Resin composition, pressure-sensitive adhesive composition, pressure-sensitive adhesive layer, pressure-sensitive adhesive sheet, and surface protective film

A technology of resin composition and pressure-sensitive adhesive, which is applied in the field of pressure-sensitive adhesive composition, pressure-sensitive adhesive sheet and surface protection film, and high-transparency pressure-sensitive adhesive layer, and can solve the problem of pressure-sensitive adhesive sheet or surface protection film Poor wettability, adhesive residue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

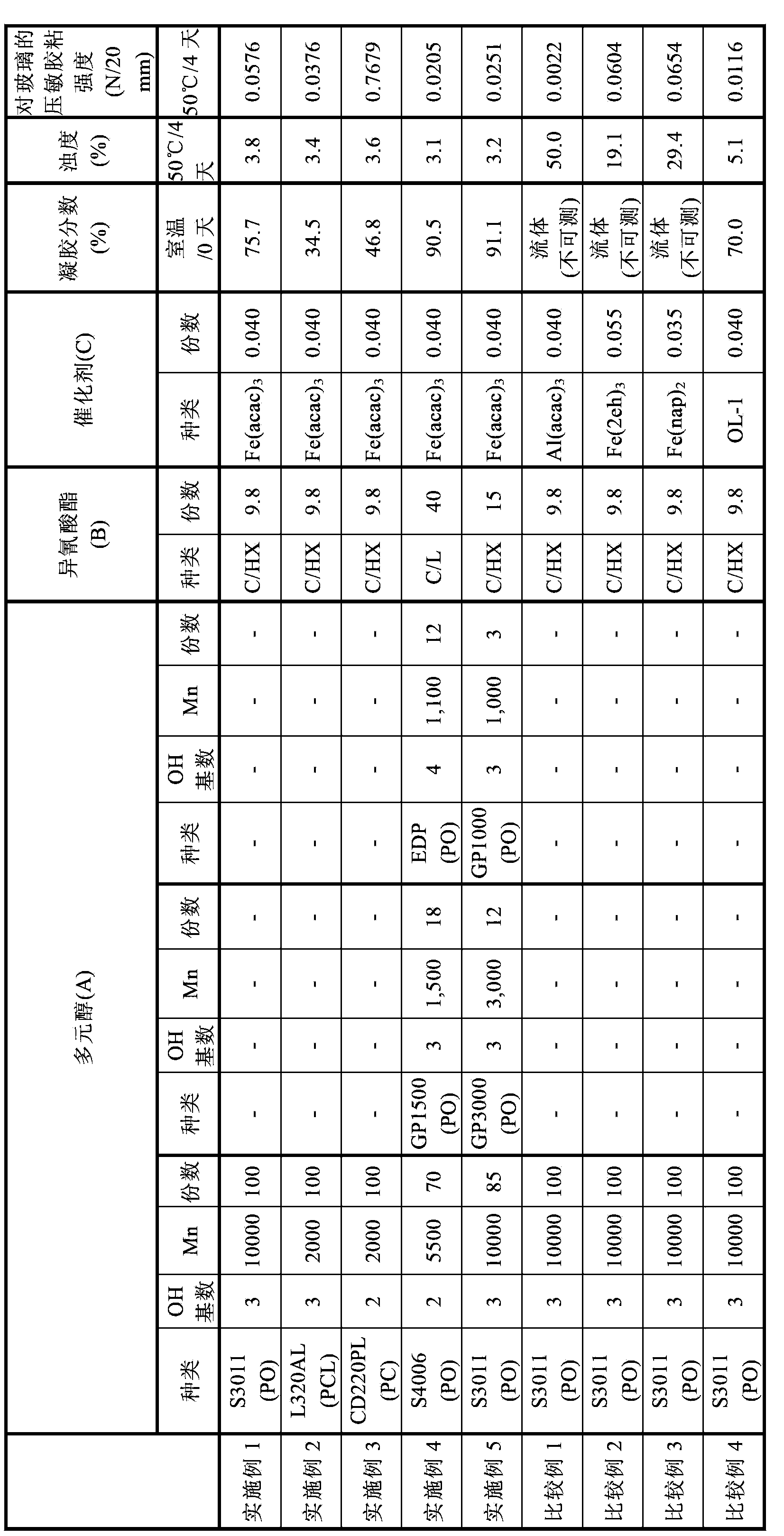

[0101] To 100 parts by weight of polyol (A) having three OH groups and having a number average molecular weight Mn of 10000 (manufactured by ASAHI GLASS CO., LTD., PREMINOL S3011), was added as polyol 9.8 parts by weight of the functional isocyanate compound (B) Trimer (isocyanurate form) of hexamethylene diisocyanate as a multifunctional alicyclic isocyanate compound (Nippon Polyurethane Industry Co., Ltd. , Ltd.), trade name: CORONATE HX) and 0.04 parts by weight of tris(acetylacetonate)iron as catalyst (C) (manufactured by NIHON KAGAKU SANGYO CO., LTD.), trade name : Nacem Ferric Iron), and the mixture was diluted with ethyl acetate to have a solid content of 35% by weight, followed by stirring to provide the resin composition (1).

[0102] The obtained resin composition (1) was defined as a pressure-sensitive adhesive composition (1) and various evaluations were performed on the resin composition (1) or the pressure-sensitive adhesive composition (1).

[0103] Table 1 sho...

Embodiment 2

[0105] Except using 100 parts by weight of a polyol having three OH groups and having a number average molecular weight Mn of 2000 (manufactured by Daicel Corporation, PLACCEL L320AL) as the polyol (A), in the same manner as in Example 1 Resin composition (2) was obtained in the same manner as in .

[0106] The obtained resin composition (2) was defined as the pressure-sensitive adhesive composition (2) and various evaluations were performed on the resin composition (2) or the pressure-sensitive adhesive composition (2).

[0107] Table 1 shows the results.

Embodiment 3

[0109] In the same manner as in Example 1, except that 100 parts by weight of a polyol having two OH groups and having a number average molecular weight Mn of 2000 (manufactured by Daicel Corporation, PLACCEL CD220PL) was used as the polyol (A) A resin composition (3) was obtained.

[0110] The obtained resin composition (3) was defined as a pressure-sensitive adhesive composition (3) and various evaluations were performed on the resin composition (3) or the pressure-sensitive adhesive composition (3).

[0111] Table 1 shows the results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| gel fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com