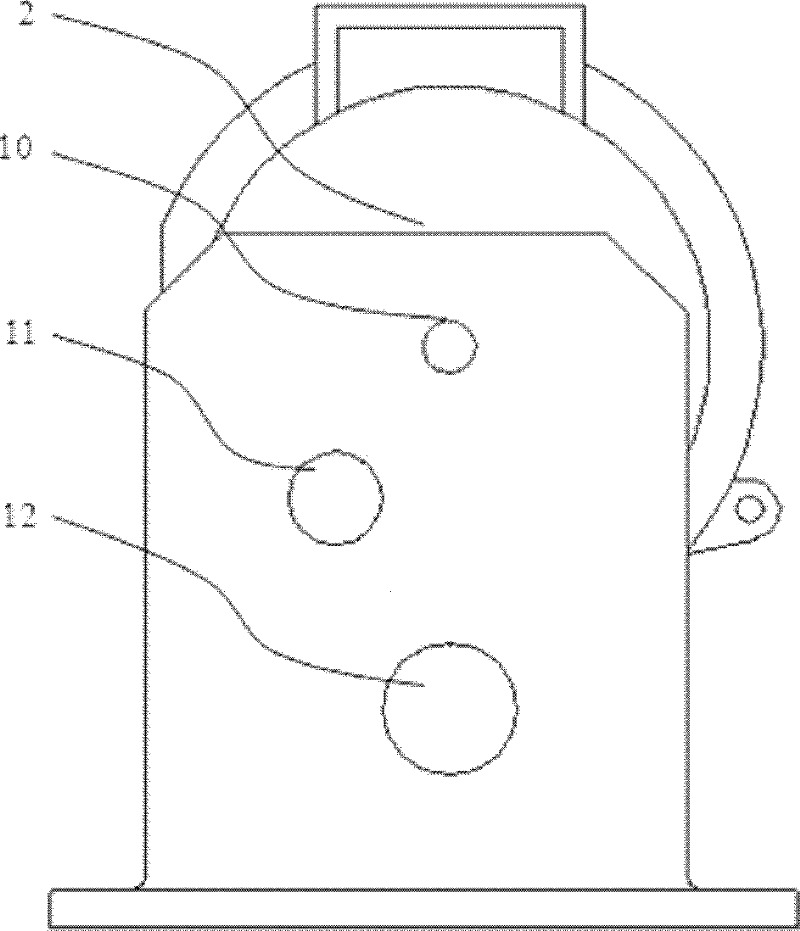

[0030] see Figure 5 The difference between this embodiment and Embodiment 1 is that the reduction box 2 of the elevator traction machine of this embodiment is a one-stage reduction structure, and the end of the input shaft 10 is provided with a worm 13, and the worm 13 passes through the corresponding The meshed worm wheel 14 is connected to the output shaft 12 which is concentrically connected to the main shaft of the traction sheave 1 .

[0031] Based on the above structure, after the synchronous motor 8 is energized and started, the rotation of the synchronous motor main shaft drives the reduction box input shaft 10 connected with it to rotate synchronously, and the input shaft 10 drives the worm gear 14 through the worm 13 arranged at its end, and the worm gear 14 The traction sheave 1 is driven to rotate through the output shaft 12 and the main shaft of the traction sheave. Through the above transmission process, the synchronous motor 8 finally transmits its power to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com