Elevator traction system

An elevator traction and traction rope technology, applied in the elevator field, can solve the problems of difficulty in further reducing the diameter of the traction sheave, large size of system components, large system cost, etc., and achieves saving design materials, compact structure, and small moment of inertia Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

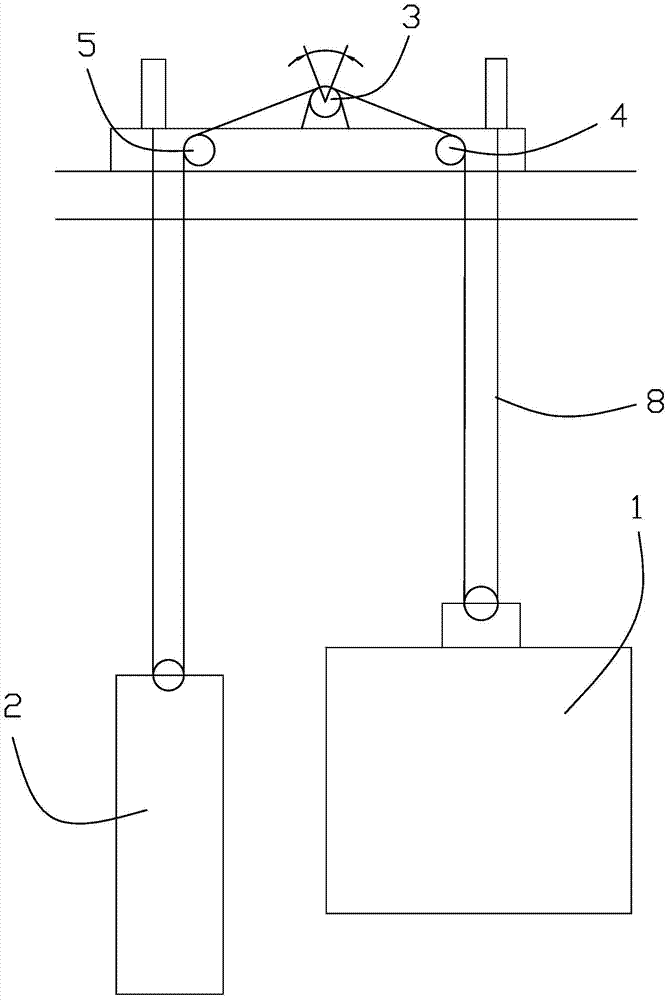

[0029] In this embodiment, an elevator traction system, such as image 3 As shown, it includes a car 1, a counterweight 2, a traction machine, a traction wheel 3, a guide wheel and a traction rope 8, the traction wheel is installed on the traction machine shaft, and the traction machine is installed on the top of the hoistway.

[0030] There are two guide wheels, respectively the car guide wheel 4 and the counterweight guide wheel 5, and the car guide wheel and the counterweight guide wheel are respectively symmetrically arranged at lower positions on both sides of the traction sheave. The traction rope is wound on the traction sheave, and one end of the traction rope goes around the guide wheel of the car, then goes down the pulley on the top of the car, and then fixes it upwards on the top of the hoistway. The other end of the traction rope goes around the counterweight guide wheel and then goes down the pulley on the top of the counterweight, and then fixes it upwards on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com