Polyester polyol for polyurethane hot melt adhesive as well as preparation method and application of polyester polyol

A polyurethane hot-melt adhesive and polyester polyol technology, which is applied in the field of polyester polyol, can solve the problems of complex process route, long positioning time, and low initial bonding strength, so as to improve production efficiency, increase crystallinity, and enhance cohesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

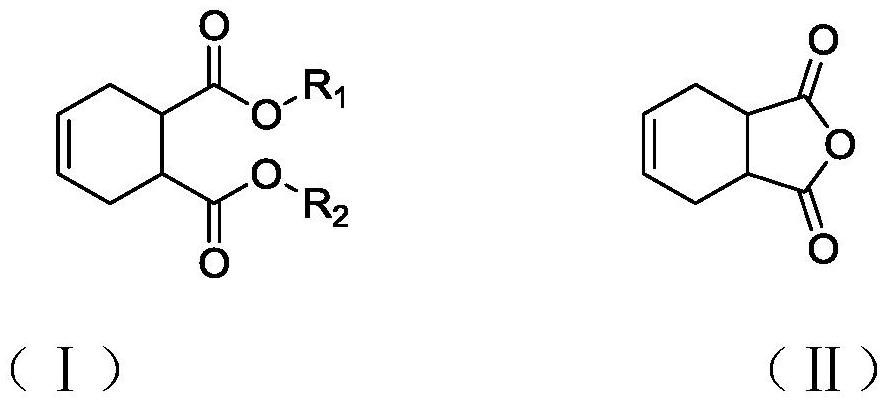

Image

Examples

Embodiment 1-10

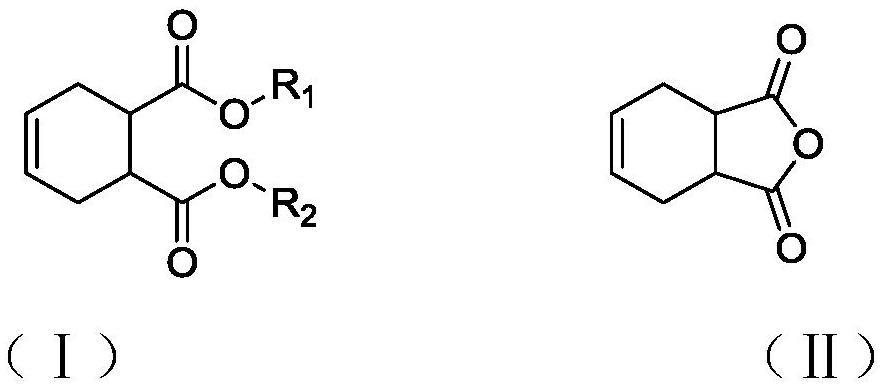

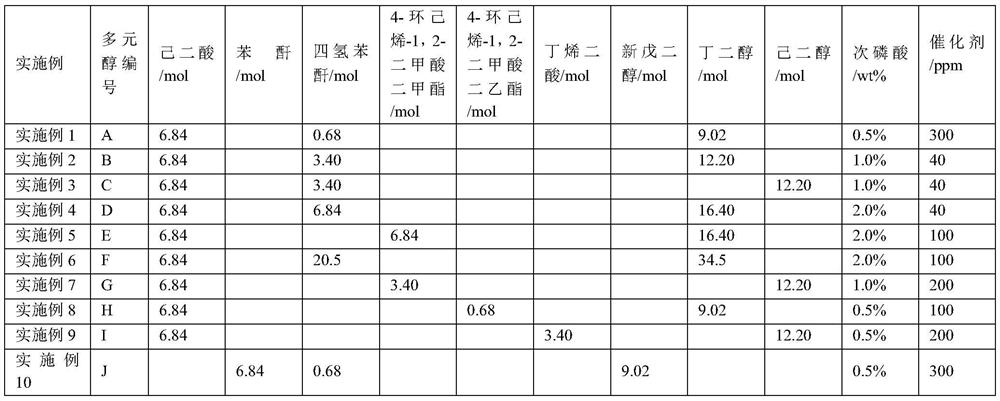

[0060] Prepare the polyester polyol A-J that is used to prepare polyurethane hot-melt adhesive, and step is:

[0061] Under the condition of nitrogen protection, component A), component B) and component C), and tetraisopropyl titanate catalyst, polymerization inhibitor hypophosphorous acid were sequentially added into the 5L reactor, and the ratio of raw materials was shown in Table 1. ;The system temperature was raised to 140~160°C, and kept at this temperature (Example 1-8: 150°C, Example 9: 140°C, Example 10: 160°C) for 1.0h; Internally rise to 180-210°C (Example 1-8: 210°C, Example 9: 200°C, Example 10: 180°C), and monitor the acid value and hydroxyl value, and open when the acid value is lower than 20mgKOH / g Vacuum system, the vacuum degree is slowly reduced to -0.095MPa within 0.5h, and the vacuum degree is controlled at 0.09-0.095Mpa to remove moisture and small molecule alcohol in the system. When the acid value and hydroxyl value reach the standard, stop the vacuum an...

Embodiment 11-20

[0074] Synthesis of Polyurethane Hot Melt Adhesive

[0075] Under the protection of nitrogen, add the polyester polyols A-J and isocyanate prepared in Preparation Examples 1-10 into a 2L three-necked round-bottomed flask, stir and react until the NCO content reaches the theoretical value, stop the experiment, vacuum defoam, and the obtained hot melt adhesive It was kept at a constant temperature at 130°C for standby, and the ratio of raw materials and reaction conditions were shown in Table 3.

[0076] The evaluation data of the polyurethane hot melt adhesive after curing is shown in Table 4 below.

[0077] Table 3 embodiment 11-20 raw material ratio and reaction conditions

[0078]

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com