Matte top-varnish with low ratio and low VOC and preparation method of matte top-coat paint

A clear topcoat and topcoat technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as damage to the liver, kidneys, brain and nervous system, high VOC content, large amount of curing agent, etc., to facilitate manufacturing , low VOC content, low ratio effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

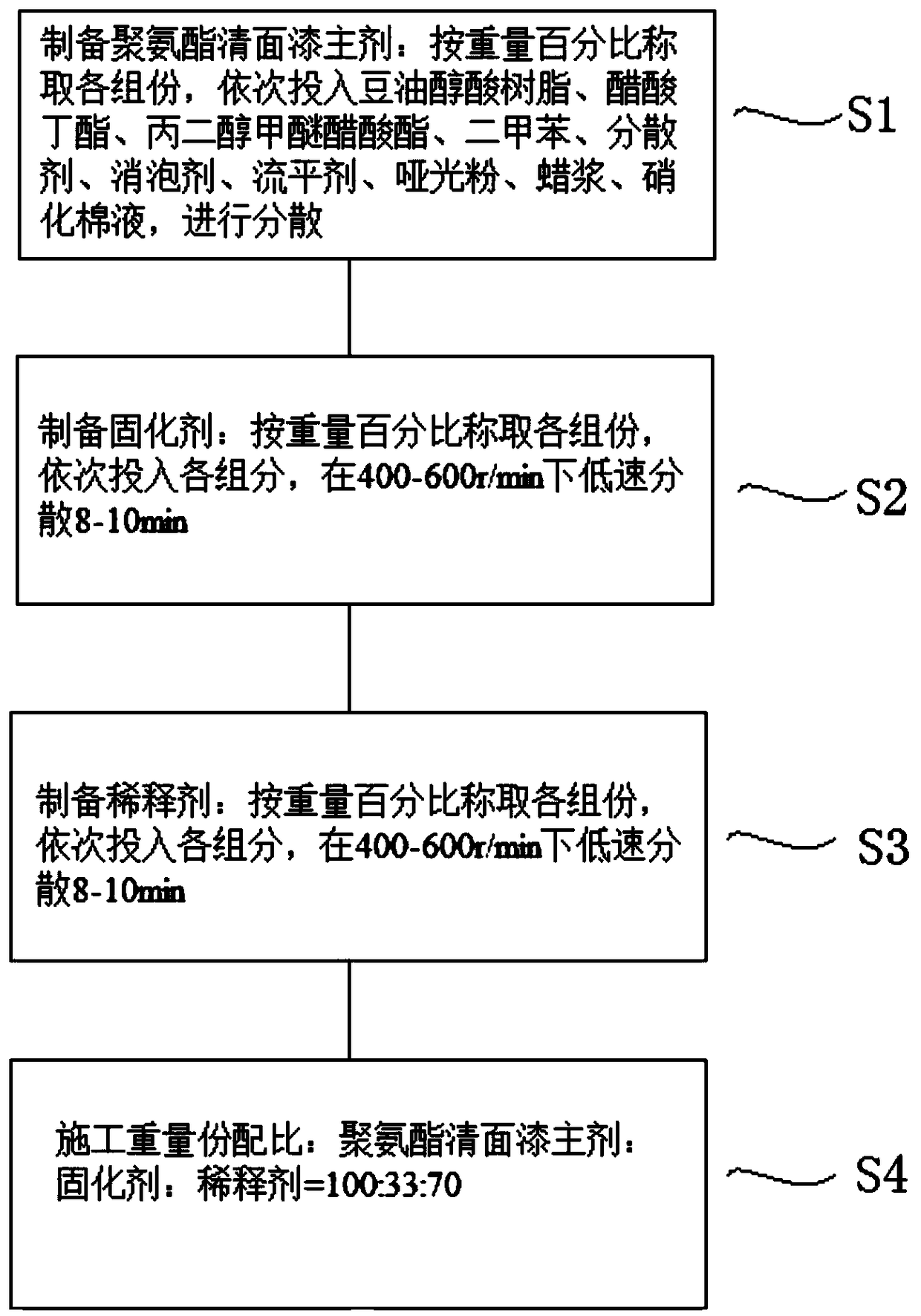

Method used

Image

Examples

Embodiment 1

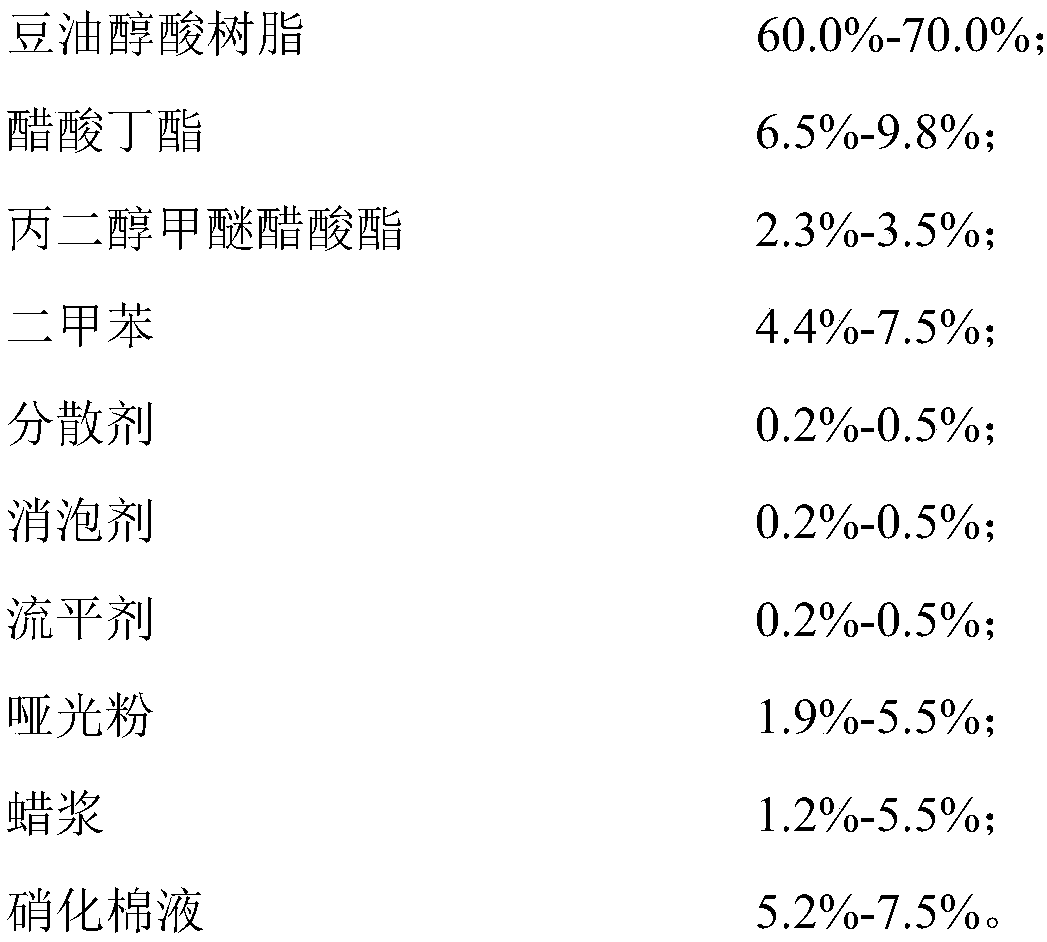

[0041] A low-proportion, low-VOC matte clear finish paint, comprising a polyurethane clear finish paint main agent, a curing agent, and a diluent, and the construction weight ratio is: polyurethane clear finish paint main agent: curing agent: thinner = 100 :33:70.

[0042] (1) The extraction of soybean oil alkyd resin in the main agent of polyurethane clear topcoat is as follows:

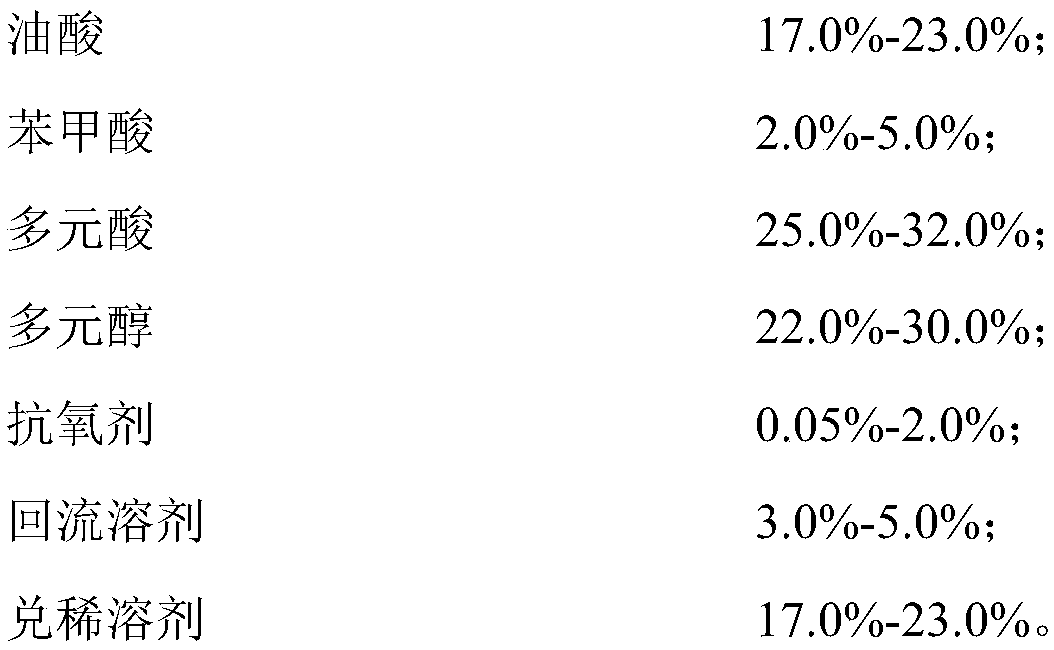

[0043] 14.28kg oleic acid, 1.428kg benzoic acid, 19.04kg phthalic anhydride, 0.952kg maleic anhydride, 8.976kg pentaerythritol, 1.972kg trimethylolpropane, 6.46kg propylene glycol, 0.204kg hypophosphorous acid antioxidant, 0.136kg phosphite antioxidant, 2.108kg xylene, 12.444kg butyl acetate.

[0044] Soybean oil alkyd resin is prepared following steps:

[0045] 1) Ingredients: 14.28kg oleic acid, 1.428kg benzoic acid, 19.04kg phthalic anhydride, 0.952kg maleic anhydride, 8.976kg pentaerythritol, 1.972kg trimethylolpropane, 6.46kg propylene glycol, 0.204kg hypophosphorous acid Antioxidant, 0.136k...

Embodiment 2

[0066] A low-proportion, low-VOC matte clear finish paint, comprising a polyurethane clear finish paint main agent, a curing agent, and a diluent, and the construction weight ratio is: polyurethane clear finish paint main agent: curing agent: thinner = 100 :33:70.

[0067] (1) The extraction of soybean oil alkyd resin in the main agent of polyurethane clear topcoat is as follows:

[0068] 14.49kg oleic acid, 1.449kg benzoic acid, 19.32kg phthalic anhydride, 0.966kg maleic anhydride, 9.108kg pentaerythritol, 2.001kg trimethylolpropane, 6.555kg propylene glycol, 0.207kg hypophosphorous acid antioxidant, 0.138kg phosphite antioxidant, 2.139kg xylene, 12.627kg butyl acetate.

[0069] The preparation steps of soybean oil alkyd resin are the same as in Example 1.

[0070] (2) The taking of the main agent of polyurethane clear topcoat is as follows:

[0071] 69.0kg soybean oil alkyd resin, 9.7kg butyl acetate, 3.5kg propylene glycol methyl ether acetate, 5.0kg xylene, 0.3kg disper...

Embodiment 3

[0083] A low-proportion, low-VOC matte clear finish paint, comprising a polyurethane clear finish paint main agent, a curing agent, and a diluent, and the construction weight ratio is: polyurethane clear finish paint main agent: curing agent: thinner = 100 :33:70.

[0084] (1) The extraction of soybean oil alkyd resin in the main agent of polyurethane clear topcoat is as follows:

[0085] 14.07kg oleic acid, 1.407kg benzoic acid, 18.76kg phthalic anhydride, 0.938kg maleic anhydride, 8.844kg pentaerythritol, 1.943kg trimethylolpropane, 6.365kg propylene glycol, 0.201kg hypophosphorous acid antioxidant, 0.134kg phosphite antioxidant, 2.077kg xylene, 12.261kg butyl acetate.

[0086] The preparation steps of soybean oil alkyd resin are the same as in Example 1.

[0087] (2) The taking of the main agent of polyurethane clear topcoat is as follows:

[0088] 67.0kg soybean oil alkyd resin, 8.5kg butyl acetate, 3.5kg propylene glycol methyl ether acetate, 7.0kg xylene, 0.3kg disper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com