Preparation method of slurry pump wear-resistant corrosion-resistant valve rubber material

A technology for corrosion valve and mud pump is applied in the field of preparation of rubber material for wear-resistant and corrosion-resistant valve of mud pump, which can solve the problem of valve body and valve rubber being quickly damaged by mud, and achieve excellent wear resistance and good compatibility. , the effect of improving cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

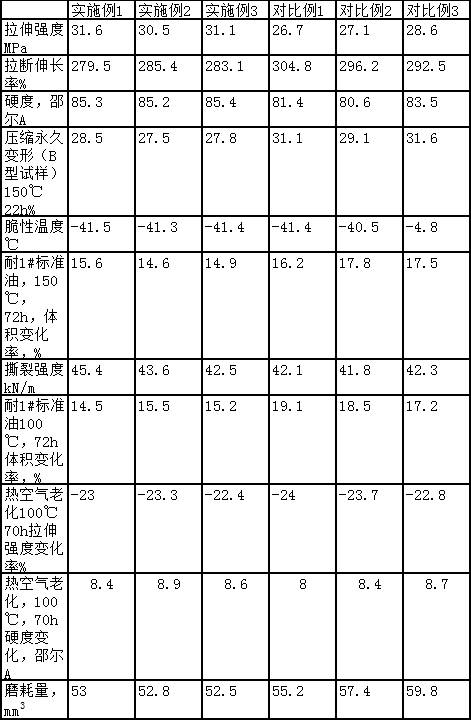

Examples

Embodiment 1

[0020] (1) In parts by weight, weigh the following raw materials: 64 parts of polychloride ether, 95 parts of acrylate rubber, 14 parts of toughening agent, 85-88 parts of plasticizer, 60 parts of filler, 35 parts of wear-resistant agent, 2 parts of antioxidant, 1.5 parts of processing aid, 1 part of vulcanized cross-linking agent, 1 part of cross-linking accelerator, 1 part of anti-aging agent; Add oxidant, processing aid and lubricant to the high-speed mixer and mix evenly; (3) Transfer the materials in step (2) to the low-speed mixer, then add acrylate rubber, vulcanized cross-linking agent, cross-linking accelerator and anti-aging (4) Put the material in step (3) into the open mill for mixing. When the temperature of the mixed rubber is 70°C, it will be vulcanized and molded at 190°C, vulcanized at 6MPa for 15 minutes, and then cooled naturally to obtain a mud pump resistant The preparation method of wear and corrosion resistant valve rubber material, the toughening agent ...

Embodiment 2

[0022] (1) In parts by weight, weigh the following raw materials: 58 parts of polychloride ether, 88 parts of acrylate rubber, 10-14 parts of toughening agent, 85 parts of plasticizer, 45 parts of filler, 15 parts of wear-resistant agent, 1 part of antioxidant, 0.5 part of processing aid, 0.5 part of vulcanized crosslinking agent, 0.5 part of crosslinking accelerator, 0.5 part of antiaging agent; Add oxidant, processing aid and lubricant to the high-speed mixer and mix evenly; (3) Transfer the materials in step (2) to the low-speed mixer, then add acrylate rubber, vulcanized cross-linking agent, cross-linking accelerator and anti-aging (4) Put the materials in step (3) into the open mill for mixing. When the temperature of the mixed rubber is 50°C, vulcanize and mold at 180°C, vulcanize at 4.5MPa for 10 minutes, and cool naturally to obtain a mud pump A method for preparing wear-resistant and corrosion-resistant valve rubber materials, the toughening agent is styrene-methyl me...

Embodiment 3

[0024] (1) In parts by weight, weigh the following raw materials: 64 parts of polychloride ether, 88 parts of acrylate rubber, 10 parts of toughening agent, 85 parts of plasticizer, 60 parts of filler, 35 parts of anti-wear agent, antioxidant 2 parts, 0.5 parts of processing aids, 0.5 parts of vulcanization crosslinking agent, 0.5 parts of crosslinking accelerator, 0.5 parts of antiaging agent; (2) polychloroethers, plasticizers, fillers, wear agents, antioxidants, Add processing aids and lubricants to a high-speed mixer and mix evenly; (3) Transfer the materials in step (2) to a low-speed mixer, then add acrylate rubber, vulcanized cross-linking agent, cross-linking accelerator and anti-aging agent, Mix evenly; (4) Put the materials in step (3) into the open mill for mixing and mixing. When the temperature of the mixed rubber is 70°C, vulcanize and form at 190°C, vulcanize at 6MPa for 15 minutes, and then cool naturally to obtain a wear-resistant mud pump. The preparation met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com