Combined recycling and comprehensive utilizing apparatus and method of inertia energy of car wheels and vibration energy of suspension

A technology of inertial energy and vibration energy, applied in auxiliary drive devices, control devices, transportation and packaging, etc., can solve the problems of long transmission chain and unfavorable centralized recovery of discrete energy of automobiles, and achieve short transmission chain and small change of wheel hub structure , The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

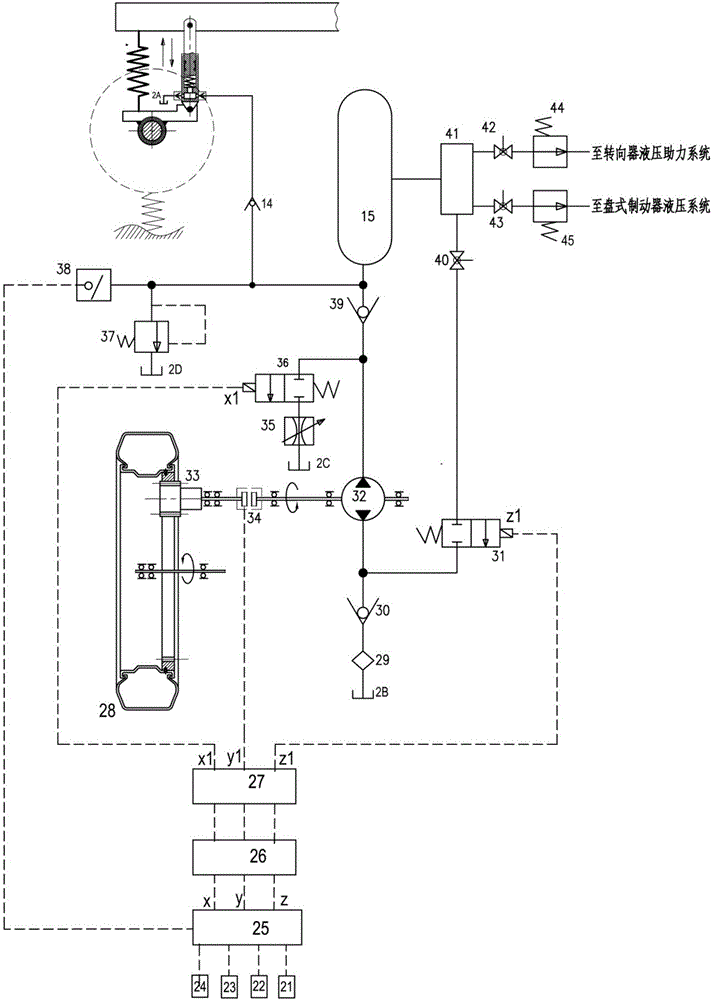

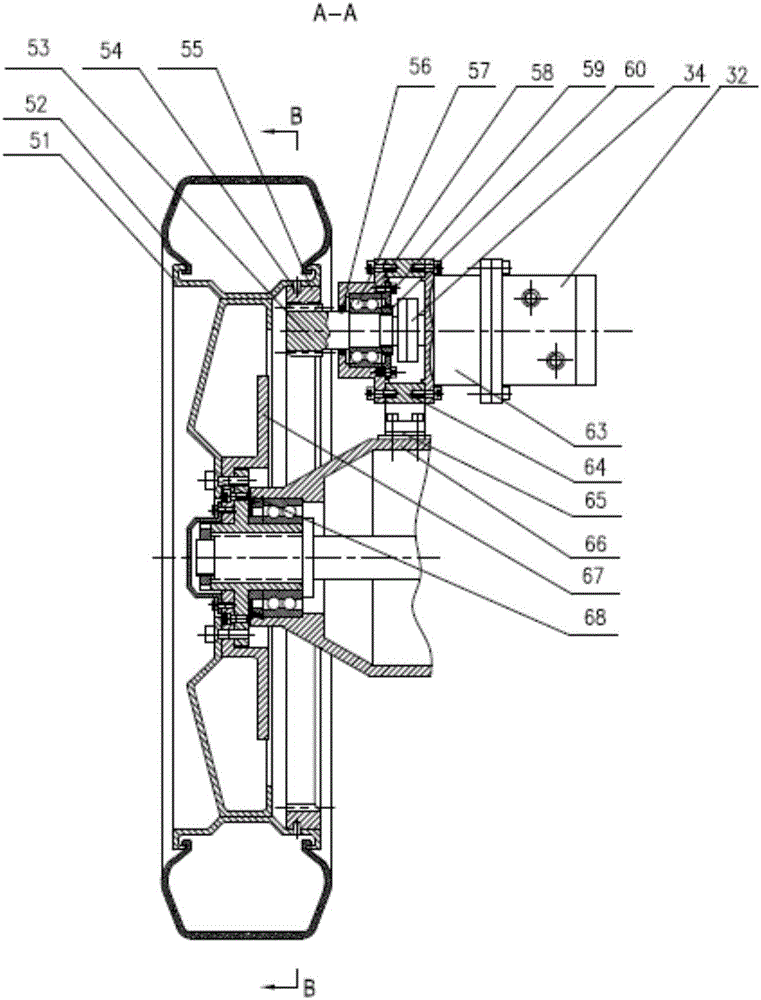

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, and the protection scope of the present invention is not limited thereto.

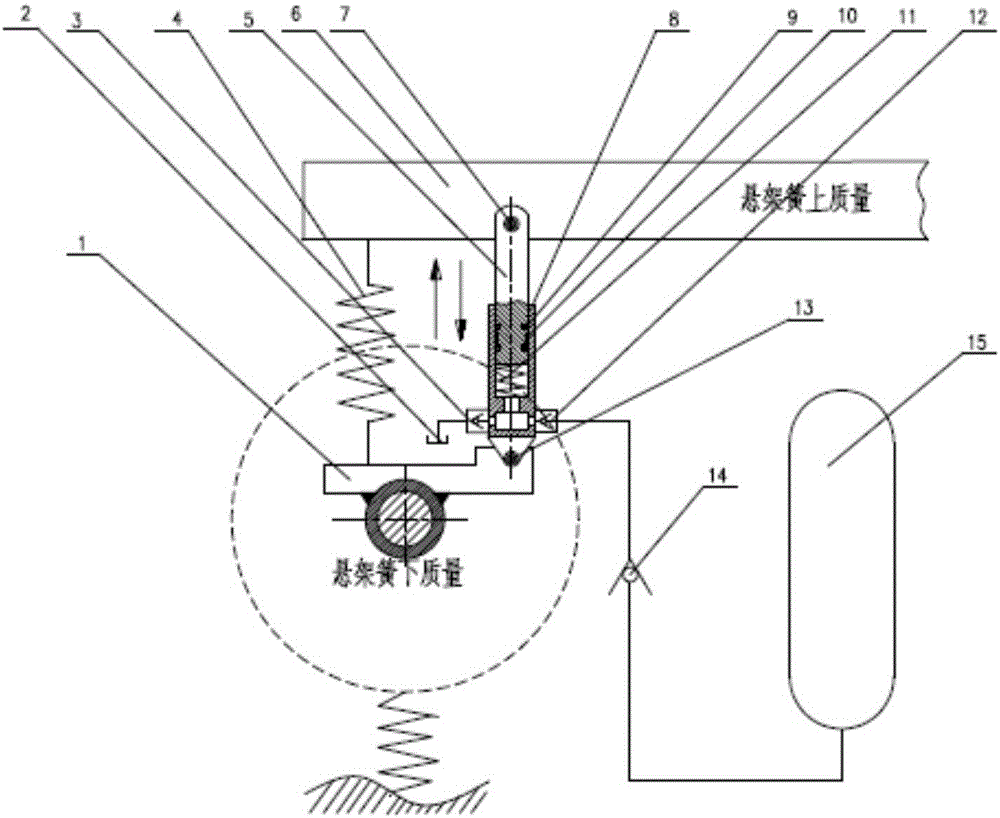

[0043] Such as figure 1 , figure 2 As shown, the present invention connects the plunger rod 5 of a plunger oil pump at the automobile suspension sprung mass 6 (body part) by the upper lug pin 7; Plunger body 8. The plunger oil pump mainly consists of a plunger rod 5 and a plunger body 8. An oil inlet valve 3 is installed on the lower left side of the plunger body 8, and an oil outlet valve 12 is installed on the lower right side. Three annular grooves are arranged up and down on the outer circle of the plunger rod 5, and a Y-shaped oil seal 9 is respectively installed in the upper and lower two annular grooves, and a wear-resistant ring 10 is installed in the middle. A buffer spring 11 is installed in the lower end of the plunger rod 5 and the inner cavity of the plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com