Coupler with controllable start function

A technology of couplings and brakes, which is applied in the direction of brake types, liquid resistance brakes, mechanical equipment, etc., can solve the problems of poor safety performance, large volume of hydraulic couplings, and heavy maintenance workload, etc., and achieves easy combination and use. The effect of small dynamic torque and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

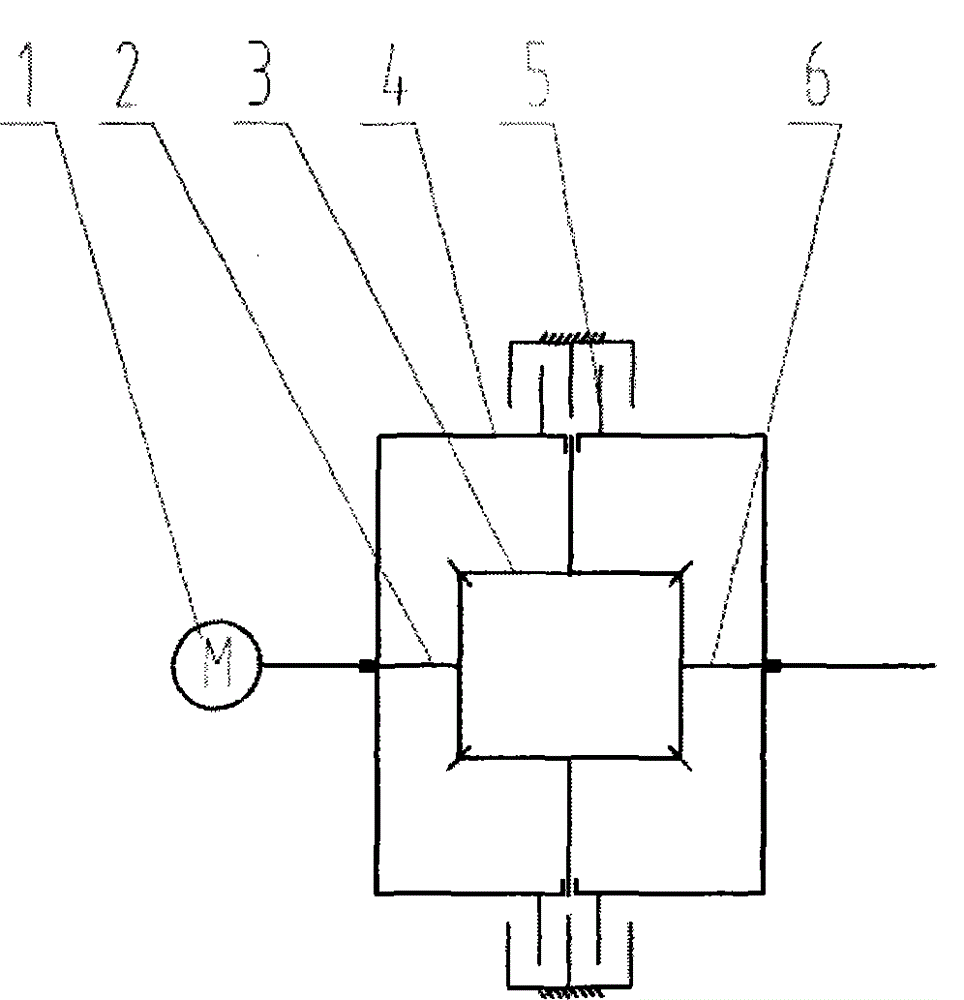

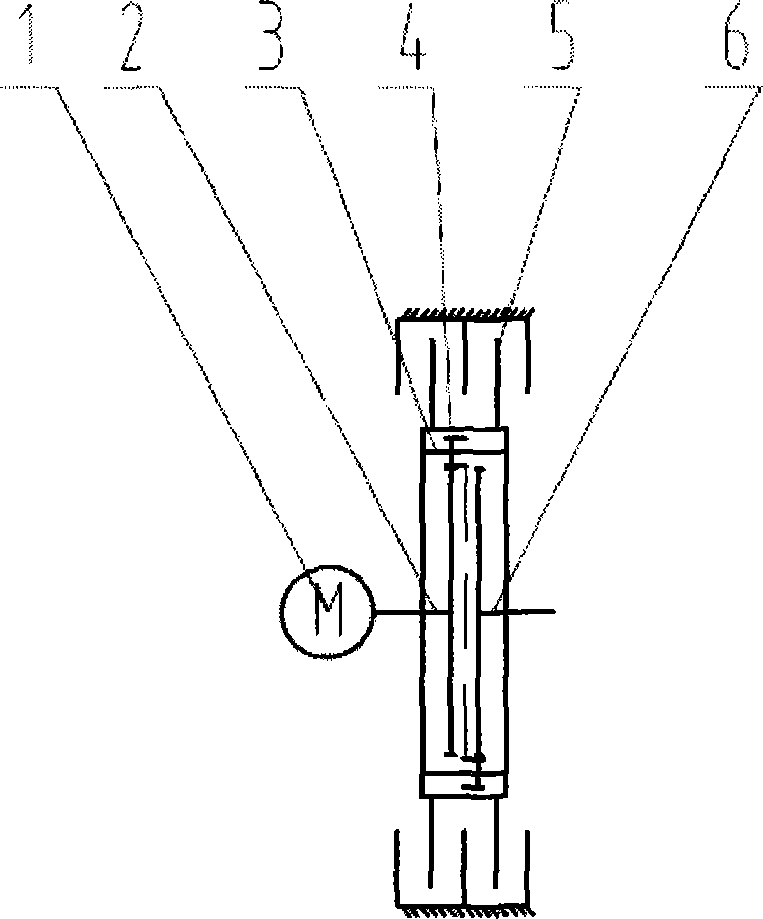

[0009] exist figure 1 Among them, the motor (1) is connected with the left half-shaft (2) of the bevel gear planetary mechanism, and the right half-shaft (6) is used as the output. When the hydraulic brake (5) is released, the planetary carrier (4) rotates freely, and the right half-shaft ( 6) The output torque is close to zero. Controlling the pressure of the fluid viscous brake (5) can realize gradual loading, then the speed of the left half shaft (2) will gradually decrease, and the torque of the left and right half shafts will gradually increase. When the increase is large enough, the right half shaft (6) will start to drive The load starts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com